General casting machine feeding device

A feeding device and casting machine technology, applied in the field of feeding system, can solve the problems of reducing work efficiency and increasing cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

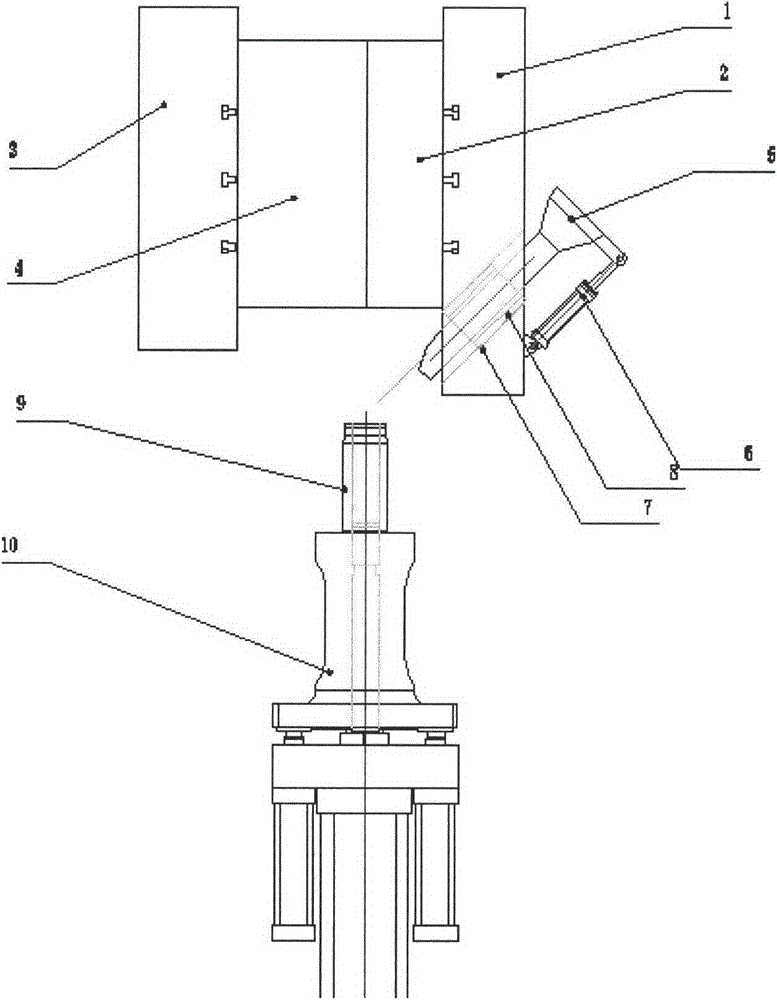

[0015] There are oblique holes in the lower part of the fixed formwork, two sets of slide rails are installed inside, and the guide cylinder lies on the slide rails. After the general casting machine closes the mold and before feeding the material, the traction cylinder drives the material guide cylinder to slide, and the tail end enters the extrusion cylinder, the feeder pours the material into the mouth of the material guide cylinder, and the material flows into the extrusion cylinder through the material guide cylinder. After the material is finished, the traction cylinder pulls the guide cylinder to slide out of the range of the extrusion cylinder and slides into the fixed template. The extrusion cylinder rises and combines with the mold to complete the casting process. The end enters the extrusion barrel to work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com