Planet surface landing system

A landing system and planetary technology, applied in the field of planetary landing equipment, can solve the problems of reducing rocket exhaust energy, poor landing accuracy of the landing system, and low propulsion efficiency of the landing system, and achieve the goal of improving propulsion efficiency, reducing speed, and improving utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

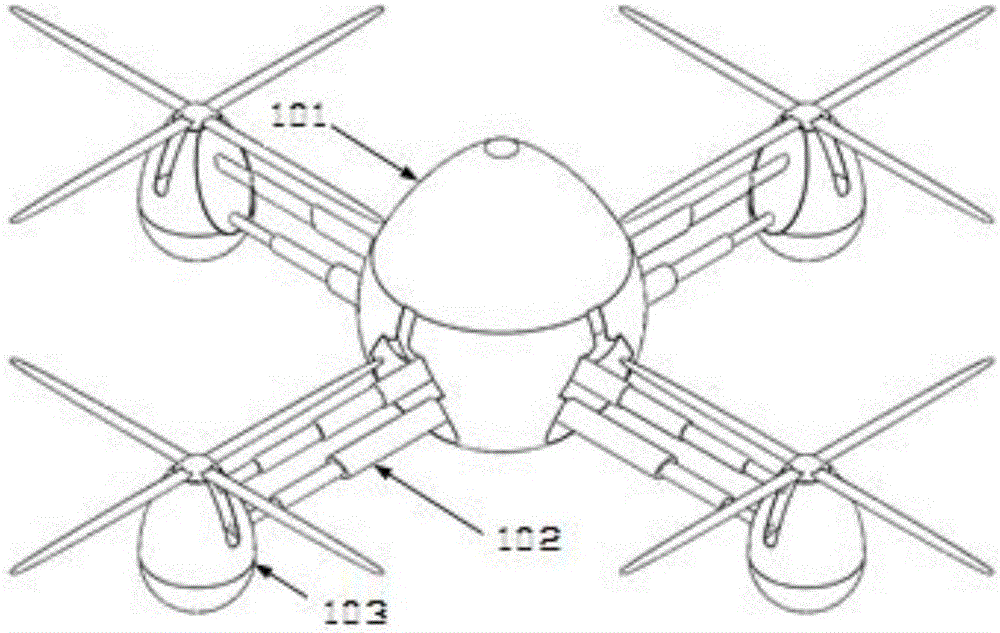

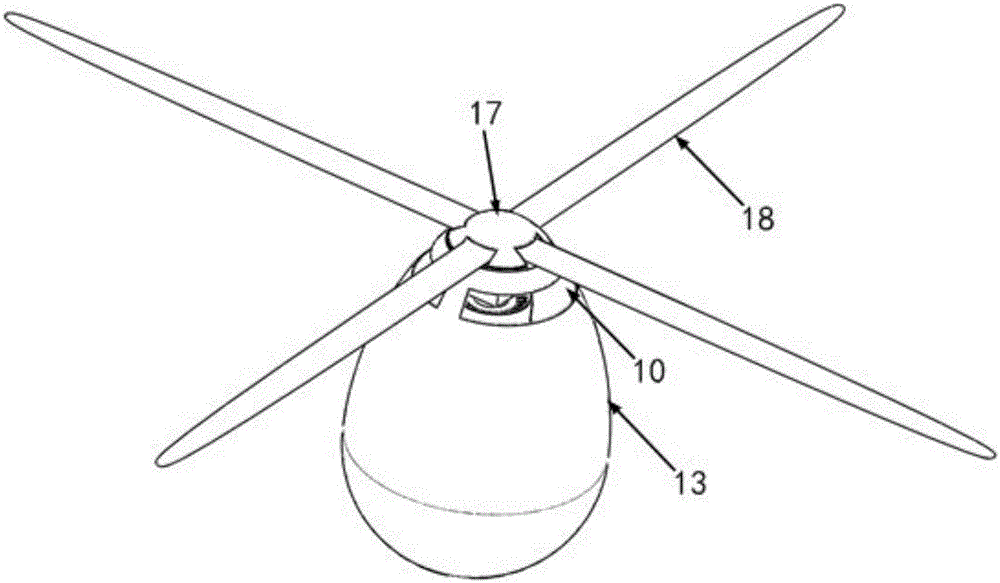

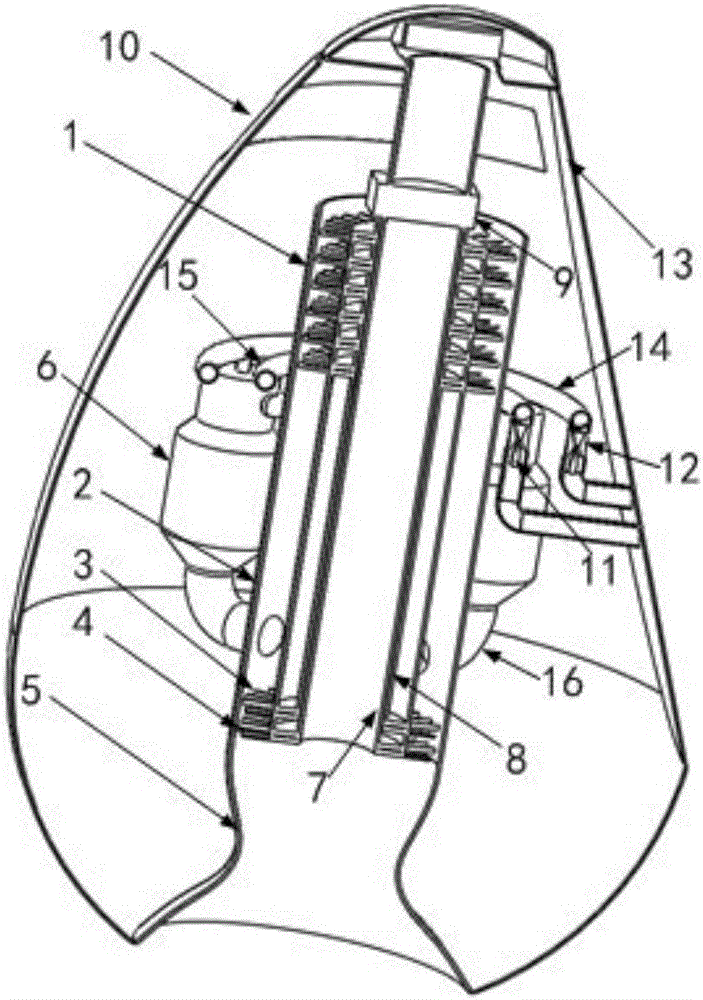

[0036] refer to figure 1 , Embodiment 1 provides a schematic structural diagram of a planetary surface landing system. A planetary surface landing system of the present invention comprises a load cabin 101, a connecting mechanism 102 and a rocket rotor combined engine 103, the load cabin 101 is used for carrying payload and storing propellant, and 4 rocket rotor combined engines 103 connect with the connecting mechanism 102 The load compartment 101 is connected. Described rocket rotor combined engine 103 comprises casing 13, rotor and the power system that is arranged in casing 13 and is used for driving rotor, and described rotor is arranged on the top of casing 13 and is connected with the power system in casing 13, and rotor is in the power system. The driven rotation generates aerodynamic lift, which provides the resistance required for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com