Patents

Literature

79results about How to "Play a role in rectification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

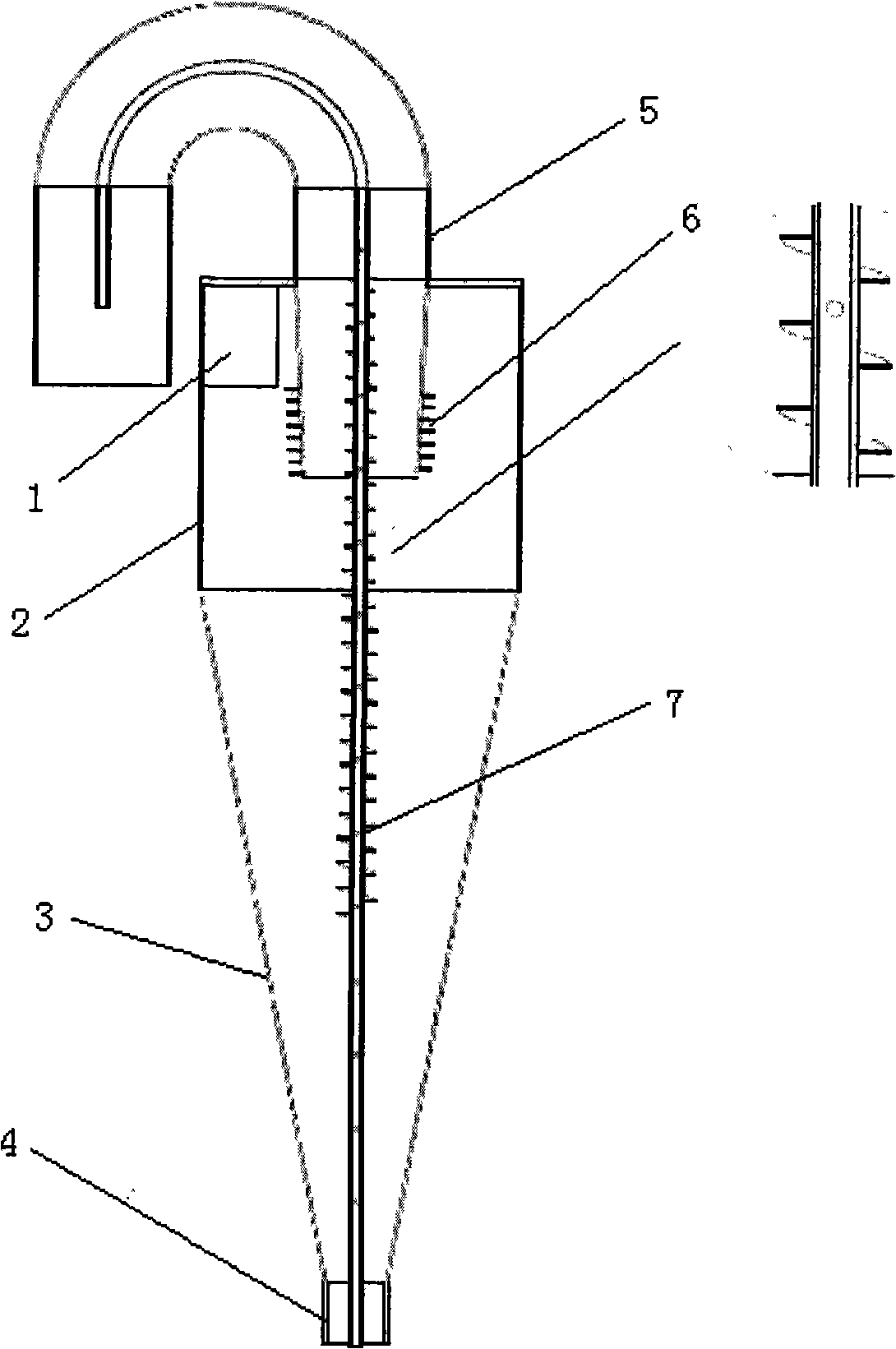

Water cyclone with improved base pipe and overflows structure

InactiveCN101254489ASimple structureReduce energy consumptionReversed direction vortexCycloneEngineering

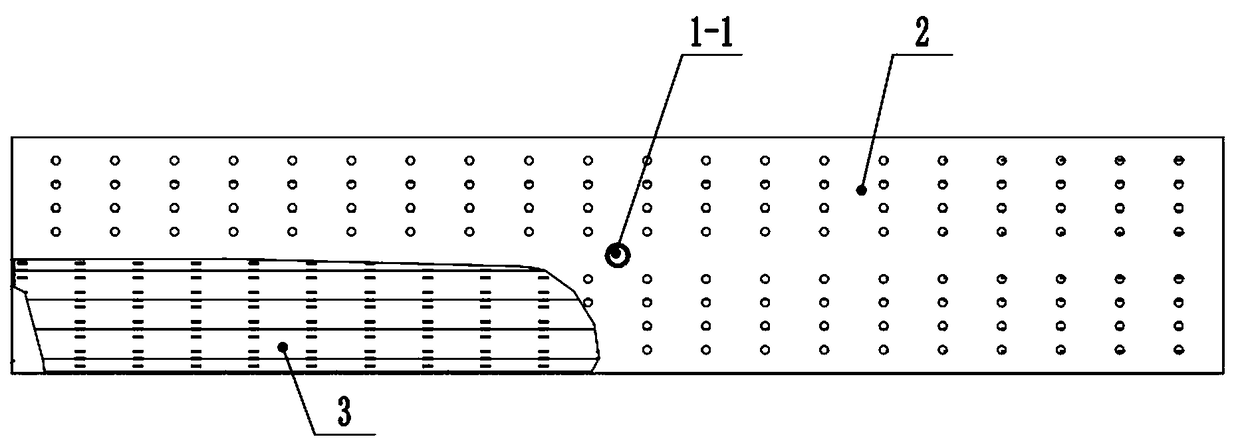

The invention belongs to a device for solid-liquid separation / classification and non-homogeneous separation, specifically a hydraulic cyclone with improved structure of central post and overflow pipe. The device comprises a feed pipe, a cylindrical section, a coniform section, an overflow pipe and a hollow tubular central post with partial-spiral fins and spiral flow deflectors and provided outside the overflow pipe. The central post is a hollow tube provided thereon with a plurality of holes. The spiral flow deflectors are provided on the outer surface of the central post. The spiral fins are provided on the overflow pipe from the bottom of the overflow pipe to a height below the bottom of an inlet pipe. Compared with the prior art, the separation efficiency of the hydraulic cyclone is increased by 5-10% and the energy consumption is reduced by 20%. The hydraulic cyclone has high stability and reliability in separation efficiency and is suitable for solid-liquid separation in ore dressing, dredging, chemical and petroleum industries.

Owner:EAST CHINA UNIV OF SCI & TECH

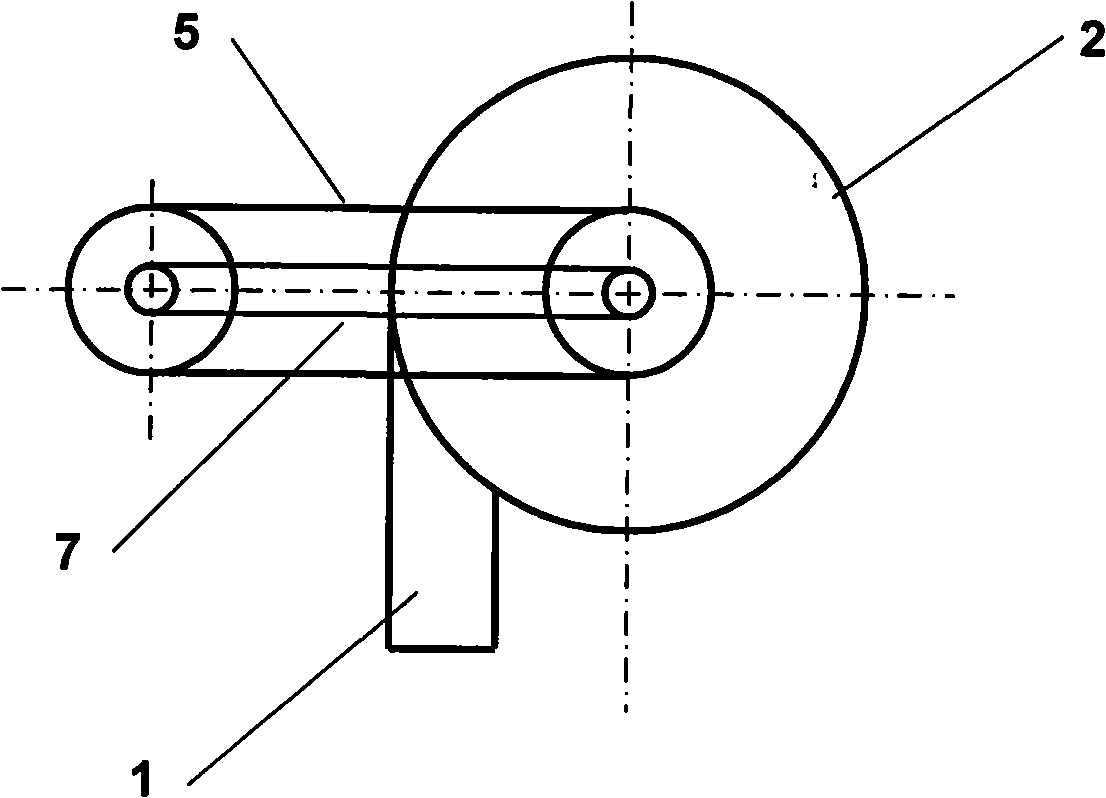

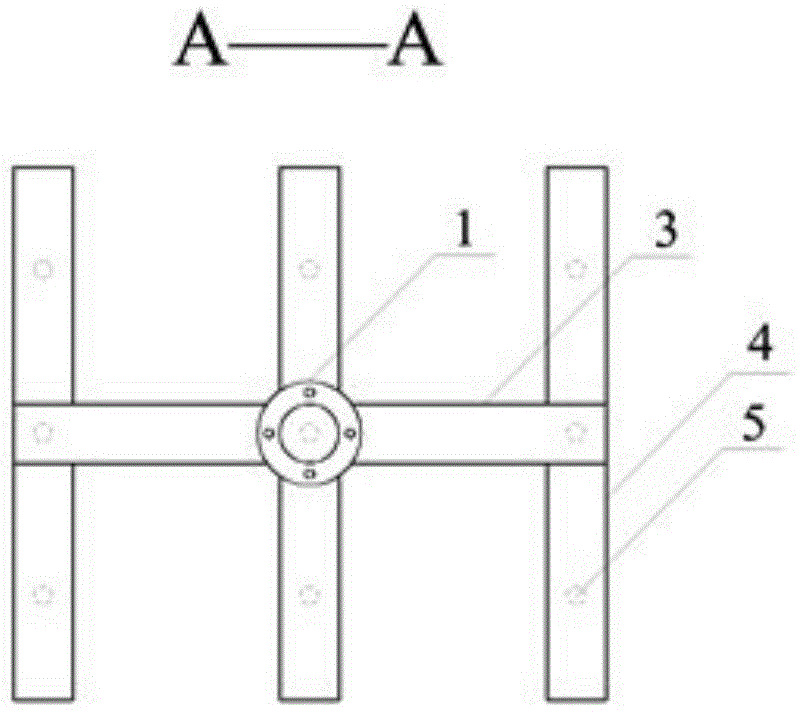

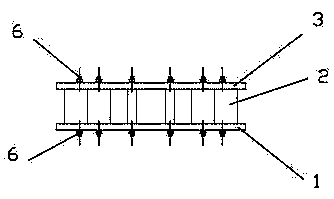

Uniform overflow type liquid distributor

InactiveCN104307192AAvoid effusionEasy to overflowEvaporator accessoriesEvaporators with horizontal tubesButt jointEngineering

The invention relates to a liquid distribution device, and particularly relates to a uniform overflow type liquid distributor used for uniformly distributing liquid on a horizontal heat exchange pipe. The liquid distributor comprises a flange, a feeding pipe, a horizontal branch pipe, a spray pipe, a folded-plate type overflow groove, a connecting channel and liquid distributing teeth, wherein the flange is arranged at a feeding opening; one end of the feeding pipe is connected with the flange, and the other end of the feeding pipe is connected with horizontal branch pipe; the spray pipe and the horizontal branch pipe are not in central butt joint, and occurrence of liquid accumulation in the spray pipe can be avoided; liquid in the overflow groove slowly increases by using the spray pipe, so that liquid overflows stably and has small fluctuation.

Owner:SHENYANG AEROSPACE UNIVERSITY

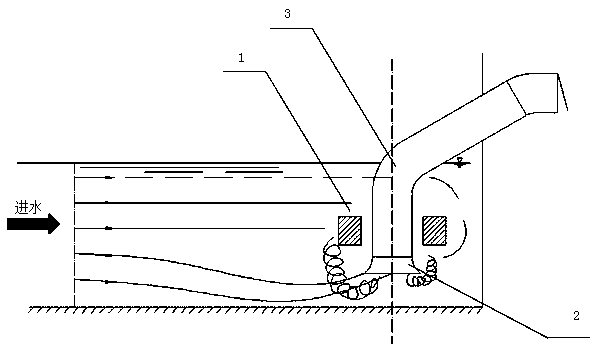

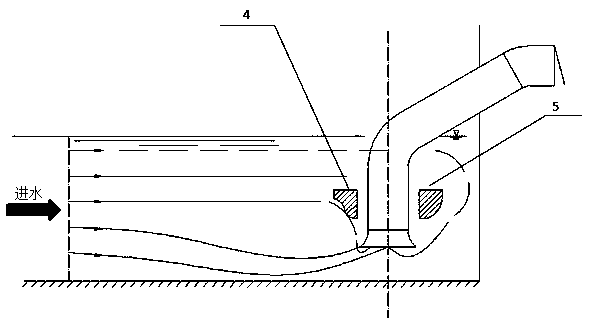

Combined hydraulic rectification device of pump station water inlet pool at ultralow water level

The invention discloses a combined hydraulic rectification device of a pump station water inlet pool at an ultralow water level. The combined hydraulic rectification device comprises a diversion canal, a front pool, a water inlet pool, a water inlet pipe, a water inlet flared pipe, a flow guide table, an underwater vortex elimination cover plate and a W-shaped flow guide pier, wherein the water inlet pipe downwards extends into the rear end of the water inlet pool; the water inlet pipe is connected with the water inlet flared pipe; the flow guide table is arranged on a bottom plate of the water inlet pool and is coincident with the axial line of the water inlet flared pipe; the circumference surface of the flow guide table is a smooth curve surface; the cross section of the flow guide table is a round plane, and the area is gradually decreased from bottom to top; the underwater vortex elimination cover plate is arranged at the rear end of the water inlet pool, and is positioned in a connection position of the water inlet pipe and the water inlet flared pipe; the W-shaped flow guide pier is arranged on the bottom plate of the water inlet pool and is tightly attached to the rear wall of the water inlet pool; the W-shaped flow guide pier is formed by two flow guide edge piers and one flow guide middle pier; the W-shaped flow guide pier is higher than the underwater vortex elimination cover plate. The combined hydraulic rectification device has the advantages that the water flow of the water inlet pool is enabled to be uniform and stable, so that a water pump machine unit stably, safely and reliably operates at the ultra-low water level of the water inlet pool.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

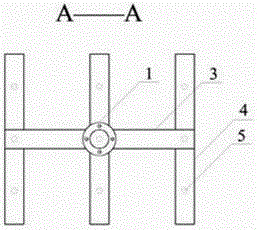

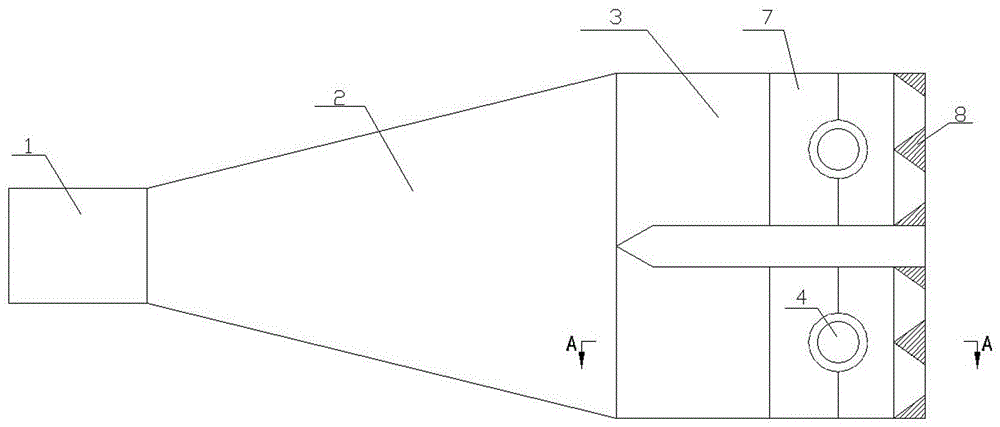

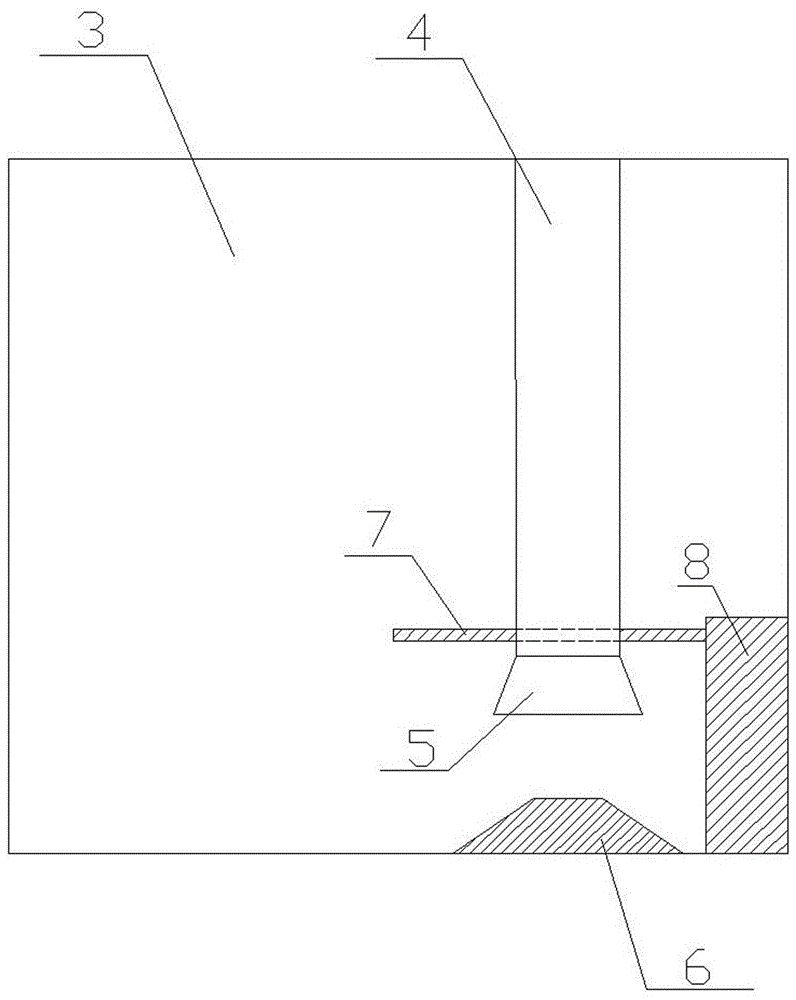

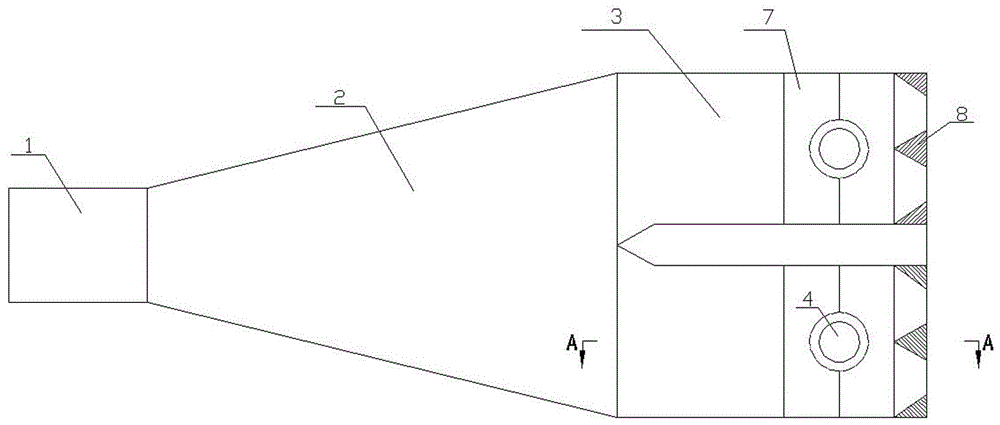

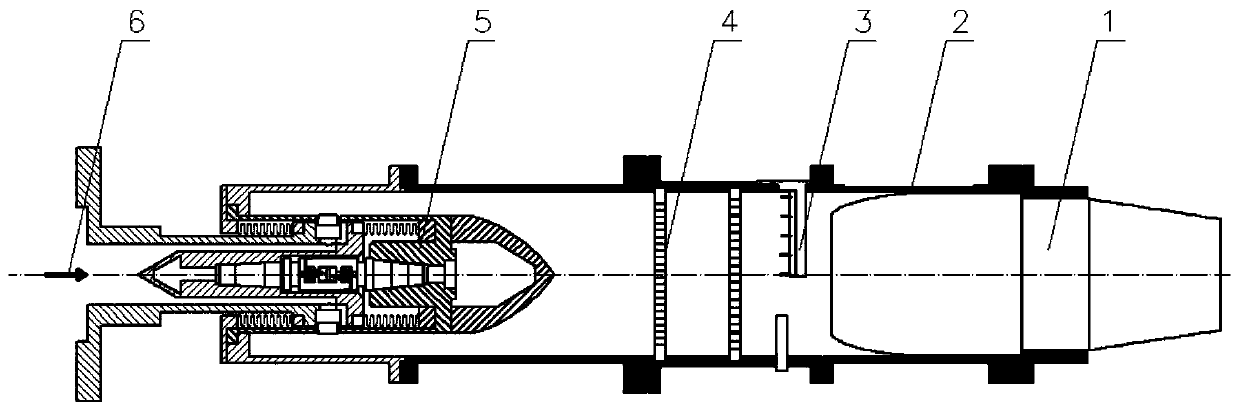

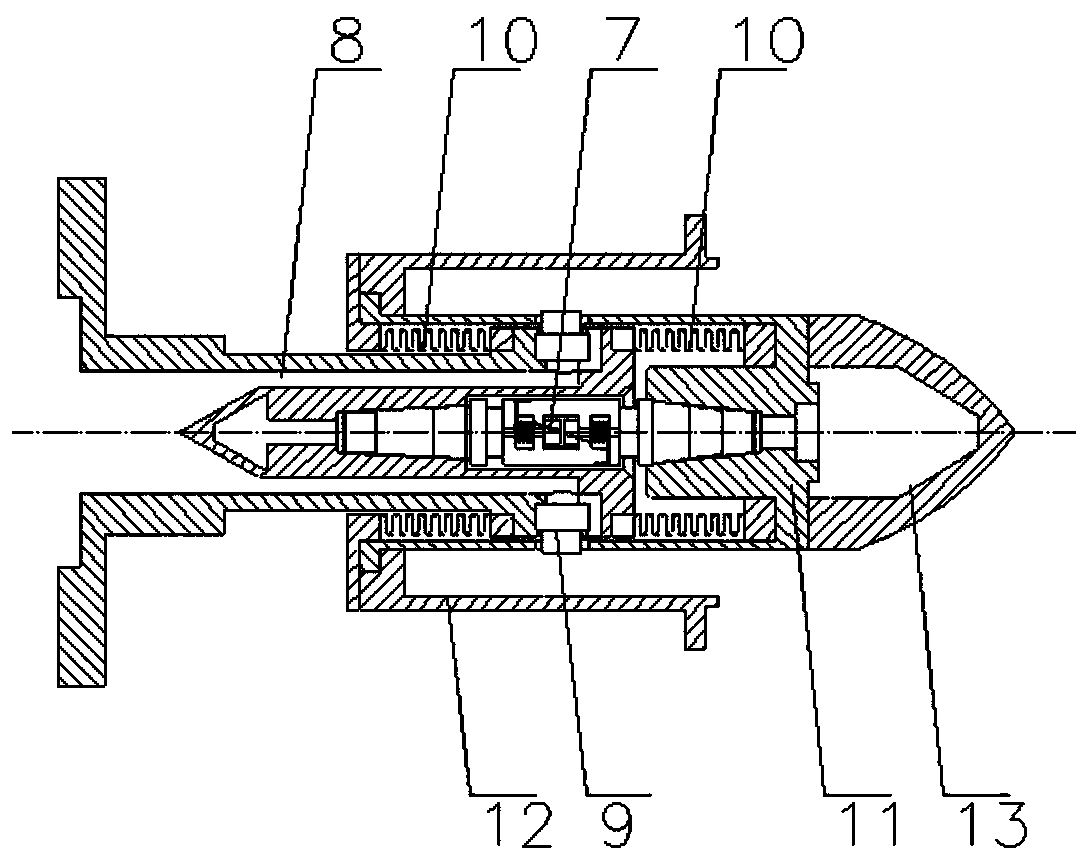

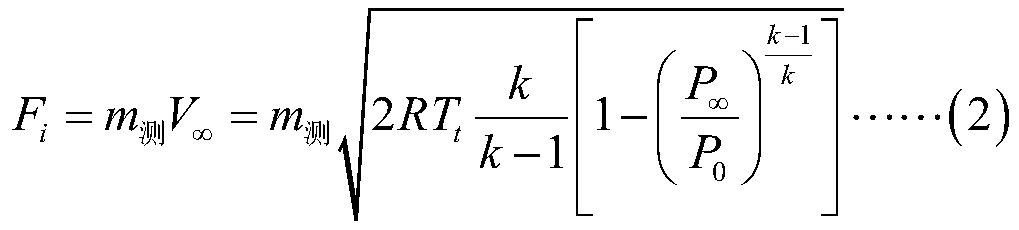

Internal flow resistance measuring method and device based on corrugated tube balance system

