Patents

Literature

110results about How to "Big propulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

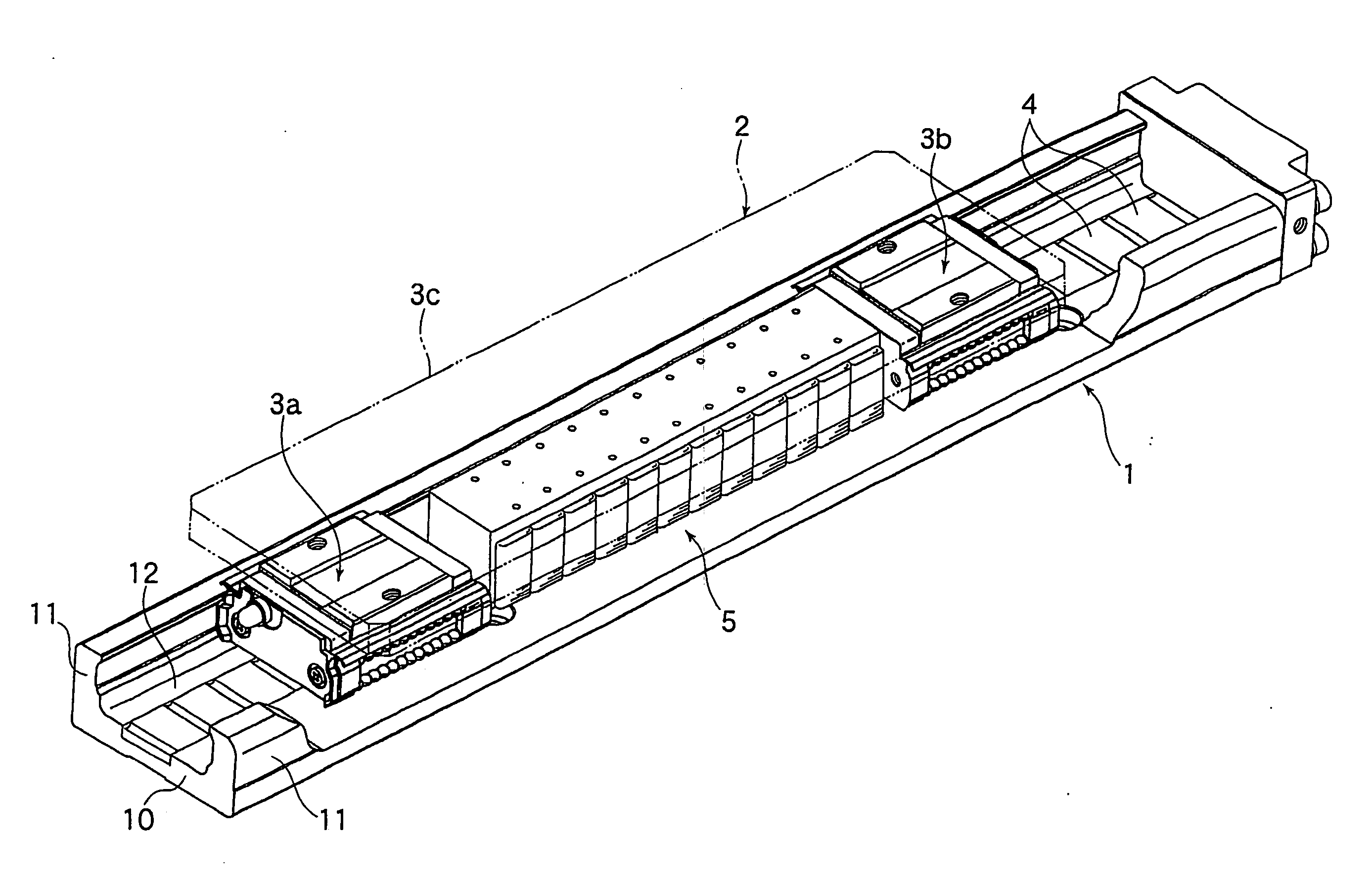

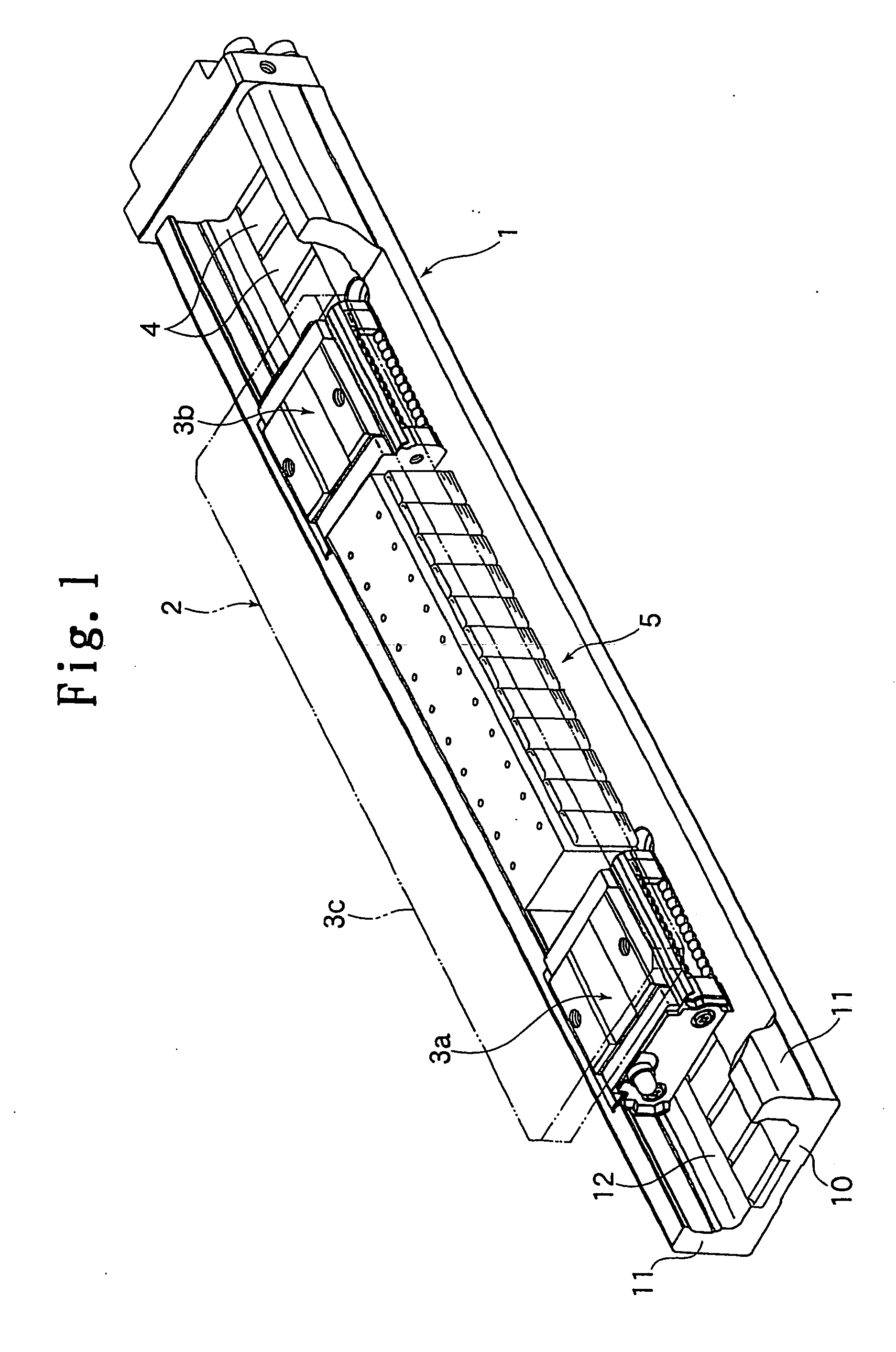

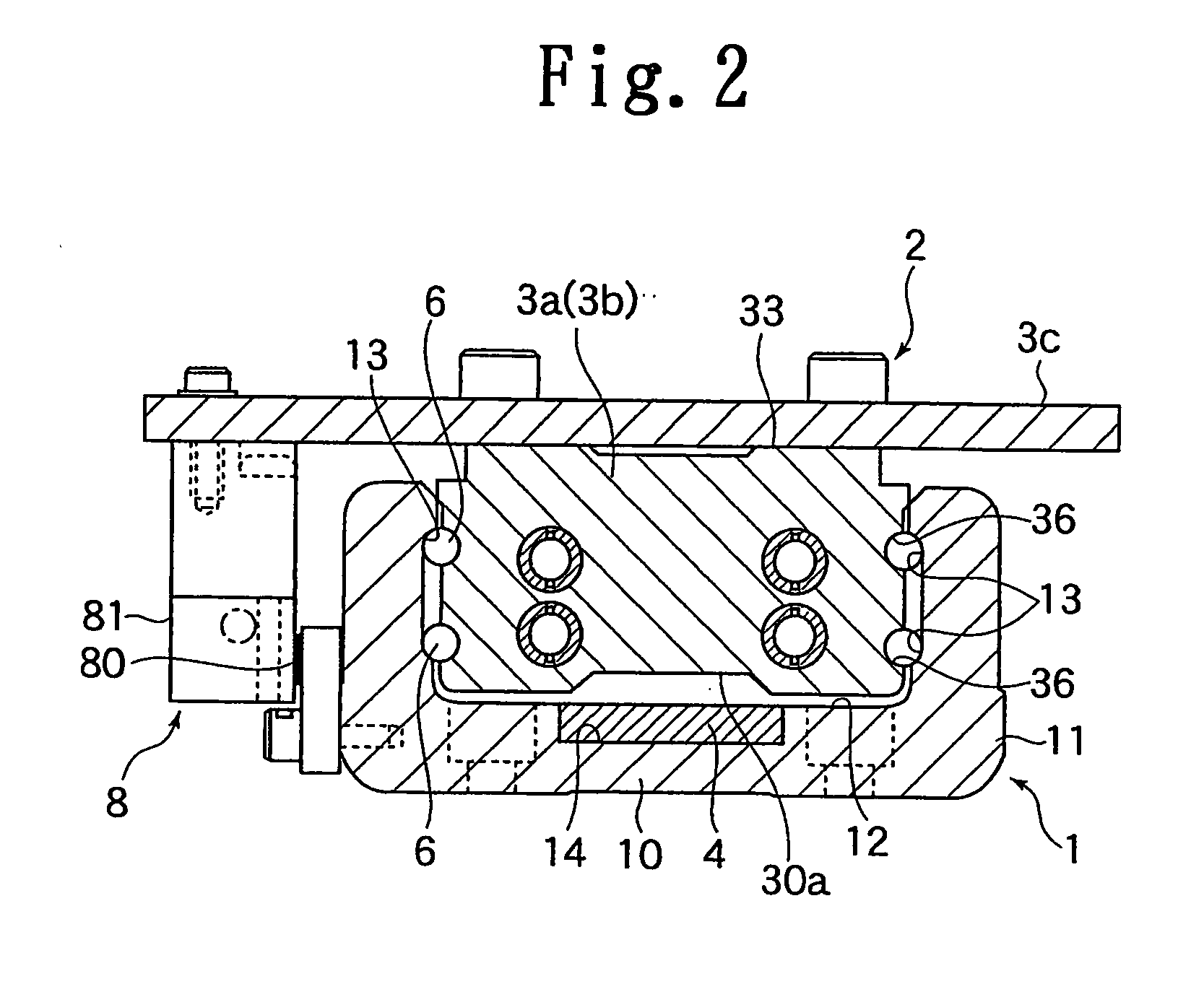

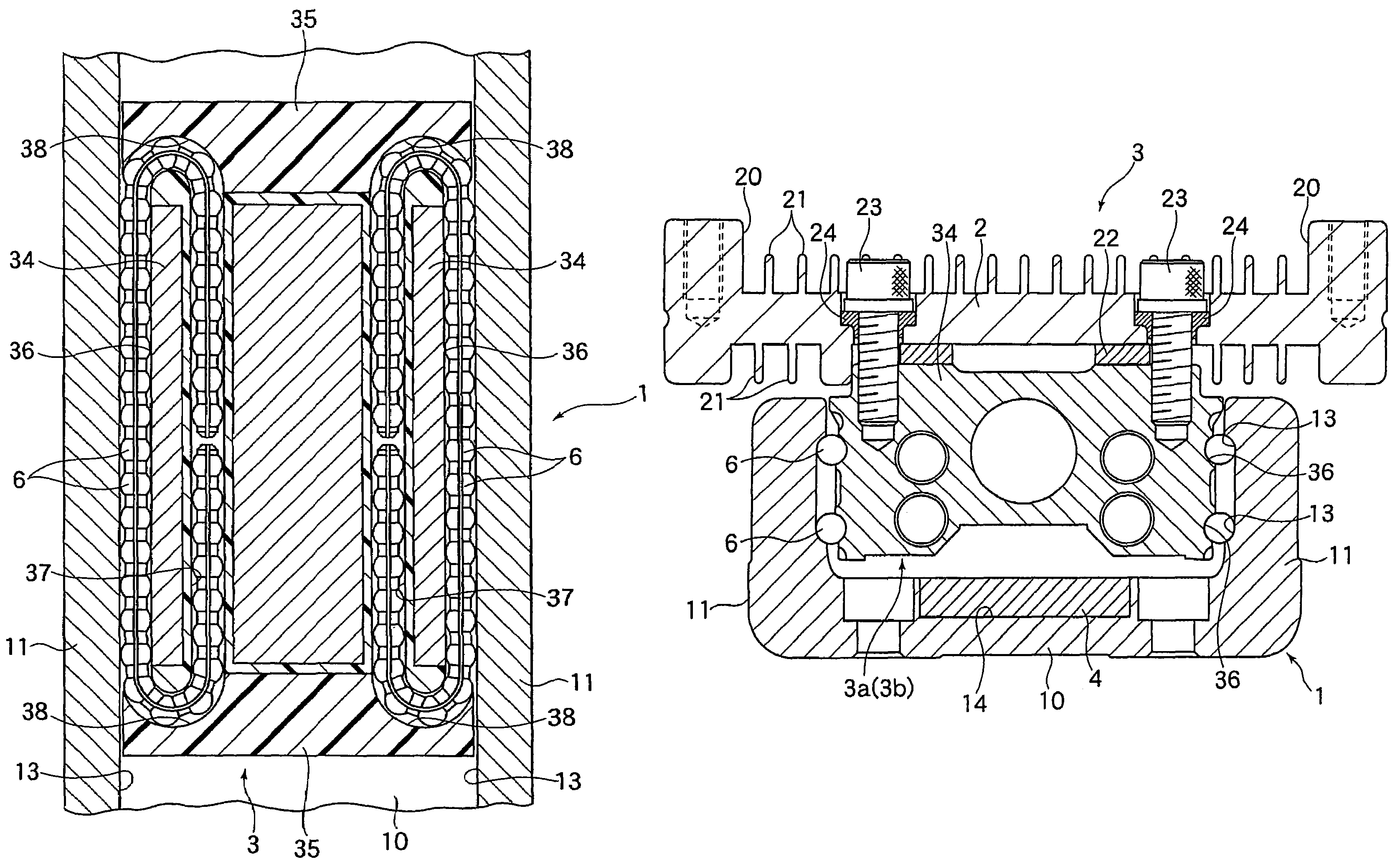

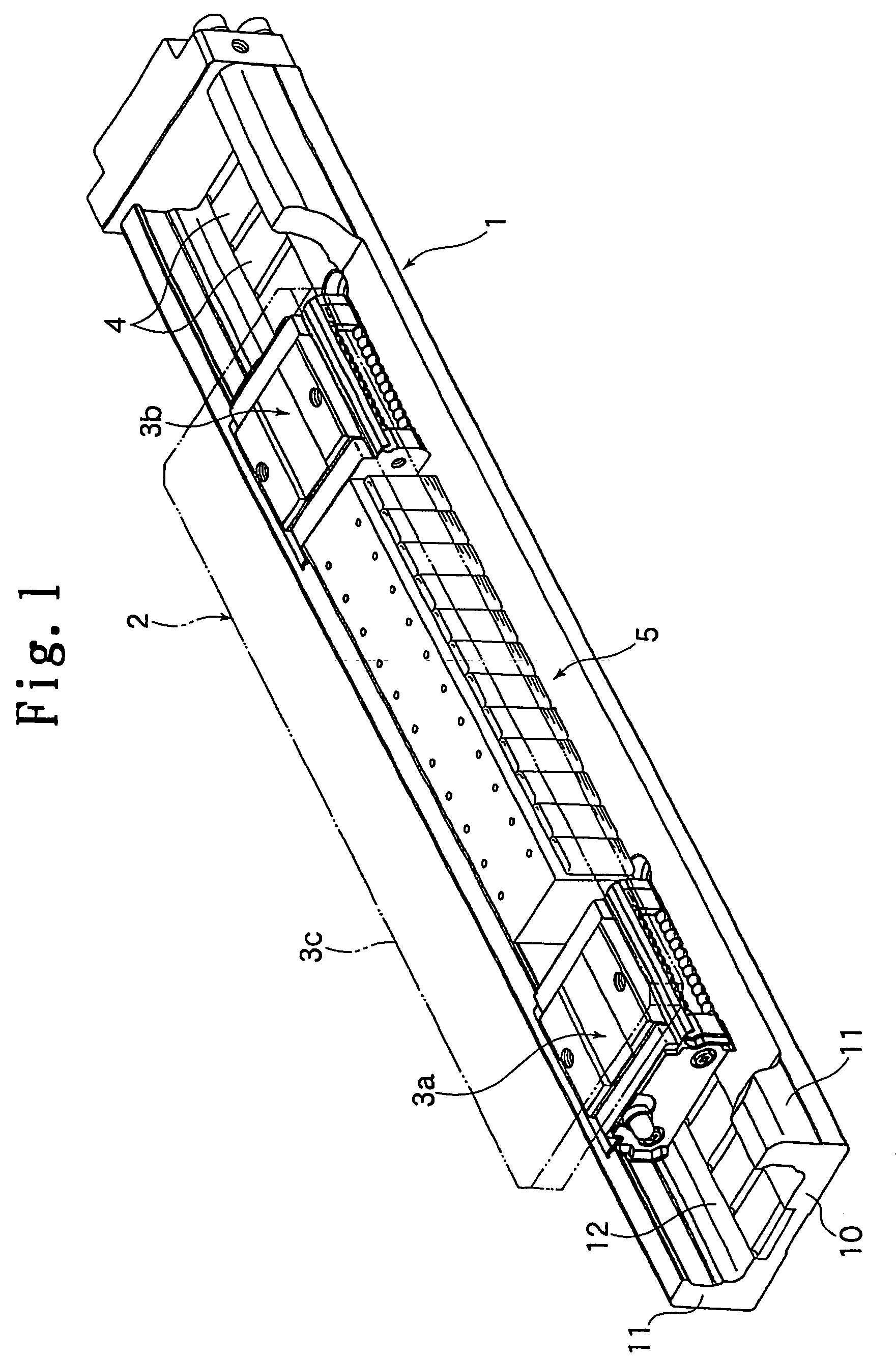

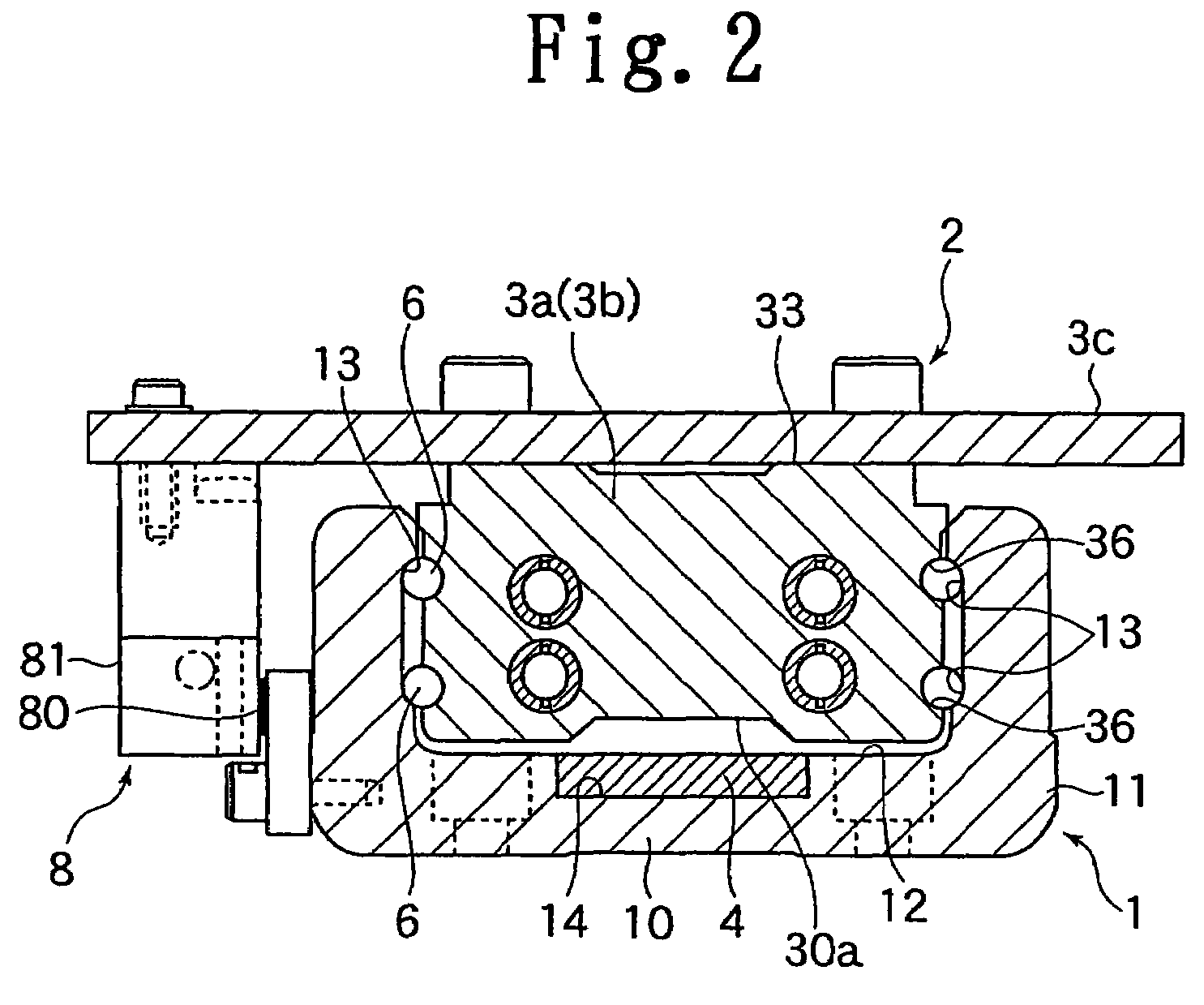

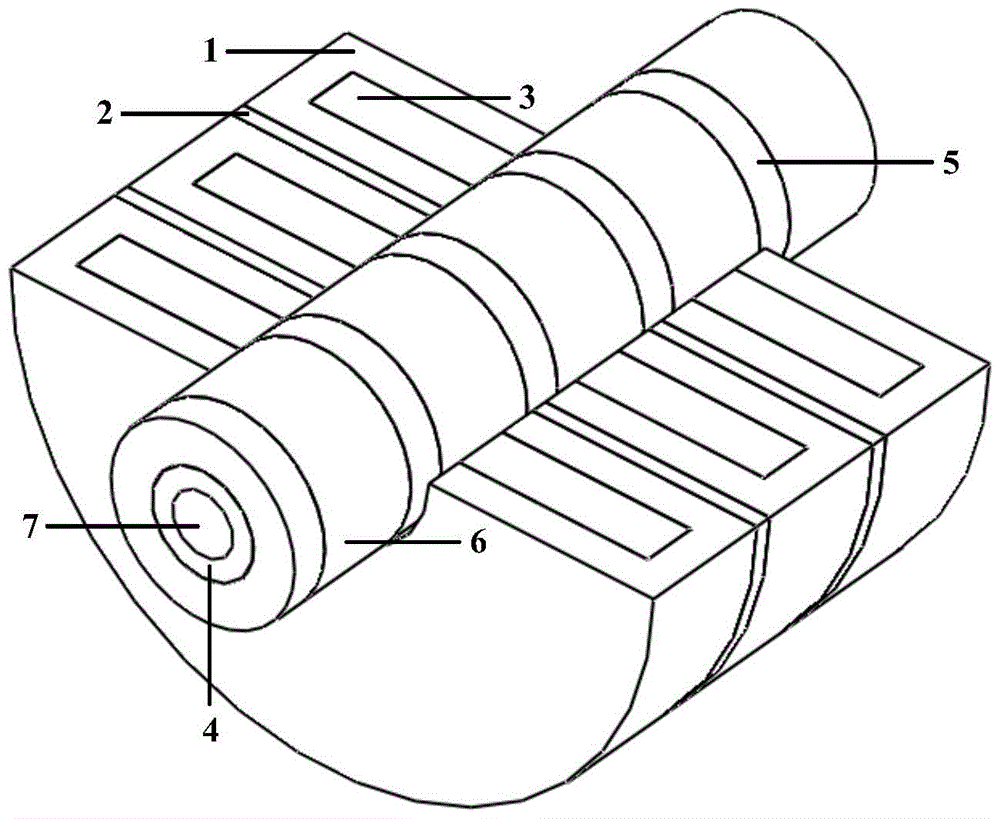

Linear motor actuator

ActiveUS20060232141A1Eliminate coggingCompact structureLinear bearingsBearing assemblyMagnetActuator

A track rail is formed in a channel-like configuration while having a guide passage for sliders. A table structure that moves within the guide passage includes:a pair of sliders that move forwards and backwards within the guide passage; and a connecting top board connecting those sliders to each other with a predetermined interval therebetween and provided with a mounting surface for a movable member. An armature constituting a linear motor is received between the pair of sliders, and field magnets constituting the linear motor are arranged in the track rail so as to face the guide passage. The armature and the field magnets, which constitute the linear motor, are completely integrated with the table structure and the track rail, which constitute a linear guide, and are entirely contained inside the linear guide.

Owner:THK CO LTD

Linear motor actuator

A track rail is formed in a channel-like configuration while having a guide passage for sliders. A table structure that moves within the guide passage includes: a pair of sliders that move forwards and backwards within the guide passage; and a connecting top board connecting those sliders to each other with a predetermined interval therebetween and provided with a mounting surface for a movable member. An armature constituting a linear motor is received between the pair of sliders, and field magnets constituting the linear motor are arranged in the track rail so as to face the guide passage. The armature and the field magnets, which constitute the linear motor, are completely integrated with the table structure and the track rail, which constitute a linear guide, and are entirely contained inside the linear guide.

