Shifting register unit and array substrate gird driving device

A shift register and gate connection technology, which is applied to instruments, static indicators, etc., can solve problems such as inability to work stably for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

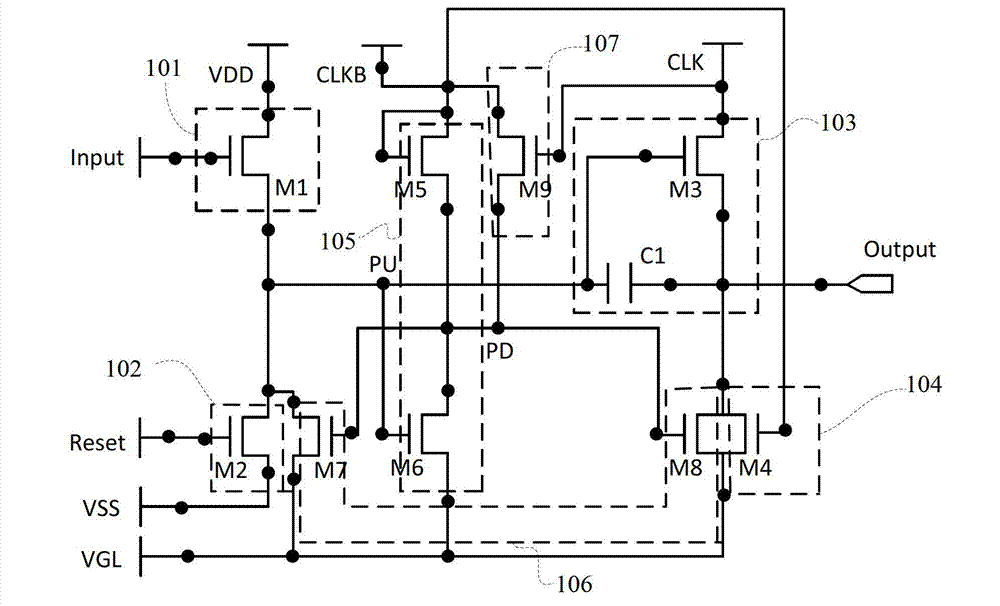

[0044] A shift register unit provided by Embodiment 1 of the present invention is suitable for bidirectional scanning, such as figure 2 As shown, the shift register unit consists of:

[0045] The input module 101, the reset module 102, the pull-up module 103, the first pull-down module 104, the second pull-down module 105 and the first pull-down control module 106 also include a second pull-down control module 107; wherein,

[0046] The input module 101 is used to provide the first working voltage VDD to the pull-up node PU point of the pull-up module in response to the input signal INPUT, wherein the pull-up node is the output node of the input module;

[0047] The reset module 102 is connected to the pull-up node, and is used for reducing the voltage of the pull-up node to the second working voltage VSS in response to the initialization signal RESET;

[0048] The pull-up module 103 is connected to the pull-up node for storing the first working voltage VDD, and in response ...

Embodiment 2

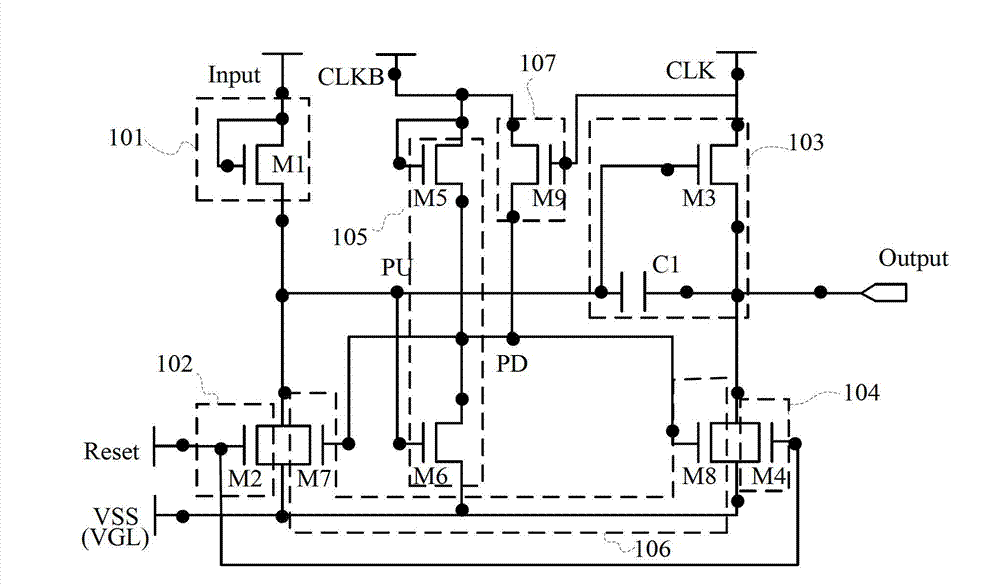

[0078] The shift register unit provided by Embodiment 2 of the present invention is also suitable for unidirectional scanning, such as image 3 As shown, when the shift register unit is used for single-phase scanning, the difference from Embodiment 1 is:

[0079] The first pull-down module 104 is configured to provide the third working voltage VGL to the output terminal OUTPUT in response to the initialization signal RESET;

[0080] Wherein the first drop-down module 104 includes:

[0081] The source of the fourth thin film transistor M4 is connected to the output terminal OUTPUT, the gate is connected to the initialization signal line RESET, and the drain is connected to the third working voltage VGL.

[0082] When the shift register unit described in Embodiment 2 of the present invention is used for single-phase scanning, refer to Figure 4 In the control signal timing diagram shown, the second working voltage VSS is the same as the third working voltage VGL, and the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com