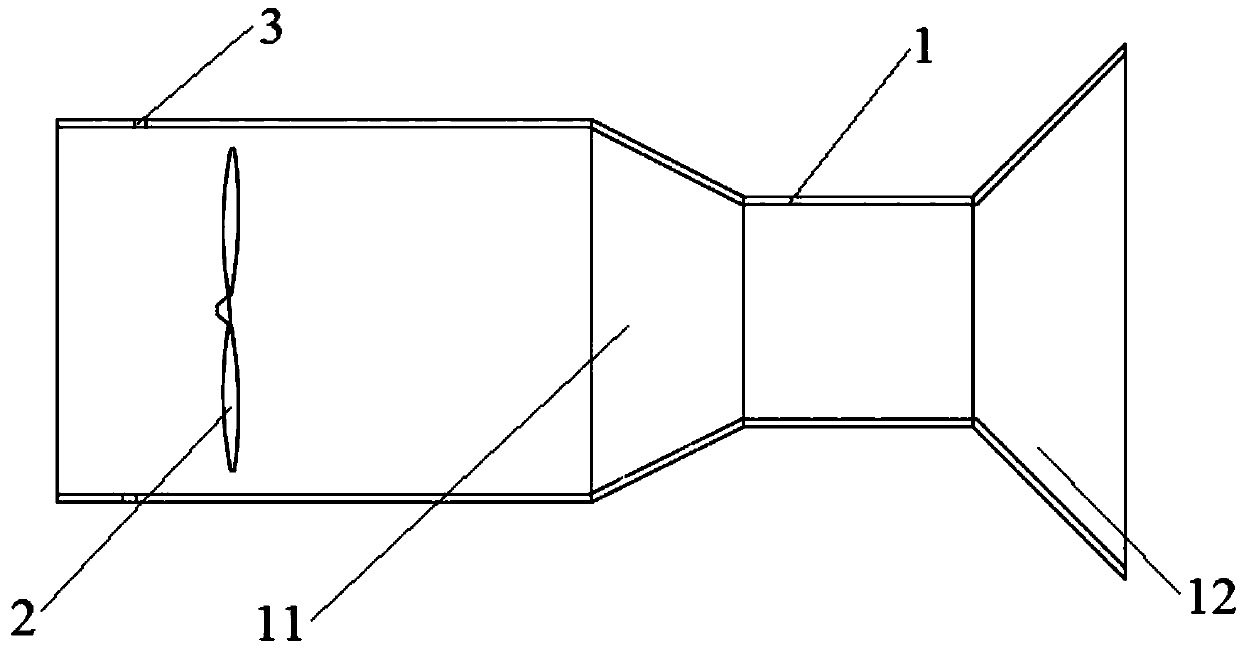

PendingCN110455491ALittle flow disturbanceImprove reliabilityAerodynamic testingAircraft components testingMeasurement testMomentum

The invention discloses an internal flow resistance measuring method and device based on a corrugated tube balance system, belongs to the technical field of internal flow resistance measurement testson aircrafts, and solves the problems of interference existence and insufficient accuracy when exit momentum is obtained by a pressure measuring rake arranged at an internal flow pipeline exit traditionally. The method is characterized in that the method indirectly measures internal resistance by calibrating thrust of an internal flow passage on a ground rack and comprises the steps as follows: acquiring entrance parameters of a to-be-measured part to obtain entrance momentum of an internal flow pipeline; directly acquiring exit momentum of the internal flow pipeline on the basis of the corrugated tube balance system; taking the internal flow resistance of the to-be-measured part as the momentum difference between the entrance and the exit. Besides, the measuring device mainly comprises the corrugated tube balance system, a rectification device, a measuring section and a connecting section and can accurately acquire to-be-measured parameters mentioned in the method under the conditionthat flow of the internal flow pipeline is not interfered, and particularly, the corrugated tube balance system can solve the problem of interference influence of a high-pressure pipeline on balance measurement when high-pressure air supply and aerodynamic measurement are performed synchronously in internal resistance measurement tests.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

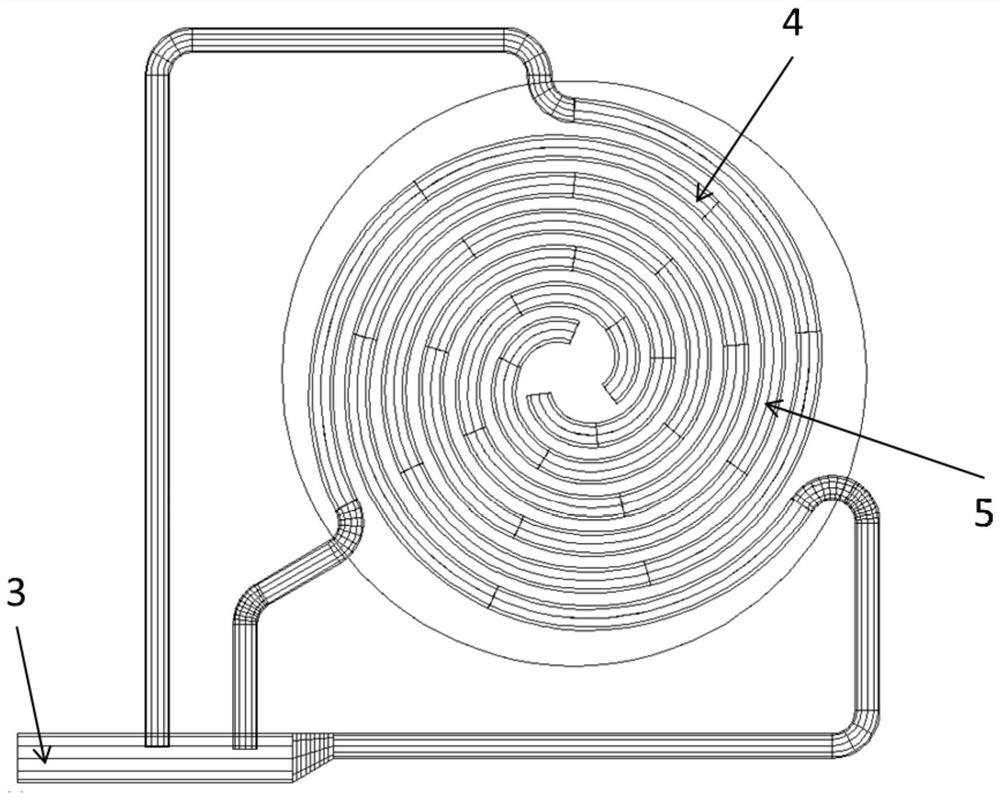

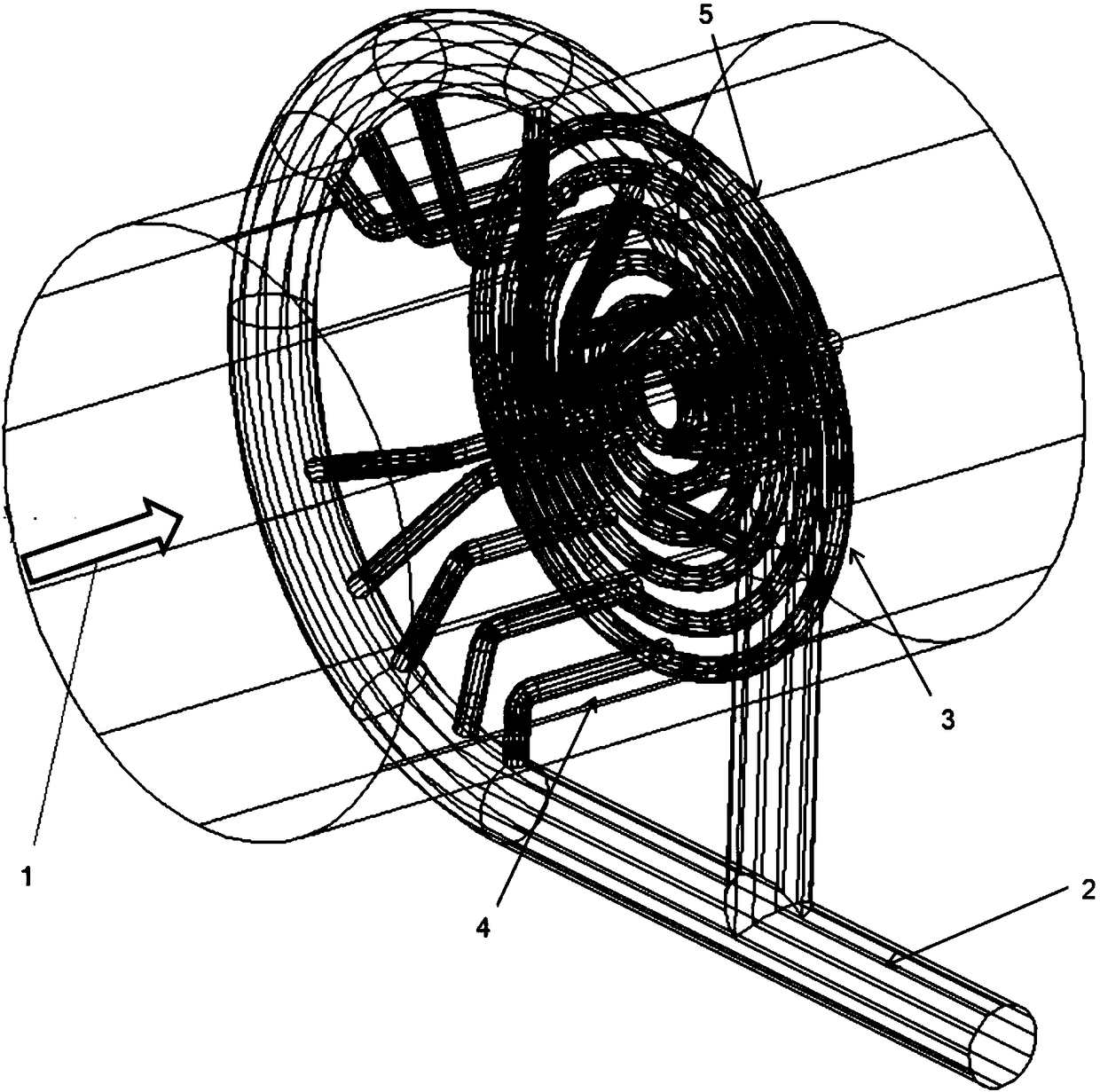

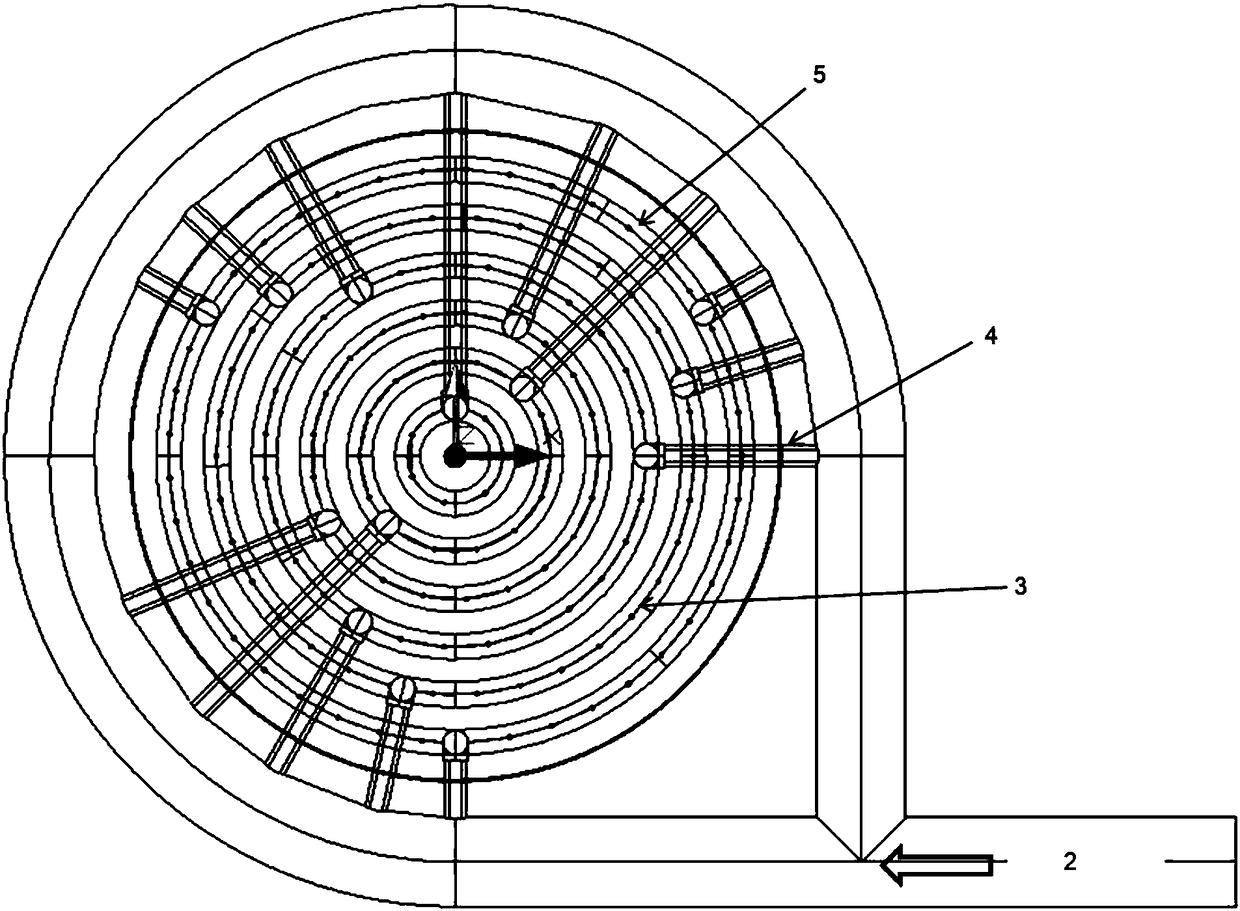

Rapid mixing equipment for ethylene and oxygen

ActiveCN108310989BFlexible structureSimple structureFlow mixersTransportation and packagingAlkeneMaterials science

The invention relates to a rapid mixing device for ethylene and oxygen, which mainly solves the problem of unsatisfactory mixing effect of olefin and oxygen in the prior art. The present invention adopts a kind of rapid mixing equipment of ethylene and oxygen, comprising ethylene main pipe and mixing chamber, the end of ethylene main pipe is connected to the mixing chamber, a number of oxygen spiral distribution pipes are arranged in the mixing chamber, the plane of the spiral distribution pipe is perpendicular to the flow direction of ethylene, A number of oxygen nozzles are evenly distributed on each spiral distribution pipe. The direction of the nozzles is consistent with the flow direction of ethylene. The oxygen feed pipe is divided into several branch distribution pipes in the main pipe and enters the main pipe of ethylene, so that the ethylene entering from the main channel and the nozzle of the spiral distribution pipe are sprayed. The technical scheme of rapid mixing of the oxygen produced in the mixing zone solves the above problems well, and can be used in the mixing of ethylene and oxygen.

Owner:SINOPEC SHANGHAI ENG +1

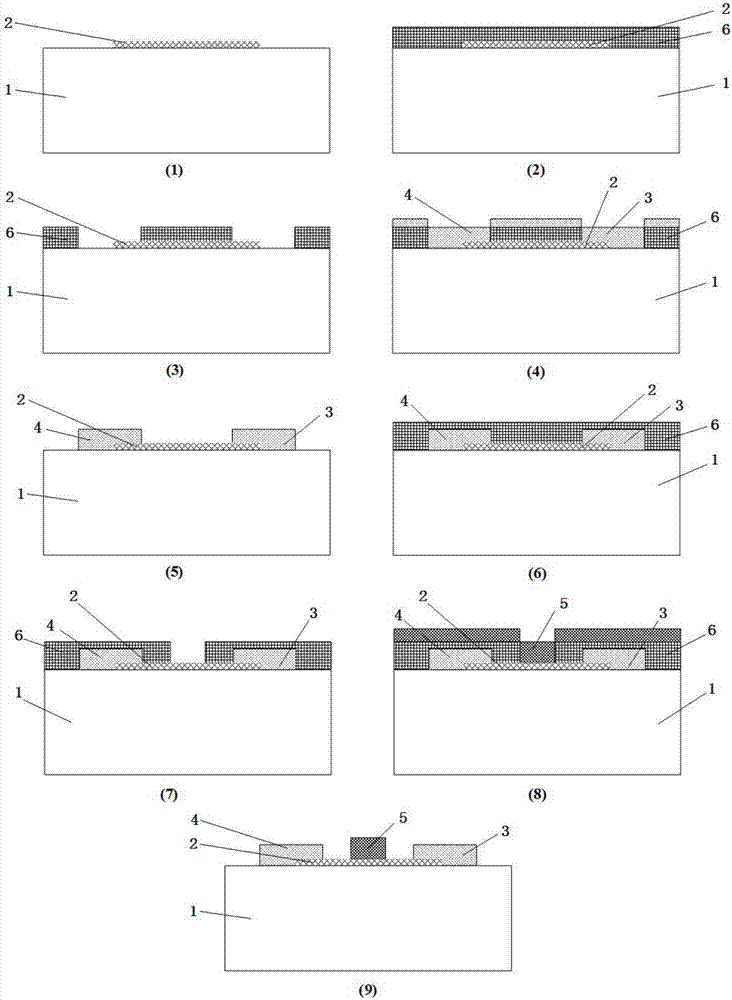

Schottky gate field effect transistor and preparation method and application thereof

InactiveCN107146815ASimple preparation processImplement the arraySemiconductor/solid-state device manufacturingSemiconductor devicesApplication areasPhotoresist

The invention discloses a preparation method of a schottky gate field effect transistor. According to the preparation method, a two-dimensional material is prepared on a substrate firstly, then the substrate and the two-dimensional material are coated with photoresist in a spin coating manner, and photoetching exposure and developing are performed to expose source and drain electrode windows; metal is coated, and the photoresist is washed off, and next, annealing in gas atmosphere is performed to form a source electrode and a drain electrode; next, the whole piece of a sample is coated with photoresist in a spin coating manner, and photoetching exposure and developing are performed to expose a gate electrode window; and next, metal is coated, and the photoresist is washed off to form the schottky gate field effect transistor. The schottky gate field effect transistor has the advantages of small dimensions, high switch ratio, high mobility, capability of well eliminating a short-channel effect and the like, so that the application field of a two-dimensional material device can be expanded.