Owner:THK CO LTD

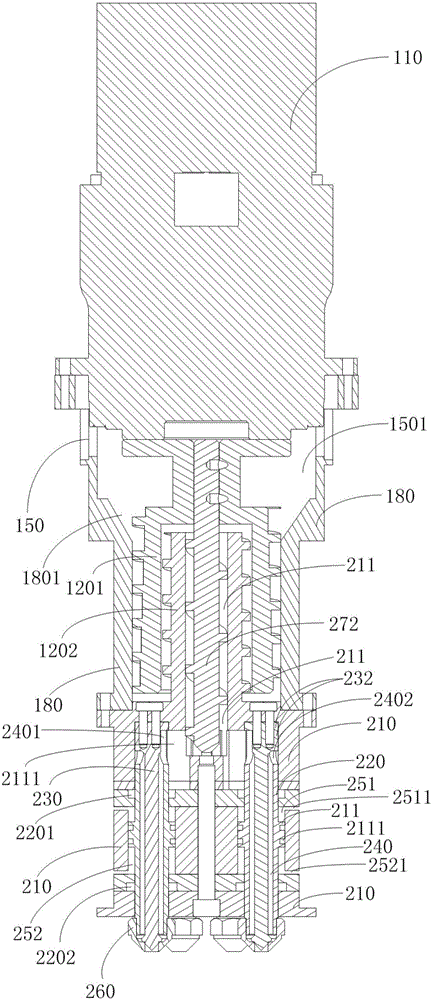

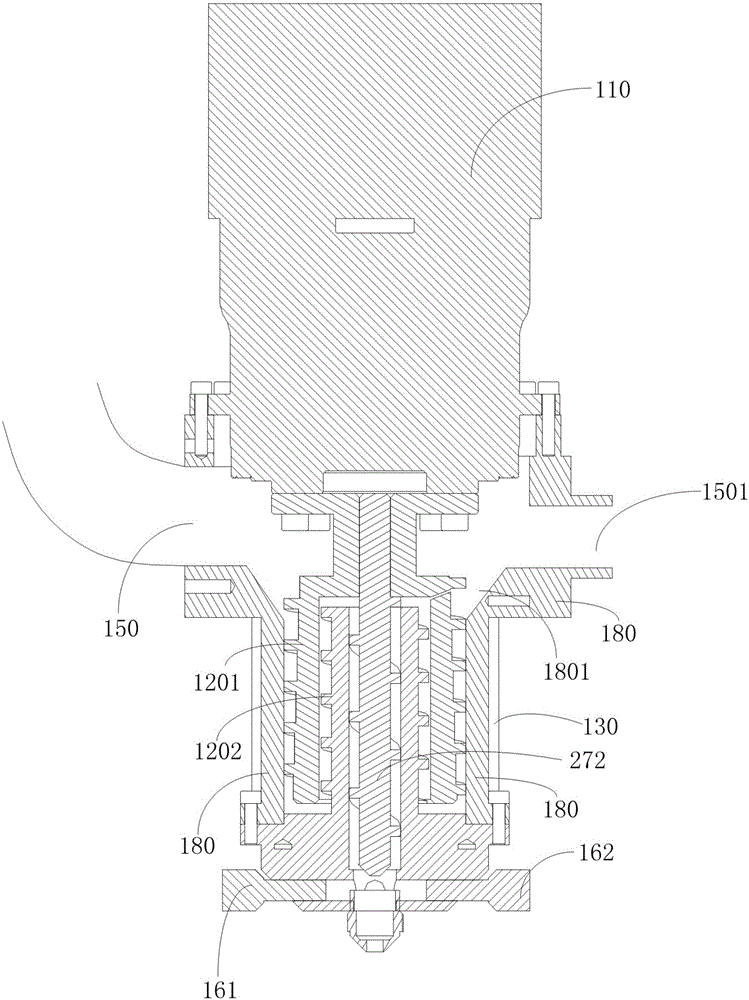

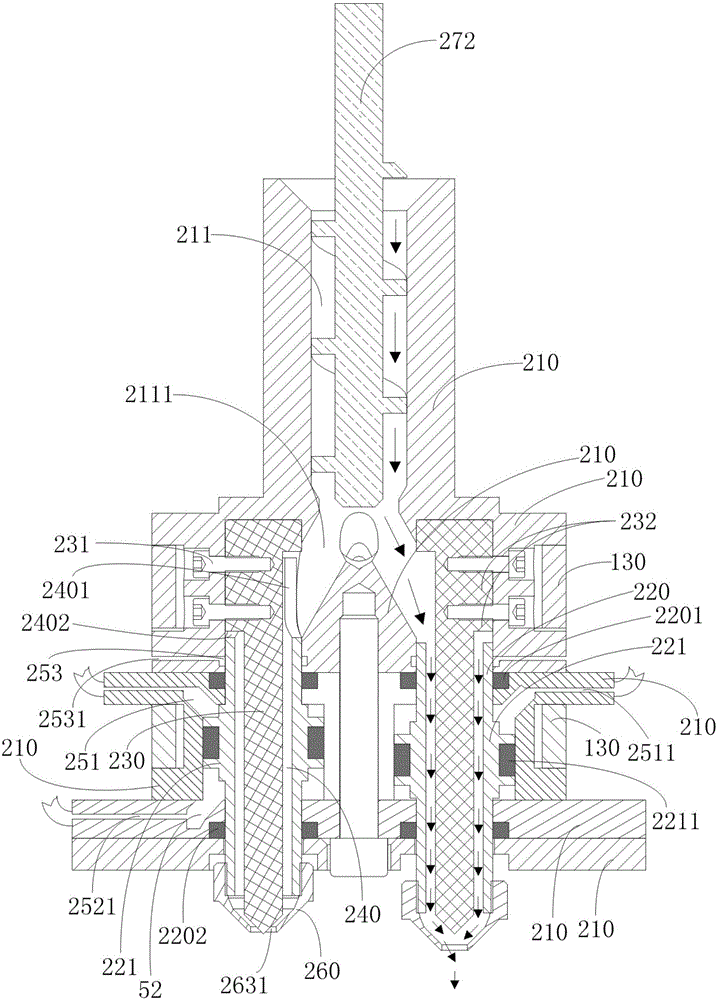

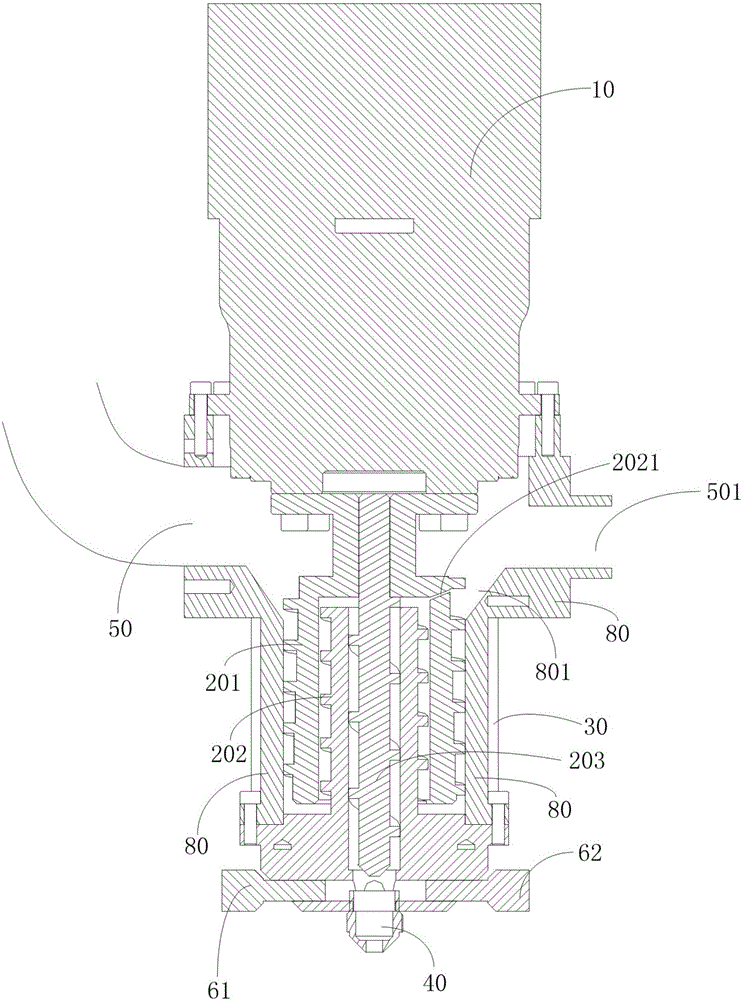

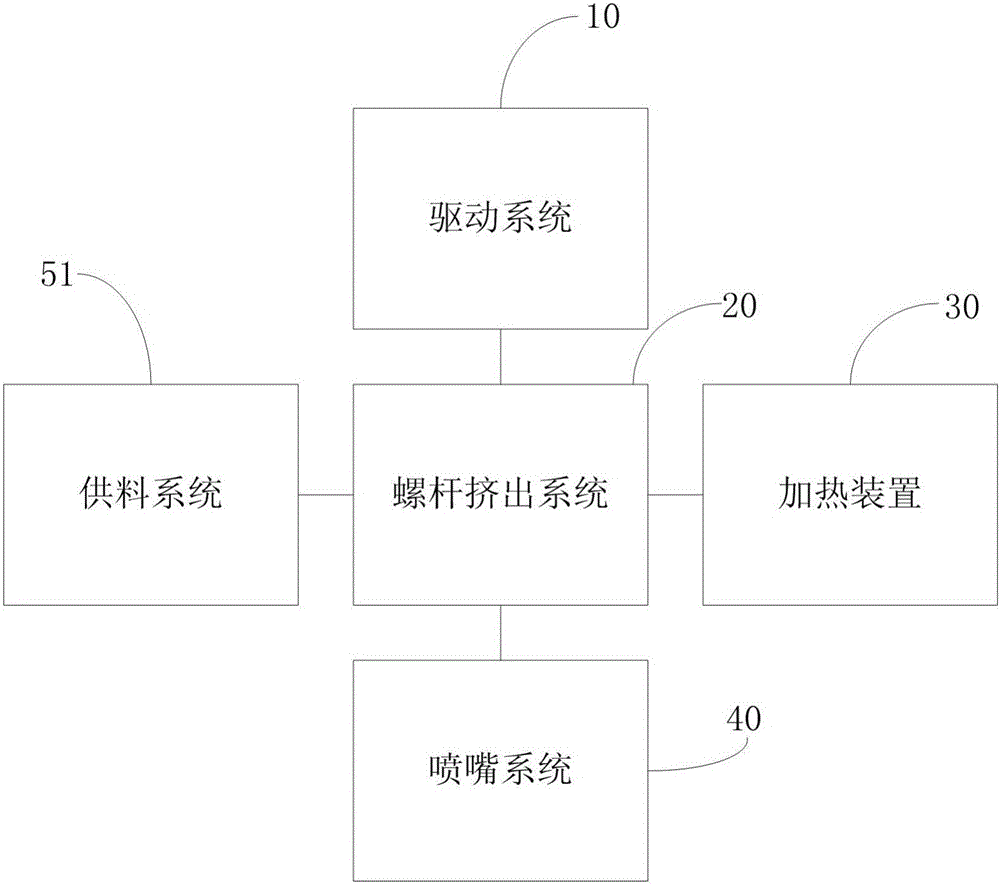

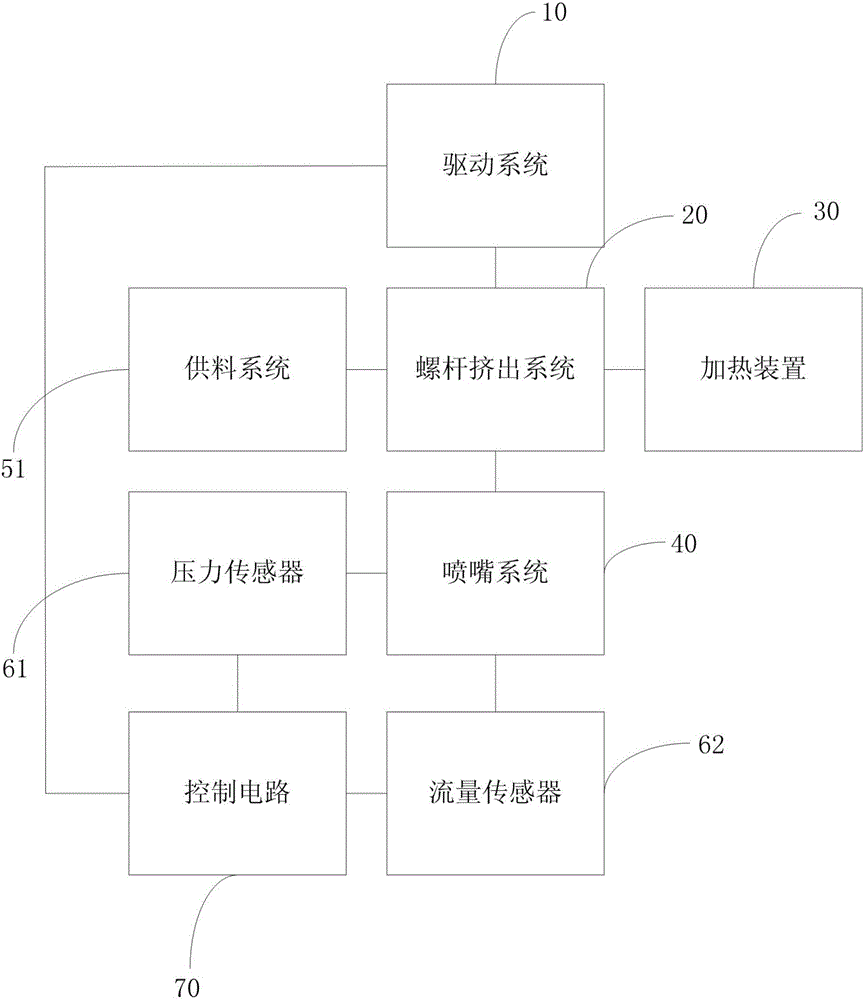

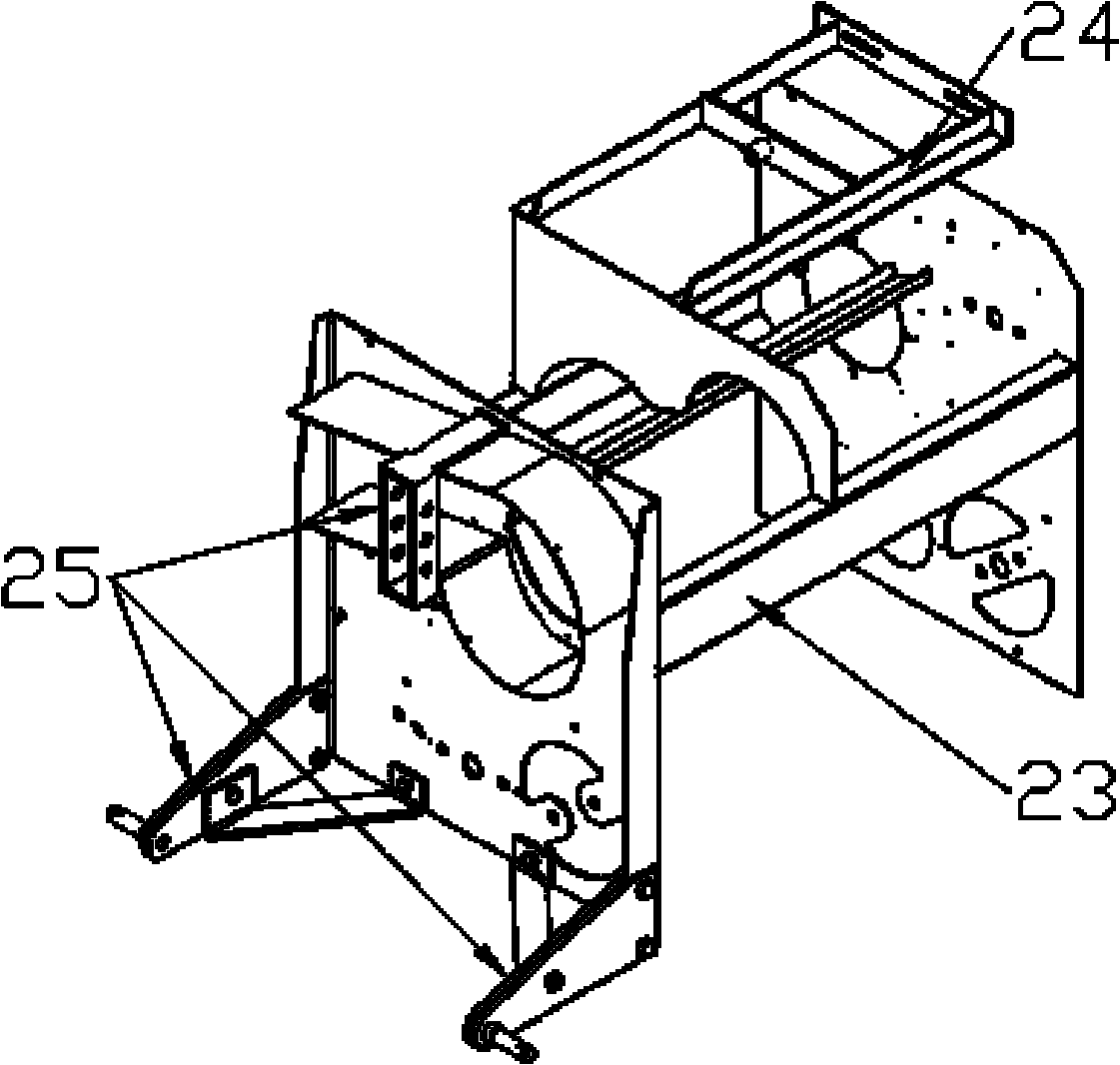

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

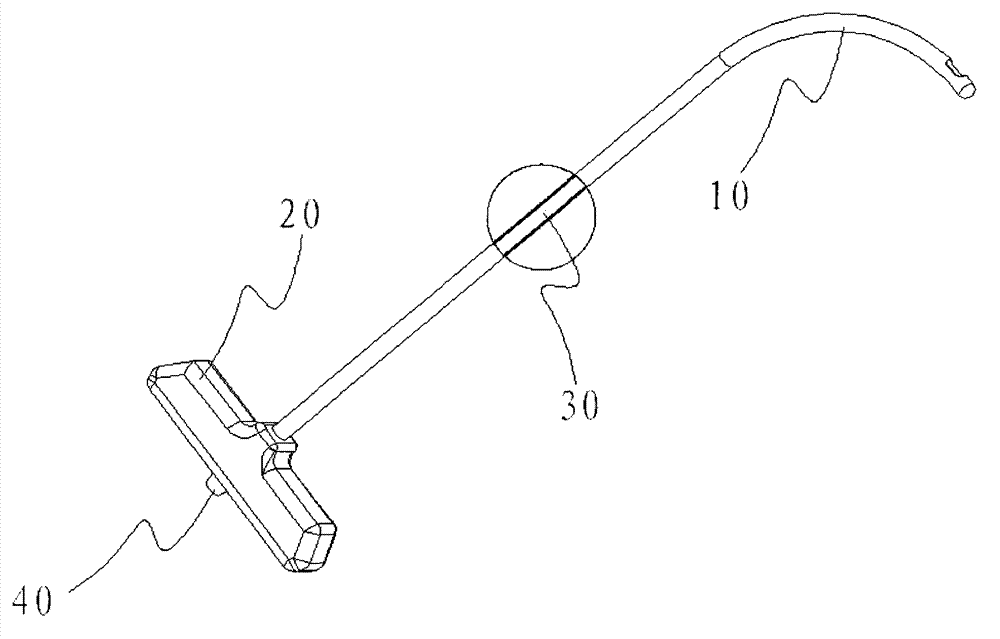

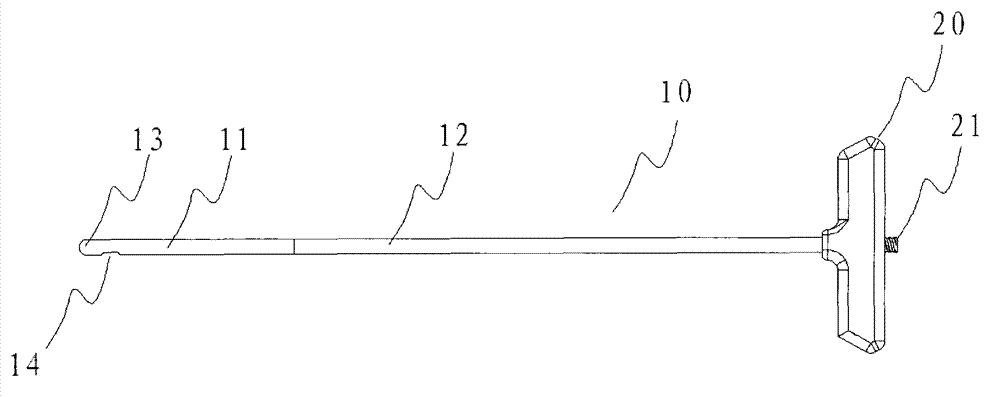

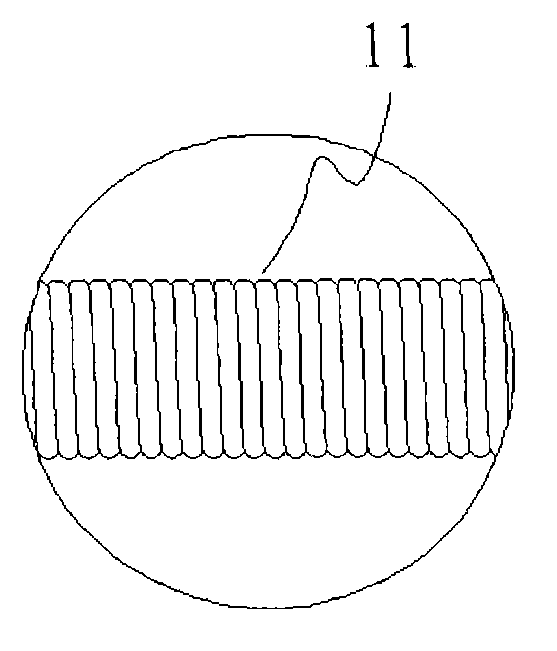

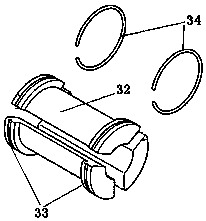

Bone filler conveying sleeve

The invention relates to a bone filler conveying sleeve which comprises a conveying tube, a conveying tube handle and a sheath core. A flexible tube is arranged at a far end of the conveying tube, a rigid tube is arranged at a near end of the conveying tube, a near end of the flexible tube is fixedly connected with a far end of the rigid tube, a near end of the rigid tube is fixedly connected with the conveying tube handle, the sheath core is slidably inserted into the conveying tube, a near end of the sheath core is fixedly connected with an adjusting handle, and a far end of the sheath core is bent to form a fixed angle which is a fixed bent section of the sheath core. The far end of the conveying tube of the bone filler conveying sleeve is provided with the flexible tube, and the sheath core with the fixed angle formed at the far end is inserted into the conveying tube, so that the purpose of controlling the bending degree of the far end of the conveying tube can be achieved by controlling the relative positions of the fixed bent section of the sheath core and the flexible tube at the far end of the conveying tube, and the bone filler conveying sleeve is convenient to operate, simple in structure and low in cost.

