Range hood

A range hood and chassis technology, which is applied in the field of kitchen appliances, can solve the problems that the smooth air flow of the rotating filter cannot be reflected to the greatest extent, the large wind resistance, the short path, etc., so as to achieve the effect of improving the effect of the range hood and the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

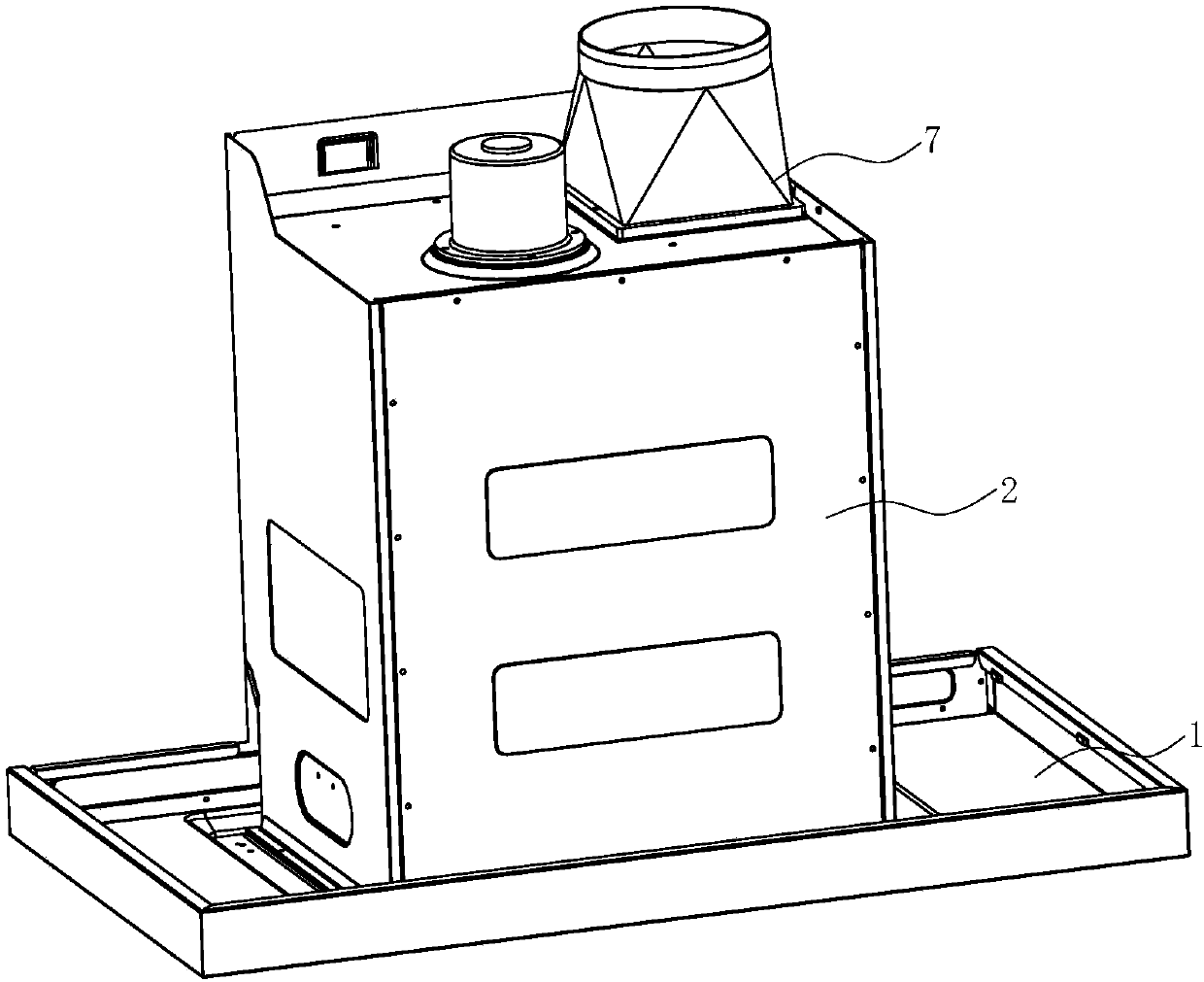

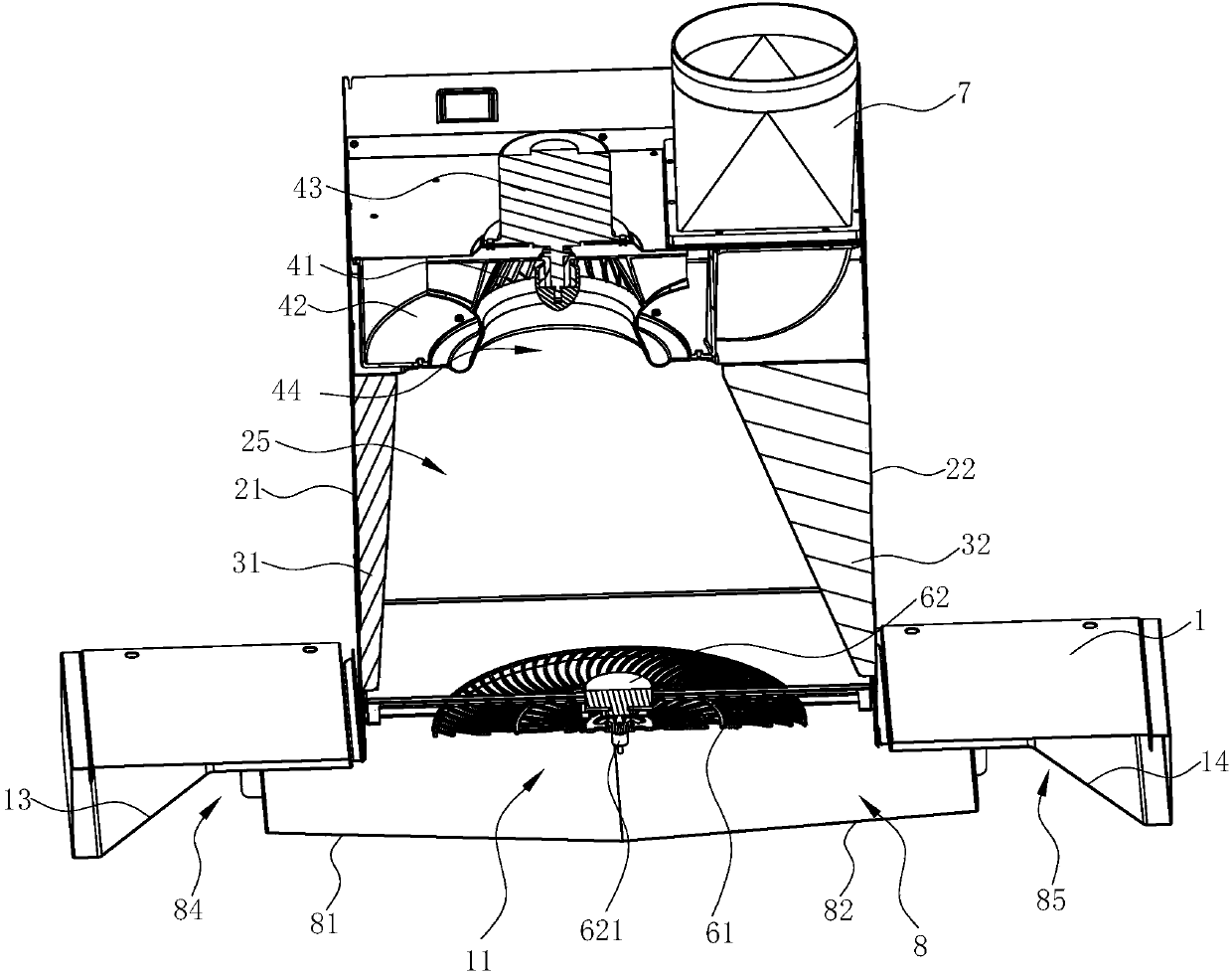