Owner:GUANGDONG UNIV OF TECH

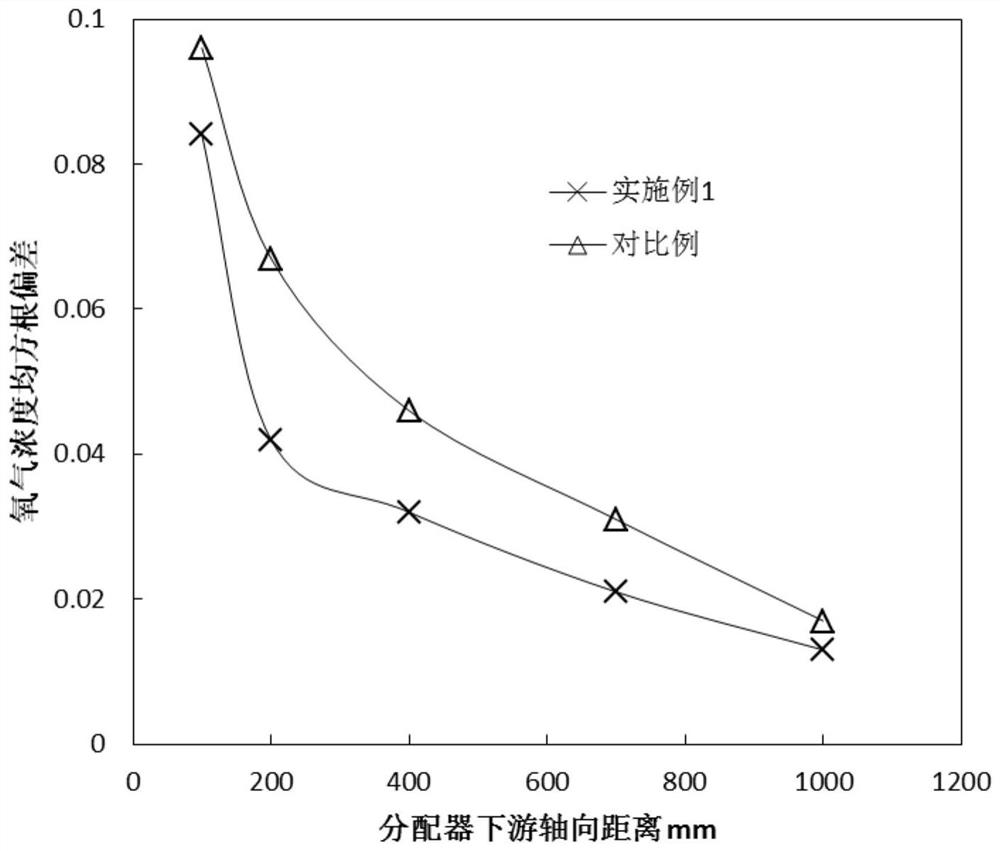

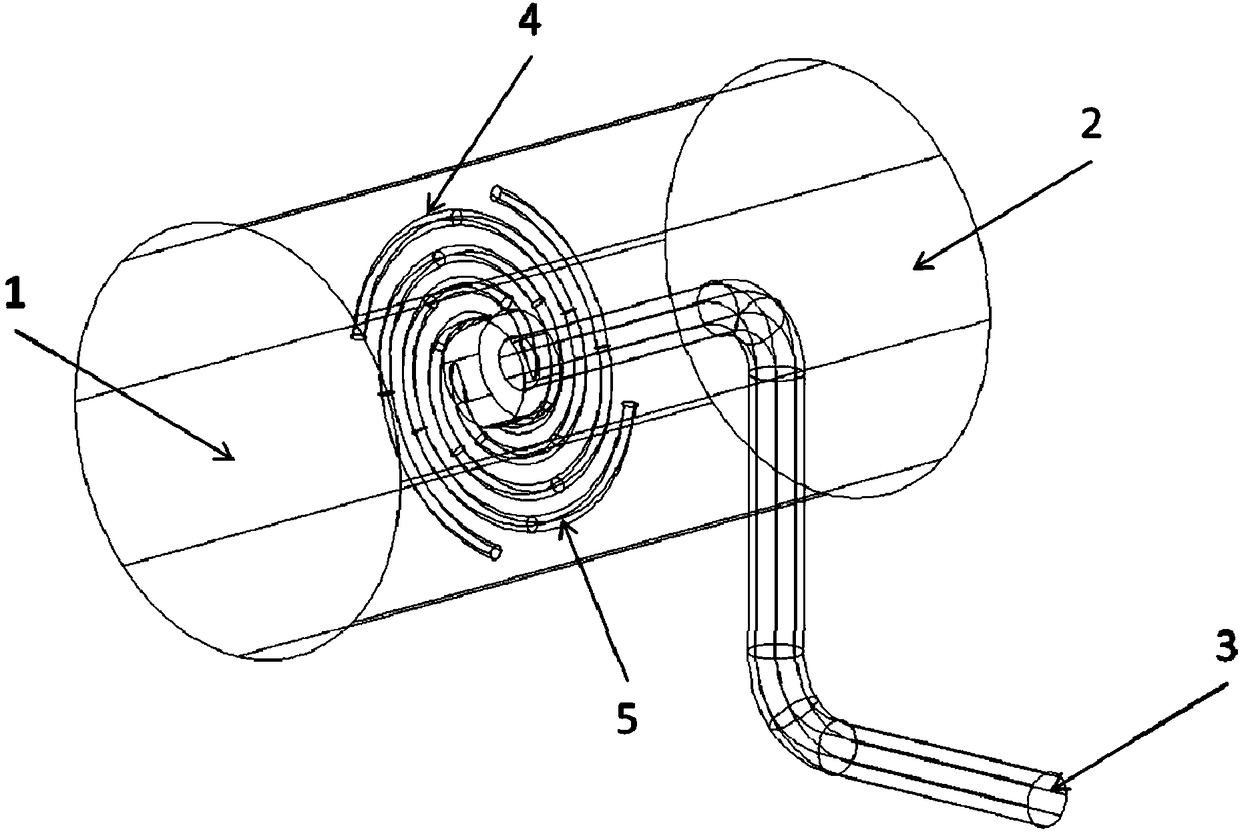

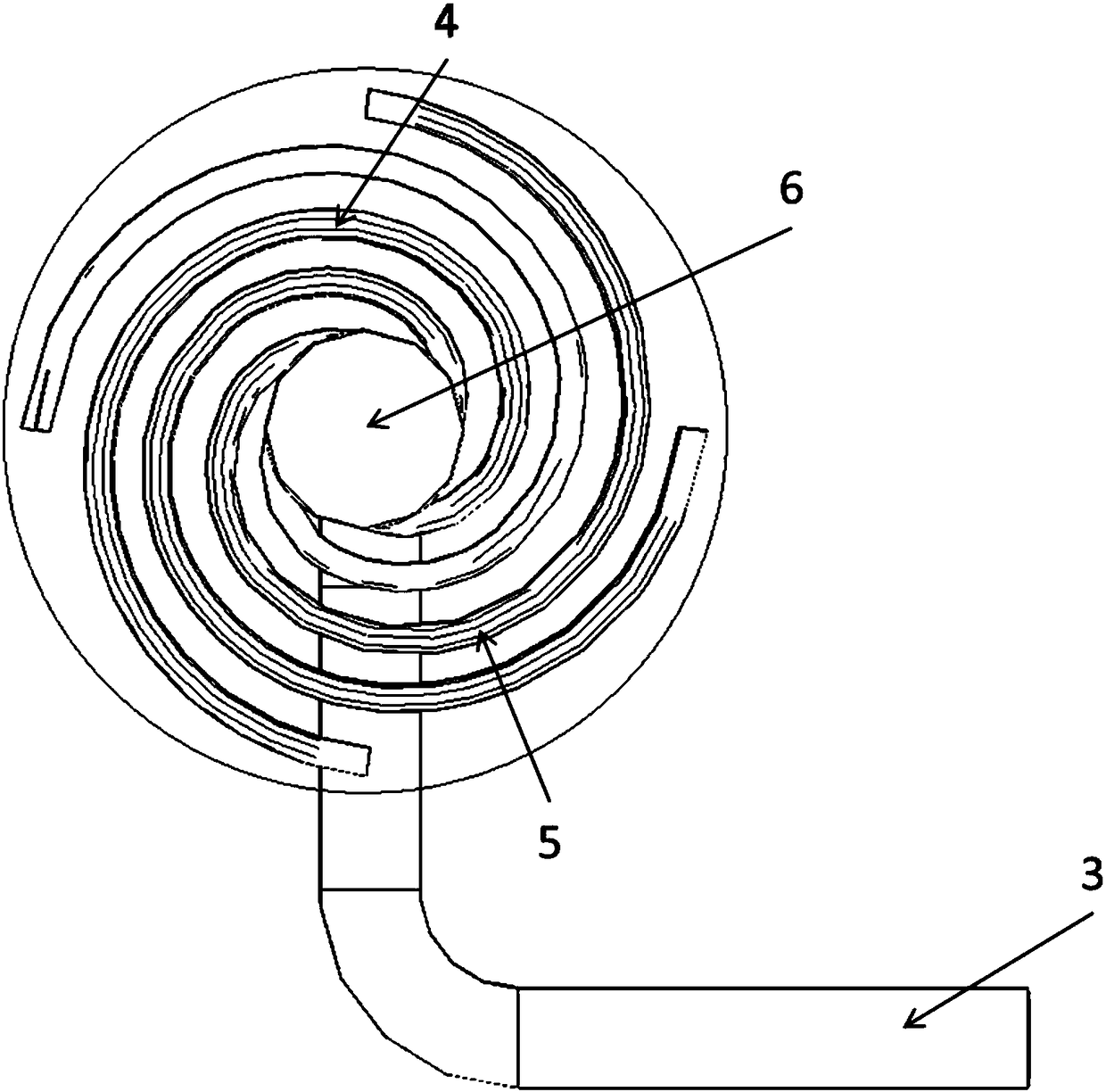

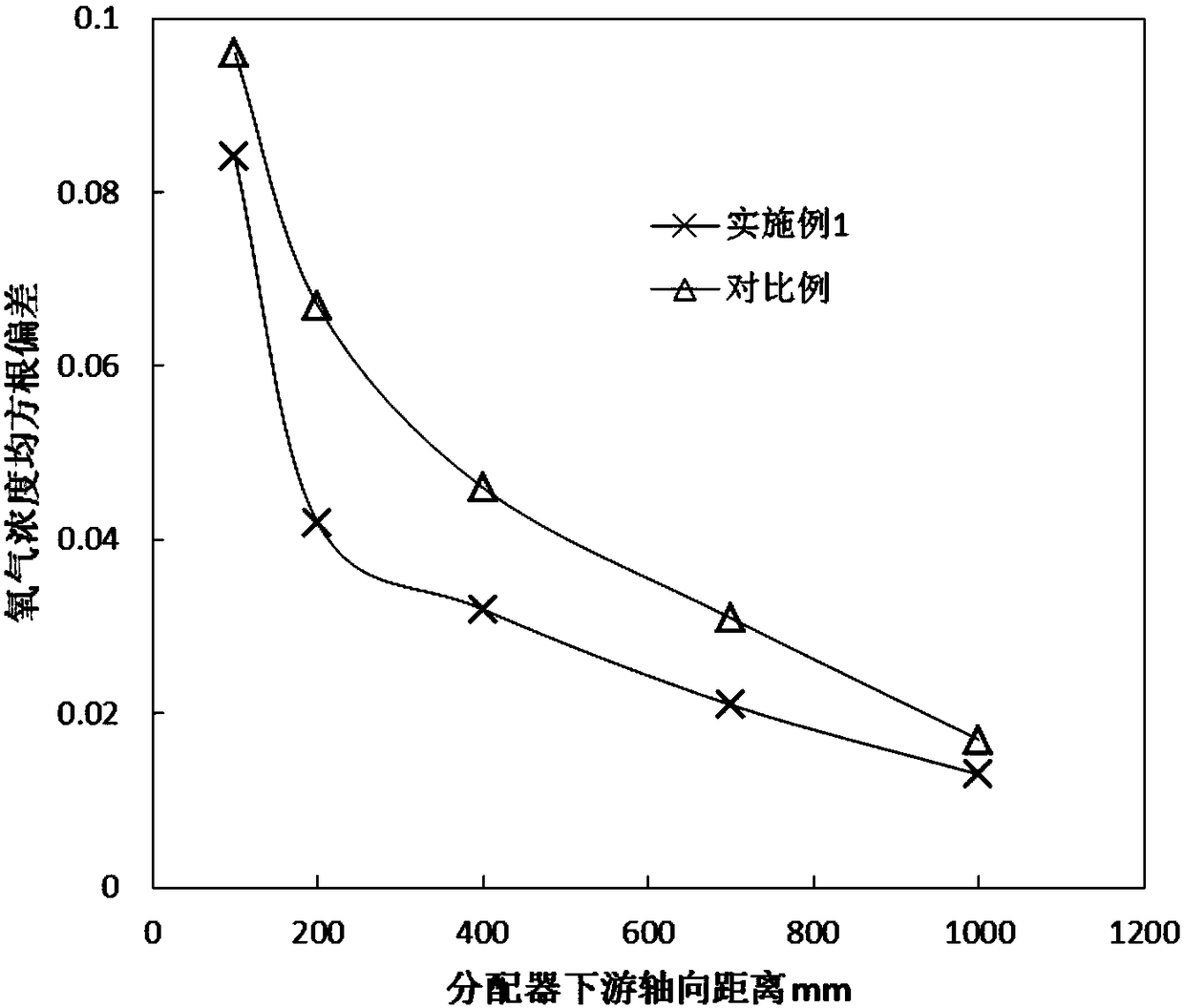

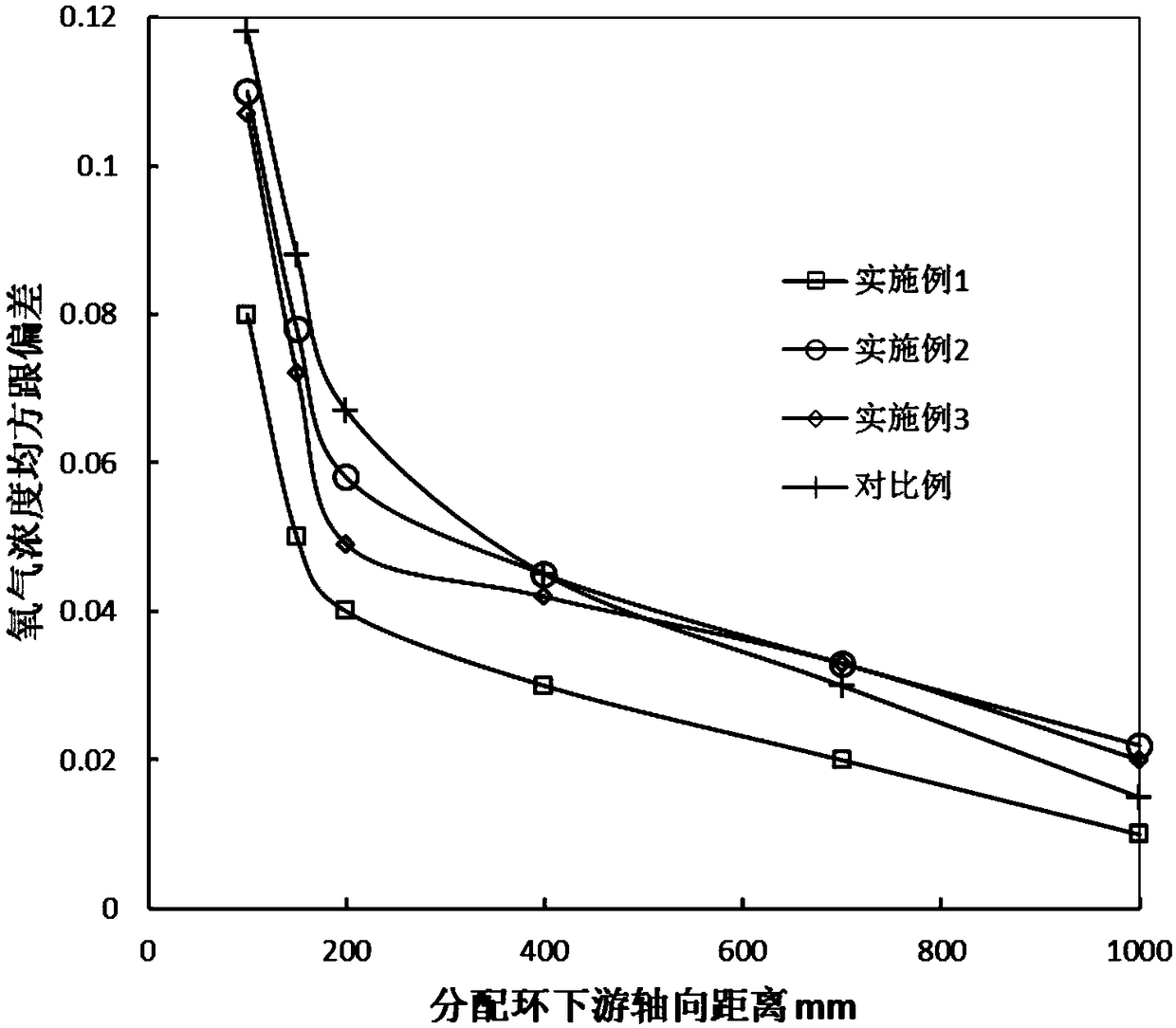

Static mixer for ethylene and oxygen

ActiveCN108295689AUniform upstream and downstream speedGuaranteed to minimizeFlow mixersTransportation and packagingStatic mixerOxygen

The invention relates to a static mixer for ethylene and oxygen and mainly solves the problem that the mixing effect of olefin and oxygen is not ideal in the prior art. The static mixer for ethylene and oxygen comprises a main ethylene pipeline, wherein the tail end of the main ethylene pipeline is communicated with a mixing chamber, a plurality of spiral oxygen allocating pipes are arranged in the mixing chamber, an oxygen pipeline enters the center of the main ethylene pipeline from the side surface and enters an oxygen allocator, oxygen enters the spiral allocating pipes through the allocator, the plane of the spiral allocating pipes is perpendicular to the flowing direction of ethylene, a plurality of oxygen nozzles are uniformly distributed on each spiral allocating pipe, and the nozzle direction is consistent with the flowing direction of ethylene. By means of the technical scheme, the problem is better solved, and the mixer can be used for mixing ethylene and oxygen.

Owner:SINOPEC SHANGHAI ENG +1

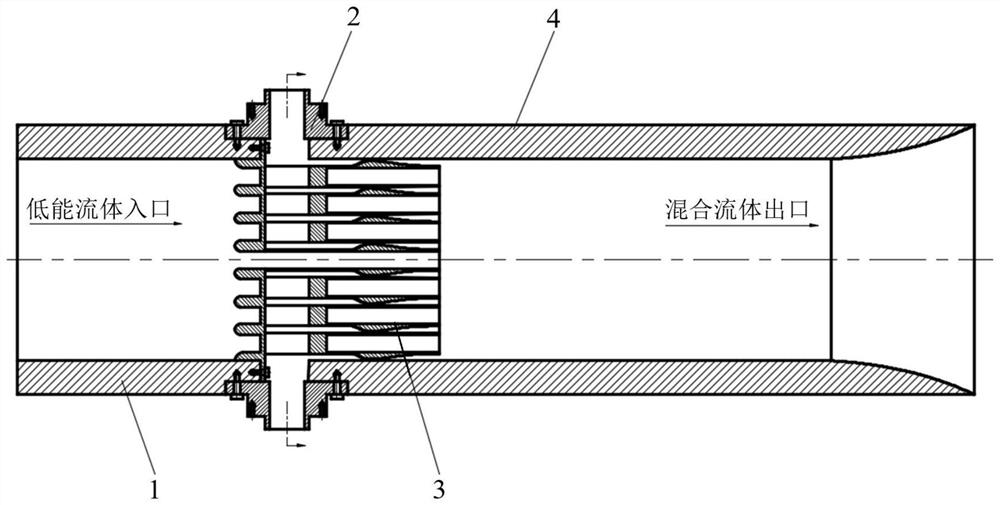

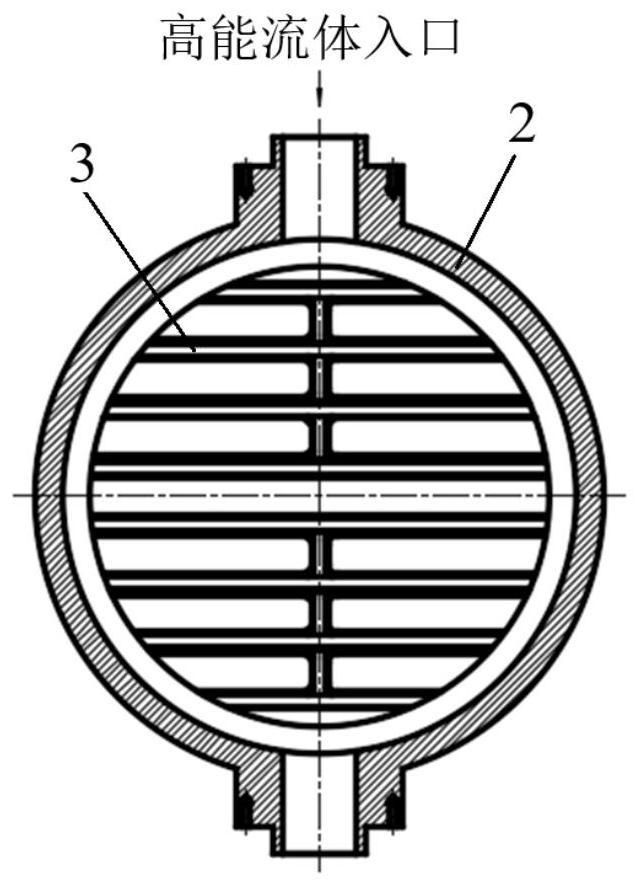

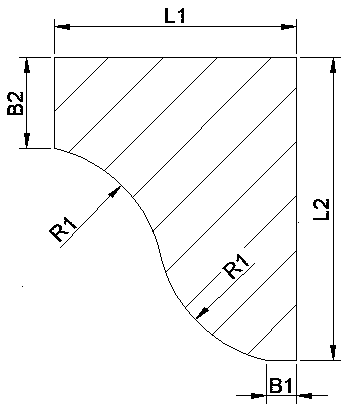

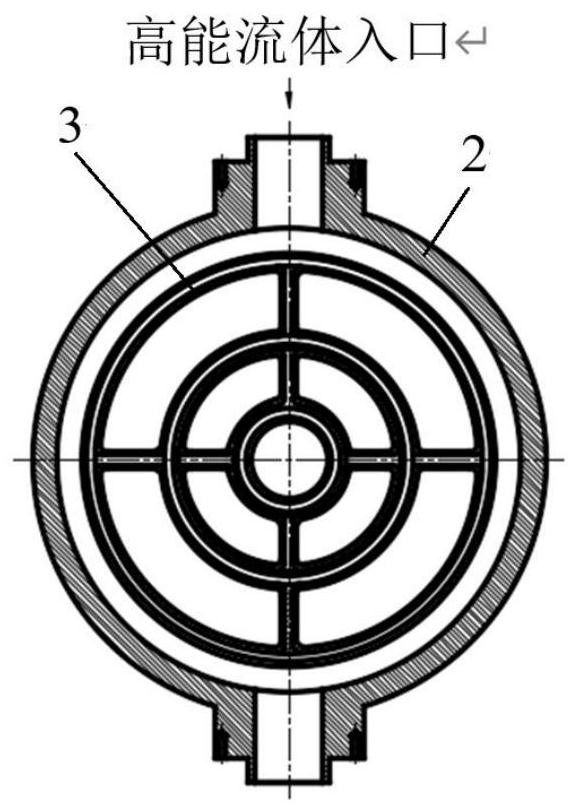

Distributed two-dimensional spray pipe ejector device

ActiveCN111911465AEnough storage spaceIncrease contact surfaceJet pumpsMachines/enginesEngineeringMechanical engineering

The invention discloses a distributed two-dimensional spray pipe ejector device. The distributed two-dimensional spray pipe ejector device uses a pipeline connection mode, and sequentially comprises alow-energy fluid inlet section, a high-energy fluid inlet section and a mixed fluid outlet section which are connected in sequence, wherein an two-dimensional spray pipe ejector is arranged in a pipeline near the high-energy fluid inlet section; a through hole is formed in the surface of the high-energy fluid inlet section and communicates with an external high-pressure tank; the low-energy fluidinlet section, the high-energy fluid inlet section and the mixed fluid outlet section share the same central axis; the two-dimensional spray pipe ejector comprises linear spray pipe unit bodies arranged in parallel; the spray pipe unit bodies are connected through reinforcing ribs; part of the reinforcing ribs are of hollow structures; high-energy fluid enters the spray pipe unit bodies from thethrough hole of the high-energy fluid inlet section and is sprayed out from outlets of the spray pipe unit bodies; and spray pipes are arranged in the spray pipe unit bodies. The distributed two-dimensional spray pipe ejector device is suitable for fluid ejection control of gas and liquid, and has the advantages that the ejection efficiency is improved; the appearance dimension of the ejector device is reduced; and the space installation requirement of the ejector device is lowered.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Novel pumping station water pump beam anti-vortex device and method

The invention relates to a novel pumping station water pump beam anti-vortex device and method, belonging to the technical fields of hydraulic engineering and municipal engineering. The novel pumping station water pump beam anti-vortex device comprises a water pump beam arranged in a water inlet tank. The novel pumping station water pump beam anti-vortex device is characterized in that the water pump beam is composed of a front water pump beam and a back water pump beam which are respectively arranged on both sides of a water outlet bent pipe in the water inlet tank; the front water pump beam is faced with the water inlet side of the water inlet tank; the upstream face of the front water pump beam is a streamlined section connected with double semicircular arcs; the upstream side of the front water pump beam is streamlined without rectangular edges; the cross section of the back water pump beam is a semicircular arc; and the side face of the back water pump beam adjacent to the water inlet tank is cambered. The novel water pump beam can effectively improve the flow state in the water inlet tank, reduces the occurrence of the reflux on the back wall of the water inlet tank and performs a flow regulation function. Meanwhile, the device can reduce the occurrence of the vortex around the water pump beam, thereby avoiding forming the vortex strip. The device and method are used for constructing and reconstructing a pumping station, can effectively enhance the operating efficiency of the pumping station, and improve the cavitation property of the pump unit.

Owner:YANGZHOU UNIV

Online olefin and oxygen mixing device

InactiveCN108355505AFlexible structureUniform upstream and downstream speedFlow mixersTransportation and packagingPolymer scienceMixing effect

The invention relates to an online olefin and oxygen mixing device. The device is mainly used for solving the problem of unsatisfactory mixing effect of olefin and oxygen in the prior art. The onlineolefin and oxygen mixing device comprises a main olefin pipeline, an oxygen pipeline and a mixing chamber, the tail end of the main olefin pipeline is communicated with the mixing chamber, a pluralityof annular distribution tubes are arranged in the mixing chamber, the plane of the annular distribution tubes is perpendicular to the flow direction of olefin, every annular distribution tube is uniformly provided with a plurality of oxygen nozzles, the opened directions of the nozzles are consistent with the flow direction of the olefin, and the oxygen pipeline is divided into a plurality of branch tubes outside the main pipeline, then enters a main circulating gas tube, and is connected with a circular distribution tube to make the olefin entering the main pipeline and oxygen ejected by thenozzle of the circular distribution tube rapidly mixed in a mixing area. The device well solves the problem, and can be used for online mixing the olefin and oxygen.

Owner:SINOPEC SHANGHAI ENG +1

Cooling device for high-precision gear forging machining

InactiveCN105964874AAvoid deformationAvoid impuritiesPositive displacement pump componentsPumpsCold airCooling effect

The invention discloses a cooling device for high-precision gear forging machining. The cooling device comprises a cooling box, a cooling pipe, a circulating oil pump, a cooler, a refrigerating machine and a cooling nozzle; the cooling pipe is arranged on the four walls of the cooling box, one end of the cooling pipe is connected with an inlet of the circulating oil pump, and the other end of the cooling pipe is connected with an outlet of the cooler; one path of cold air generated by the refrigerating machine enters the cooler to cool hot oil, and the other path of the cold air generated by the refrigerating machine is guided into the cooling nozzle arranged on the upper portion of the cooling box; and cold oil cooled by the cooler is conveyed to the cooling pipe to cool a forging mold in the cooling box and then returns to the inlet of the circulating oil pump. According to the cooling device for high-precision gear forging machining, oil indirect cooling and air cooling are simultaneously adopted, and the cooling effect is good; the circulating oil amount can be precisely controlled, so that the cooling temperature is controlled; and the cooling device has the advantages of being good in heat dissipation condition, long in operation cycle, convenient to overhaul and the like.