Owner:NINGBO HICREN BIOTECH

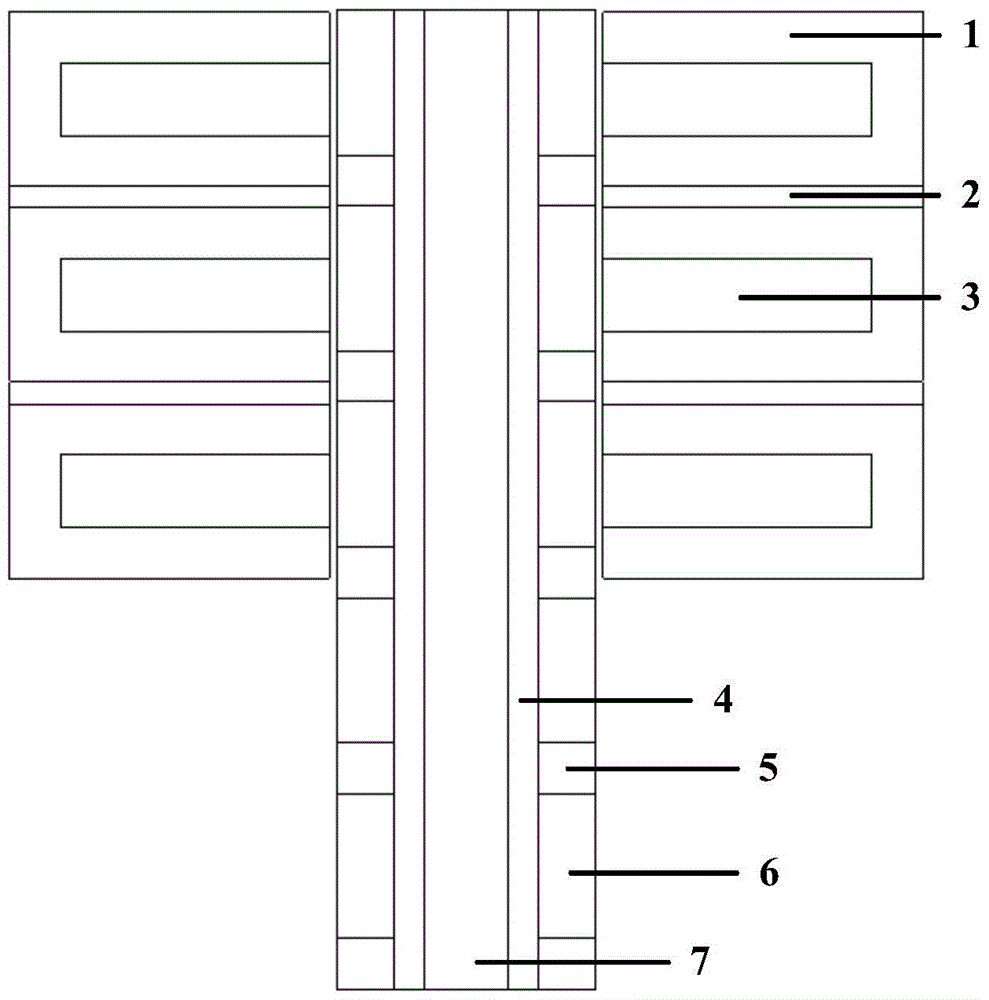

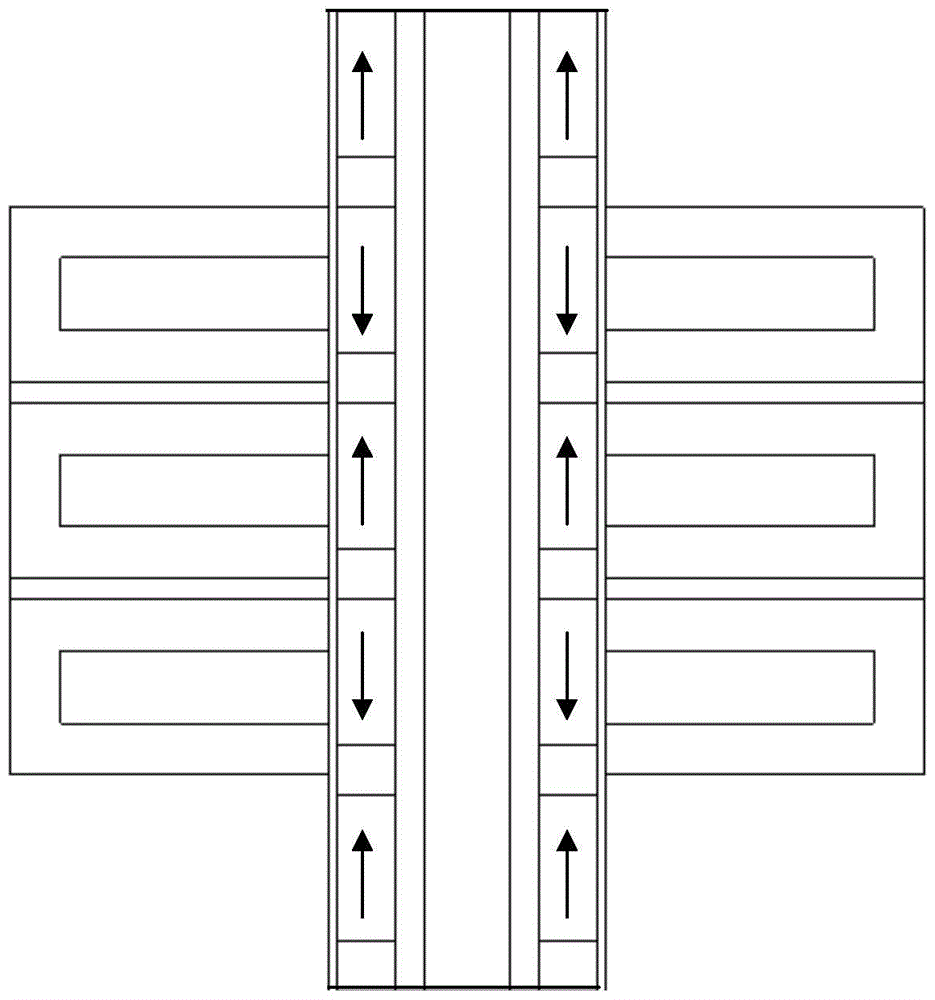

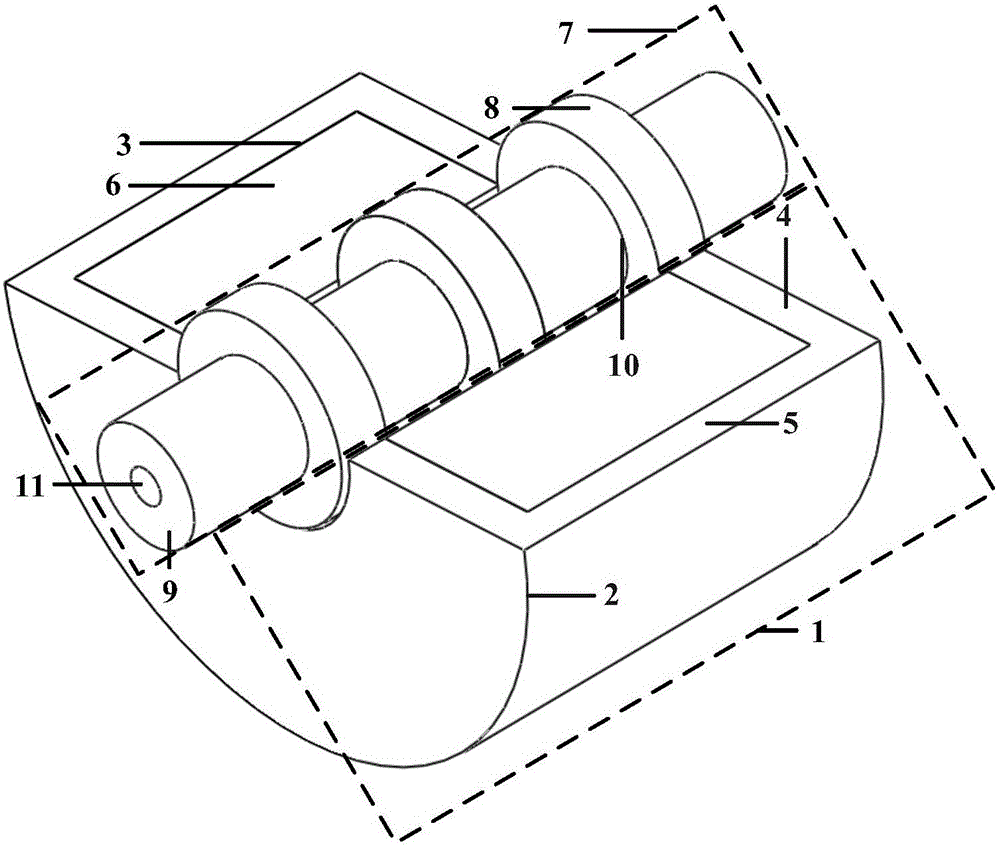

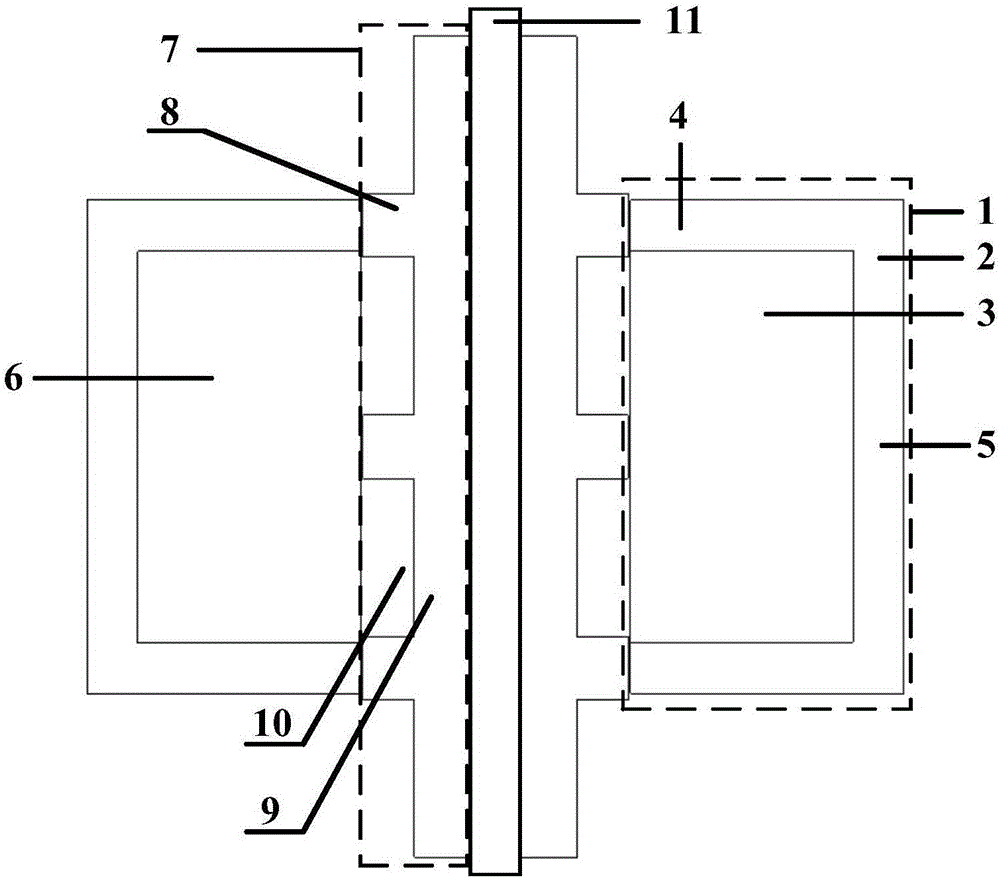

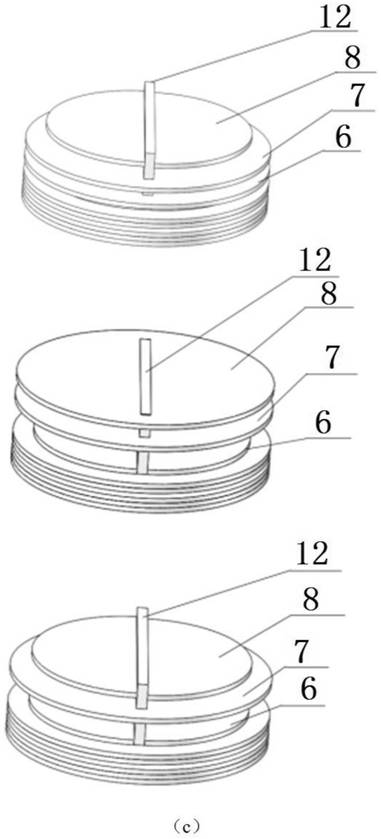

Single-phase cylindrical linear vibration motor

InactiveCN105048763AIncrease effective fluxSimple manufacturing processPropulsion systemsPull forceElectric machine

The invention provides a single-phase cylindrical linear vibration motor, which comprises a motor stator, a motor rotor and a bearing, wherein the motor stator comprises three U-shaped stator cores, two non-magnetic circular rings and three concentric winding coils; the motor rotor comprises a rotor sleeve, four rotor teeth and five permanent magnet rings; the motor stator part and the motor rotor part are in clearance fit, namely the three concentric winding coils are horizontally arranged; U ends point to the bearing; and the concentric winding coils and the rotor teeth are oppositely arranged. According to the single-phase cylindrical linear vibration motor provided by the invention, a rotor yoke part is omitted; the motor manufacturing process is simplified; the slot utilization rate is improved; the propulsive force of the rotor is increased; the sealing property is good; the structure is simple and firm; the end effect and the normal magnetic pull force of the motor are removed; the motor reliability is high; the requirements of sports occasions of reciprocating linear vibration can be met; and the single-phase cylindrical linear vibration motor is suitable for popularization and application in industrial linear vibration.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH +1