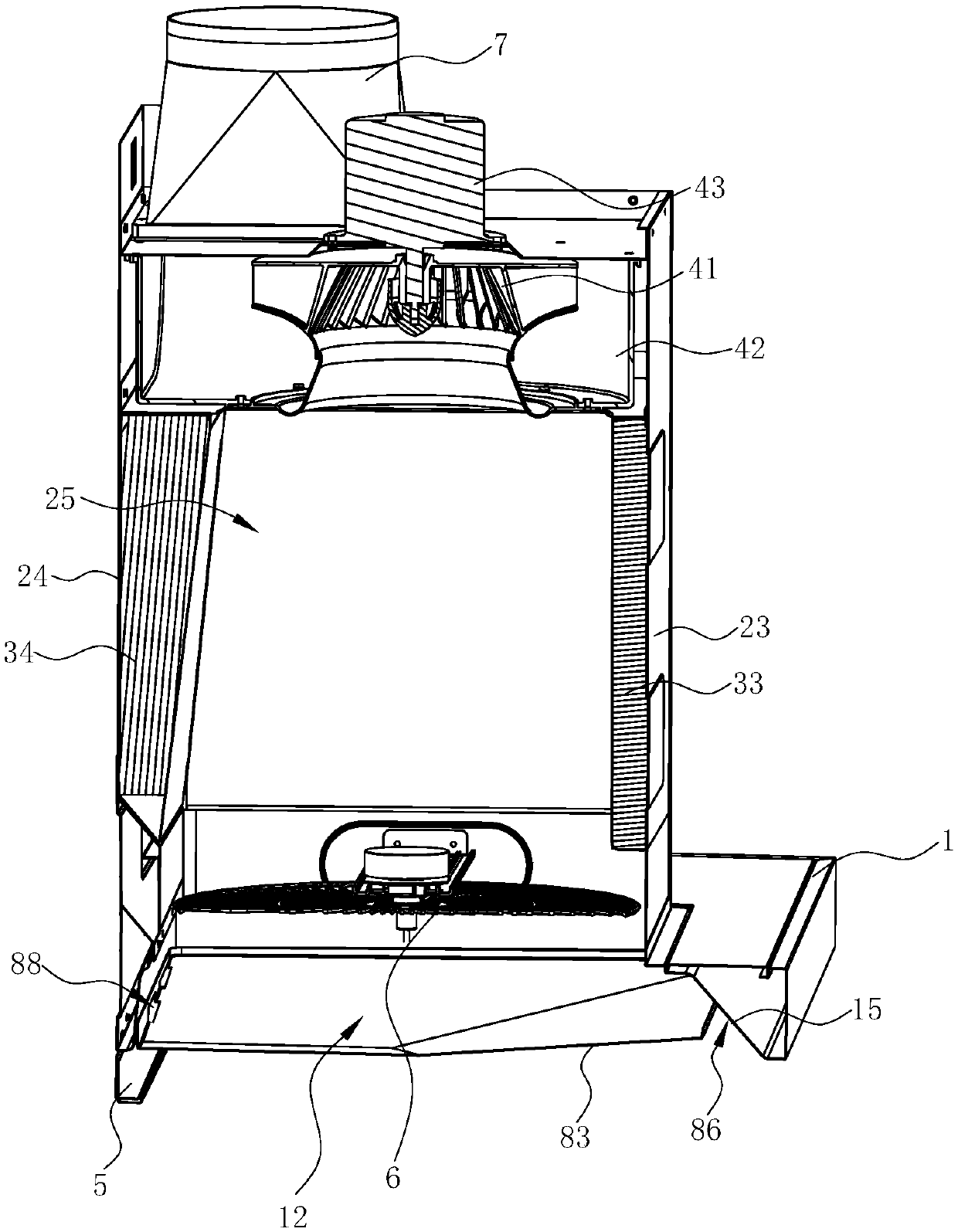

[0025] see Figure 1 ~ Figure 4 , a range hood, comprising a smoke collection hood 1, a chassis 2 arranged above the fume collection hood 1, a fan 4 is arranged in the chassis 2. An air inlet 11 is provided on the fume collecting hood 1, whereby the fan 4 in the cabinet 2 can suck oily fume into the cabinet 2 through the air inlet 11 and discharge it to the public flue.

[0026] The cabinet 2 includes a left side wall 21 , a right side wall 22 , a front side wall 23 and a rear side wall 24 . The left side wall 21 is provided with a first muffler device 31 which is gradually inclined from top to bottom to the left side wall 21, and the right side wall 22 is provided with a second muffler device which is gradually inclined from top to bottom to the right side wall 22. 32. The front side wall 23 is provided with a third muffler 33 which is grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com