Owner:董超超

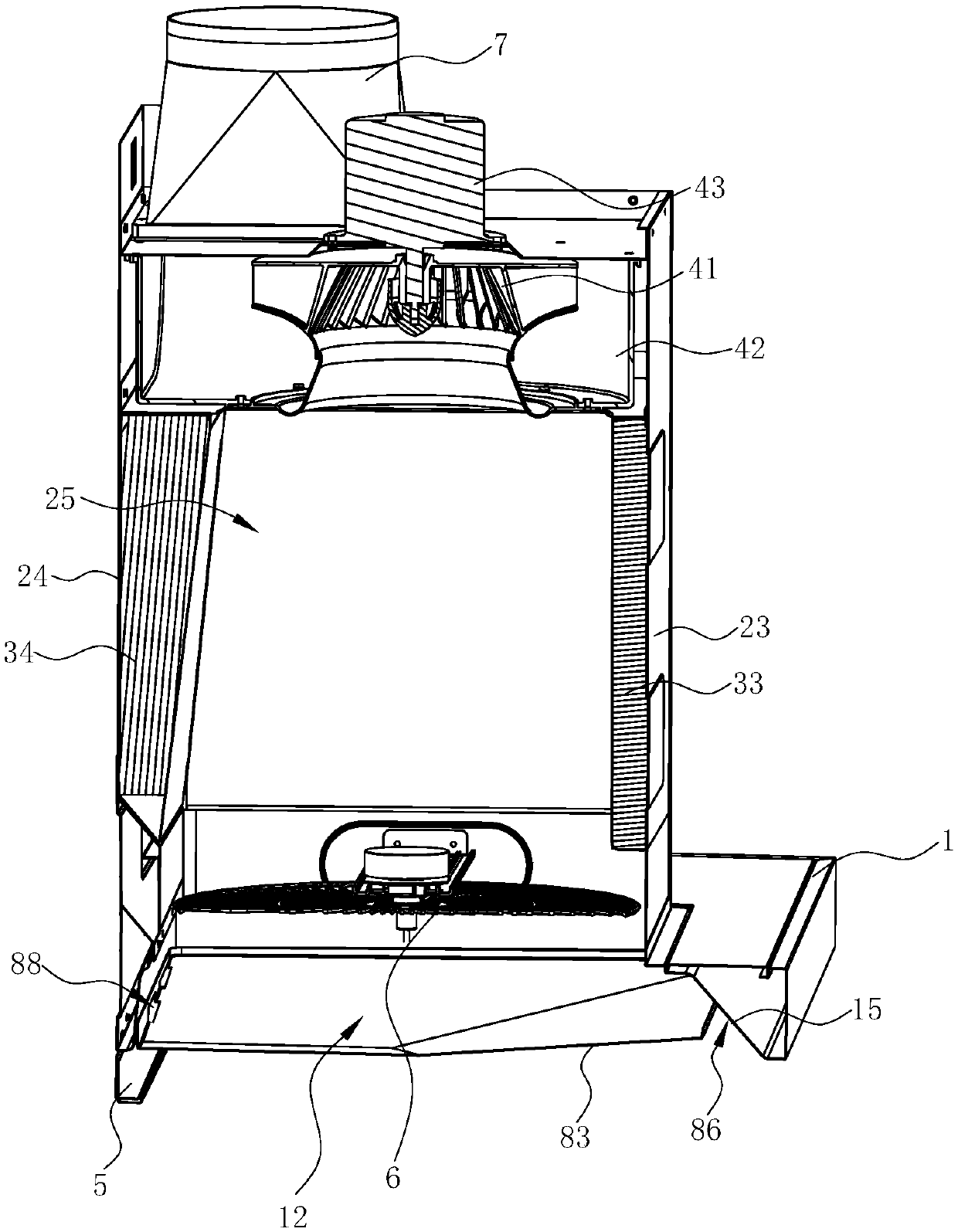

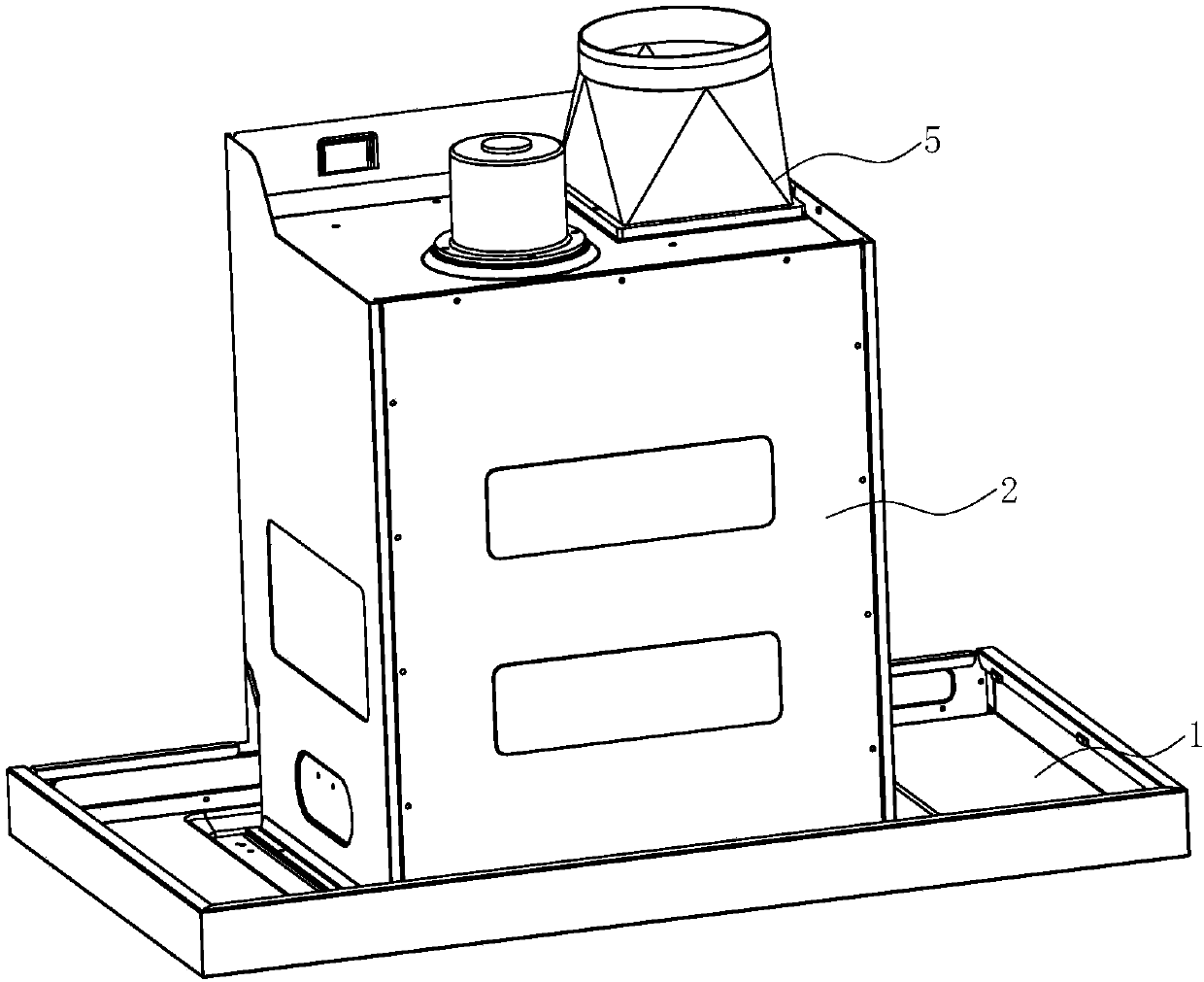

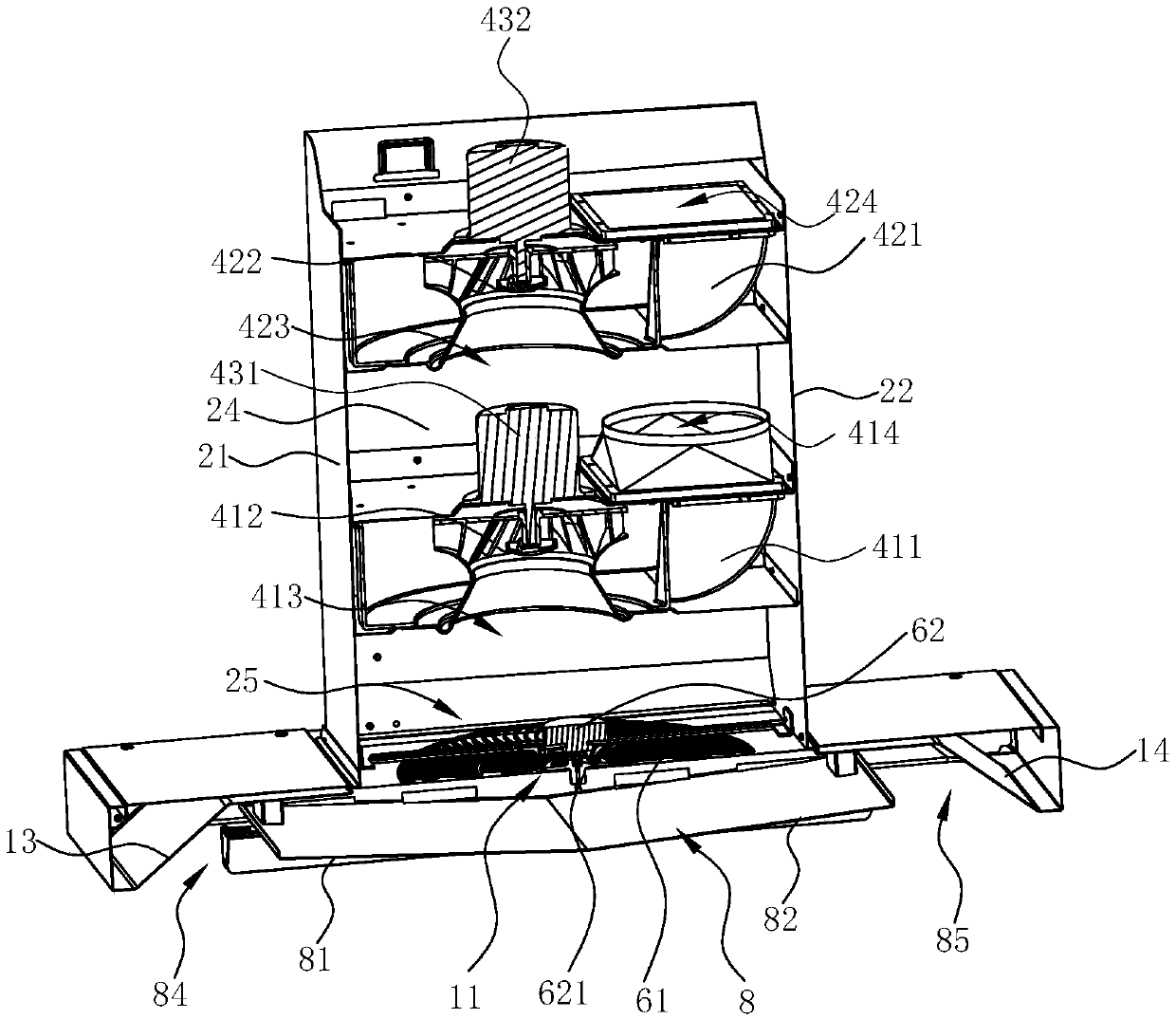

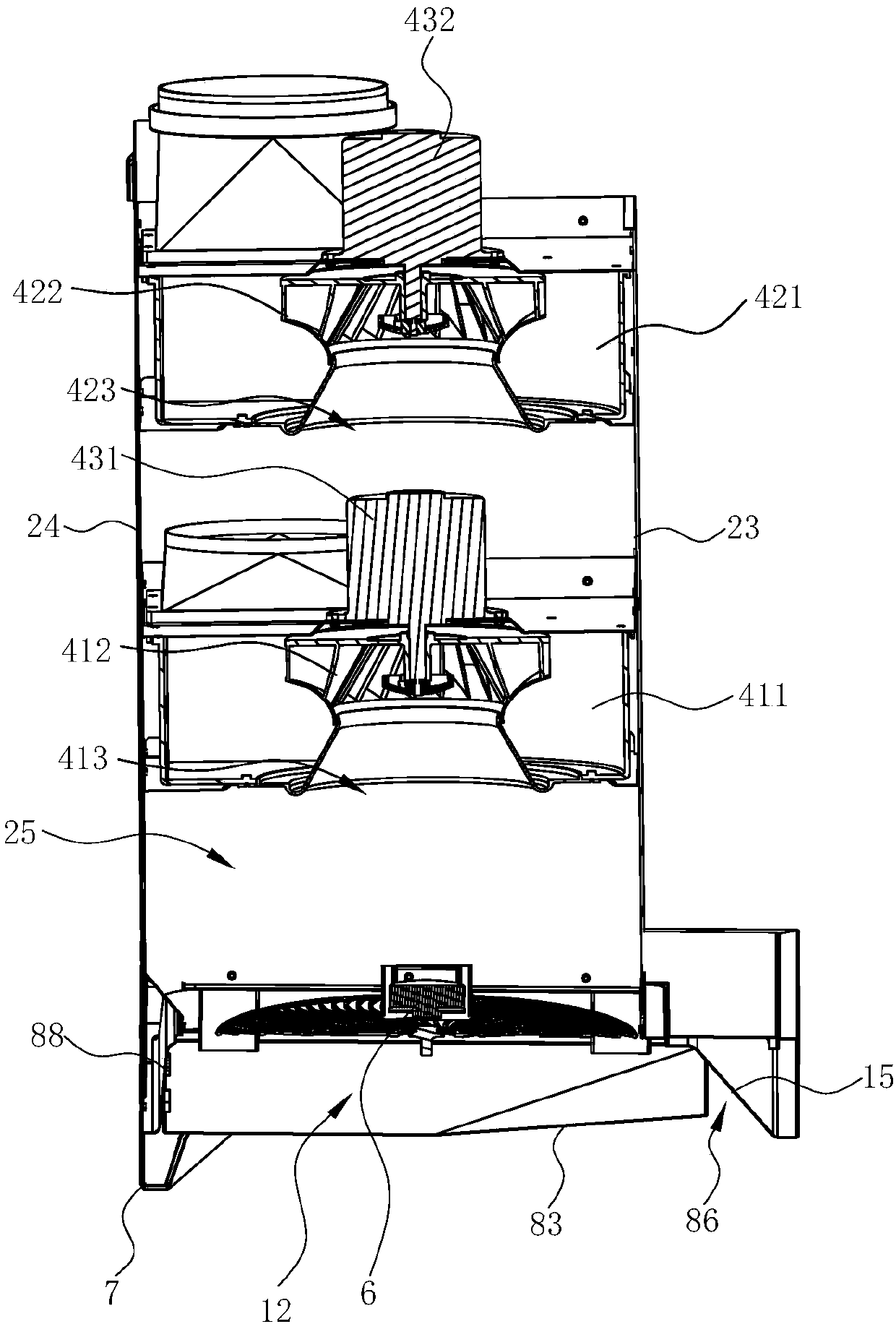

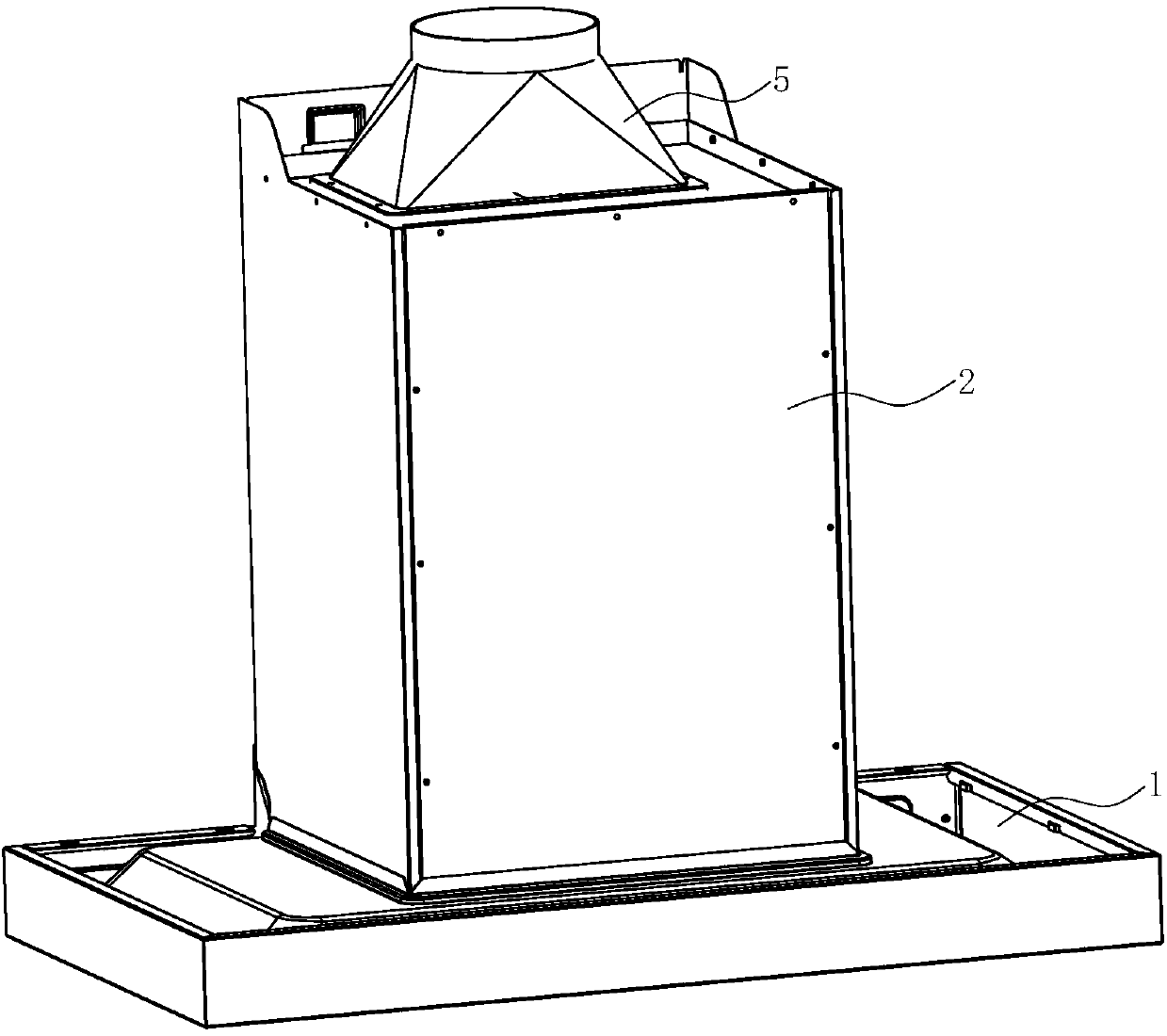

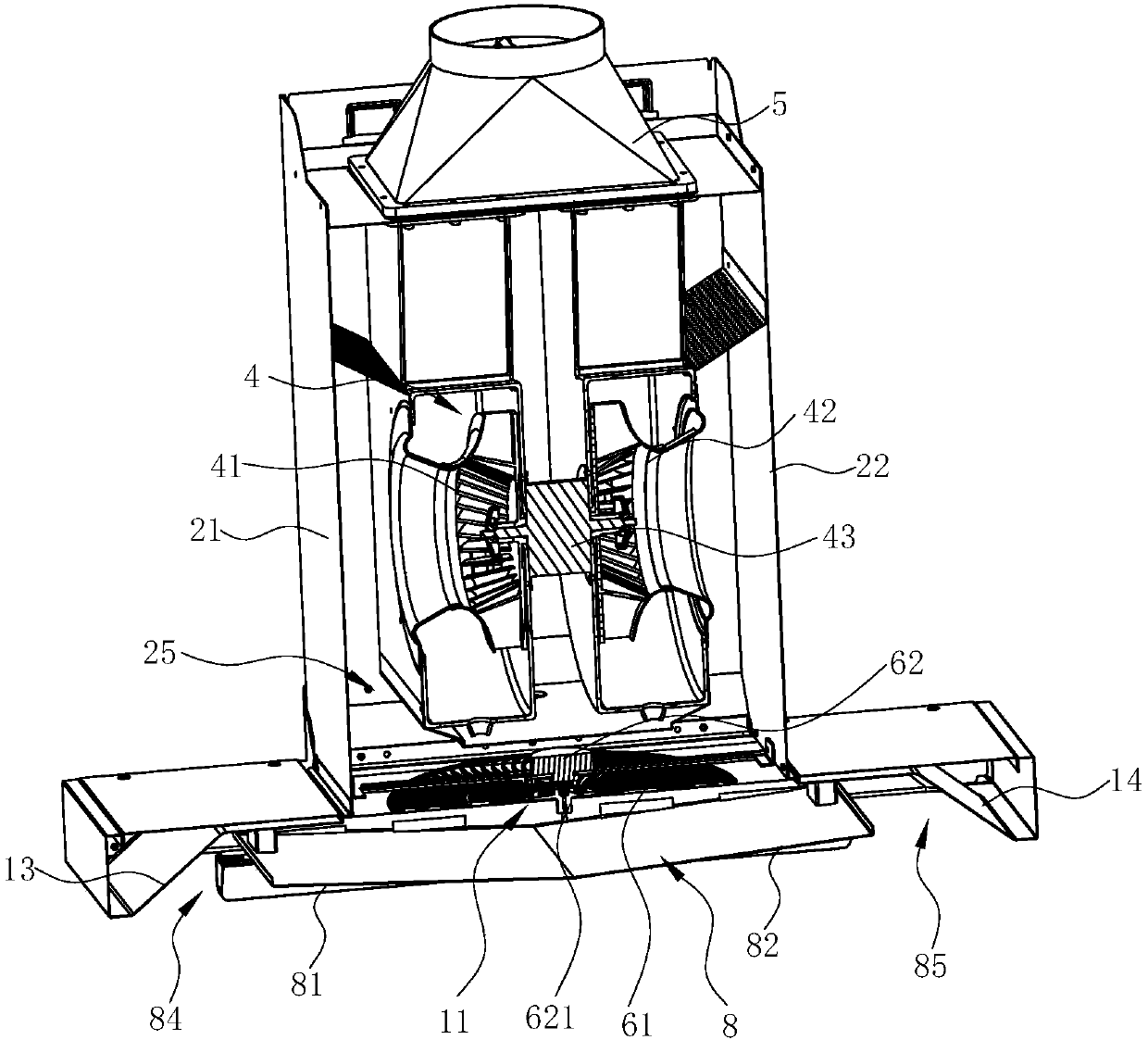

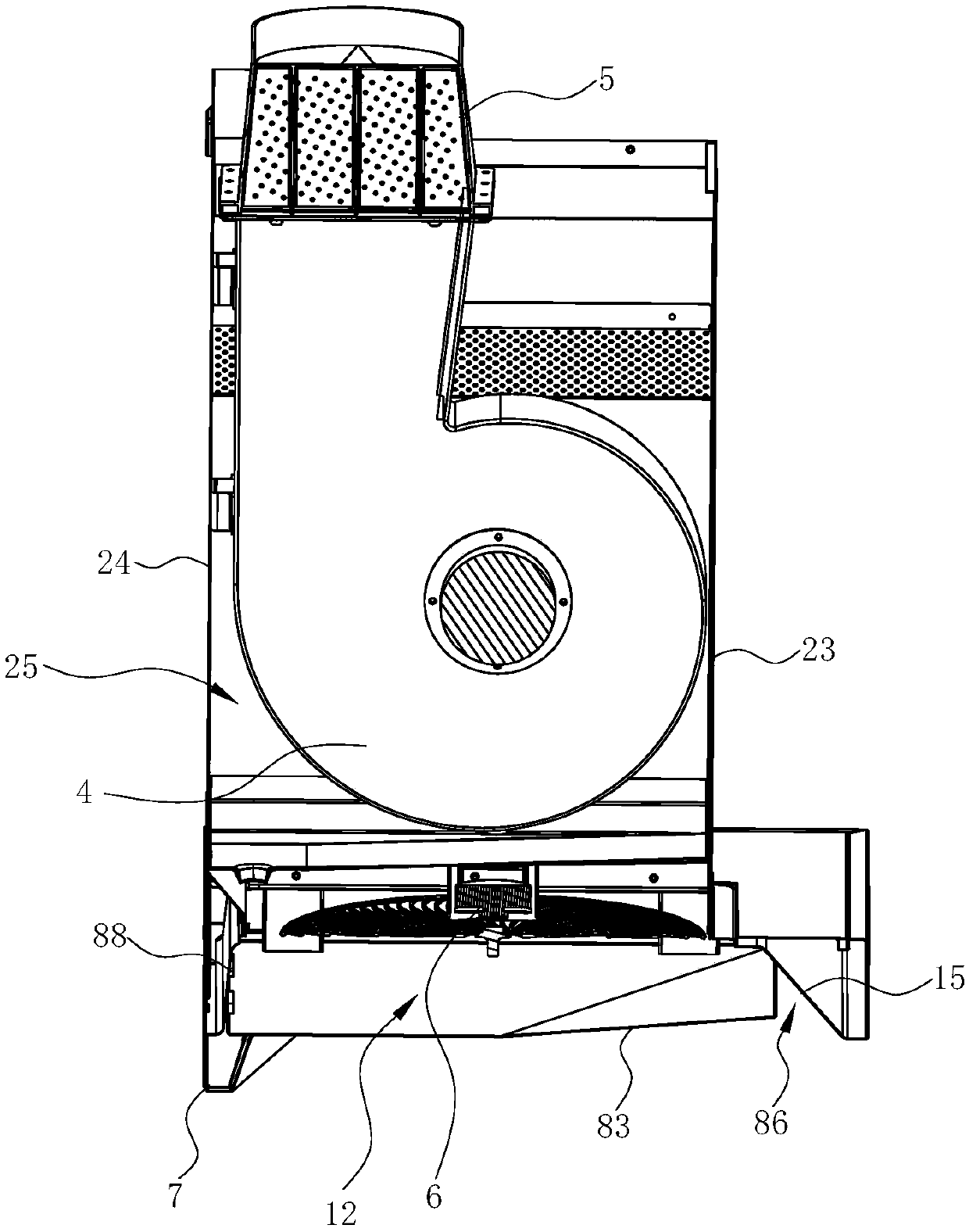

Range hood

PendingCN109595630ASmooth entryPlay a role in rectificationDomestic stoves or rangesLighting and heating apparatusContact timeMechanical engineering

The invention discloses a range hood. The range hood comprises a smoke collecting cover, a machine box arranged above the smoke collecting cover and a fan arranged in the machine box, an air inlet isformed in the smoke collecting cover, a smoke guide plate is arranged below the air inlet, the fan is a three-dimensional fan, at least a part of the lower surface of the smoke guide plate is gradually inclined upwards from the middle to the edge so as to cooperate with the corresponding wall surface of the smoke collecting cover to define an acceleration flow channel with the cross section gradually reduced from bottom to top. The amount of oil smoke entering the range hood per unit time can be increased through the acceleration flow channel, so that the oil smoke suction effect is improved;and through the horizontal three-dimensional fan and a rotary filter screen arranged at an inlet of an air duct, the oil smoke can pass through the rotary filter screen at a relatively low flow rate before not being accelerated through the air duct, then the mutual contact time between the oil smoke and the rotary filter screen is relatively long so that the oil smoke can be fully collided with the rotary filter screen.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

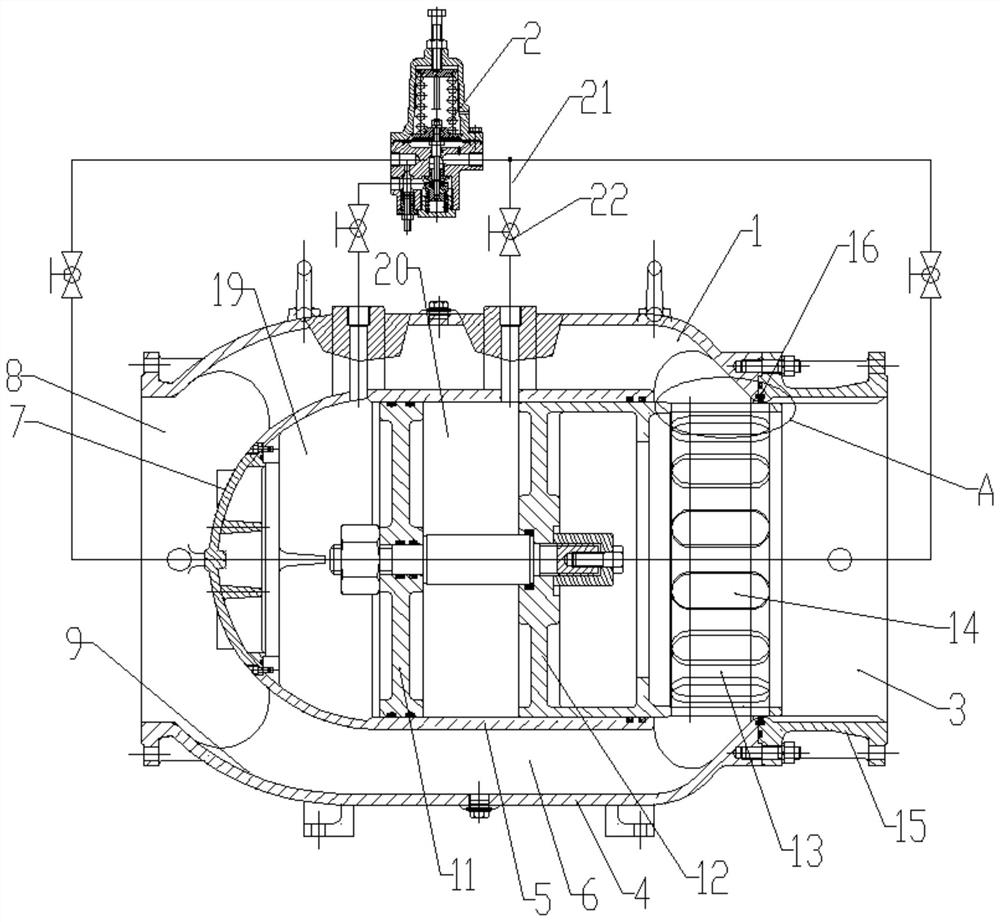

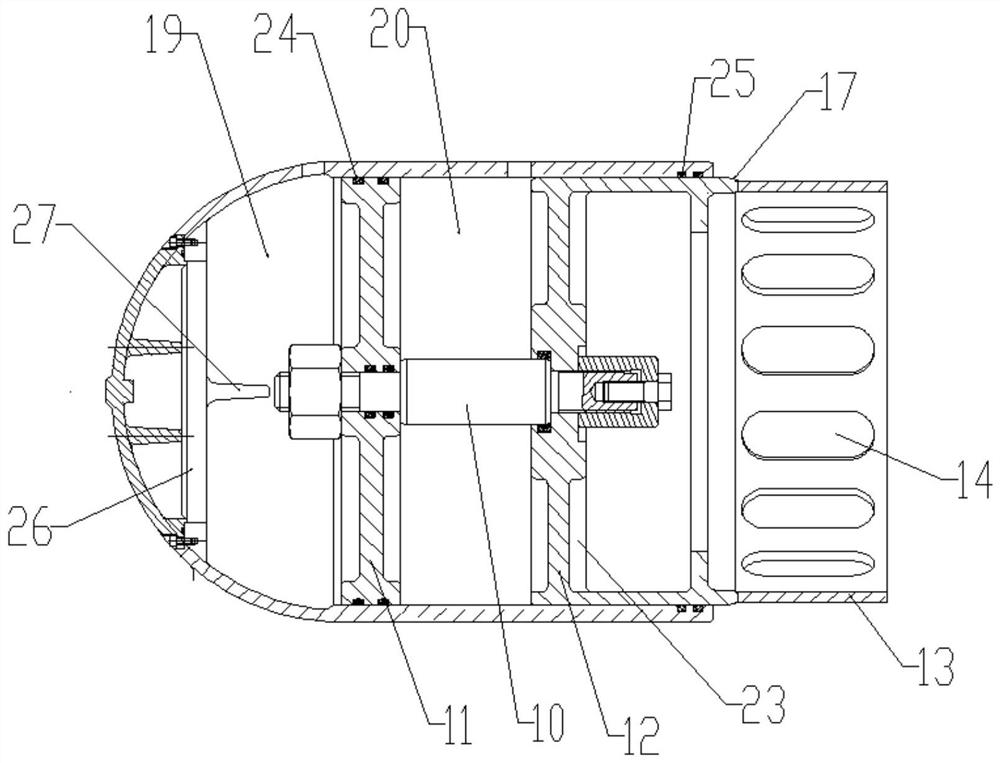

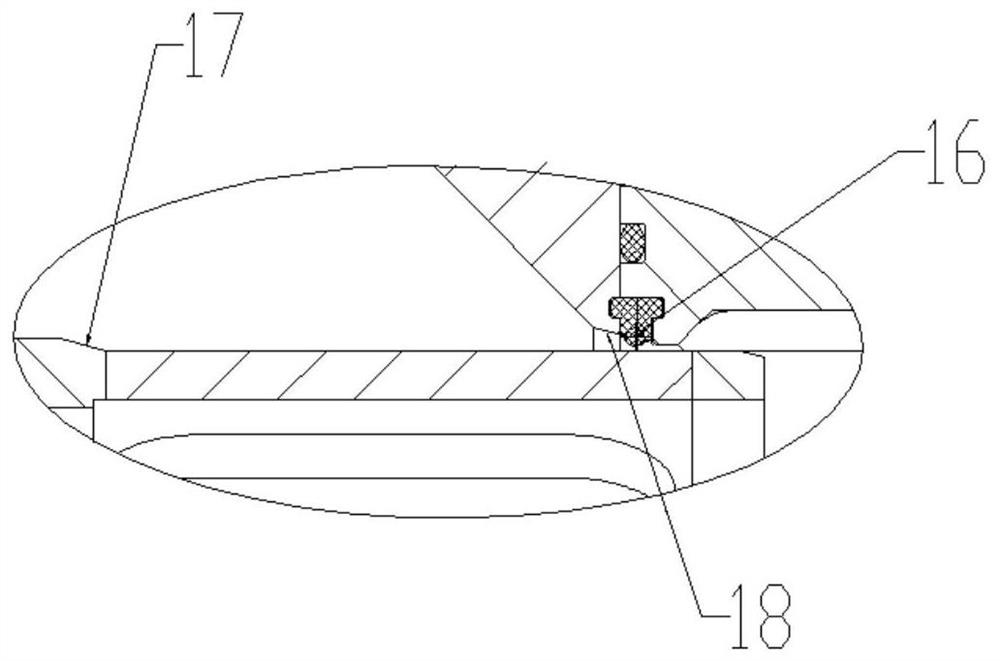

Piston-driven straight-through type pressure and flow regulating valve

PendingCN111795190AImprove liquidityWith pressure regulating functionOperating means/releasing devices for valvesValve members for absorbing fluid energyWater flowEngineering