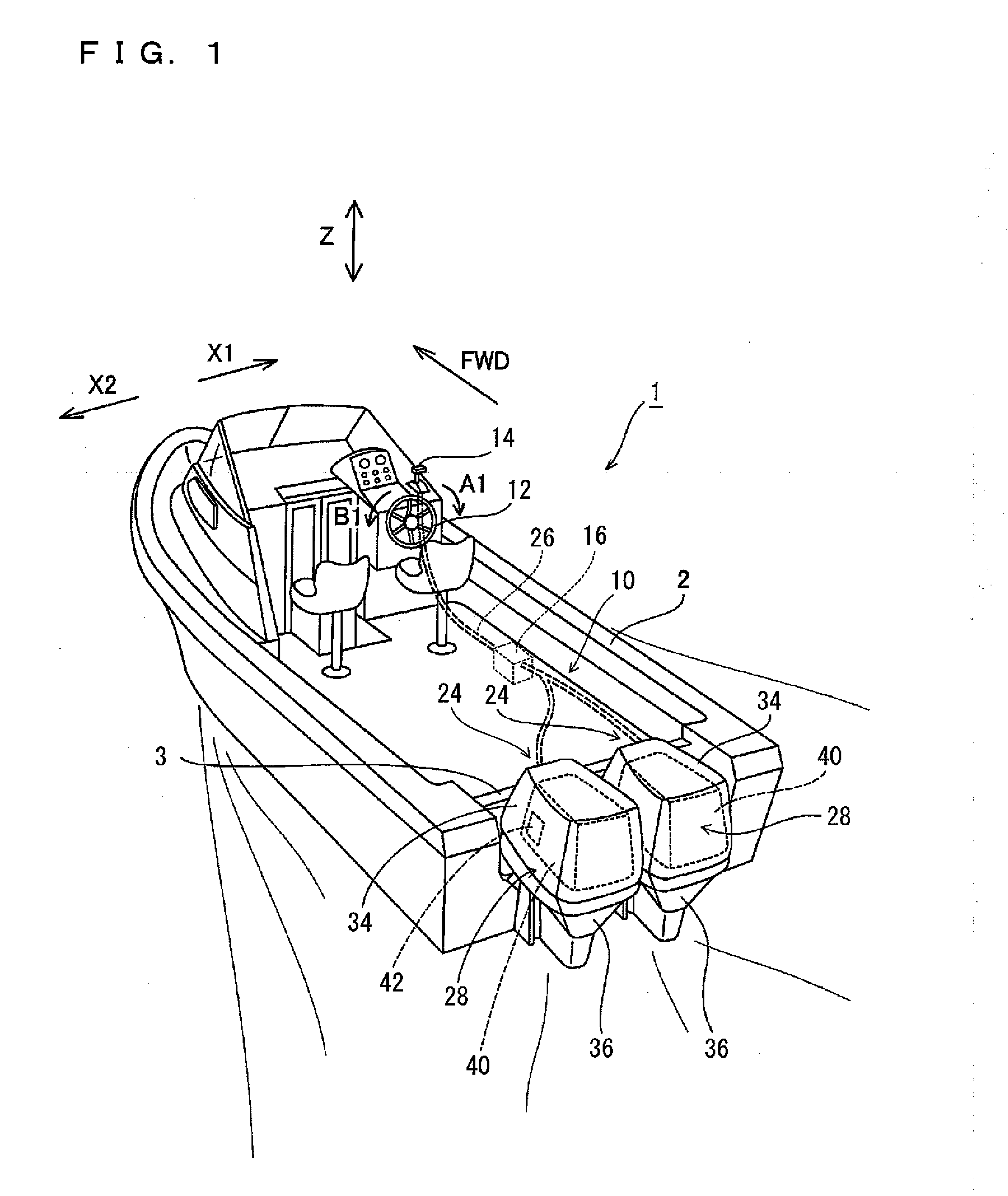

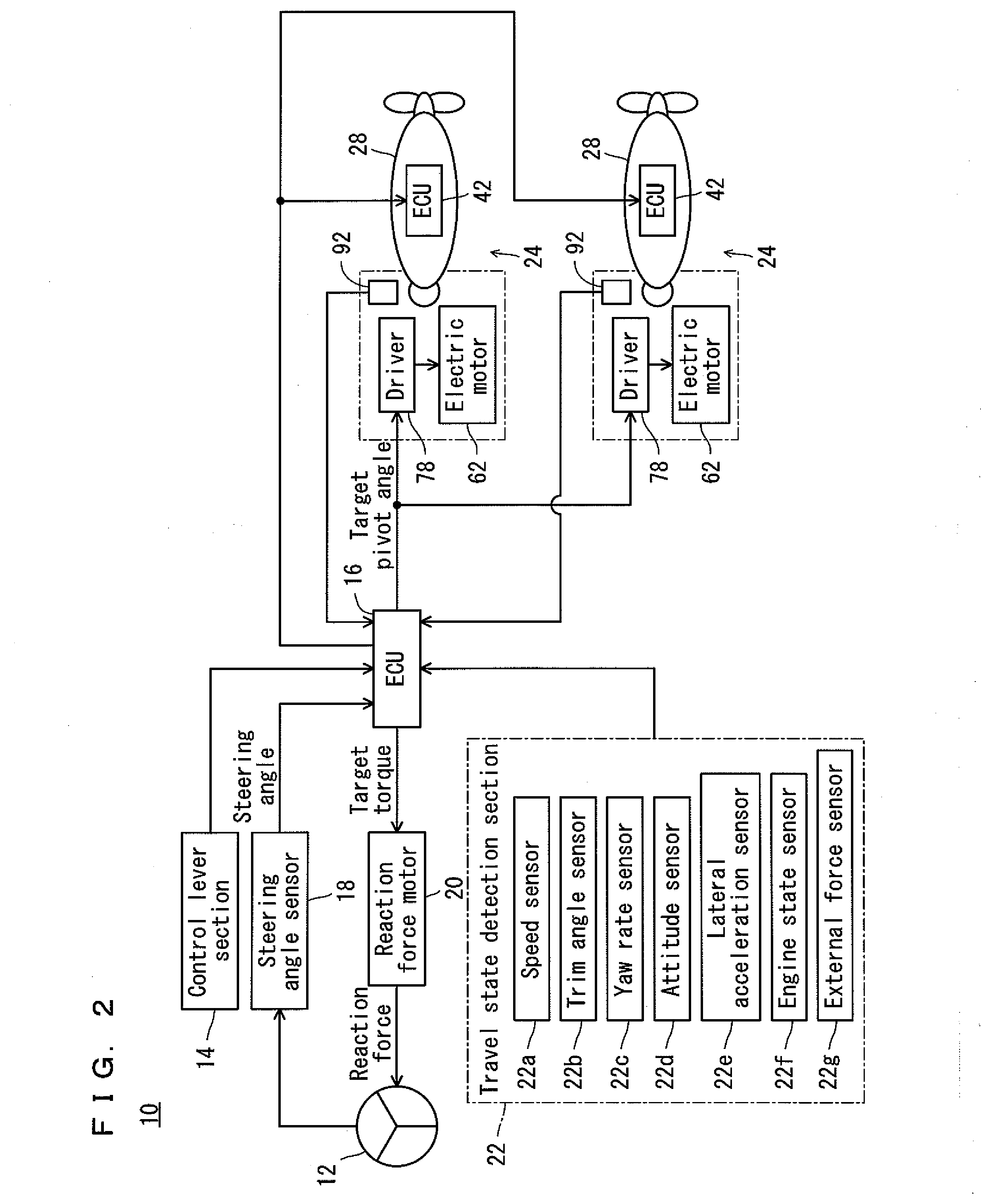

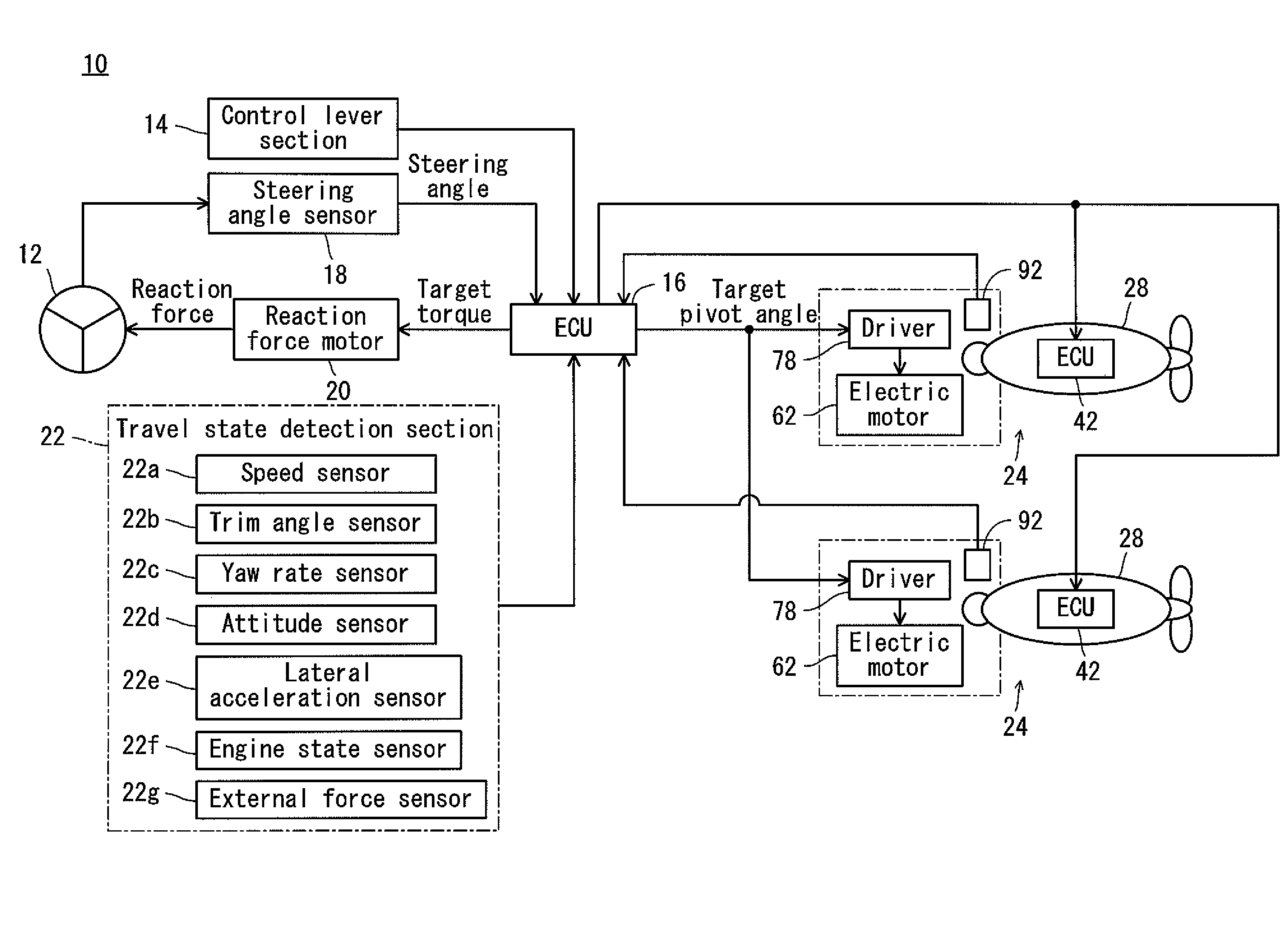

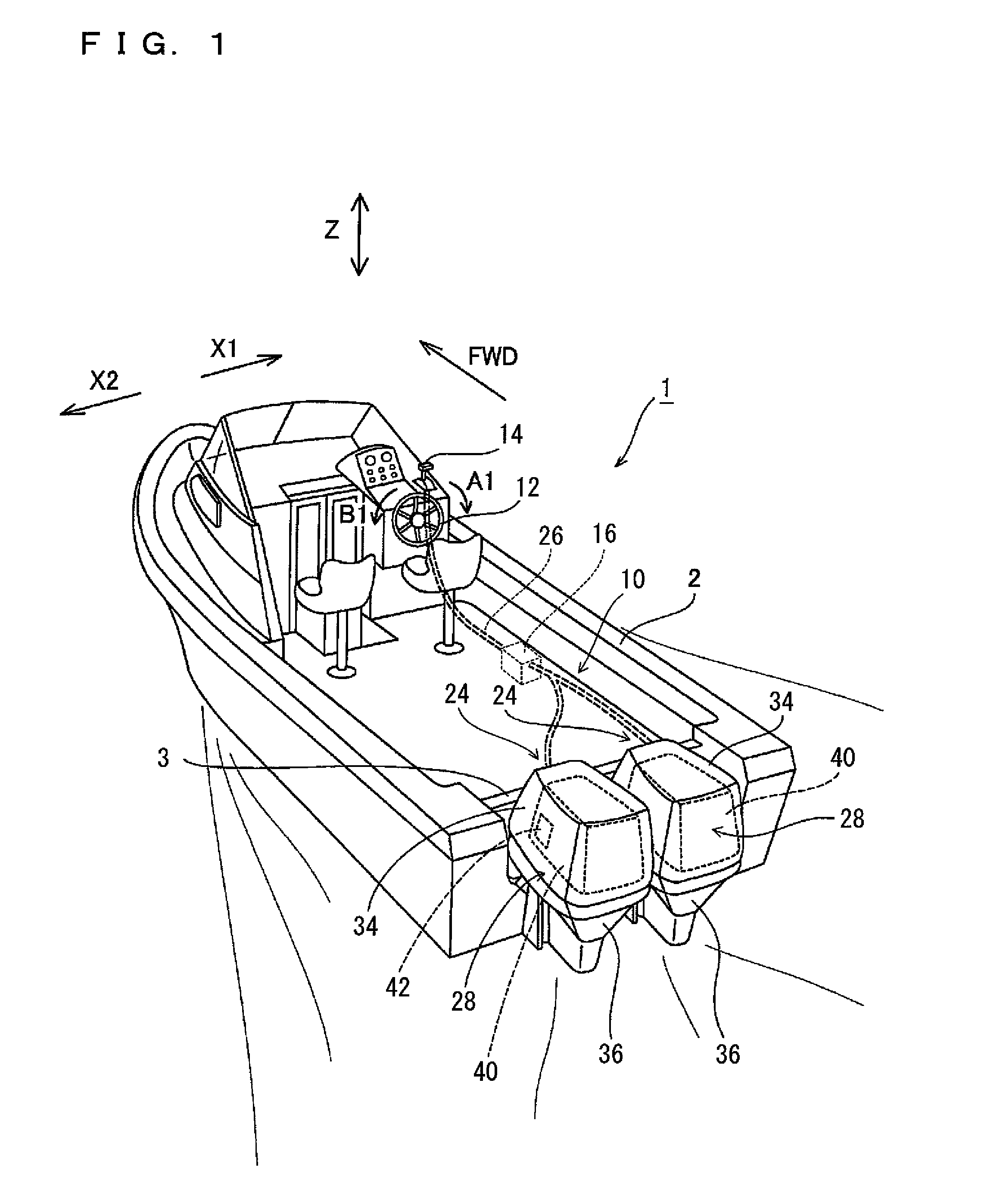

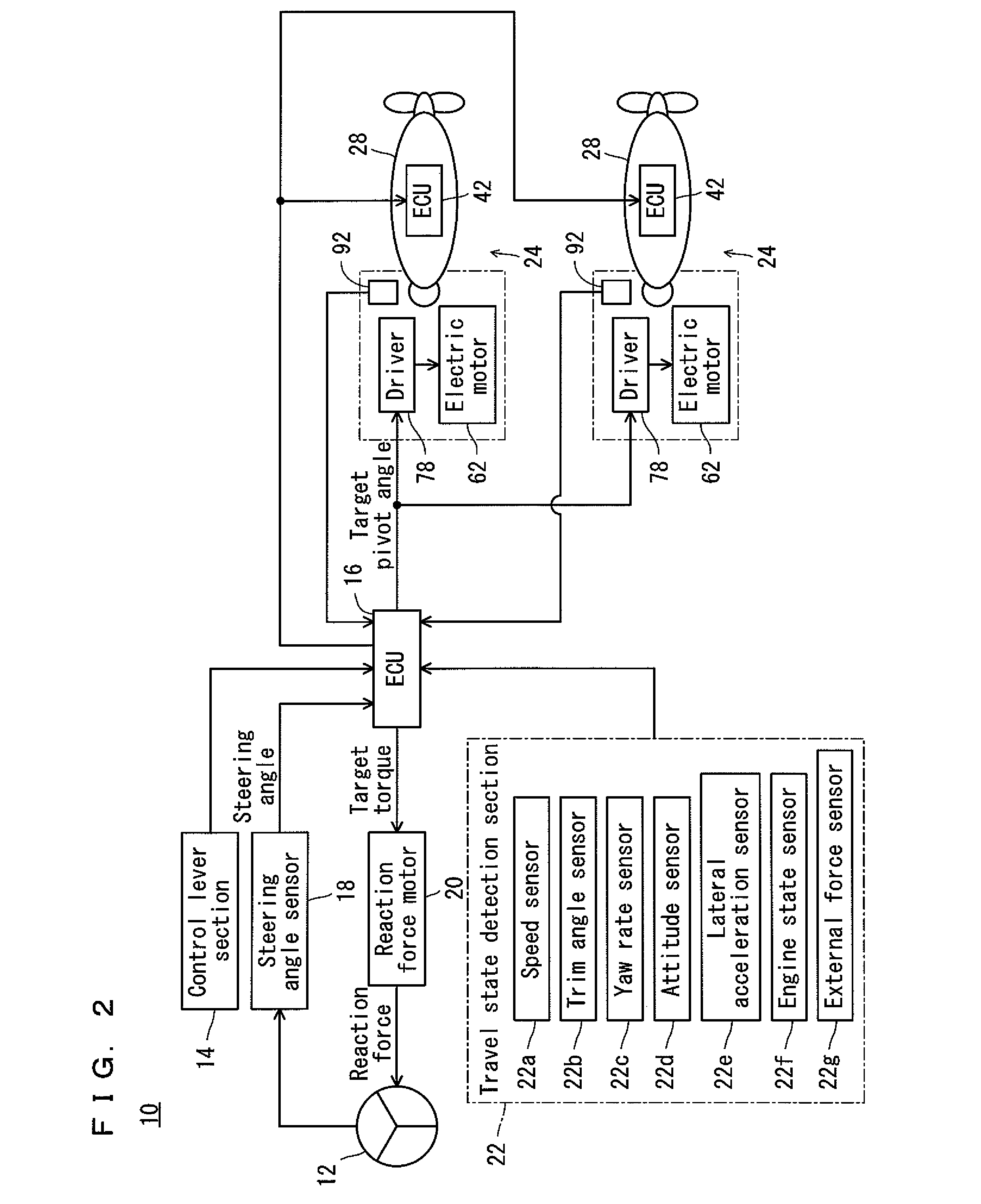

Boat propelling system

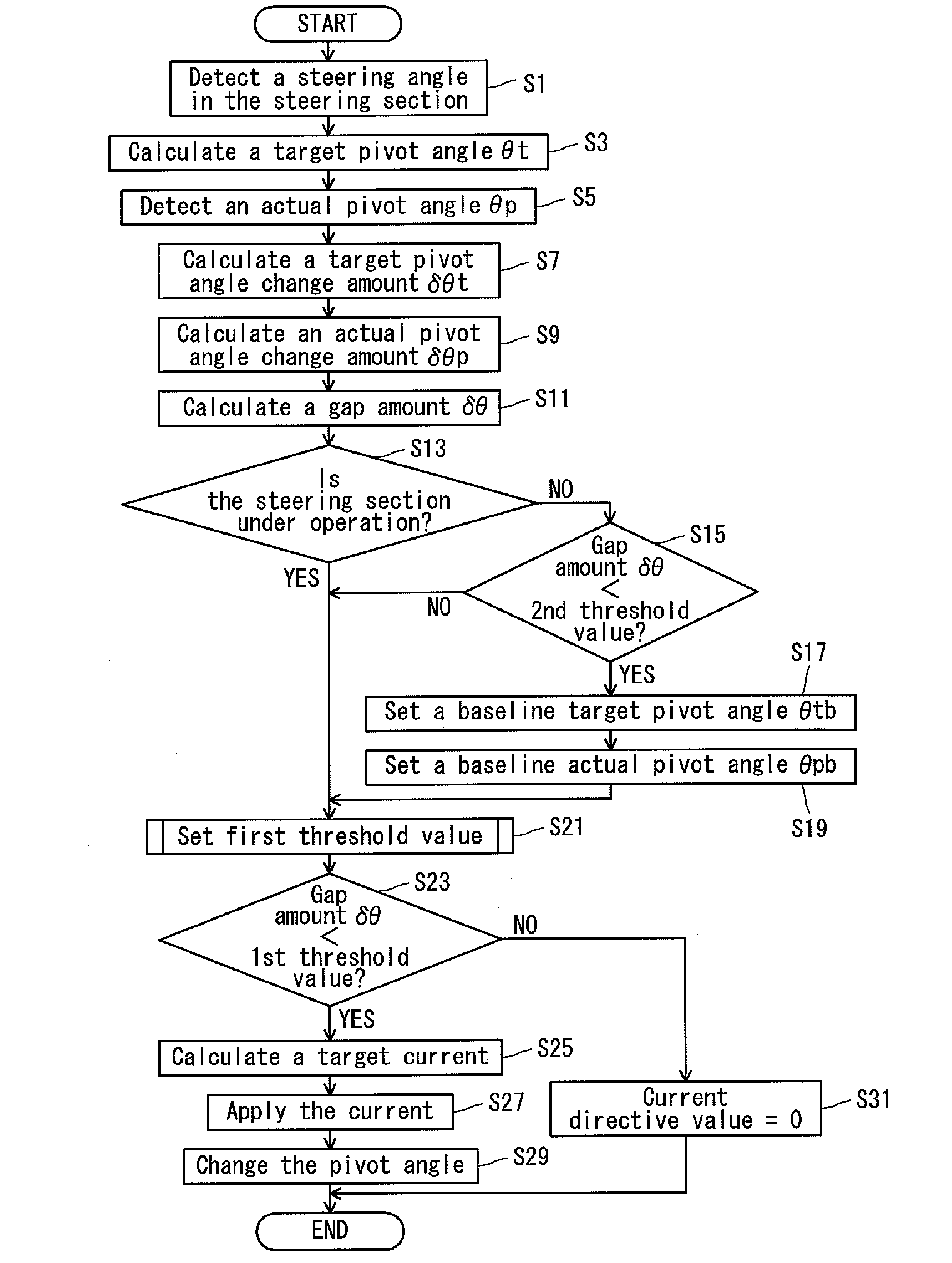

ActiveUS20110010028A1Sure easyQuicker increase in the target pivot angleSpeed controllerElectric devicesSteering angleEngineering

A boat propelling system capable of determining an abnormality regarding steering of a propelling system main body includes an outboard engine main body, a steering section arranged to steer the outboard engine main body, a steering angle sensor arranged to detect a steering angle of the steering section, a pivot sensor arranged to detect an actual pivot angle of the outboard engine main body, and an ECU. The ECU calculates a target pivot angle change amount based on a target pivot angle derived from the steering angle and a baseline target pivot angle, calculates an actual pivot angle change amount based on the actual pivot angle and a baseline actual pivot angle, and obtains a gap amount between the target pivot angle change amount and the actual pivot angle change amount. Then, the ECU determines an abnormality regarding steering of the outboard engine main body based on a result of comparison between the gap amount and the first threshold value. Setting of the baseline target pivot angle and the baseline actual pivot angle is based on a result of a comparison between the gap amount and a second threshold value.

