Drill bit, drill bit monitoring system and drill bit torque monitoring method

A monitoring system and drill bit technology, which is applied to the automatic control system of drilling, drill bits, drilling tools, etc., can solve the problems of limited applicable formations and early damage of PDC drill bits, and achieve improved service range and life, strong reliability, and mechanical The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

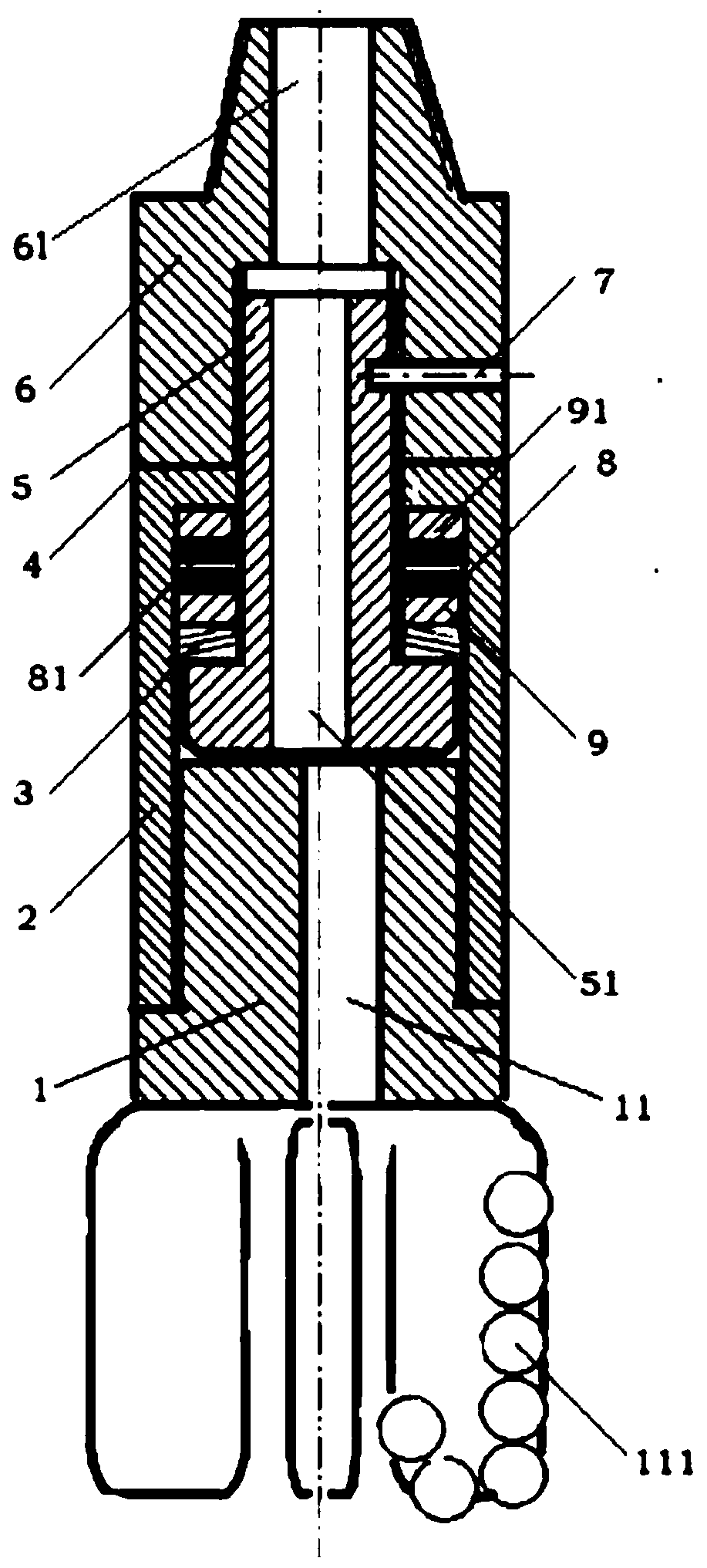

[0036] a drill such as figure 1 As shown, it includes a joint 6, a drill body 1 and a torque adjustment assembly, wherein the joint 6 is used to connect the drill string and is connected to the drill body 1 through the torque adjustment assembly, and the joint 6 is used to transmit the torque provided by the drill string to the drill body 1 connection to the torque adjustment assembly.

[0037] A polycrystalline diamond composite drill bit 111 is fixedly arranged on the drill bit body 1. The polycrystalline diamond composite drill bit 111 is arranged on the side of the drill bit body 1 away from the torque adjustment assembly. When the drill bit body 1 rotates, the drilling process can be realized. The drill bit 111 is welded and fixed with the drill bit body 1 .

[0038] The torque adjustment assembly includes a housing 2, a disc spring 3, a connecting shaft 5, a first friction plate 8, a first rigid body 9, a second friction plate 81, and a second rigid body 91, wherein the...