The invention provides a piston-driven straight-through type pressure and flow regulating valve. The piston-driven straight-through type pressure and flow regulating valve comprises a main valve and apilot valve connected with the main valve, an outer shell and an inner shell of a valve body of the main valve are coaxially arranged, a valve cavity is formed between the outer shell and the inner shell, and a driving device is installed in the inner shell in a sliding mode in the axial direction; an end cover with a spherical structure is arranged on the side, facing a first port, of the innershell; and the inner walls of the two ends of the shell are each of an arc-shaped structure, the inner diameter of each arc-shaped structure is gradually reduced from inside to outside, long grooves are formed in the axial direction of a pup joint, and the outlet side pressure of the valve body is adjusted through the length of the long grooves in a pressure reduction opening-closing piece extending into the valve cavity. A pressure reducing valve provided by the straight-through type pressure and flow regulating valve has high distribution capacity, water flow energy counteracts each other atthe arc-shaped structure at the outlet of the valve body, cavitation and vibration can be effectively avoided, and due to the fact that the pressure reducing opening and closing piece is subjected tothe effect of control pressure of the guide valve, the valve has a pressure regulating function, water head loss is very small during opening and closing, and resistance is small during complete opening; and meanwhile, the valve is closed tightly and is good in sealing performance.

Owner:TIANJIN TANGGU NO 1 VALVE FACTORY

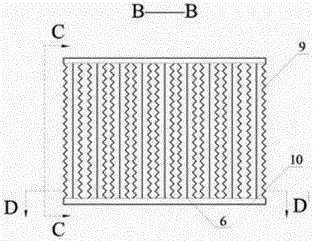

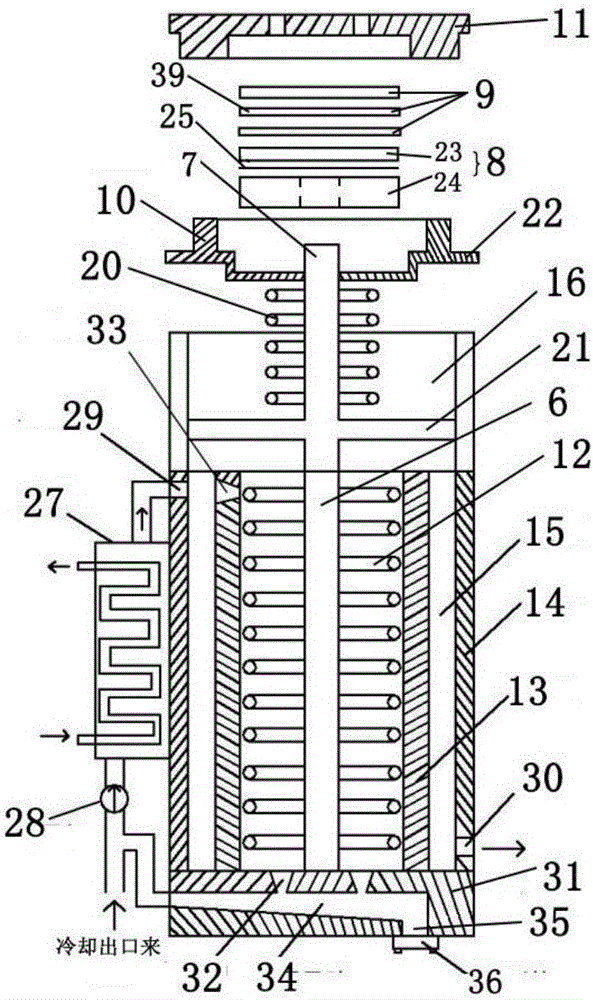

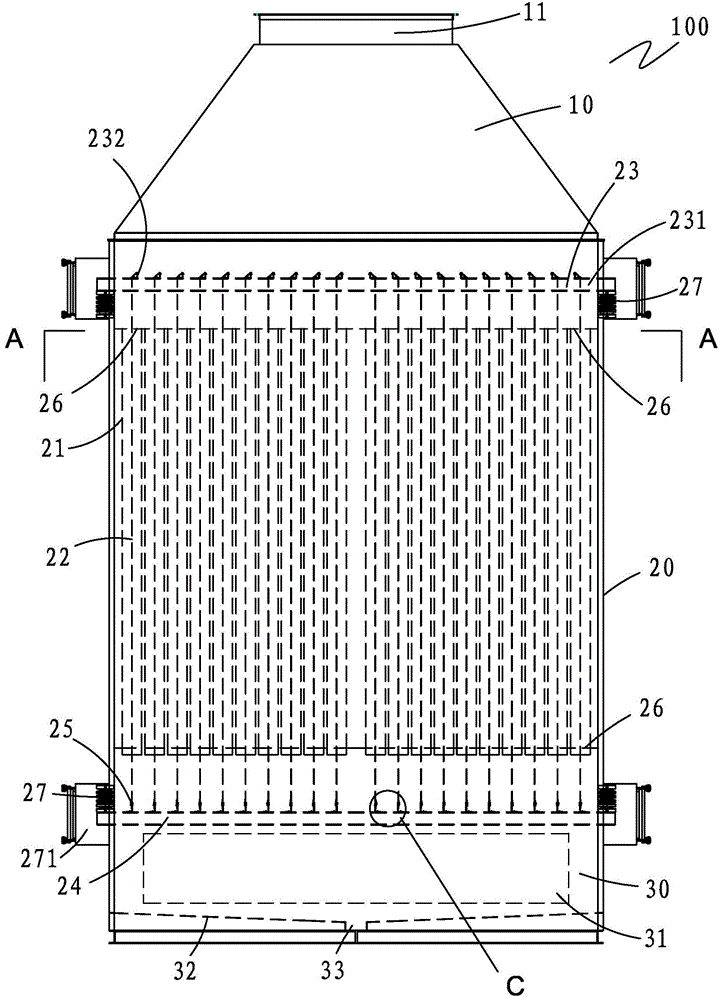

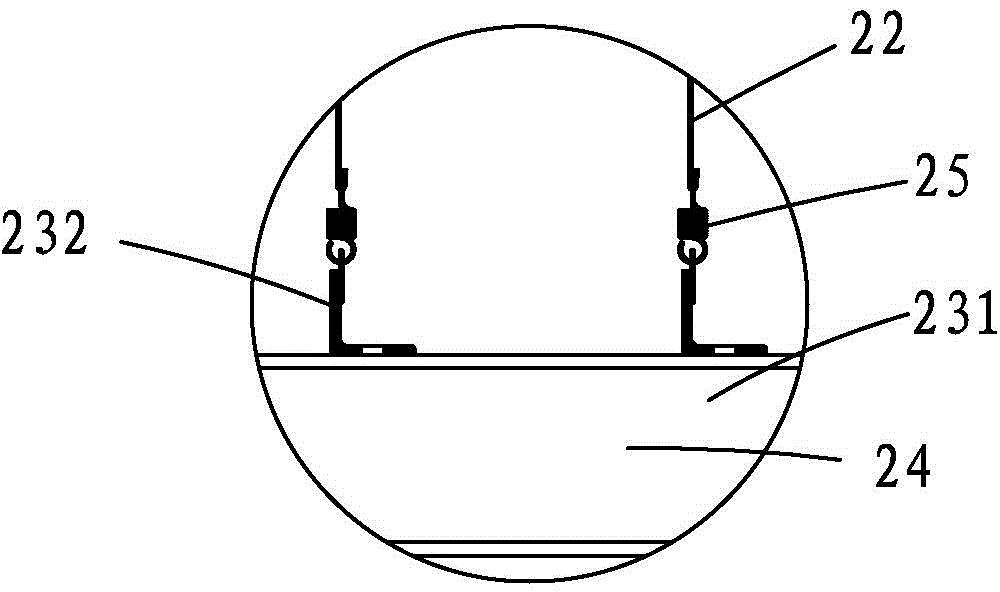

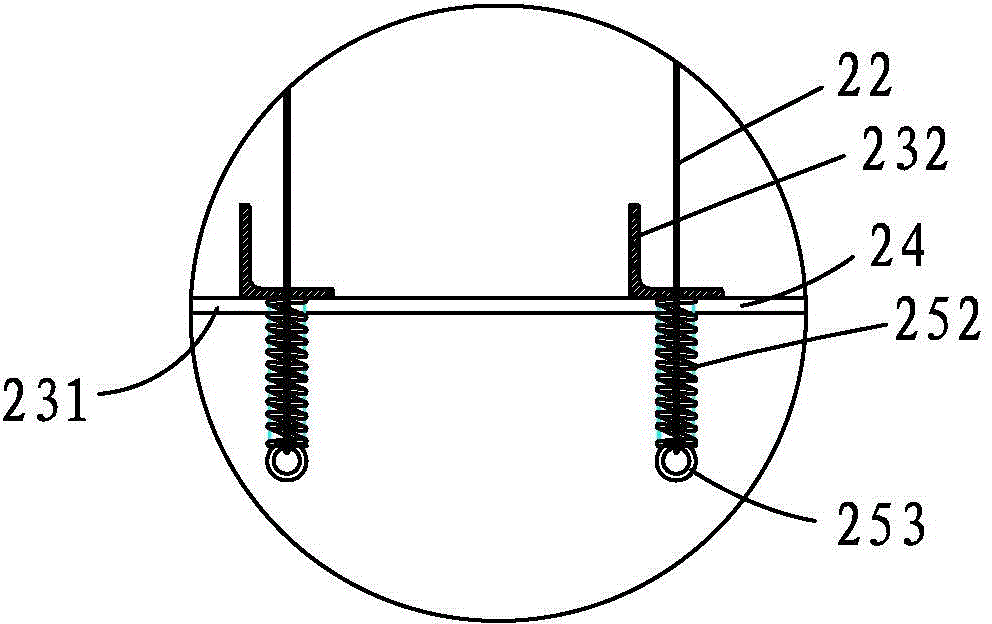

Purification and dust removal device

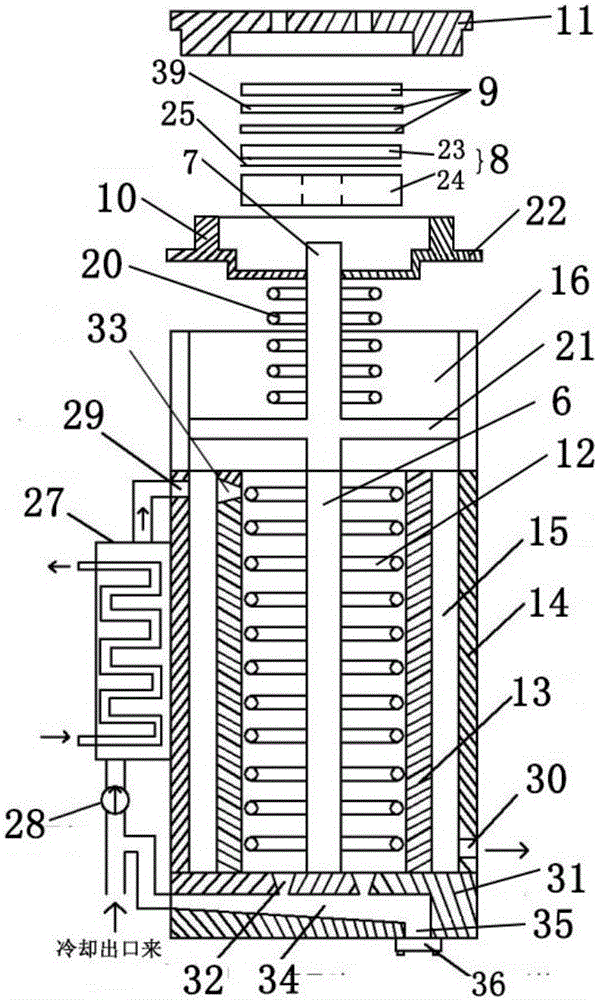

InactiveCN104353553ALarge effective areaImprove stabilityExternal electric electrostatic seperatorElectrostatic separation detailsEngineeringHigh pressure

The invention provides a purification and dust removal device. A plurality of dust suction pipes are vertically distributed in a box body of the purification and dust removal device; cathode lines penetrate through the dust suction pipes respectively and are fixed by an upper frame and a lower frame; the upper end parts of the cathode lines are fixed on the upper frame, and the lower end parts of the cathode lines are fixed on the lower frame; the upper frame and the lower frame are both fixed on the box body; the upper frame or the lower frame is connected with a high-voltage power supply system through a wire. The dust suction pipes are arranged to greatly enlarge the dust collection area; the cathode lines penetrate through the centers of the dust suction pipes, so that the internal part of each dust suction pipe forms a high electric field which is uniform in strength, large in onset area, and capable of rectifying the exhaust gas when the exhaust gas passes through each of the dust suction pipes; the cathode lines are fixed through elastic elements, so that the cathode lines can be tensioned tightly; the elastic elements are low in wind resistance and low in possibility of swing, so that the cathode lines are better in stability.

Owner:福建省沃特宝环保科技有限公司

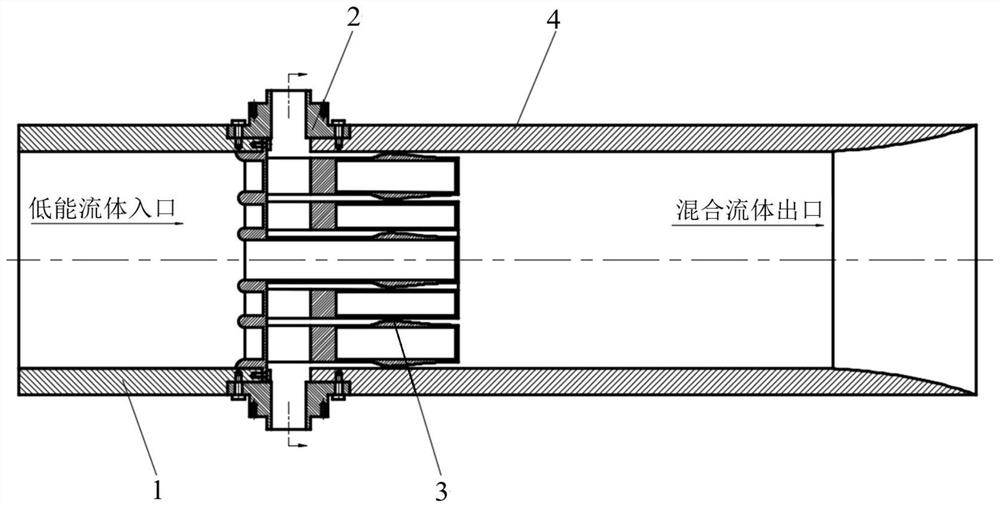

Distributed circular seam ejector device

ActiveCN112058526AIncrease contact surfaceImprove blendingLiquid spraying apparatusEngineeringMechanical engineering

The invention discloses a distributed circular seam ejector device. The device adopts a pipeline connection mode and sequentially comprises a low-energy fluid inlet section, a high-energy fluid inletsection and a mixed fluid outlet section which are connected in sequence, and a binary circular seam ejector is arranged in a pipeline near the high-energy fluid inlet section; through holes are formed in the surface of the high-energy fluid inlet section and communicate with an external high-pressure tank; the low-energy fluid inlet section, the high-energy fluid inlet section and the mixed fluidoutlet section share the same central axis; the binary circular seam ejector comprises annular spray pipe unit bodies which are arranged in an annular mode, the spray pipe unit bodies are connected through reinforcing ribs, part of the reinforcing ribs are of a hollow structure, and high-energy fluid enters the spray pipe unit bodies from the through holes in the high-energy fluid inlet section and is sprayed out from outlets of the spray pipe unit bodies; and annular spray pipes are arranged in the spray pipe unit bodies. The device is suitable for fluid ejection control of gas and liquid. According to the device, the ejection efficiency is improved, the boundary dimension of the ejector device is reduced, and the space installation requirement of the ejector device is lowered.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