Owner:SIEMENS ENERGY INC +1

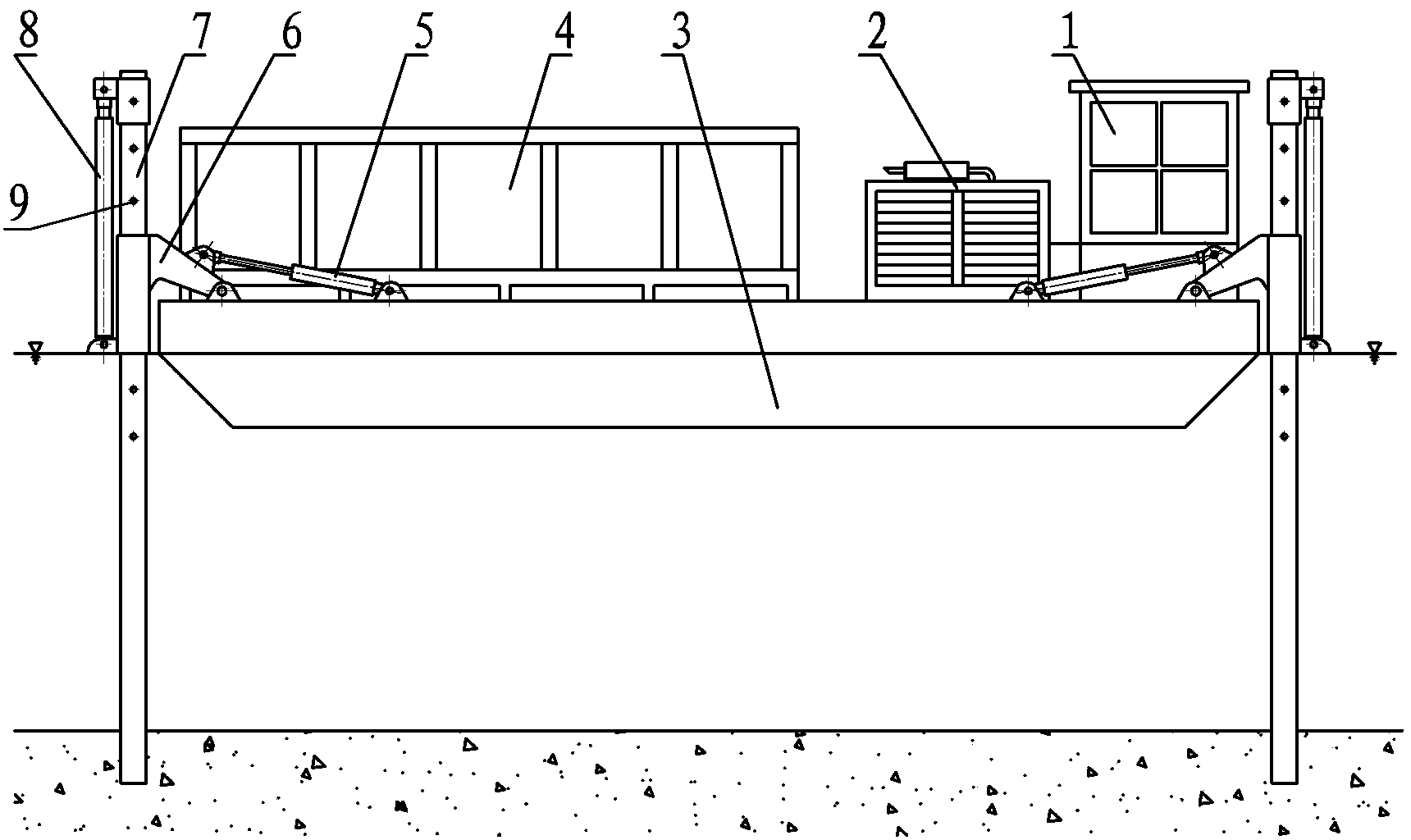

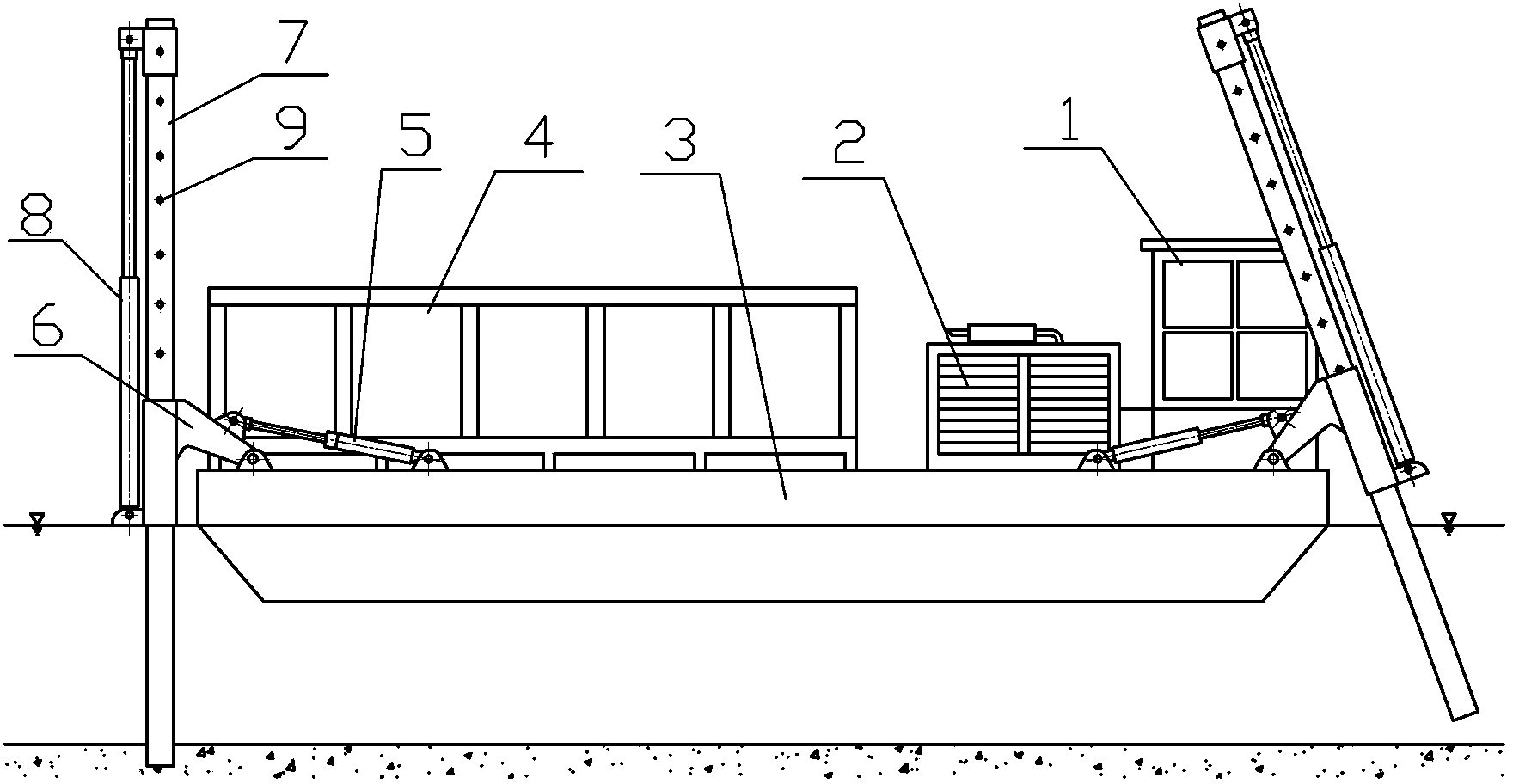

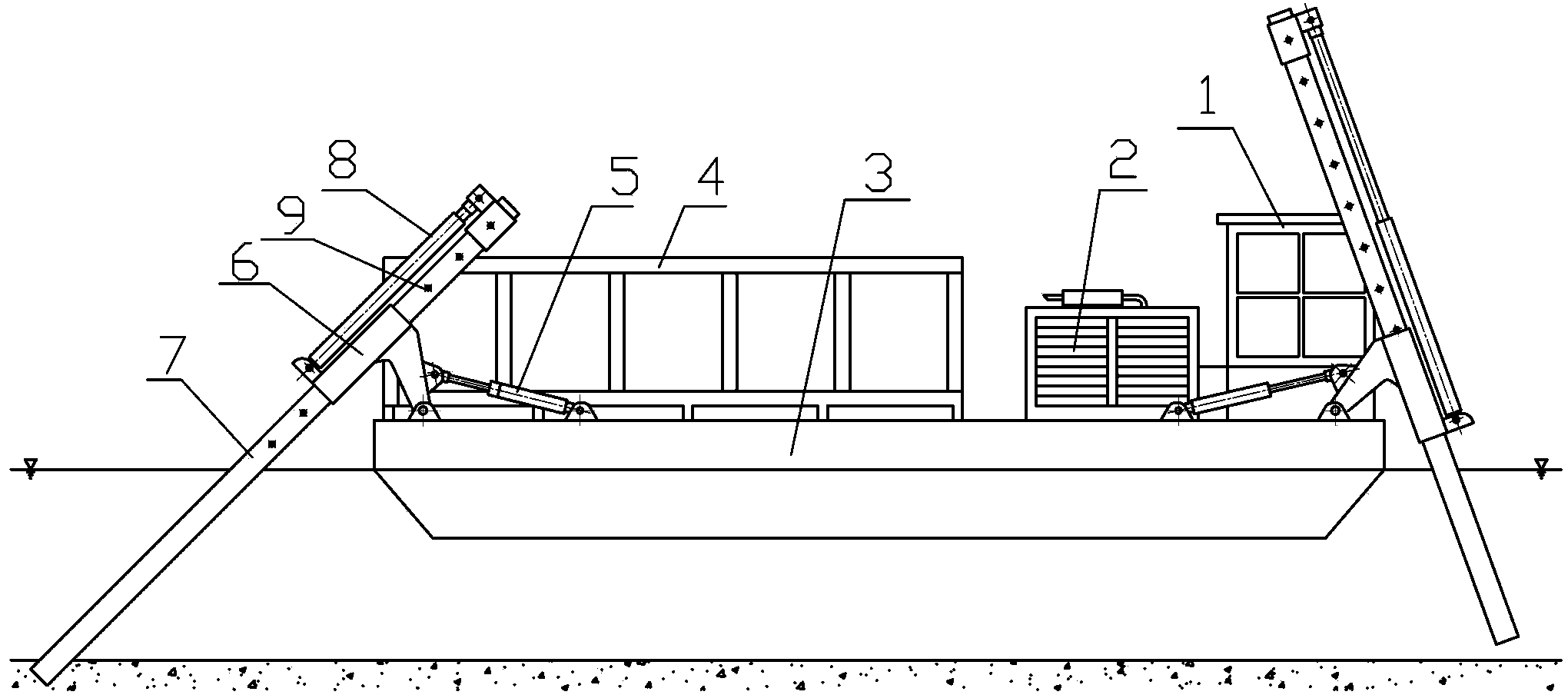

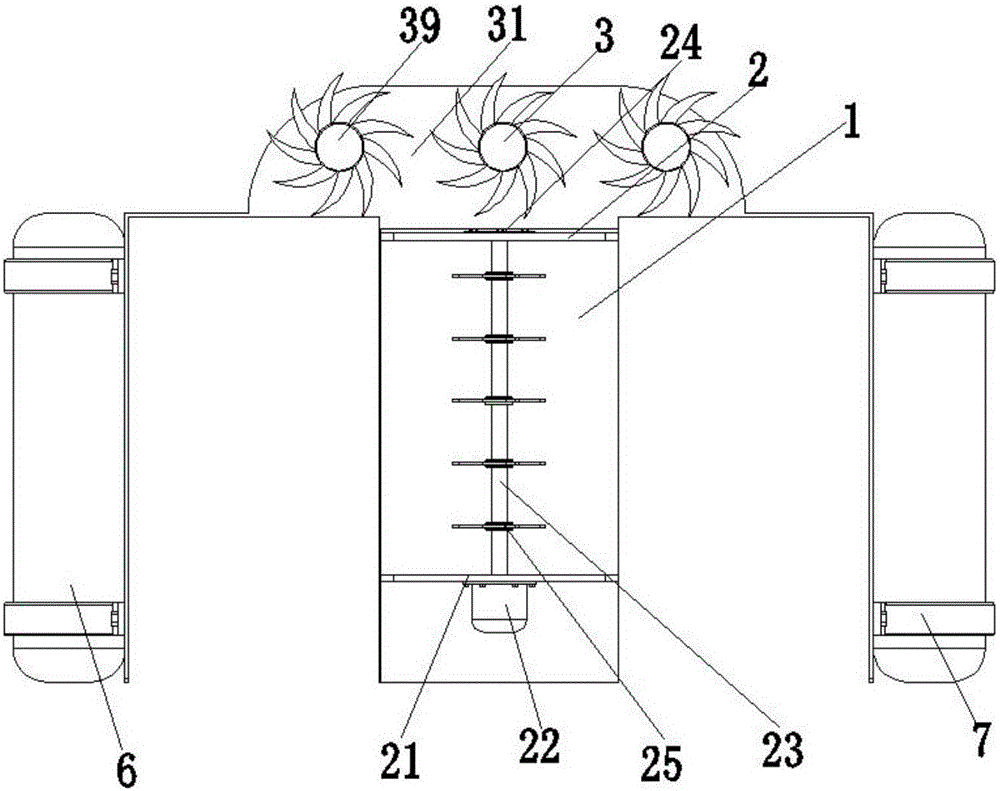

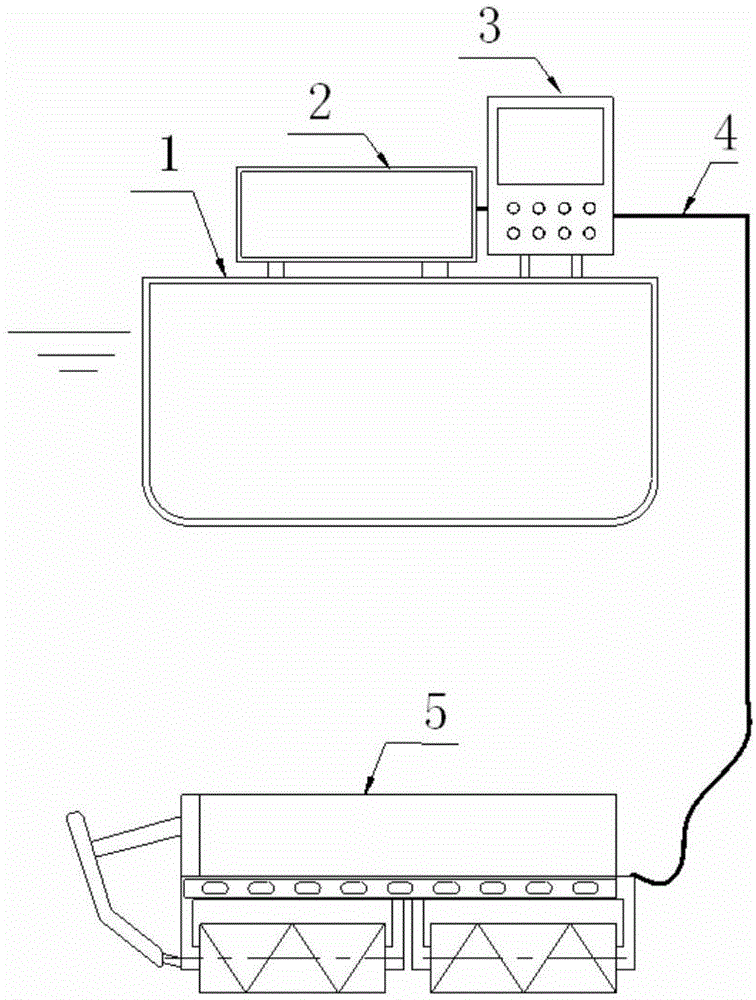

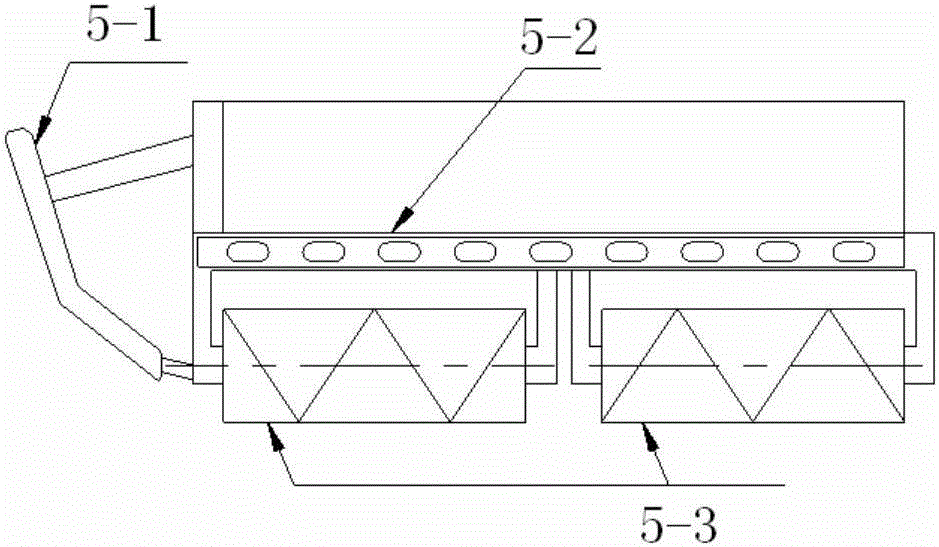

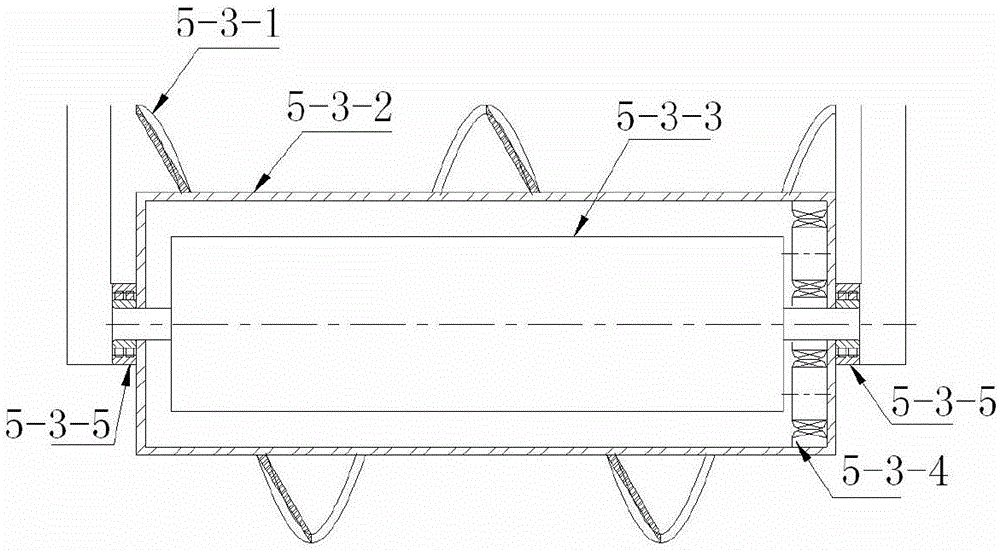

Workboat moving in hydraulic stay bar mode

InactiveCN103407566APropagation with noiseBig propulsionPropulsive elementsTransmission with non-mechanical gearingHydraulic cylinderHydraulic pump

The invention discloses a workboat moving in a hydraulic stay bar mode and belongs to workboats. The workboat structurally comprises a workboat body, a control cabinet and a working device, wherein the working device and the control cabinet are arranged on the upper portion of the workboat body, hydraulic stay bar devices are arranged on the front side and the rear side of the workboat body respectively, the hydraulic stay bar devices and the control cabinet are connected with a hydraulic pump station respectively, and the hydraulic pump station is arranged on the upper portion of the workboat body. The workboat based on the bionics theory of how hippos moving in water and adopting a theory of poling a boat through bamboo spars uses a hydraulic cylinder as power and moves in a stay bar mode, and the workboat can be used for tugging of fleets moving shallow channels in inland rivers, can be used for performing dredging, transportation and other operations in mire lands severe in sedimentation or shallow rivers and lakes with tufty reeds and aquatic plants, can move silently close to water bottom under water and can be used for executing special operations as subwater sneaking devices.

