Novel marine propeller for speed increasing

A technology for marine propellers and propellers, which is applied in the direction of rotating propellers, ship propulsion, ship parts, etc., to achieve the effects of erosion improvement, safety protection, and improvement of propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

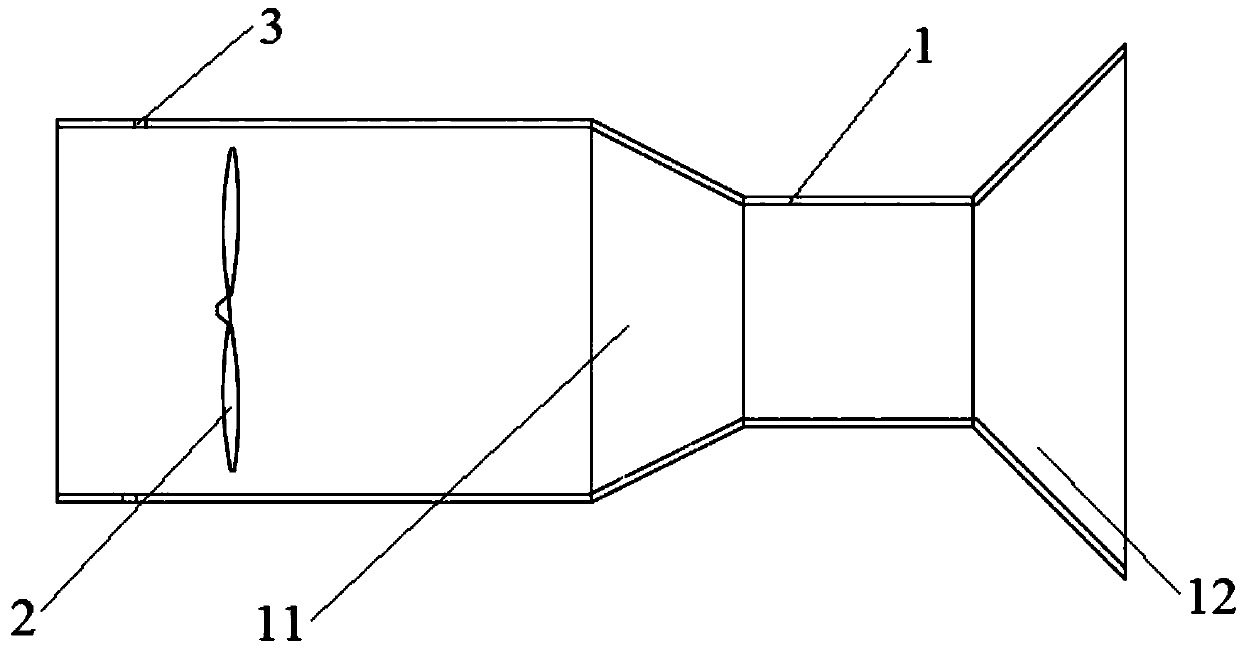

[0015] refer to figure 1 A new type of speed-increasing marine propeller shown includes a propeller body 2, and a Laval nozzle 1 is provided outside the propeller body 2.

[0016] The Laval nozzle 1 includes a contraction tube 11 and an expansion tube 12, the propeller body 2 is located in the contraction tube 11 of the Laval nozzle 1, and the Laval nozzle 1 is fixed on the hull or the propeller shaft.

[0017] The shrink tube 11 wall of the Laval nozzle 1 is provided with some water inlet holes 3 or water inlet grooves 3, and the water inlet holes 3 or water inlet grooves 3 are directly fixed on the hull when the shrink pipe 11 port of the Laval nozzle 1 , as the main water intake; when the Laval nozzle 1 is fixed on the propeller shaft, it is used as a supplement to the water intake.

[0018] The working principle of the present invention is as follows: the water flow enters from the end of the contraction tube 11 and is discharged from the end of the expansion tube 12. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com