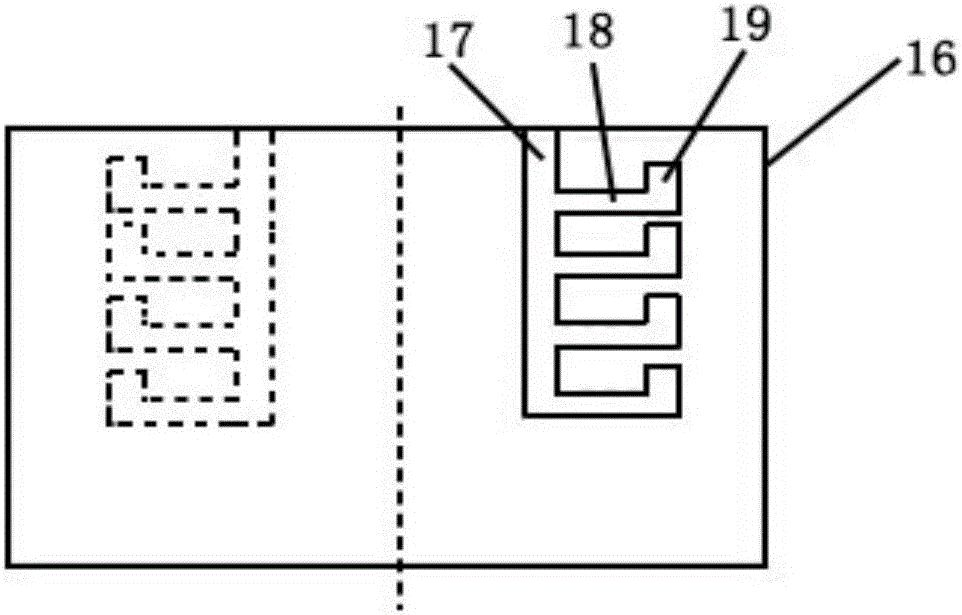

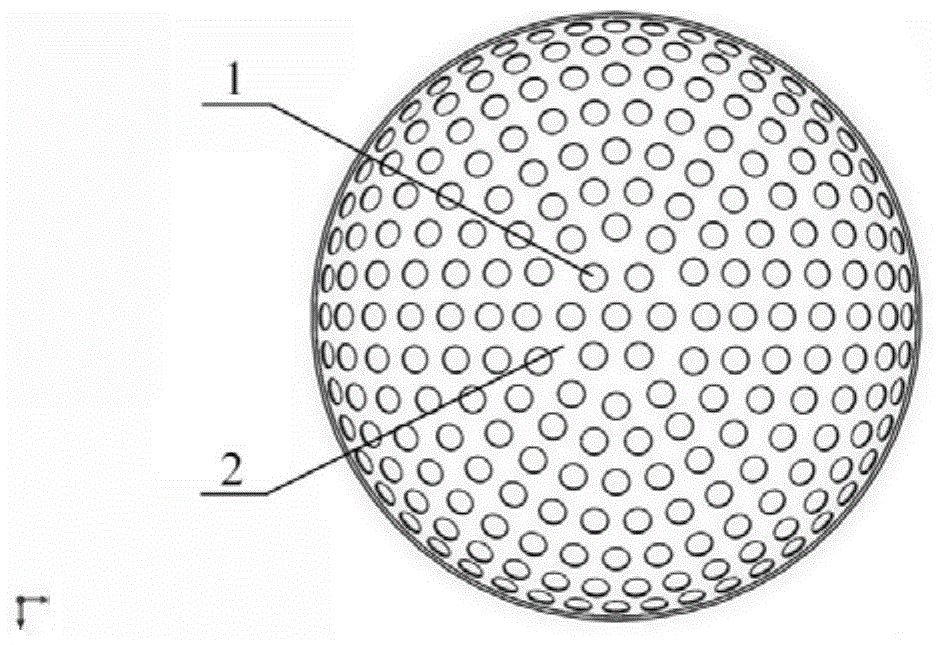

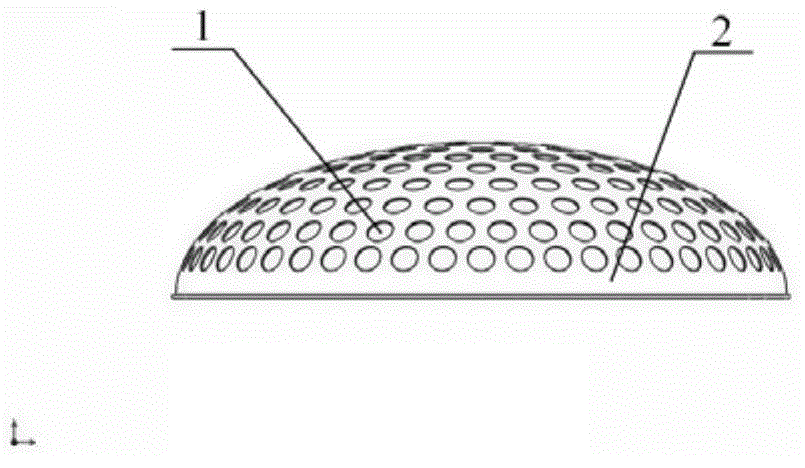

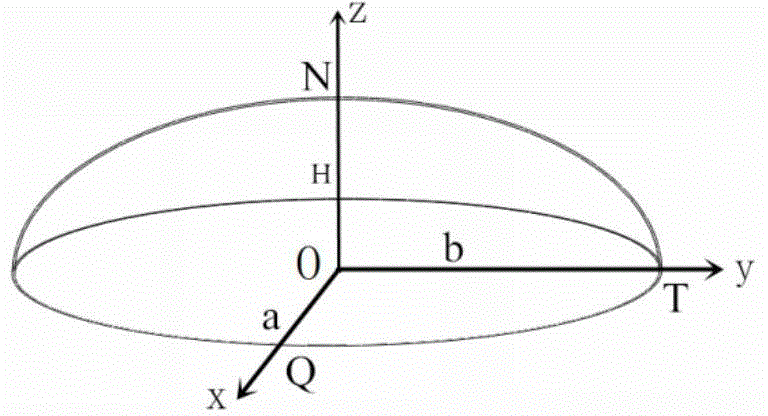

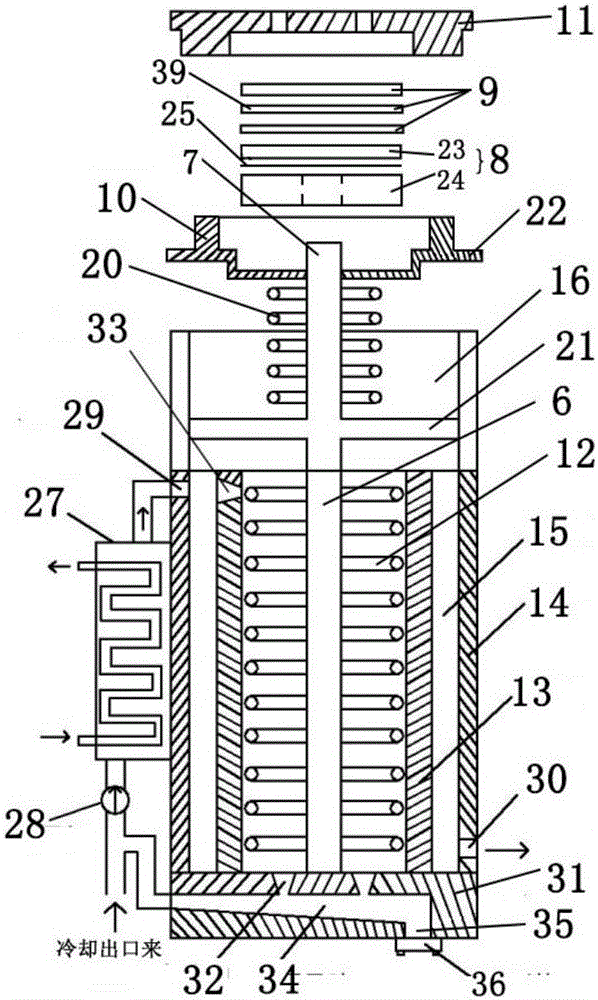

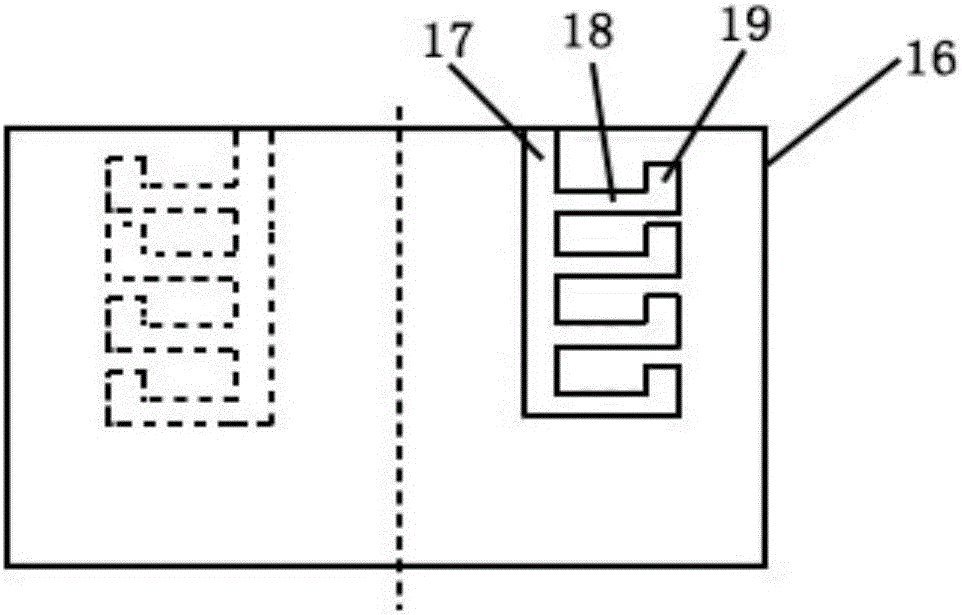

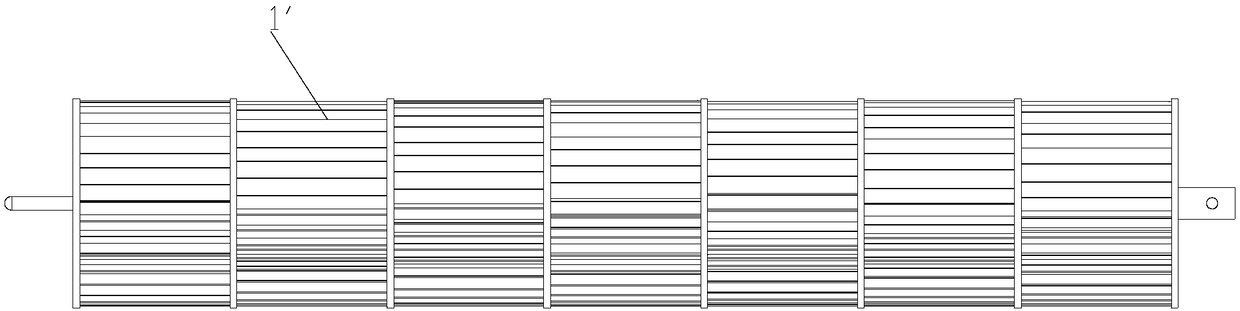

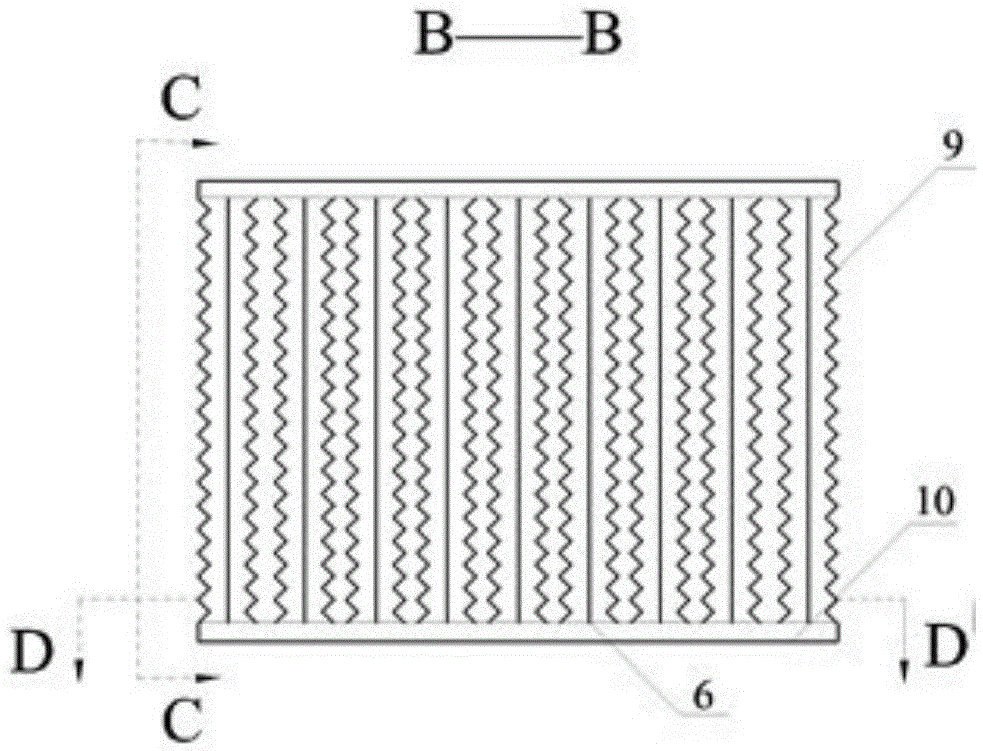

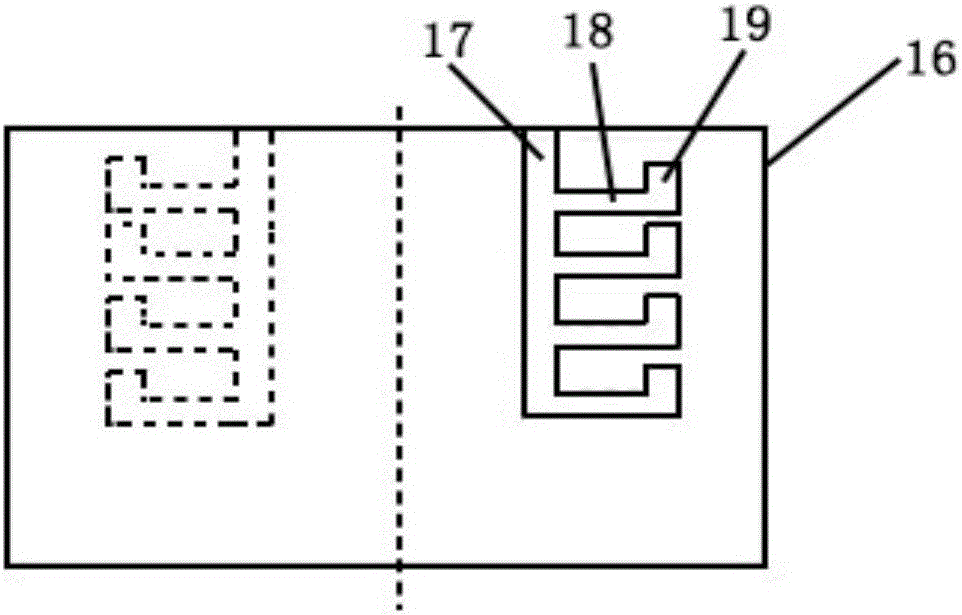

Gas turbine condenser cooling water secondary filter screen and design method of disc filter screen framework

ActiveCN104699922AIncrease vacuumGood water flowSpecial data processing applicationsWater flowEngineering

A gas turbine condenser cooling water secondary filter screen comprises a shell, a sewage discharge and suction mechanism, a power device and a sewage discharge outlet, wherein the sewage discharge and suction mechanism is disposed in the shell and comprises a disc filter screen framework and a double-sided sewage suction opening formed below the disc filter screen framework, a driven bevel gear fixedly connected to the rotary shaft of the sewage discharge and suction mechanism is meshed with a power bevel gear fixedly connected to the shaft end of the power device, and the sewage discharge outlet is formed in the shell located on the lower portion of the sewage discharge and suction mechanism. The invention further provides the design method of the disc filter screen framework. The gas turbine condenser cooling water secondary filter screen has the advantages that flowing of water flows of a condenser inlet water chamber can be improved, the water flow uniformity coefficient is increased, flow rectifying is achieved, the heat exchanging conditions of the cooling tube bundles in a condenser are improved effectively and reasonably, condenser vacuum is increased, power plant standard coal consumption rate is lowered, and energy is saved; the design of the disc filter screen framework is the key technology of the gas turbine condenser cooling water secondary filter screen. In addition, the design method of the disc filter screen framework is scientific and reasonable.

Owner:NORTHEAST DIANLI UNIVERSITY +2

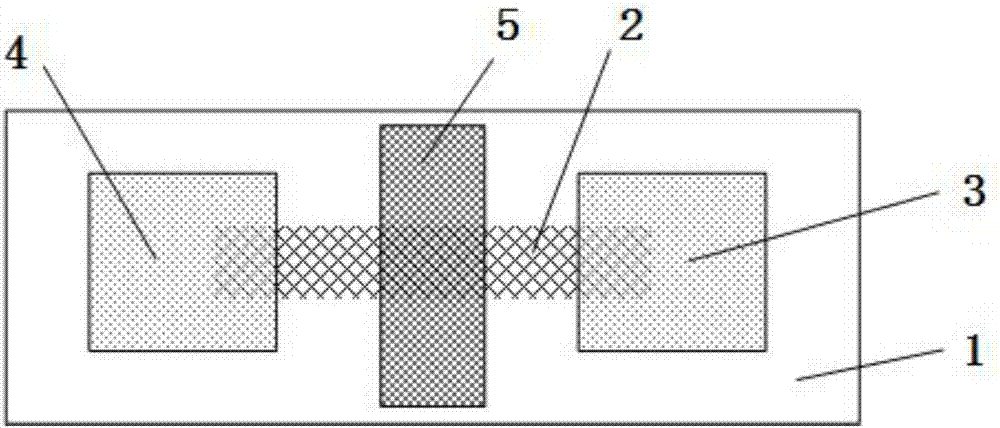

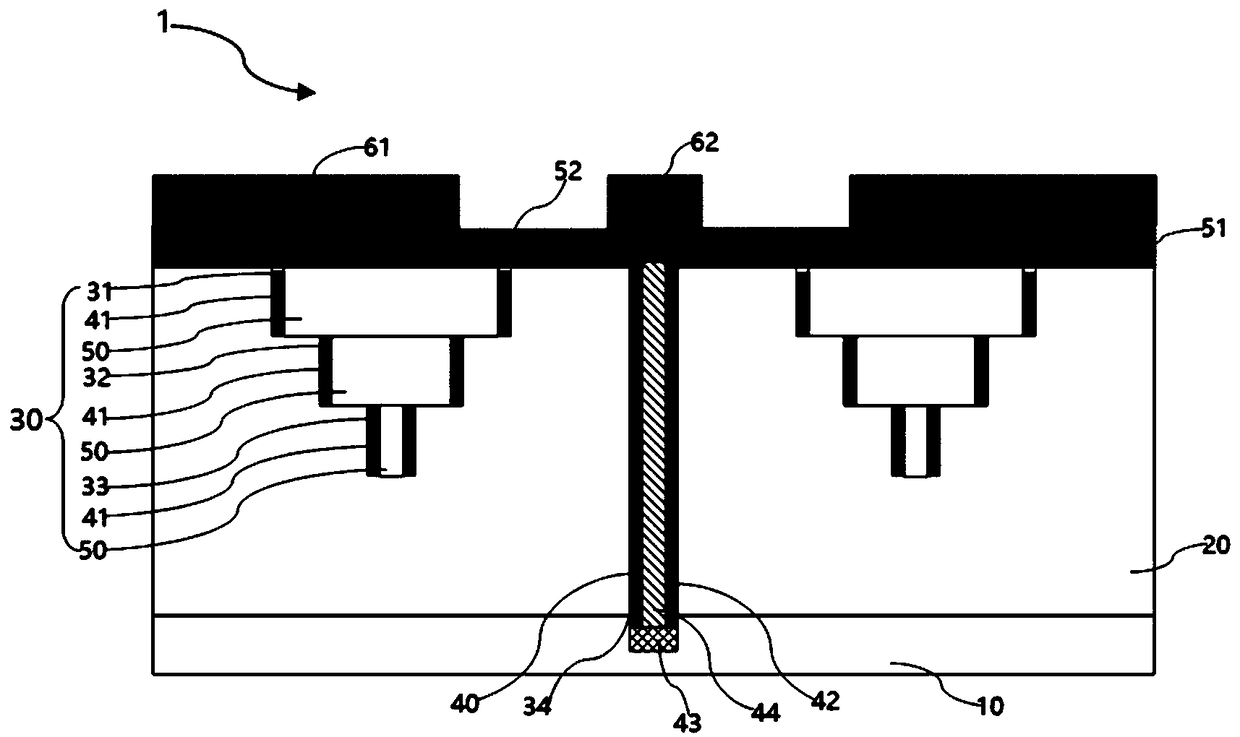

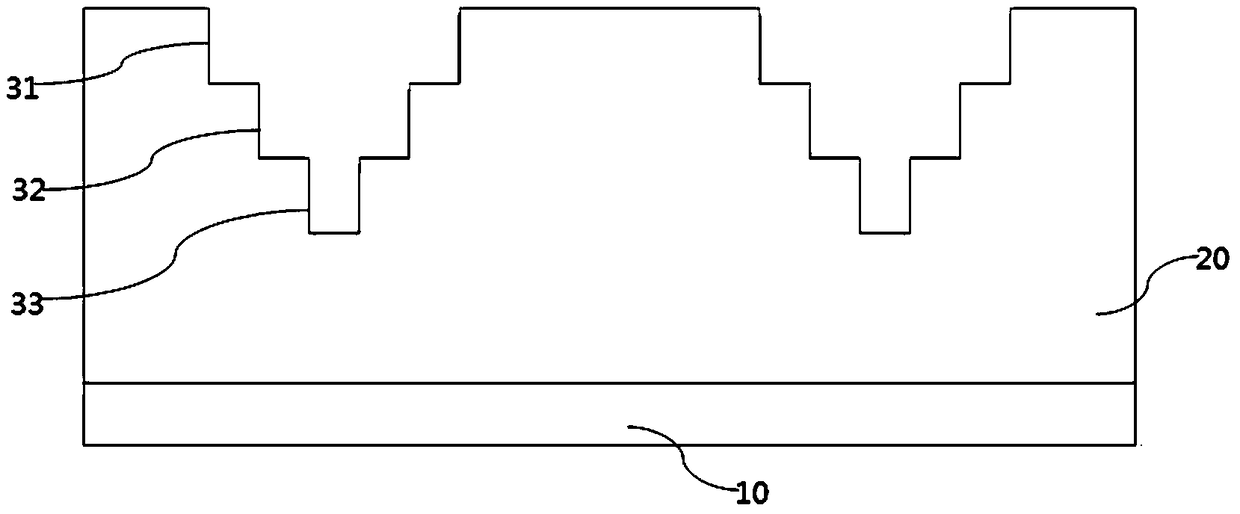

Power device protective chip and preparation method thereof

ActiveCN109300894AImprove stabilityReduce conduction lossSolid-state devicesSemiconductor/solid-state device manufacturingSchottky barrierPhysics

The invention provides a power device protective chip which comprises a substrate, a first epitaxial layer formed on the substrate, rectification areas formed in the first epitaxial layer separately,and an isolation area positioned between the two rectification areas and extending from the upper surface of the first epitaxial layer to the substrate; each rectification area comprises a first trench formed from the upper surface of the first epitaxial layer to the first epitaxial layer, a second trench formed from the bottom of the first trench to the first epitaxial layer, and a third trench formed the bottom of the second trench to the first epitaxial layer, the first, second and third trenches are communicated, the widths of the first, second and third trenches are decreased successively, and Schottky barrier heights between metal layers in the first, second and third trenches and the first epitaxial layer are reduced successively; and the isolation area comprises a fourth trench, aninjection region positioned in the bottom of the fourth trench and a second epitaxial layer formed in the fourth trench. The invention also provides a preparation method of the power device protective chip. The reliability is improved, the packaging area is reduced, and the cost is reduced.

Owner:SHENZHEN MYD INFORMATION TECH CO LTD

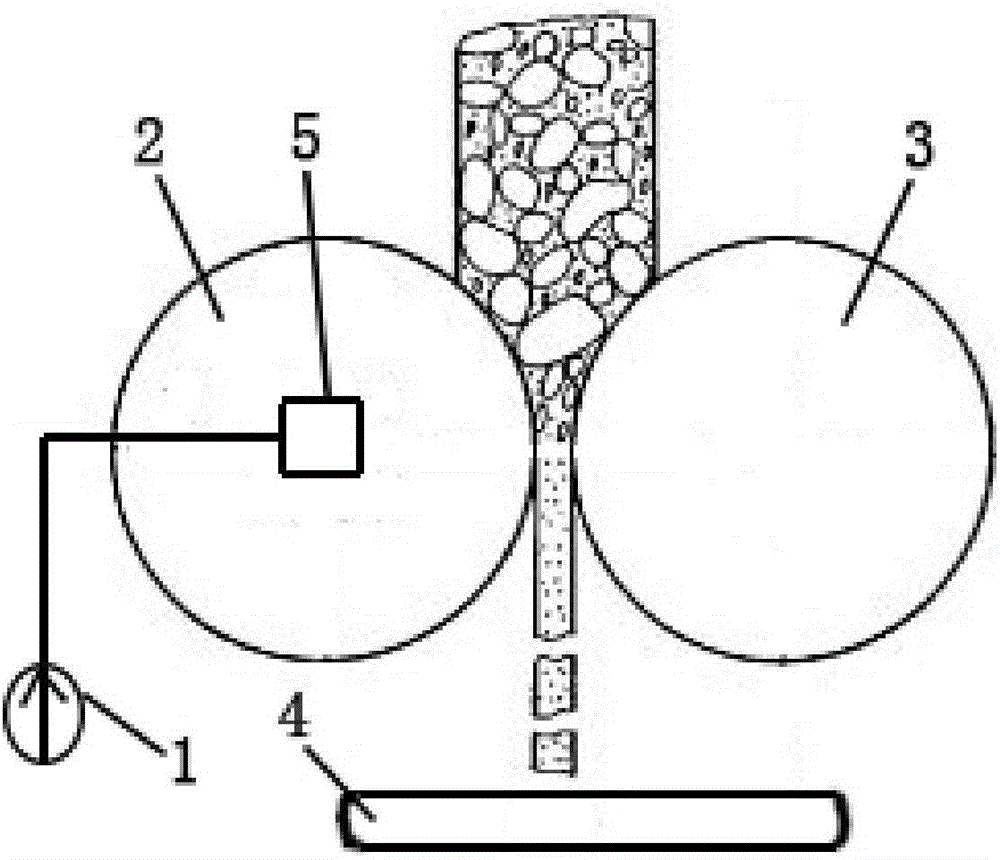

Novel strength controllable pressure roller device

InactiveCN106000524ARealize linear reciprocating motionReduced integrated weightPositive displacement pump componentsPumpsHydraulic motorEngineering

The invention discloses a novel strength controllable pressure roller device. The device comprises a driving pressure roller, a driven pressure roller and a conveying belt; a material drops down from the upper side of a gap between the driving pressure roller and the driven pressure roller, and falls into the conveying belt after rolling; the driving pressure roller is driven to rotate by a hydraulic motor; and oil is supplied to the hydraulic motor by an oil supply pump. The pressure roller device can precisely control the rotating speed of the driving pressure roller so as to control the rolling effect, in particular, is suitable for rolling materials with smaller original particle size, and has such advantages as excellent cooling conditions, long operation period and convenience for maintenance.

Owner:董超超

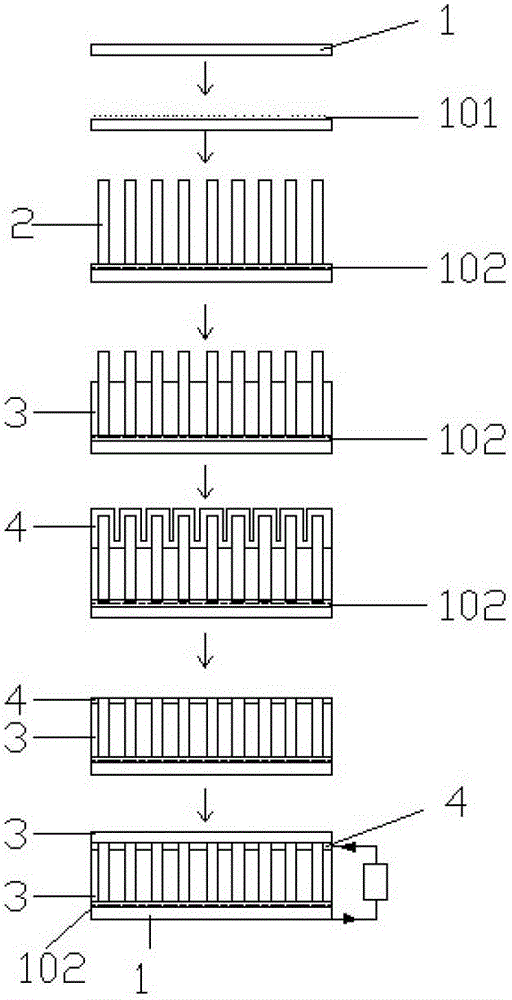

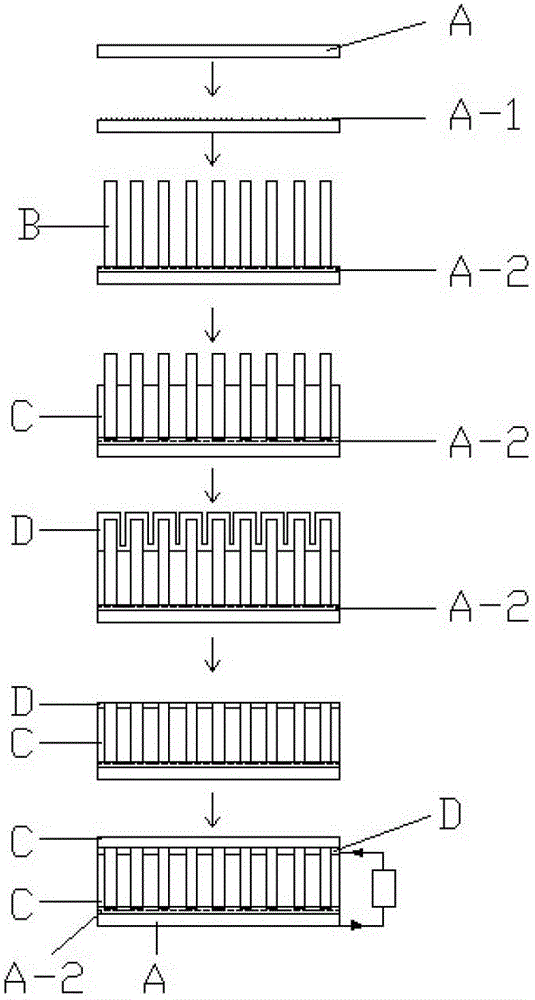

A kind of manufacture method of nano antenna solar cell

InactiveCN102709399BPlay a role in rectificationSimple processFinal product manufactureSemiconductor devicesCarbon nanotubeSubstrate modification

The invention relates to a manufacturing method of a high-efficiency nano antenna solar battery. The manufacturing method comprises the following steps of: preparing turbid liquid from an ethanol or acetone organic solvent and nano silicon powder according to a massic volume ratio of nano silicon (g) to the organic solvent (ml) of 1:200, and spin-coating the turbid liquid onto a metal substrate for carrying out substrate modification by a spin coating method; and growing a silicon-graphite-carbon nano tube composite structure on the substrate in one step under the conditions of temperature of 800-1000 DEG C and standard pressure intensity of 40-100Pa and forming a solar battery device sheet; generating a silicon rubber or silicon carbide or alumina passivation layer among carbon nano tubes by adopting a spin coating process or sputtering or evaporating; and depositing a transparent conductive film on the upper layer of the device sheet by adopting methods, such as an electron beam evaporation method and a magnetron sputtering method, and finally obtaining the high-efficiency nano antenna solar battery by taking the metal substrate and the transparent conductive film as electrodes. The manufacturing method disclosed by the invention can be used for directly generating a nano solar battery main structure by adopting a one-step method, is simple and highly-efficient, saves raw materials and cost and is suitable for large-scale production.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

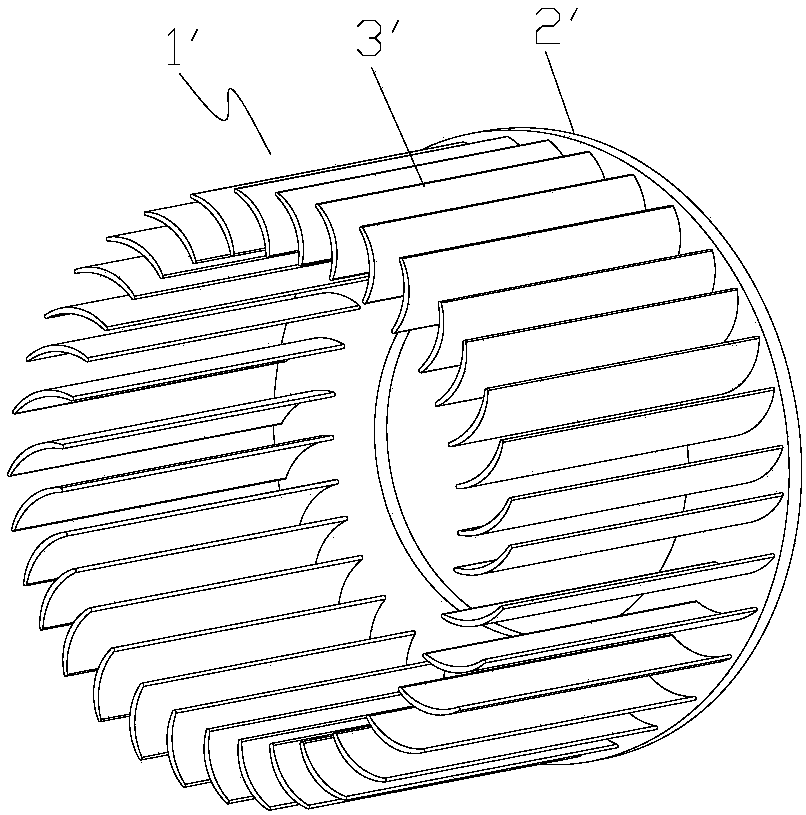

Cross-flow fan blade, cross-flow fan, indoor unit and air conditioner

PendingCN108105152APlay a role in rectificationPlay a stabilizing rolePump componentsLighting and heating apparatusPulp and paper industryFan blade

The invention provides a cross-flow fan blade, a cross-flow fan, an indoor unit and an air conditioner. The cross-flow fan blade comprises a blade body (1); the blade body (1) comprises a blade back (2); and the blade back (2) is provided with a rectification projection (3) projected on the blade back (2). The cross-flow fan blade can reduce the airflow separation phenomenon at the back part of the blade when the fan is rotated, and reduces the airflow separation loss.