Owner:李志强 +1

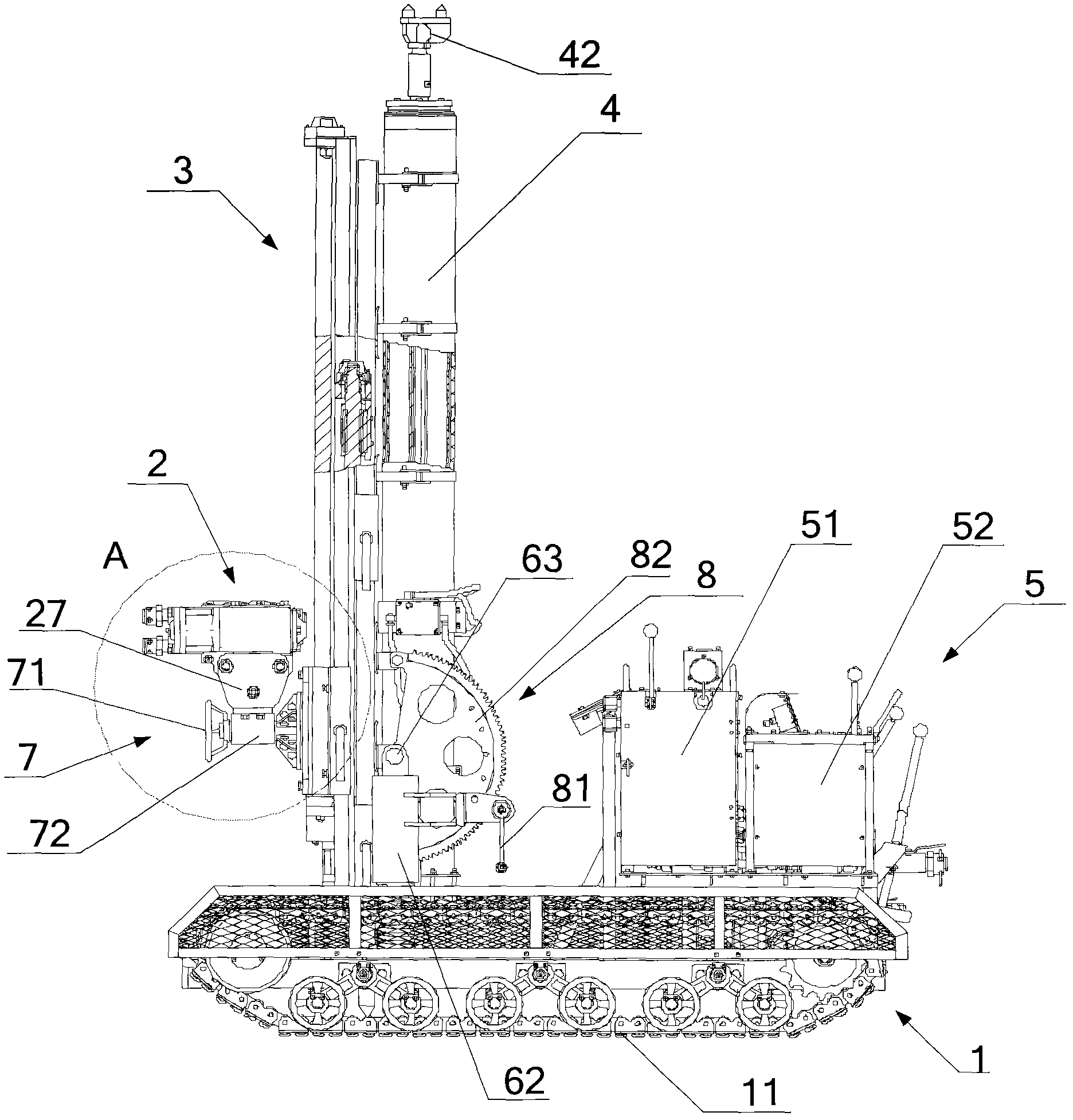

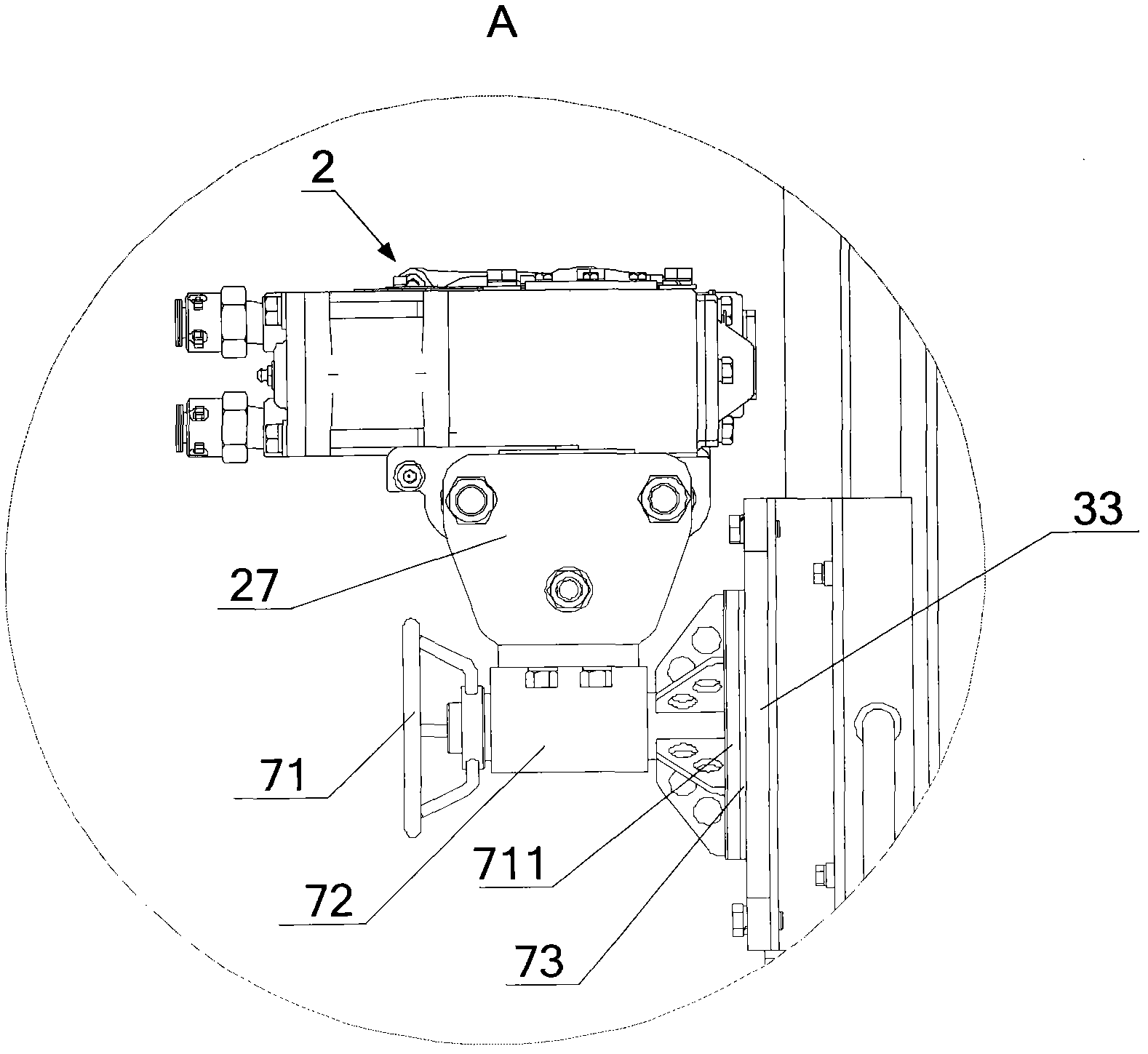

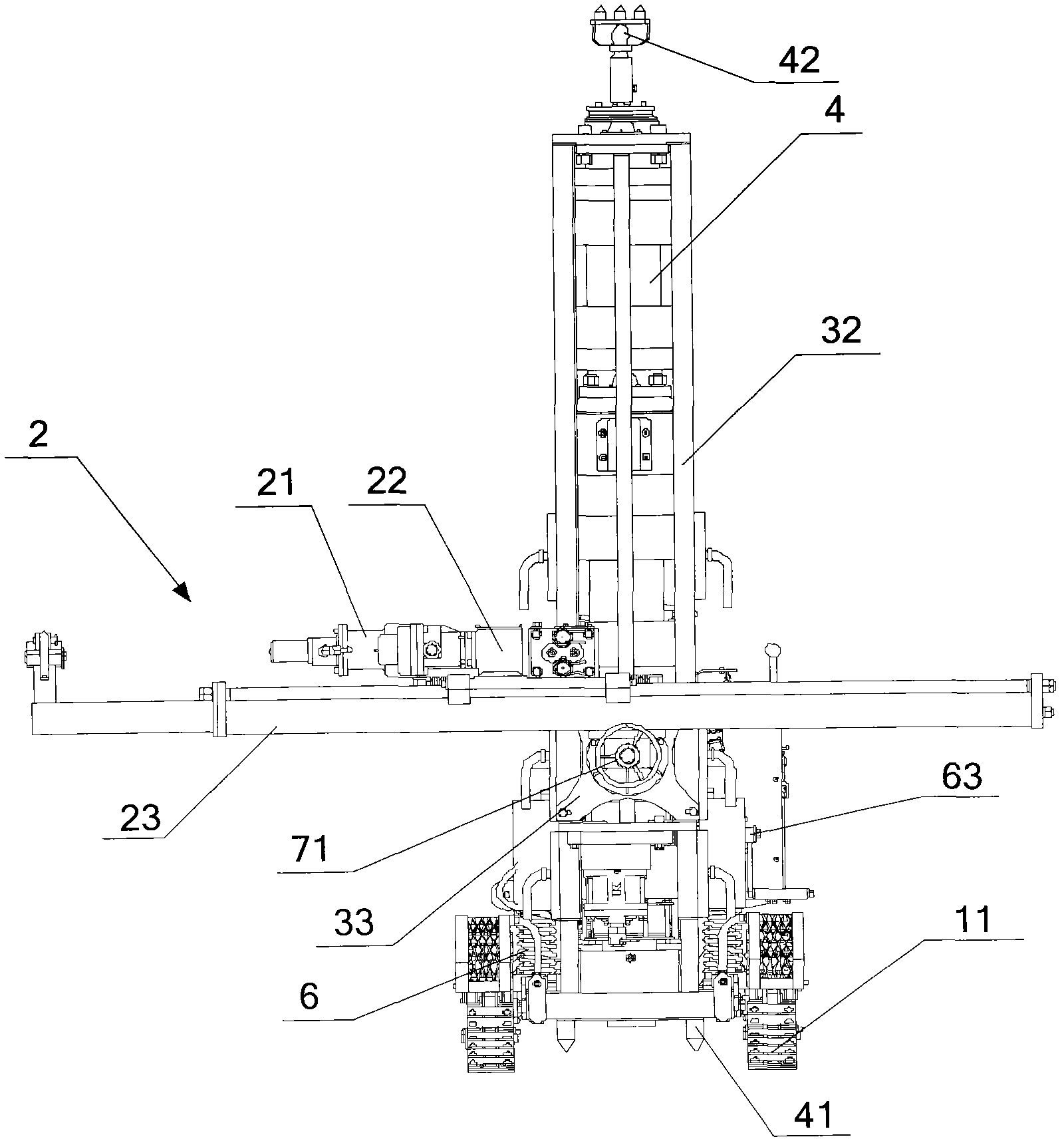

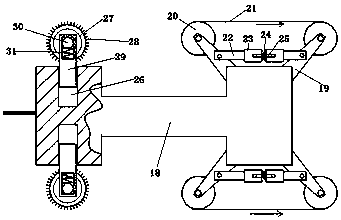

Pneumatic drill rig

InactiveCN102278064AOperational securityExtend your lifeConstructionsDerricks/mastsControl tableOperations security

The invention provides a pneumatic wagon drill which comprises a travel mechanism, a feed rotary mechanism, a support upright column and an operating and control table, wherein the operating and control table and the support upright column are arranged on the travel mechanism, the feed rotary mechanism is arranged on the support upright column through an angle adjusting mechanism and a moving mechanism, the support upright column is arranged on the travel mechanism through a spring and can adjust an inclination angle of the support upright column through an inclination angle adjusting mechanism, and the feed rotary mechanism can move up and down along the support upright column through the moving mechanism and rotate in a working face through the angle adjusting mechanism. Owing to the technical scheme provided by the invention, the feed rotary mechanism of the pneumatic wagon drill can move rapidly with high efficiency, the jacking force and the drilling force are supported on the ground, the load on the travel mechanism is reduced, the service life of the pneumatic wagon drill is increased, and the manufacturing cost is reduced; and besides, the purpose of remotely controlling the drilling operation is achieved, the working environment is greatly improved, and the operating safety of workers is improved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

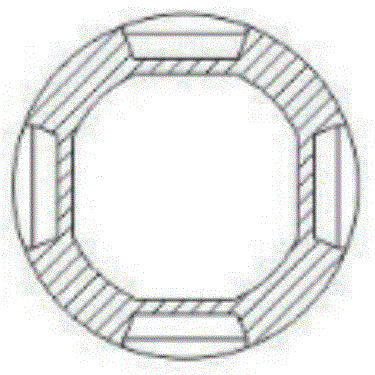

Single-phase cylindrical switch-reluctance linear motor

InactiveCN105048764ASimple and strong structureImprove reliabilityPropulsion systemsPull forceElectric machine

The invention relates to a single-phase cylindrical switch-reluctance linear motor. The single-phase cylindrical switch-reluctance linear motor comprises a motor stator part, a motor rotor part and a linear bearing, wherein the motor stator part comprises a stator sleeve and a winding coil, an annular stator groove is formed in the stator sleeve, two planes of the stator sleeve are stator teeth, arc-shaped grooves are formed in the two stator teeth, one cambered-surface plate of the stator sleeve is a stator yoke part, and the stator teeth and the stator yoke part are formed in an integrating manner; the motor rotor part comprises three rotor tooth circular rings and a rotor yoke sleeve. According to the single-phase cylindrical switch-reluctance linear motor, the manufacturing process is simplified, and the utilization rate of a groove is improved; furthermore, the propelling force of a rotor is increased, the sealing performance is good, the structure is simple and firm, an end effect and a normal magnetic pull force of the motor are eliminated, the reliability of the motor is high, and requirements on a movement location of reciprocating linear vibration can be met; the single-phase cylindrical switch-reluctance linear motor is suitable for popularizing industrial linear oscillation.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH +1