Embodiment 2

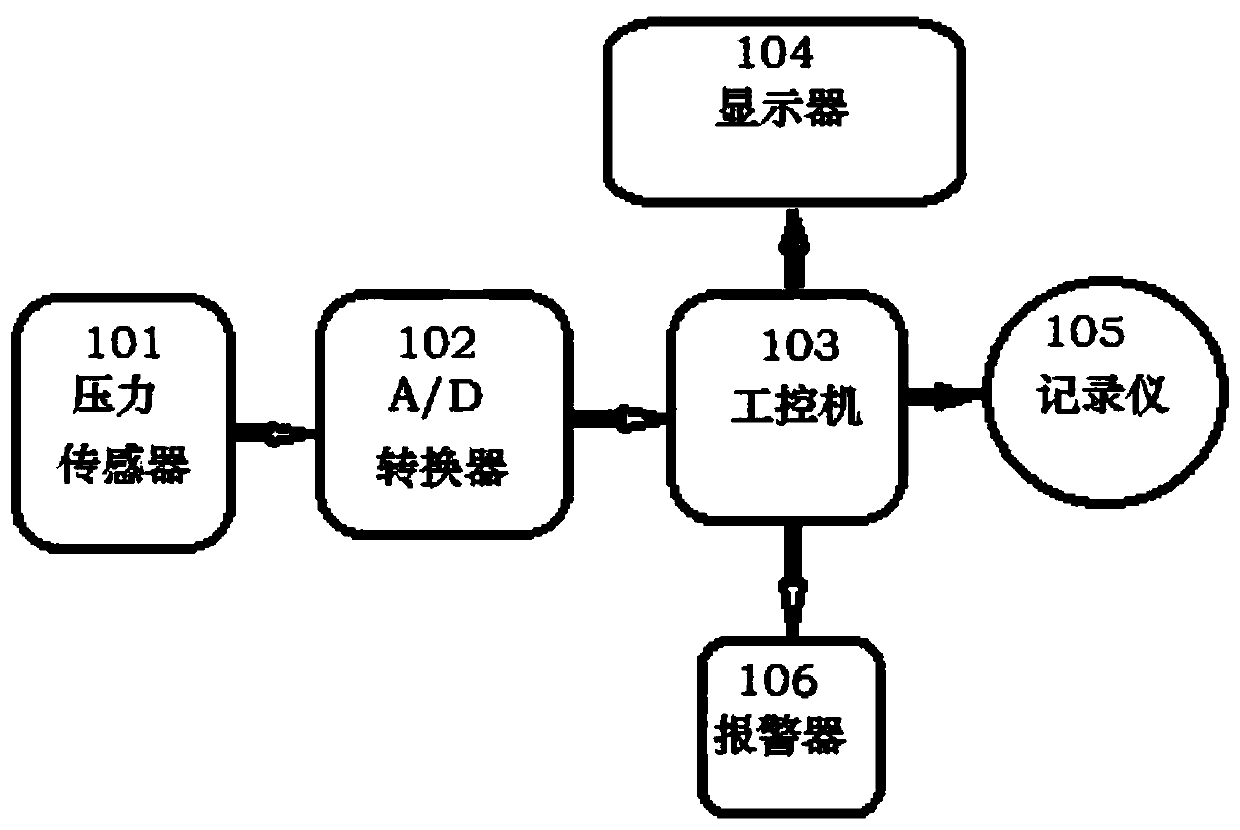

[0046] combine figure 1 and figure 2 , this embodiment provides a drill bit monitoring system, the system includes the drill bit provided in the first embodiment and a ground control device, the ground control device is used to monitor the frequency of pump pressure fluctuations for supplying drilling fluid to the drill bit.

[0047] The ground monitoring device includes a pressure sensor 101, an A / D converter 102, an industrial computer 103, a display 104, a recorder 105 and an alarm 106, the pressure sensor 101 is used to collect pump pressure signals, and the pressure sensor 101 and the A / D converter 102 The input end of the A / D converter 102 converts the analog signal into a digital signal, and the output end of the A / D converter 102 is connected with the industrial computer 103, so that the digital signal is transmitted to the industrial computer 103, and the industrial computer 103 is connected with the industrial computer 103 respectively. The display 104, the recorde...

Embodiment 3

[0049] This embodiment provides a drill bit torque monitoring method of the drill bit monitorable system described in Embodiment 2, including the following steps:

[0050] Step 1. During normal drilling, the joint 6, the drill bit body 1 and the torque adjustment assembly rotate synchronously with the drill string;

[0051] Step 2. The pressure sensor 101 collects the numerical value of the drilling fluid pump pressure and the analog signal of the fluctuation frequency and transmits the analog signal to the A / D converter 102. The A / D converter 102 converts the analog signal into a digital signal and then inputs it into the industrial computer 103 ;

[0052] Step 3, the industrial computer 103 processes the input digital signal and stores it in the industrial computer 103, displays it on the display 104 and saves it by the recorder 105;

[0053] Step 4, the industrial computer 103 judges whether the fluctuation frequency of the drilling fluid pump pressure reaches or exceeds a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com