Owner:GREE ELECTRIC APPLIANCES INC

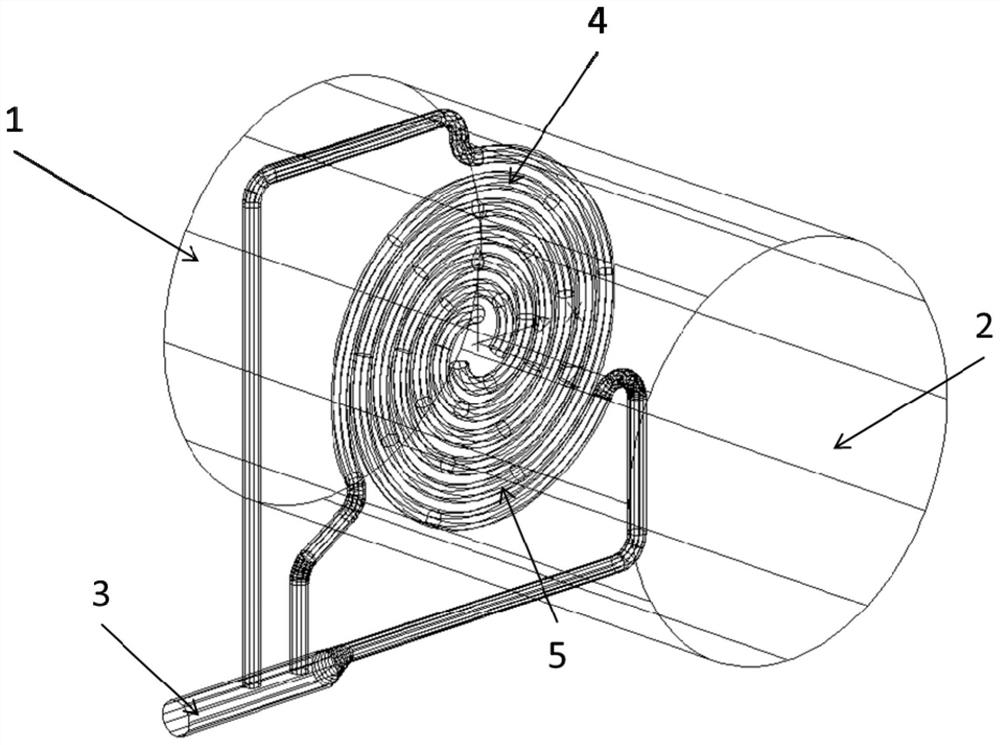

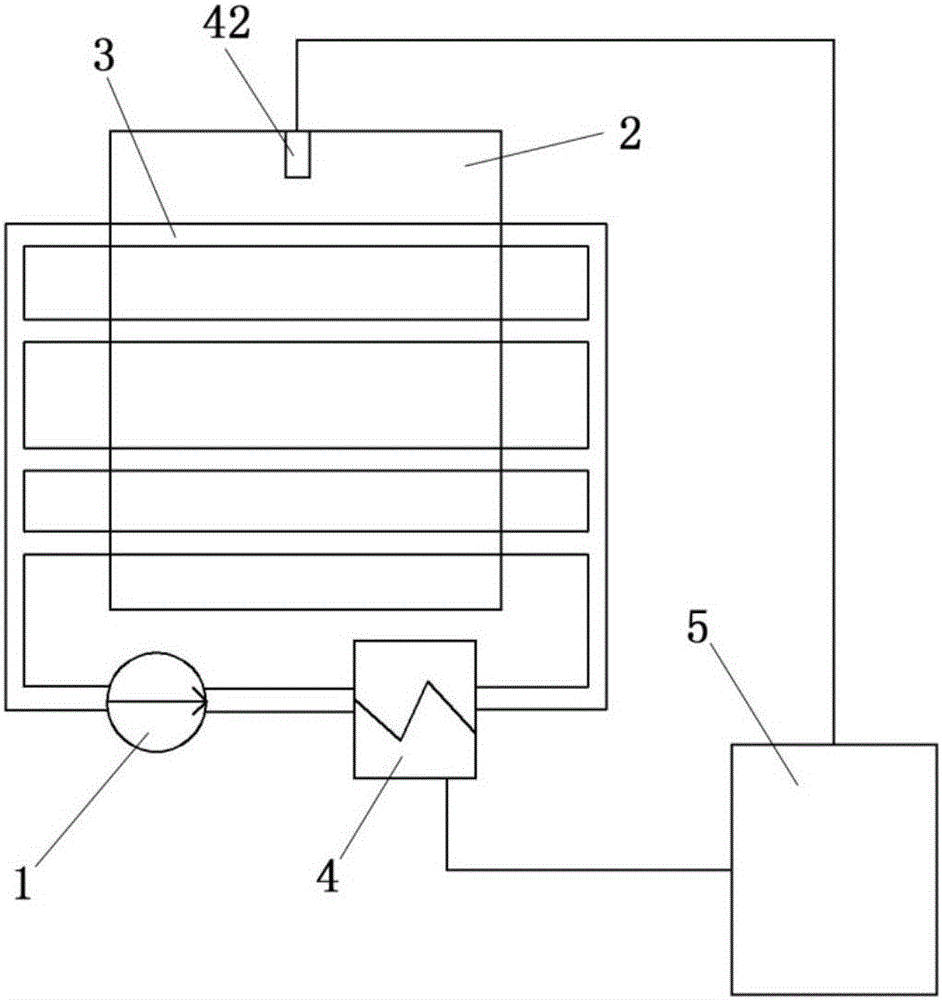

Ammonia working medium liquid distributor

ActiveCN108709343AImprove mixing uniformityEvenly distributedMechanical apparatusFluid circulation arrangementEngineeringDistributor

The invention discloses an ammonia working medium liquid distributor which comprises a liquid distributing pipe and a box-like body, wherein the body is arranged horizontally, a top plate is a gas homogenizing plate, and a bottom plate is a liquid distributing plate; the liquid distributing pipe comprises a vertical pipe, a collecting pipe and a plurality of branch pipes; the collecting pipe and the branch pipes are arranged in an inner cavity of the body, and the branch pipes communicate to the collecting pipe, separately; an upper liquid distributing hole is formed in each branch pipe; a gapis reserved between each upper liquid distributing hole and the gas homogenizing plate; the vertical pipe is arranged vertically, the upper end of the vertical pipe is a liquid inlet, and the vertical pipe penetrates above the body and communicates to the liquid distributing plate and the collecting pipe; a plurality of gas homogenizing holes are formed in the gas homogenizing plate; and a plurality of lower liquid distributing holes are formed in the liquid distributing plate. According to the ammonia working medium liquid distributor disclosed by the invention, an ammonia working medium isuniformly distributed in an evaporator and the storage capacity of the ammonia working medium in the liquid distributor can be reduced.

Owner:YANTAI MOON

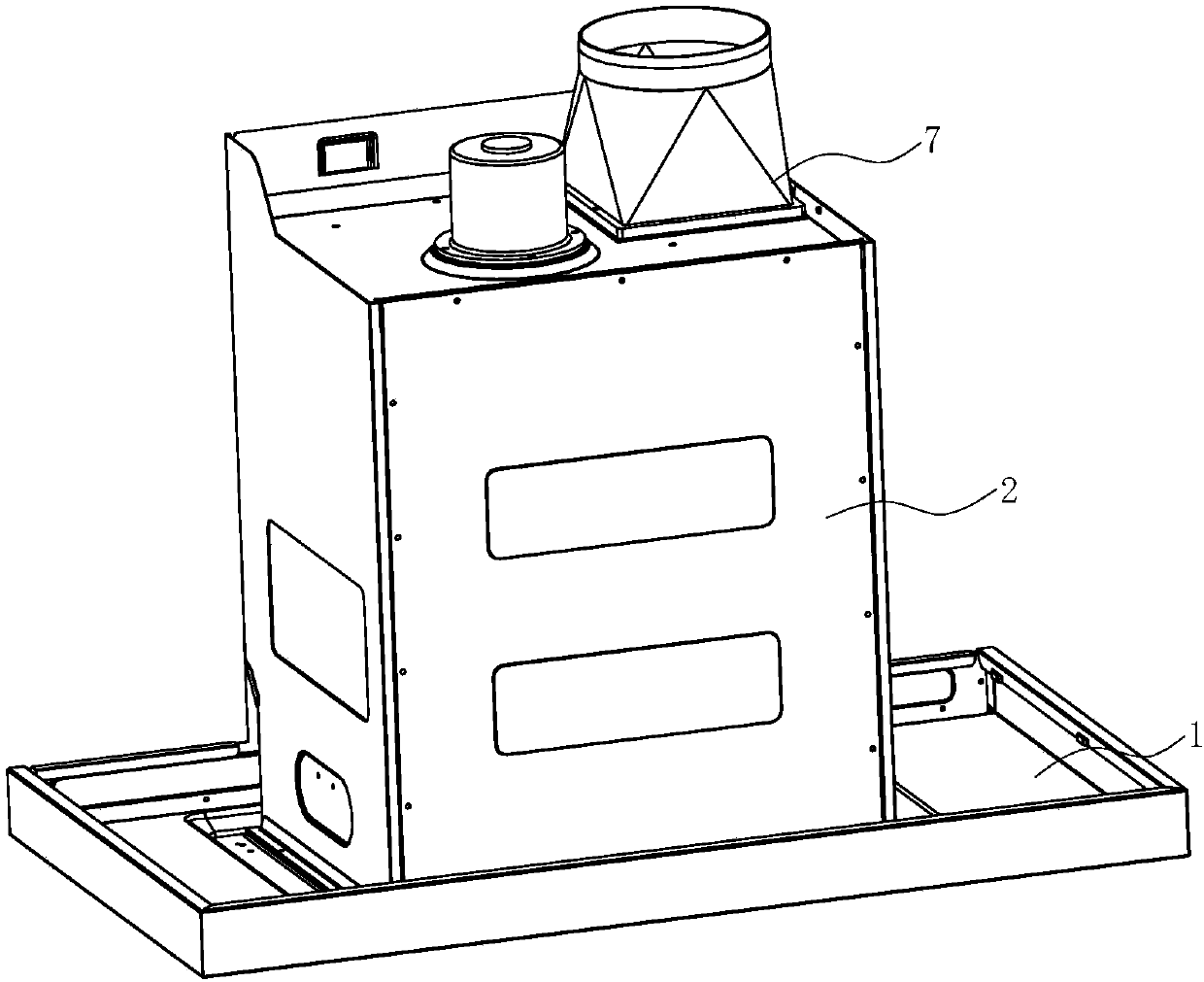

Extractor hood

PendingCN109595647APlay a role in rectificationCompact structureDomestic stoves or rangesLighting and heating apparatusContact timeEngineering

The invention discloses an extractor hood. The extractor hood comprises a fume collecting hood, a machine case arranged above the fume collecting hood, and a draught fan system arranged in the machinecase. The fume collecting hood is provided with an air inlet, a fume guiding plate is arranged below the air inlet, and the draught fan system comprises a first ternary draught fan and a second ternary draught fan which are connected in series. At least one part of the lower surface of the fume guiding plate gradually inclines upwards from the middle to the edge and is matched with the corresponding wall face of the fume collecting hood accordingly so that an acceleration runner with the cross section gradually reduced from bottom to top can be defined. Through the acceleration runner, the volume of the cooking fume entering the extractor hood within the unit time can be increased, and the cooking fume suction effect is enhanced; and through a rotation filter net arranged at the positionof an air flue inlet, the cooking fume passes through the rotation filter net with the low flow speed before being accelerated by the air flue, the mutual contact time of the cooking fume and the rotation filter net is long, and sufficient collisions between the cooking fume and the rotation filter net can be achieved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

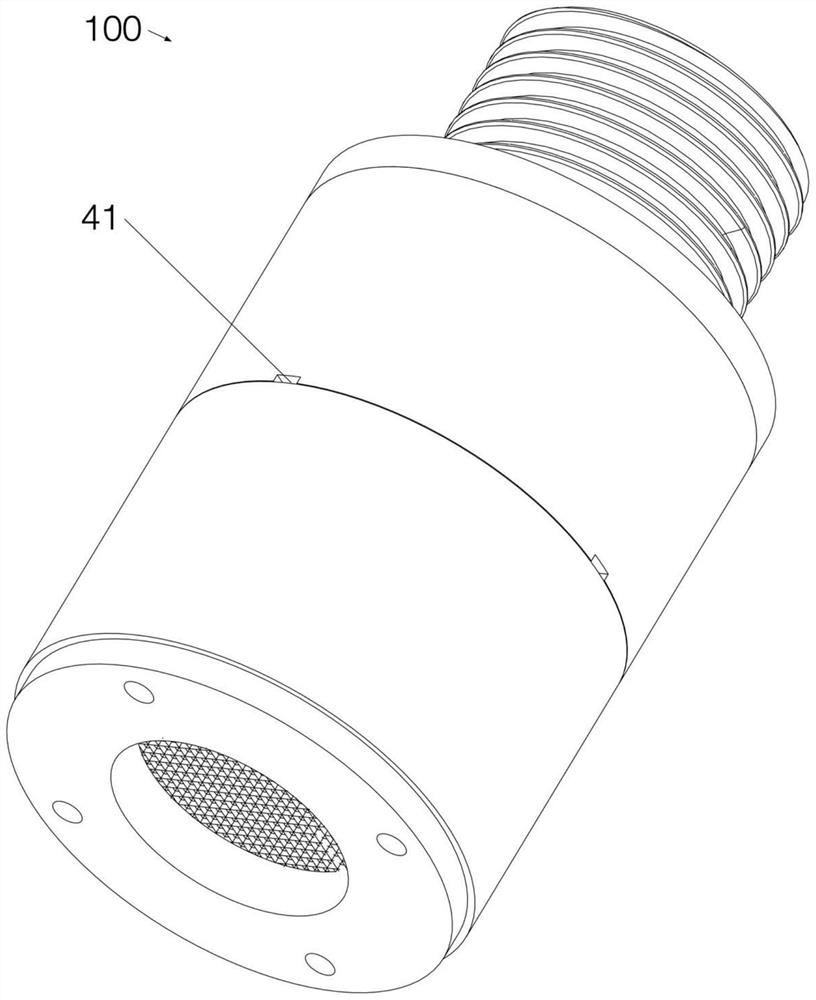

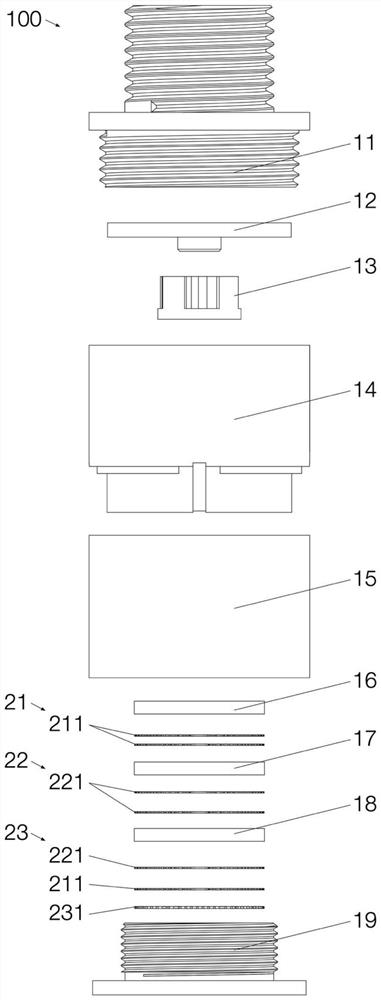

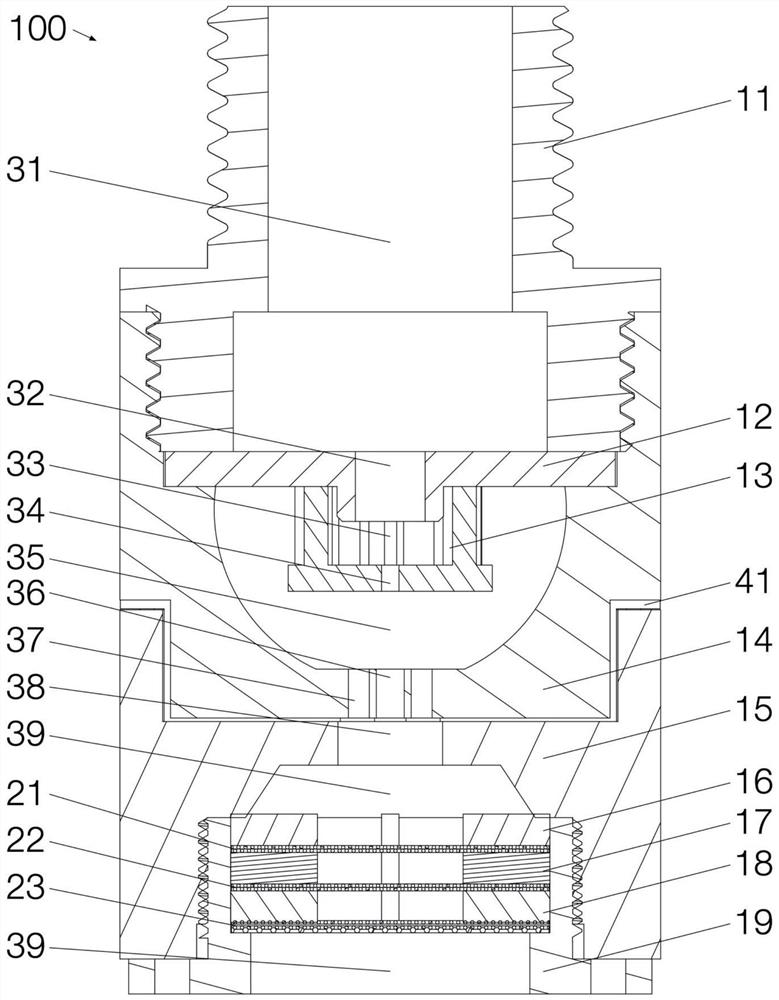

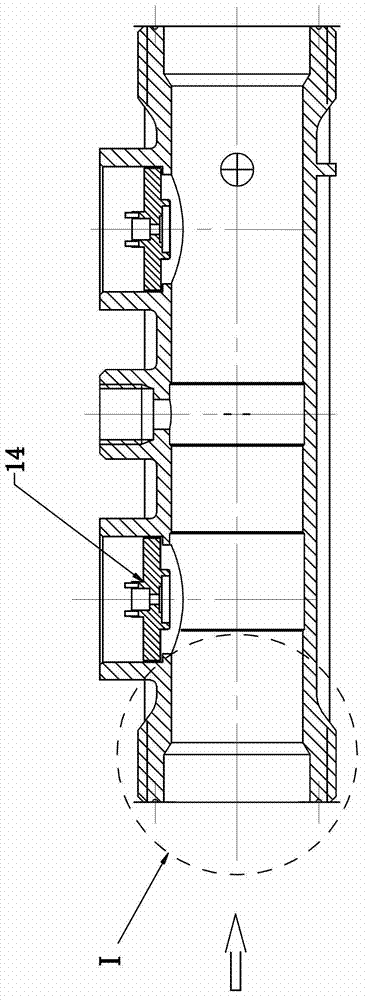

Water outlet device

PendingCN112177107AGet stableGuaranteed water flowDomestic plumbingWater flowEnvironmental engineering

The invention discloses a water outlet device. The water outlet device is provided with a water outlet flow channel, and the water outlet flow channel is provided with a vortex cavity and an air-watermixing cavity in the water outlet direction; the air-water mixing cavity communicates with the atmosphere through a bypass air passage; and the vortex cavity communicates with the air-water mixing cavity through a center hole and at least two first holes evenly distributed around the center hole in the circumferential direction. By the adoption of the structure, compared with the prior art, air can be stably sucked, flocculation and bounce are not prone to happening, and therefore stable sparkling water is output.

Owner:JOMOO KITCHEN & BATHROOM

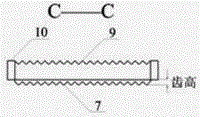

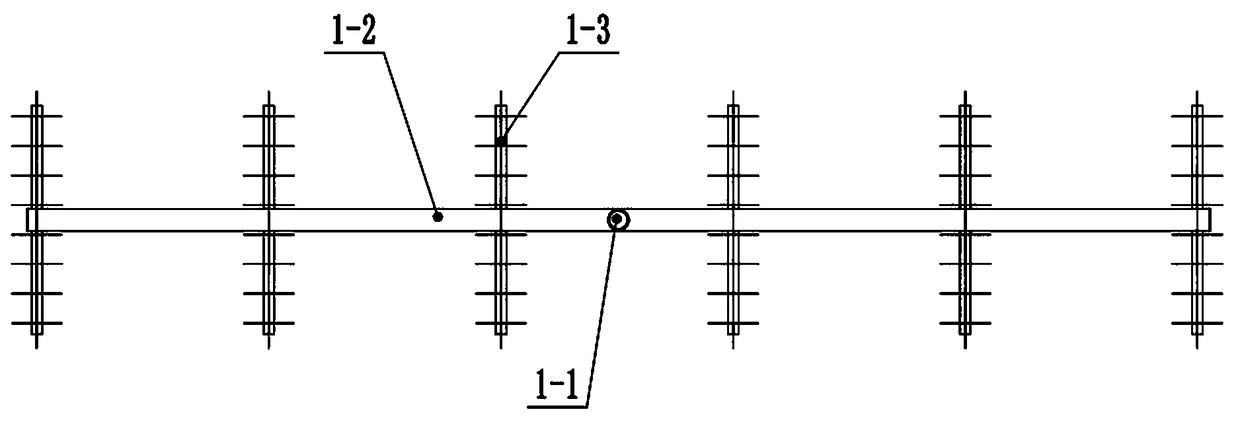

Current stabilizer for ultrasonic heat meter

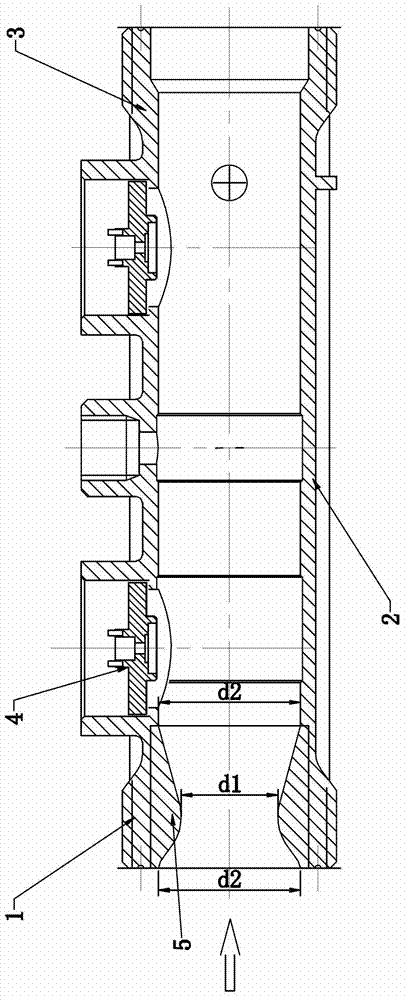

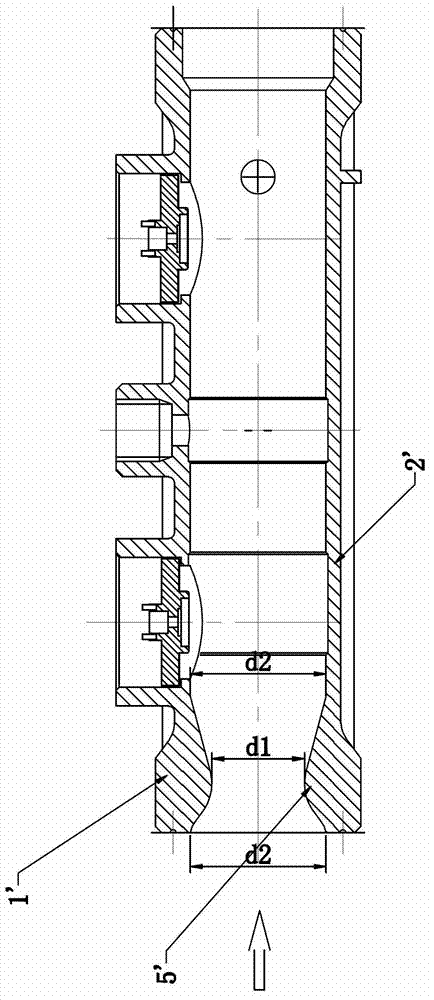

InactiveCN102829895AImprove accuracyAvoid it happening againVolume/mass flow measurementSpeed/acceleration/shock instrument detailsWater flowEngineering

The invention relates to an ultrasonic heat meter used for measuring water flow speed and flow in a heating system, in particular to a current stabilizer for the ultrasonic heat meter. The current stabilizer is simple in structure, good in current stabilizing effect and accurate in ultrasonic measuring results and comprises a water inlet portion positioned at a left end, a middle portion and a water outlet portion positioned at a right end, an inner cavity of the middle portion is in a straight shape, ultrasonic transducers are mounted at connection positions between the middle portion and the water inlet portion and the water outlet portion, an inner cavity of the water inlet portion is provided with annular protrusions with smooth surfaces, the arrangement of the annular protrusions enables the inner cavity of the water inlet portion to be in an hourglass shape with the longitudinal section area gradually reduced first and then slowly increased, and smooth transition is realized at the connection position of the inner cavity of the water inlet portion and the inner cavity of the middle portion.

