Current stabilizer for ultrasonic heat meter

A stabilizing device, ultrasonic technology, applied in measuring devices, measuring heat, measuring flow/mass flow, etc., can solve the problems of inaccurate ultrasonic measurement of flow velocity, unstable flow velocity, and affecting the measurement accuracy of heat meters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

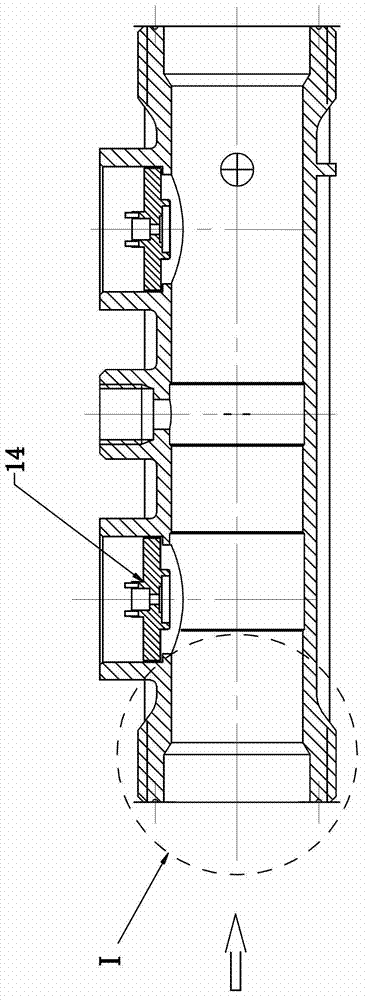

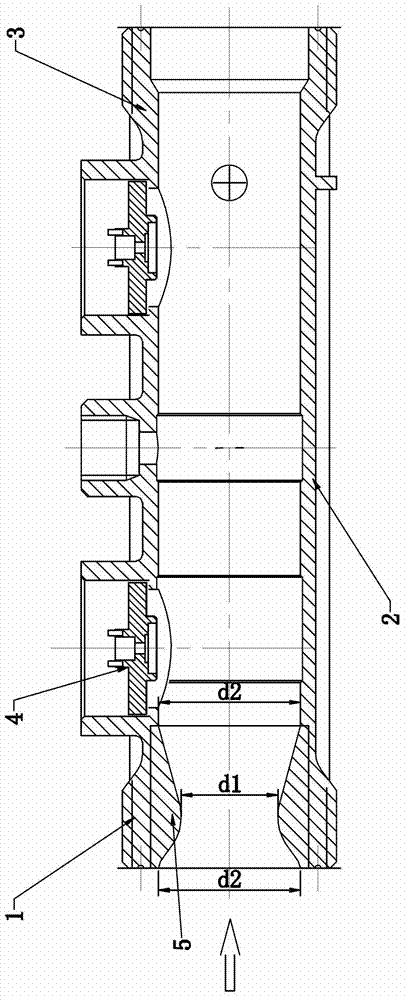

[0015] Such as figure 2 As shown, the ultrasonic heat meter flow stabilization device of the present invention includes a water inlet 1 at the left end, a middle part 2 and a water outlet 3 at the right end. The water inlet 1, the middle part 2 and the water outlet 3 are integrally formed and are all made of stainless steel. material, the shape of the inner cavity of the middle part 2 is a straight cylinder, the ultrasonic transducer 4 is installed at the connection position between the middle part 2 and the water inlet part 1 and the water outlet part 3, and the inner cavity of the water inlet part 1 is installed with Annular protrusion 5 with a smooth surface (that is, the annular protrusion 5 and the water inlet 1 are a split structure, which is convenient for installation and disassembly, or replacement of annular protrusions 5 with different inner diameters and shapes). The setting of the annular protrusion 5 makes the inner cavity of the water inlet 1 The shape is an ho...

Embodiment 2

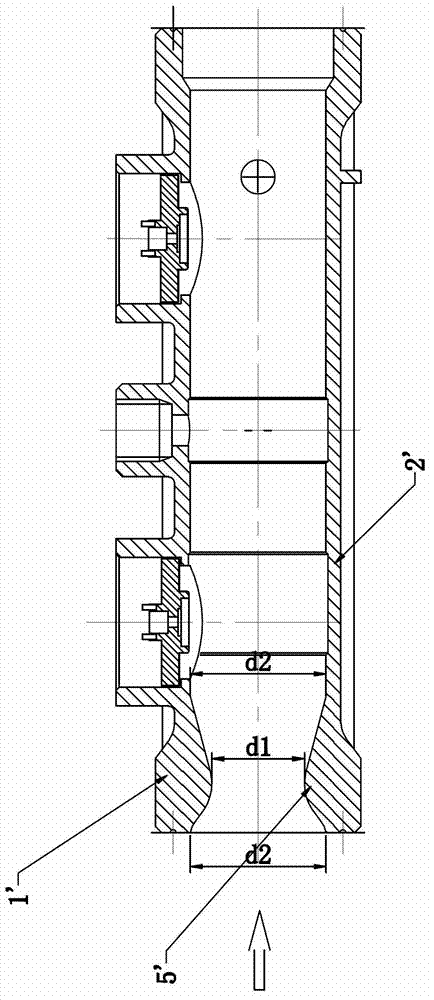

[0017] Compared with the first embodiment, this embodiment is only different in that: the annular protrusion 5' is integrally formed with the water inlet part 1'.

[0018] Such as figure 2 , image 3 As shown, the embodiment of the present invention when applied in the small watch body is: wherein the minimum diameter d1 of the inner cavity of the water inlet part 1, 1' is 15mm, and the maximum diameter d2 of the inner cavity of the water inlet part 1, 1' is 22mm, The lumen diameter of the middle part 2, 2' is 22mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum diameter | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

| Lumen diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com