Exhaust valve plate for compressor, exhaust valve module and compressor

A technology for exhaust valves and compressors, which is applied in the field of compressor manufacturing, and can solve the problems of large leakage of exhaust valve components, slow rebound speed of exhaust valves, errors, etc., to reduce leakage and improve discharge The effect of improving gas efficiency and shortening the exhaust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

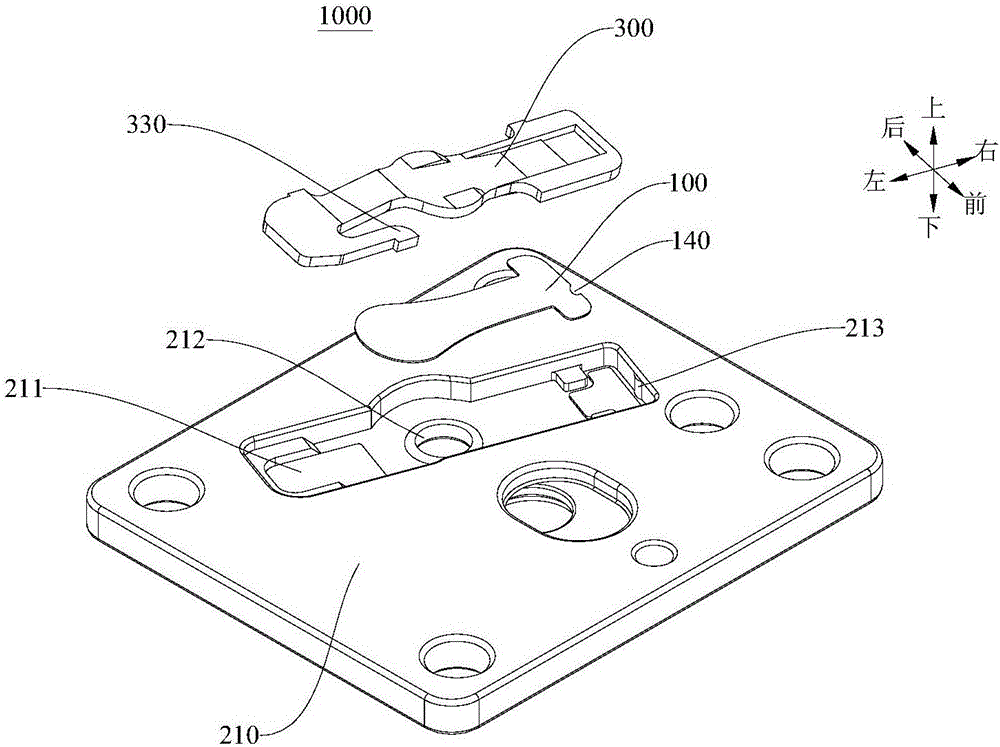

[0047] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

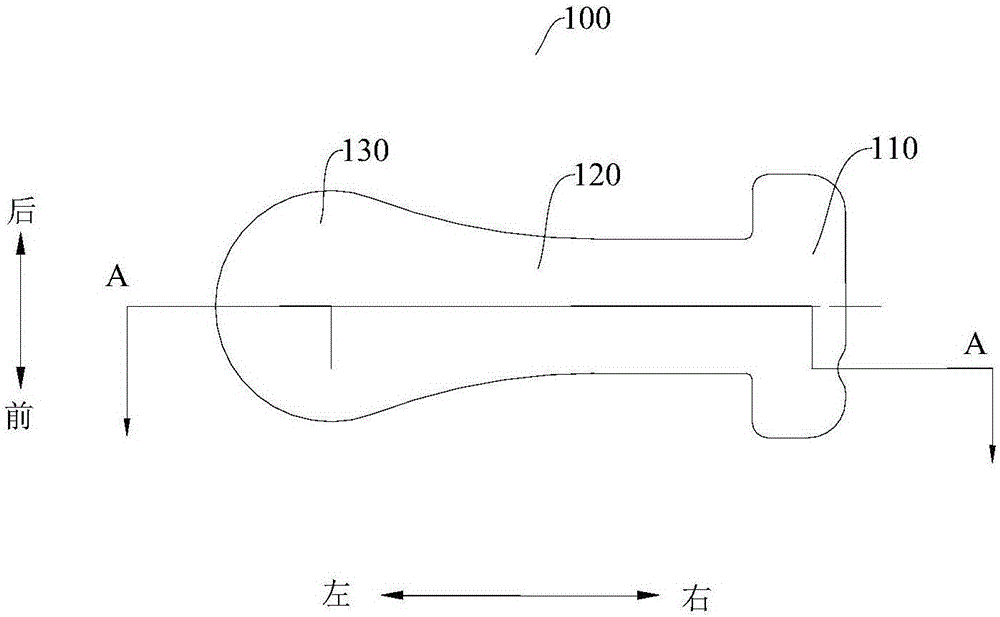

[0048] The following first combines the attached Figure 1 to Figure 12 The discharge valve plate 100 for a compressor according to the embodiment of the first aspect of the present invention will be described in detail.

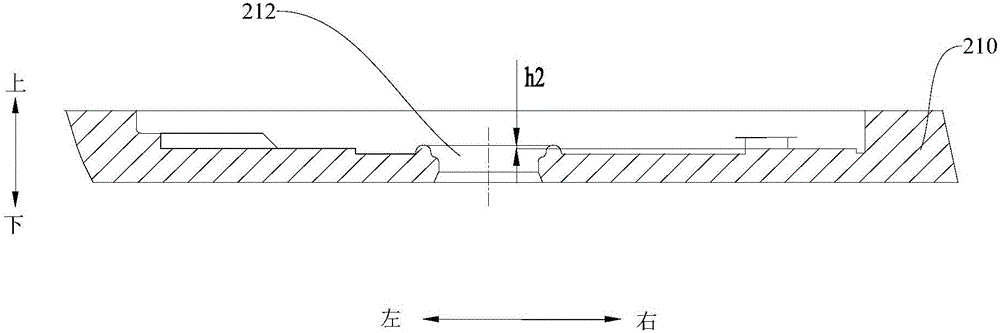

[0049] According to the discharge valve plate 100 for a compressor according to the embodiment of the present invention, the discharge valve plate 100 is roughly formed as a long strip with a length of S, 15mm<S<25mm, and at least a part of the discharge valve plate 100 faces the discharge valve. One side of the air valve port is bent so that there is a height difference h1 between one end and the other end of the exhaust valve plate 100, 0.03...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com