Owner:RUINA INTELLIGENT EQUIP CO LTD

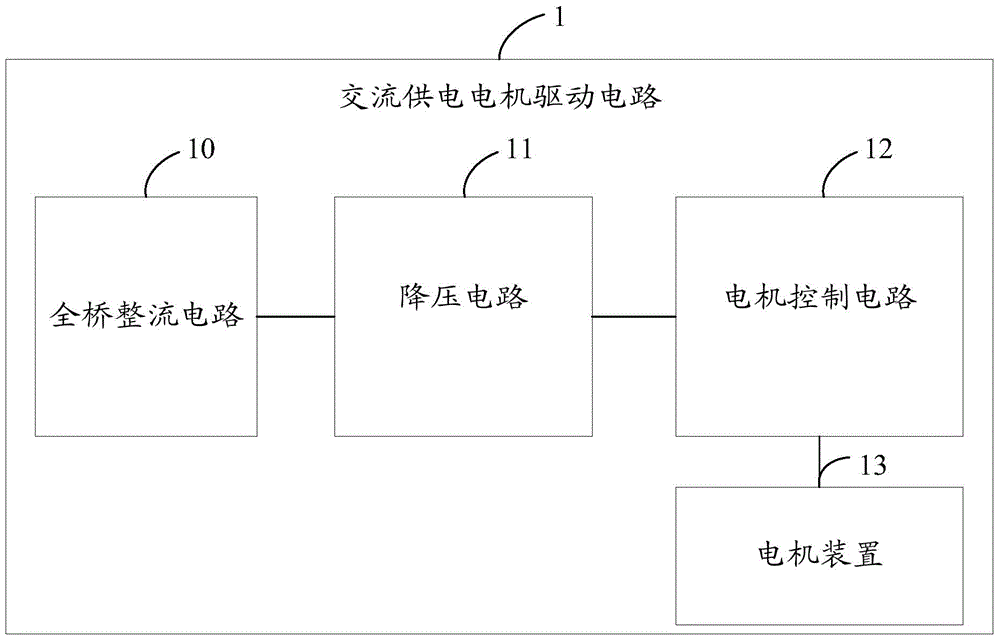

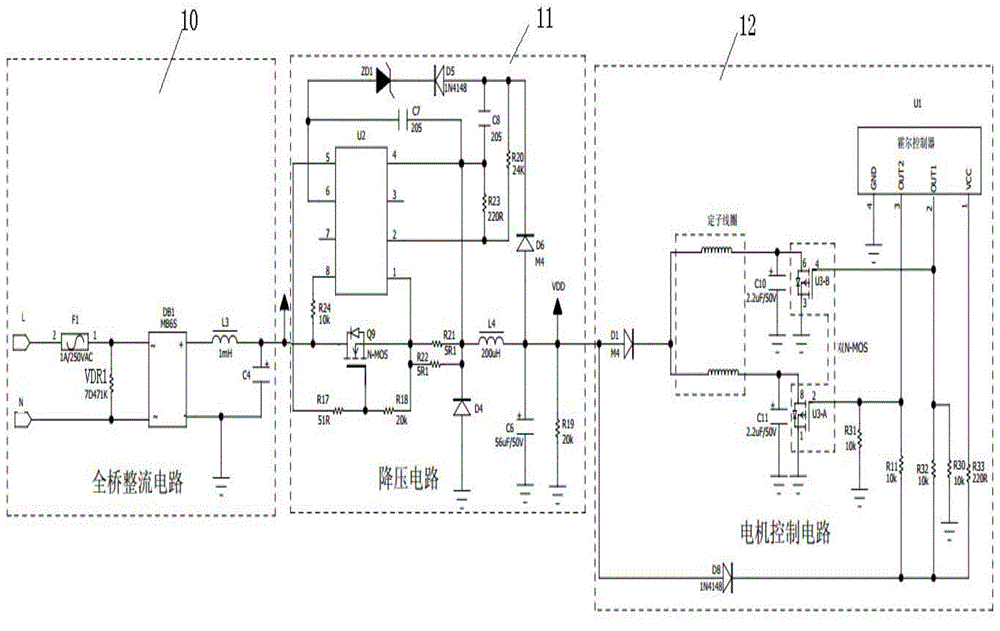

Cooling fan

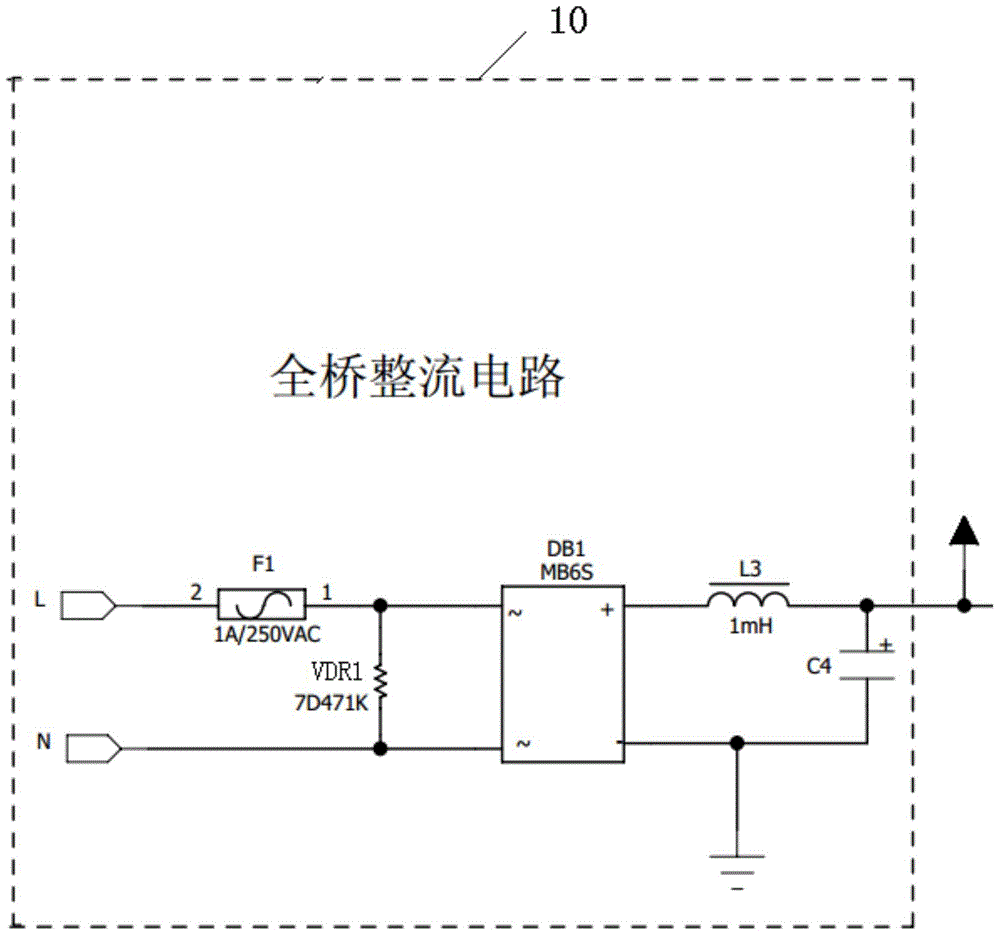

InactiveCN103607163APlay a role in rectificationIncrease speedAC motor controlPump installationsFull bridgeAlternating current

The invention discloses a cooling fan which comprises an alternating current power supply motor driving circuit, wherein the alternating current power supply motor driving circuit also comprises a full-bridge rectifier circuit, a step-down circuit, a motor control circuit, a motor device and fan blade main bodies which are sequentially connected in series; the full-bridge rectifier circuit comprises a rectifier; the motor control circuit is electrically connected with the motor device; the motor device comprises a stator, a plurality of coils and a motor shell (an iron shell and magnetic stripes); the fan blade main bodies are fixedly connected with the motor shell; the coils are annularly arranged on the stator and is positioned in the motor shell of fan blades. The cooling fan is simple in circuit structure, and has the characteristics of high and stable rotating speed, good cooling effects, low power, high efficiency, energy conservation, high practicability and the like, and can be applied to the input voltage in a wide range, a wide alternating current input voltage range of 110 to 240V, and the direct current output voltage is 24V all the time.

Owner:SHENZHEN LIANXIANG MOTOR

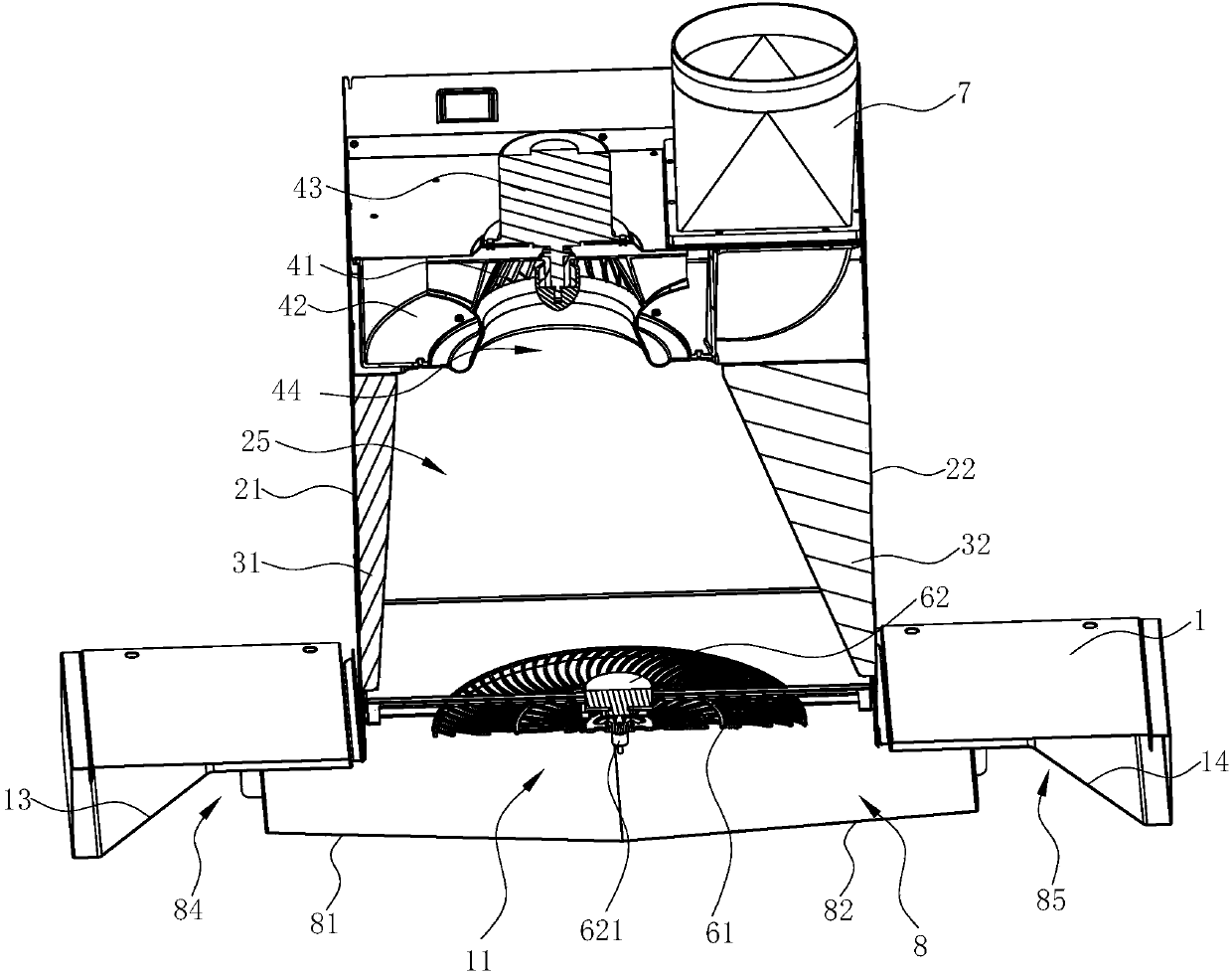

Range hood

PendingCN109595641APlay a role in rectificationCompact structureDomestic stoves or rangesLighting and heating apparatusContact timeEngineering

The invention discloses a range hood. The range hood comprises a smoke collecting hood, a cabinet arranged above the smoke collecting hood and a fan system arranged in the cabinet. An air inlet is formed in the smoke collecting hood. A smoke guide plate is arranged below the air inlet. The fan system comprises a first three-element fan and a second three-element fan which are arranged in parallel.At least a part of the lower surface of the smoke guide plate is gradually inclined upwards from the middle to the edge so as to be matched with the corresponding wall surface of the smoke collectinghood to define an acceleration flow channel with the cross section which is gradually reduced from bottom to top. The amount of oil smoke entering the range hood in unit time can be increased throughthe acceleration flow channel, so that the oil smoke suction effect is improved. A rotary filter screen is arranged at an inlet of an air duct, so that the oil smoke can pass through the rotary filter screen at a lower flow rate before being accelerated by the air flue, the contact time is long, and the oil smoke can fully collide with the rotary filter screen.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Novel marine propeller for speed increasing

PendingCN107902061AImprove propulsion efficiencyIncreased propulsion speedRotary propellersPropulsive efficiencyStructural property

The invention relates to a novel marine propeller for speed increasing. The novel marine propeller comprises a propeller body, wherein a de Laval nozzle is sleeved on the propeller body; the propellerbody is positioned inside a contraction tube of the de Laval nozzle; and the wall of the contraction tube of the de Laval nozzle is provided with a plurality of water inlet holes or water inlet grooves. The de Laval nozzle is additionally arranged outside the propeller body, so that the novel marine propeller for the speed increasing allows the entering of waterflows from the end of the contraction tube and the discharging from the end of an expansion tube by virtue of the structural characteristics of the de Laval nozzle. The speed of the waterflows changes as the sectional area changes, soas to greatly increase the propulsion efficiency of the propeller. At the same time, negative pressure caused by the rotation of the propeller inside the de Laval nozzle results in high flowing speedand low pressure of water inside the de Laval nozzle, so that the pressure difference between the inside and outside of the de Laval nozzle creates an additional propulsive force on the wall of the tubes to further increase the propulsion speed of a ship.

Owner:姚珍汉

Uniform overflow liquid distributor

InactiveCN104307192BAvoid effusionEasy to overflowEvaporator accessoriesEvaporators with horizontal tubesButt jointEngineering

The invention relates to a liquid distribution device, and particularly relates to a uniform overflow type liquid distributor used for uniformly distributing liquid on a horizontal heat exchange pipe. The liquid distributor comprises a flange, a feeding pipe, a horizontal branch pipe, a spray pipe, a folded-plate type overflow groove, a connecting channel and liquid distributing teeth, wherein the flange is arranged at a feeding opening; one end of the feeding pipe is connected with the flange, and the other end of the feeding pipe is connected with horizontal branch pipe; the spray pipe and the horizontal branch pipe are not in central butt joint, and occurrence of liquid accumulation in the spray pipe can be avoided; liquid in the overflow groove slowly increases by using the spray pipe, so that liquid overflows stably and has small fluctuation.

Owner:SHENYANG AEROSPACE UNIVERSITY

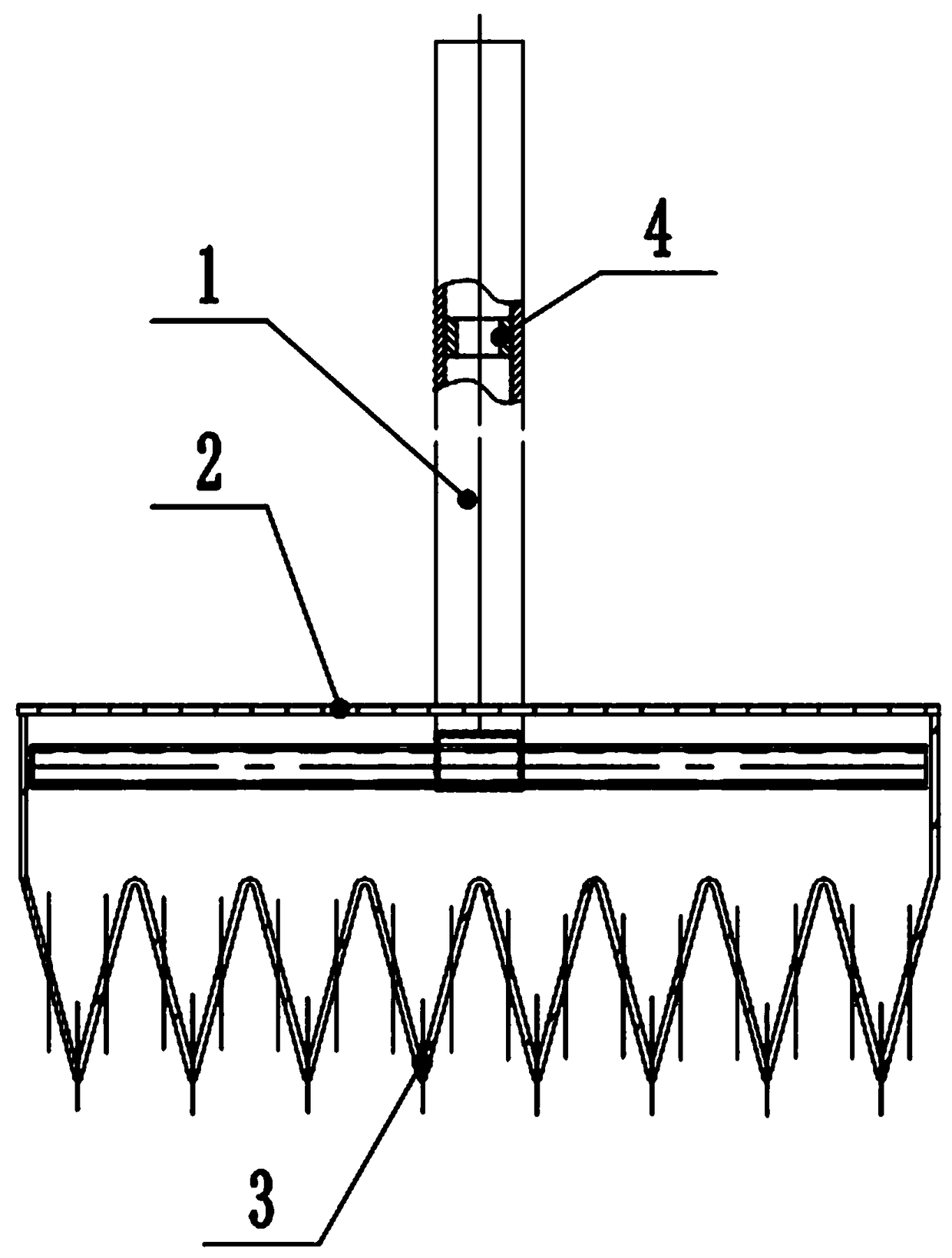

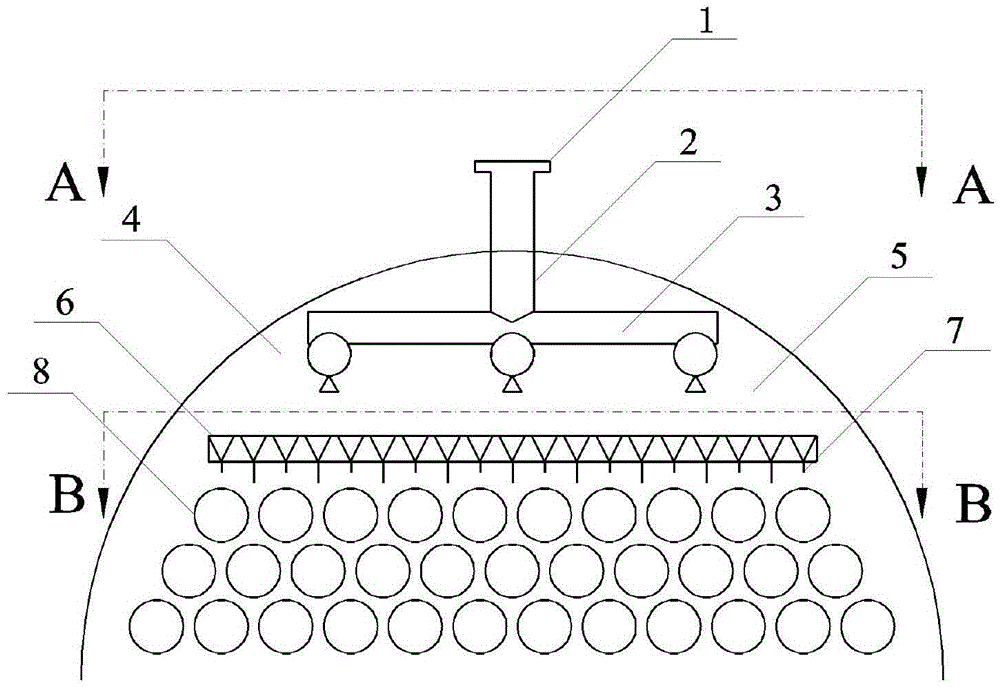

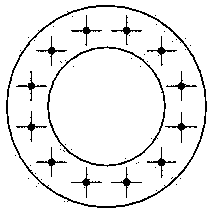

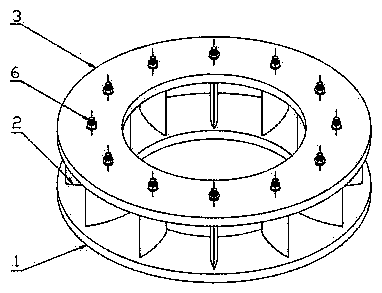

A guide vane type pump station inlet pool guide and vortex elimination device

The invention relates to the technical field of vortex suppression devices in water conservancy projects, in particular to a flow guiding and vortex suppressing device for a water inlet pool of a guide vane type pump station. The flow guiding and vortex suppressing device comprises a lower annular base, an upper annular base and a plurality of guide vanes arranged between the lower annular base and the upper annular base. The guide vanes are circumferentially arranged. By means of the flow guiding and vortex suppressing device, vortexes near an inlet of a water inlet pipe can be effectively suppressed, flow loss in the water inlet pool is lowered, the flowing uniformity in the water inlet pipe is improved, and the flow guiding and vortex suppressing device has the advantages of being simple in structure, convenient to mount and high in practicability.

Owner:CHINA AGRI UNIV

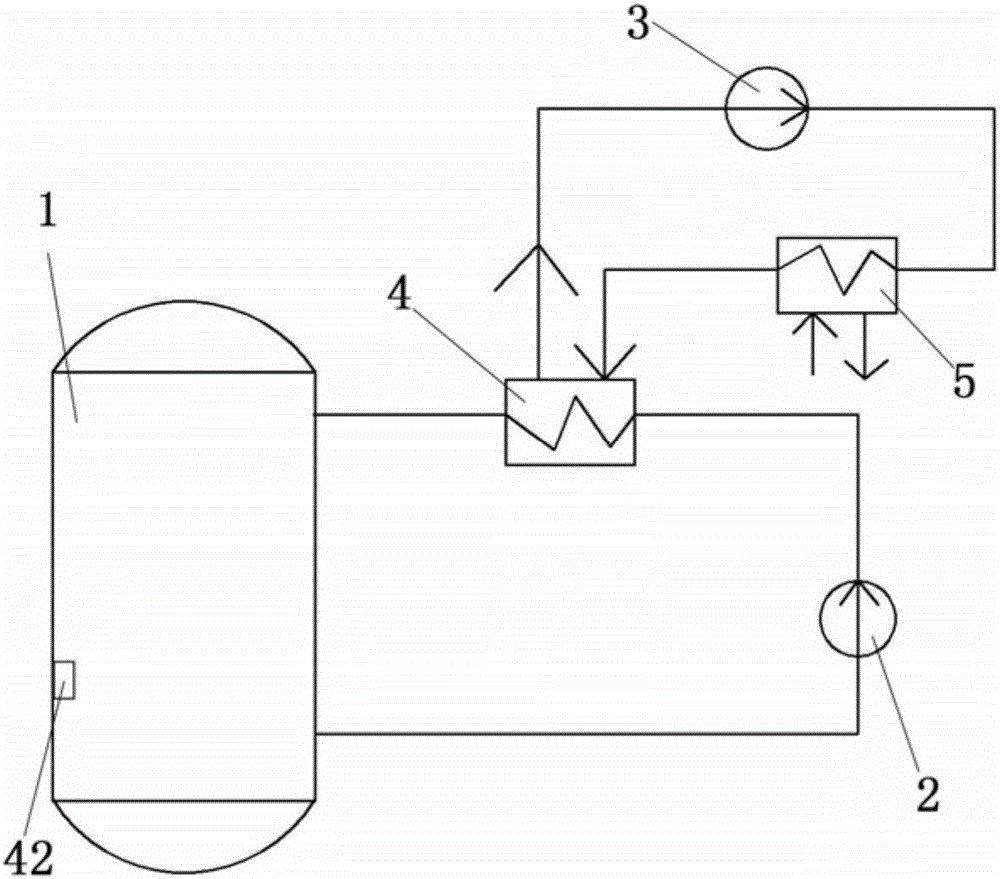

Novel temperature-adjustable dyeing device

ActiveCN105821605AAutomatic fine adjustmentReduced integrated weightTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringCirculating pump

The invention discloses a novel temperature-adjustable dyeing device. The novel temperature-adjustable dyeing device comprises a dye vat, a liquid drawing pump, a first cooler, an oil circulating pump and a second cooler. Dye at the bottom of the dye vat is fed to the first cooler through the liquid drawing pump, cooled and then fed back to the top of the dye vat; hot oil heated through the first cooler is fed to a second cooler with cooling water as a cooling source through the oil circulating pump, cooled and then returned to an inlet of the oil circulating pump; the temperature of the dye in the dye vat is adjusted by controlling the oil supply amount of the oil circulating pump in cooperation with a temperature sensor arranged on the dye vat. The dyeing device is simple in structure, the temperature of the dye can be automatically and accurately adjusted, and the dyeing device has the advantages of being good in heat dissipation condition, long in operational cycle, convenient to overhaul and the like.

Owner:嘉兴汇源纺织染整有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com