Three-component mixing head for injection molding

A mixing head and mixed injection technology, which is applied in the field of steering wheel foam molding and three-component mixing head for injection molding, can solve the problems of poor mixing effect, complicated small piston manufacturing process and high product rejection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

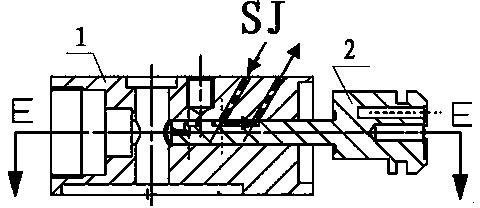

[0024] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

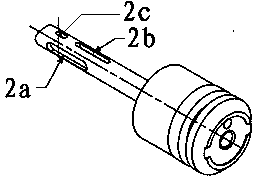

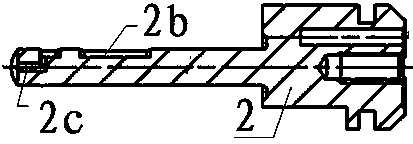

[0025] Examples of the present invention Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, it includes a pressure regulating core block 1 and a small piston 2.

[0026] Such as Figure 9 , Figure 10 , Figure 11 As shown, the pressure regulating core block 1 includes a small piston push rod installation hole, color paste input hole 1a, color paste output hole 1b, ISO input hole 1c, ISO output hole 1d, POL input hole 1e, POL output hole 1f, horizontal The mixed injection area 1g, the mixed material output hole 1h; there is an included angle of 60° between the color paste input hole 1a and the horizontal mixed injection area 1g.

[0027] Such as Figure 8 As shown, the push rod of the small piston 2 has a symmetrical high-pressure circulation tank 2a and a color paste circulation tank 2b; the color paste circulation tank 2b is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com