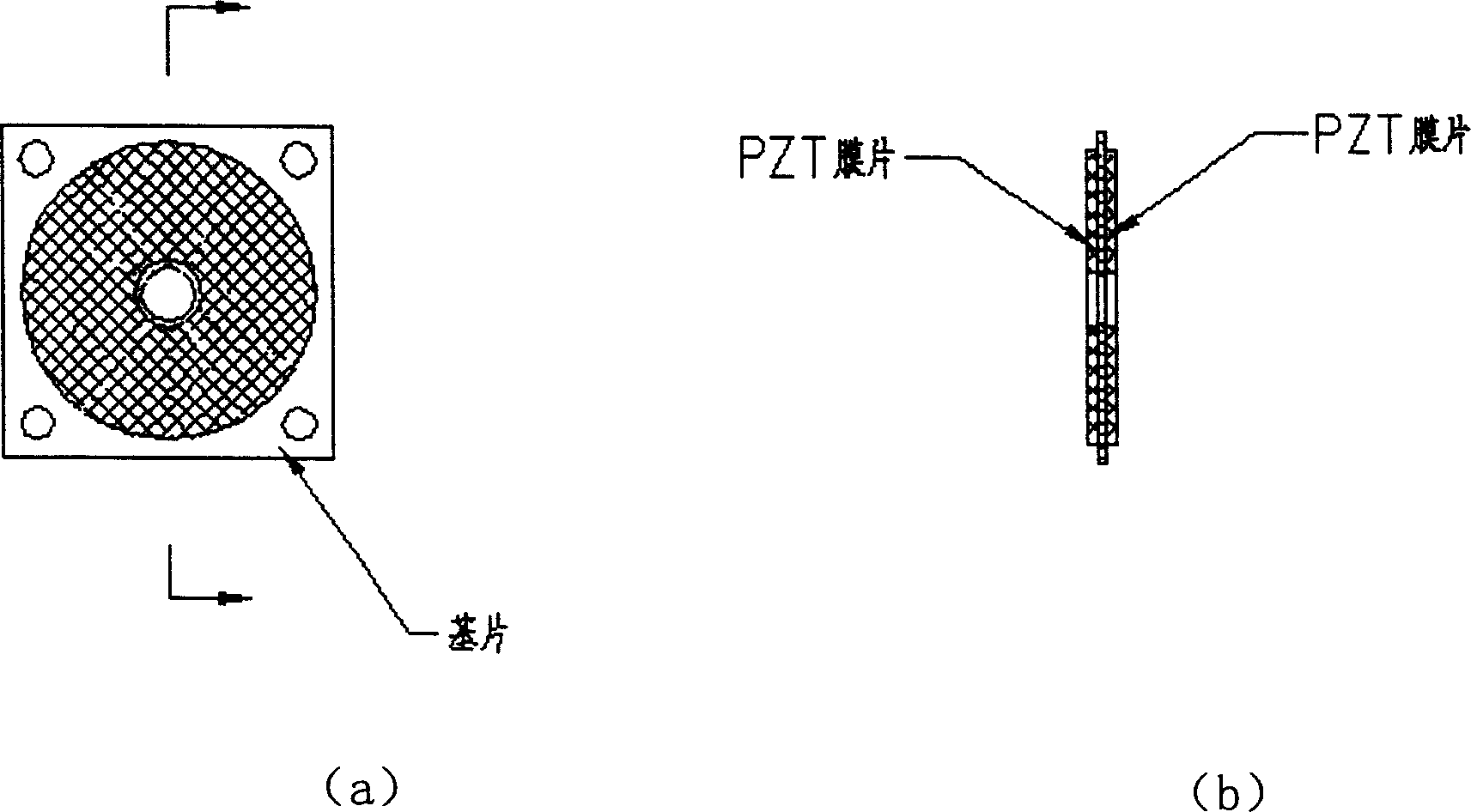

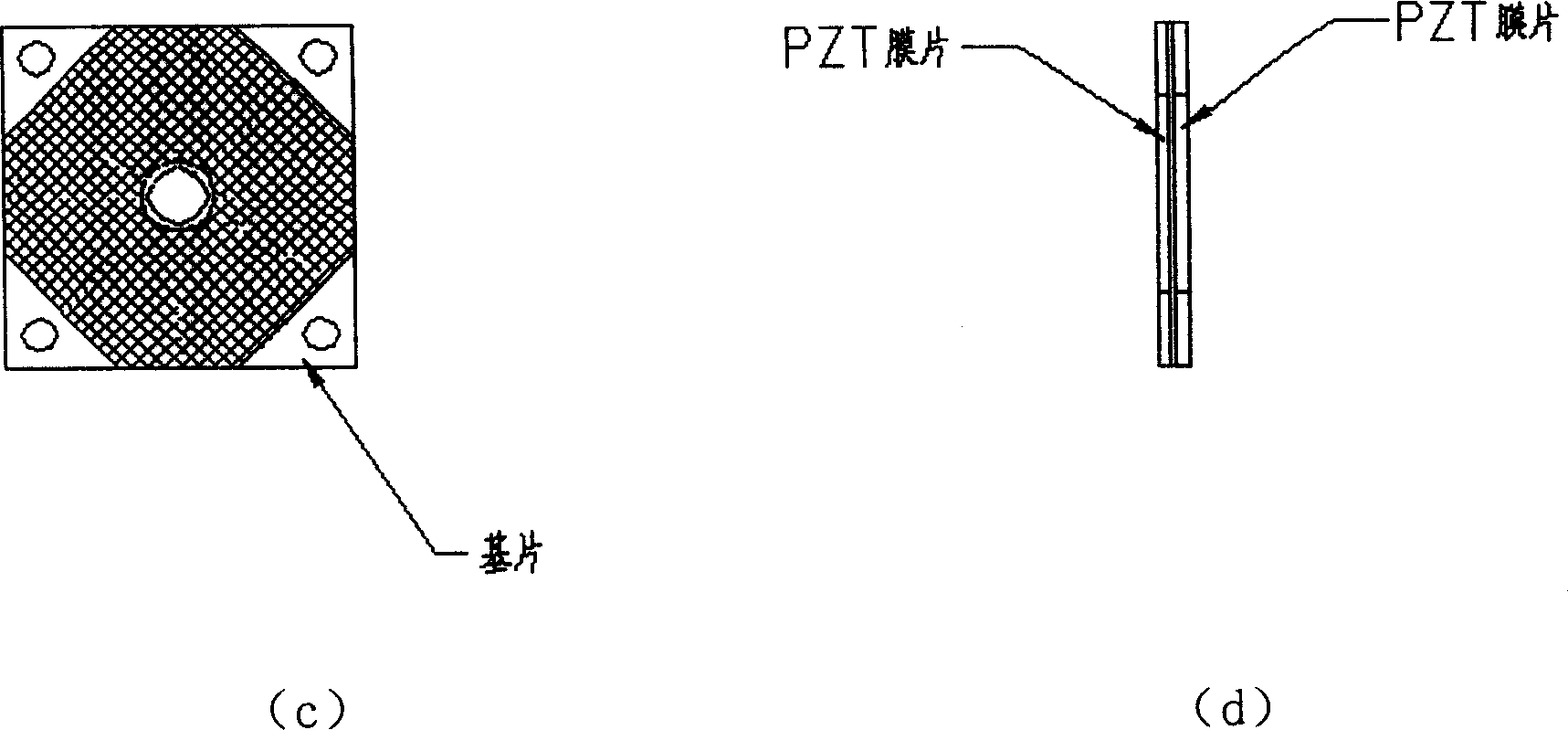

Minisize linear driver based on dimorphic crystal piezoelectric film

InactiveCN1699032AIncrease peripheral sizeReduce volumeMicromanipulatorMechanical vibrations separationMetal foilEngineering

This invention relates to a mini linear driver based on the bimorph conductive film, which comprises a driving mechanism and a moving supporting mechanism, wherein the driving mechanism covers on the central bearing and is oriented by the inertia mass block and hub in two ends, the moving supporting mechanism comprises the rigid frame of bimorph conductive film and the resilient supporting pin connecting the frame; said bimorph conductive film comprises ceramics chip of metal foil, characterized in that the rigid frame is round, quadrangle or regular polygon, on the edge there is 3~4 circular small punch holes distributed evenly; said resilient supporting pin is elastic wire through the rigid frame and small punch holes to connect them. Said invention is fit for mini robot driver in the ultra-fine pipe whose bore diameter is below 10mm.

Owner:SHANGHAI UNIV

Cable laying apparatus

InactiveCN108110680AGuarantee normal progressGuaranteed clamping effectApparatus for laying cablesRolling speedAutomation

The invention discloses a cable laying apparatus. According to the cable laying apparatus, the laying efficiency can be improved, and complete automation of cable laying is realized; propulsion is performed by employing propulsion belts so that the propulsive force is large; a boosting wheel is provided, and the boosting wheel is provided with fine needles so that the wall-holding force of the boosting wheel during rolling can be guaranteed, the propulsion of the propulsion belts is guaranteed, and the propulsion effect is greatly improved; and the applicability is high, the requirement of diameters of various laying pipelines can be met, the rolling speed of the boosting wheel and the speed of the propulsion belts can be consistent during usage, and long-distance cable laying can be wellrealized.

Owner:陈龙

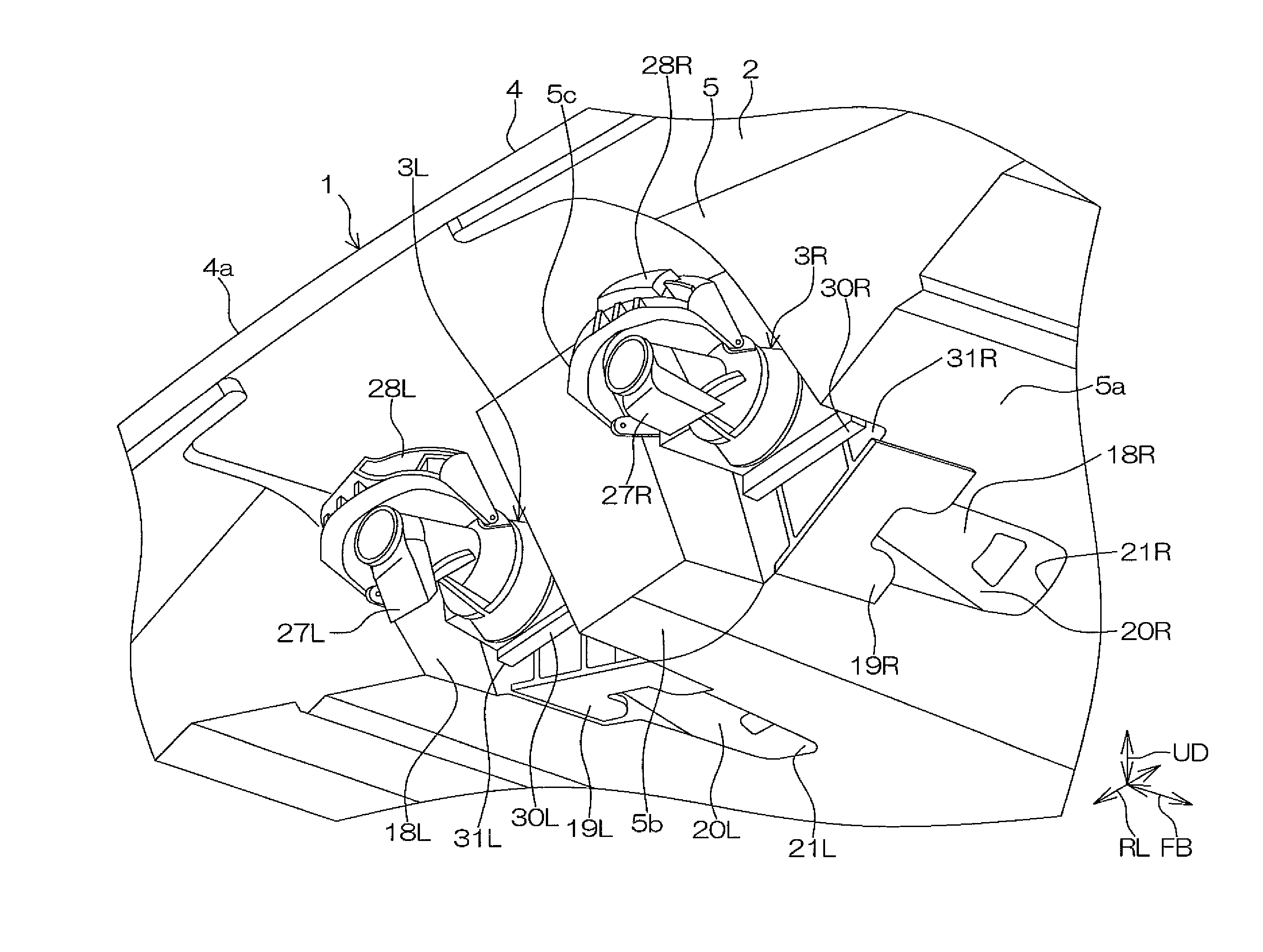

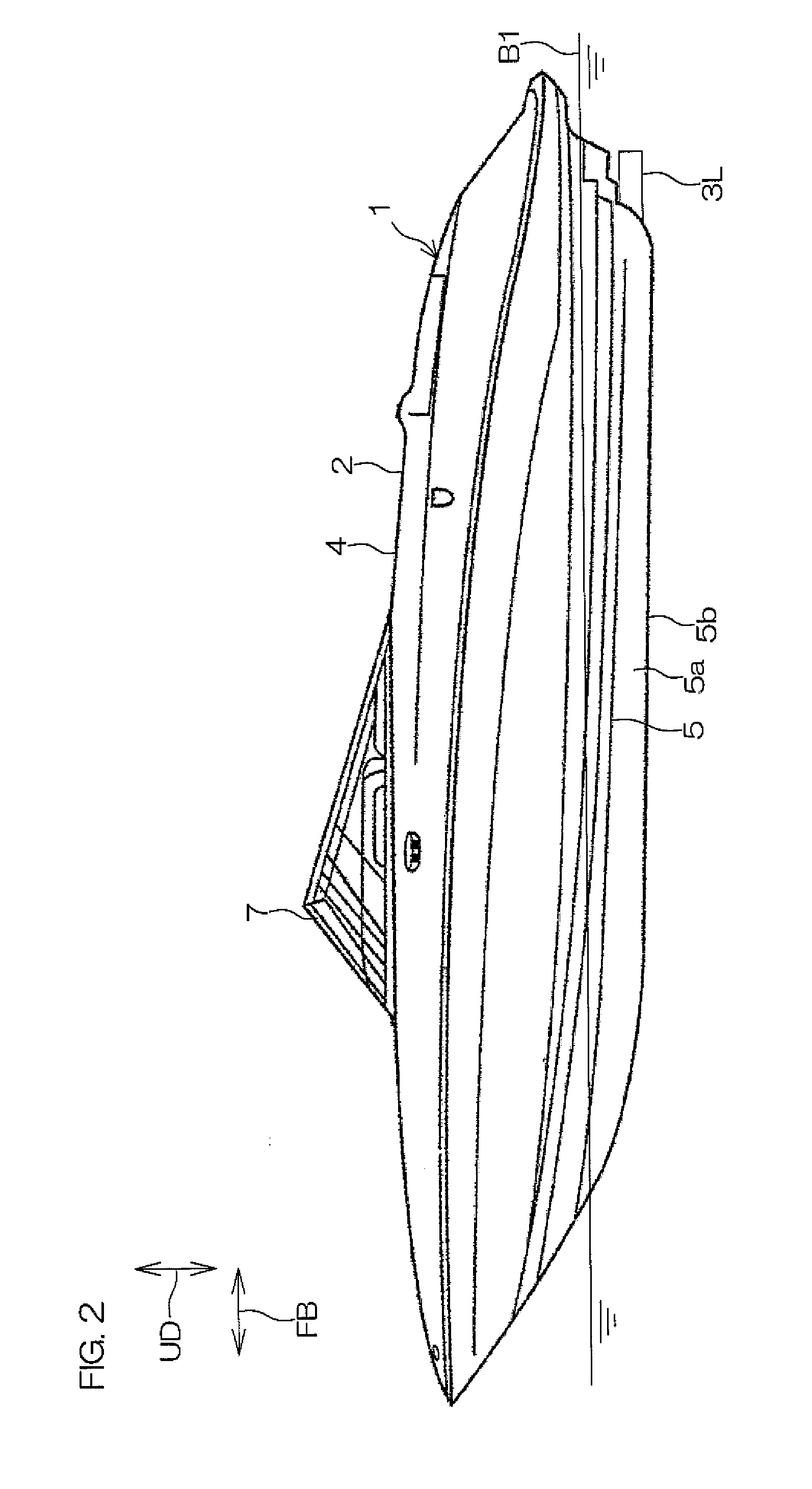

Water jet propulsion watercraft

ActiveUS20110159752A1Adequate reverse drive direction propulsive forceLarge propulsive forcePropulsive elementsLeft directionJet propulsion

A water jet propulsion watercraft includes a pair of jet propulsion devices arranged right and left of a hull centerline. Each jet propulsion device includes a jetting unit arranged to jet water, a deflector supported on the hull and arranged to rotate to right and left, the deflector including a forward drive jet port and a reverse drive jet port. Each jet propulsion device includes a bucket arranged to change between a forward drive position and a reverse drive position. The bucket includes a reflecting surface arranged to reflect the water jetted from the forward drive jet port when the bucket is at the reverse drive position, and an auxiliary nozzle including an entrance opened to the reflecting surface and arranged to jet water introduced into the entrance along a hull right / left direction. The entrance of the auxiliary nozzle is spaced away from the forward drive jet port in the hull right / left direction and does not oppose the forward drive jet port in a state where the bucket is arranged at the reverse drive position and the deflector is arranged at the straight drive position.

Owner:YAMAHA MOTOR CO LTD

Bionic underwater vehicle flapping wing propulsion device

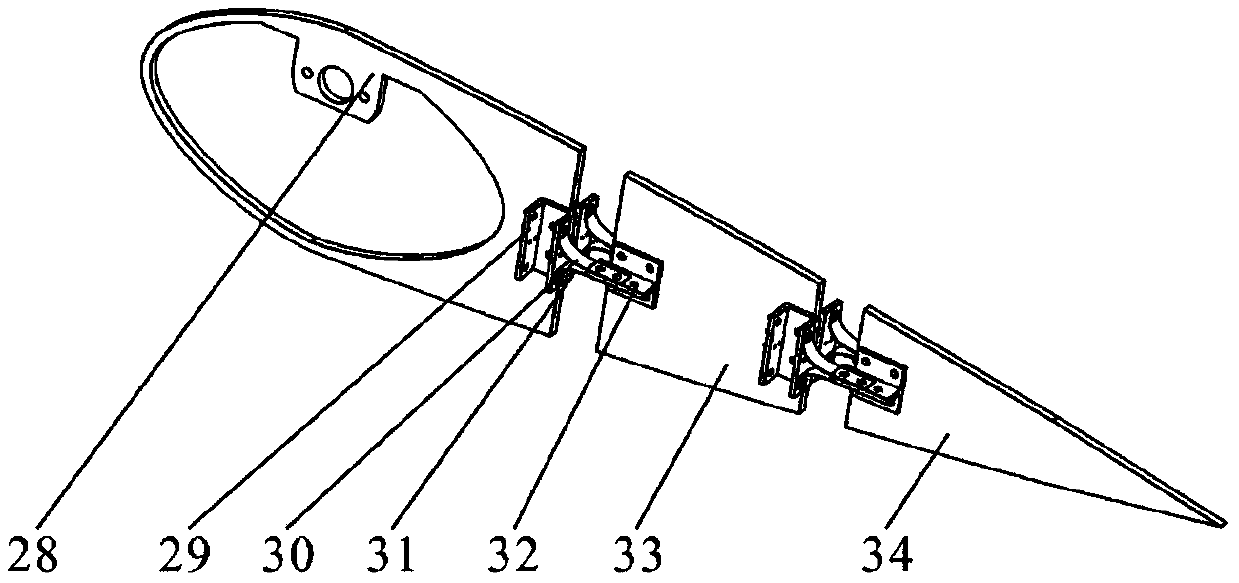

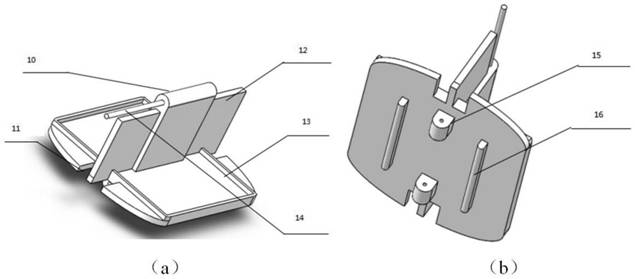

ActiveCN109533249AReduce development difficultySmall sizeSteering ruddersPropulsive elements of non-rotary typeFlapping wingBall screw

The invention discloses a bionic underwater vehicle flapping wing propulsion device. An underwater vehicle comprises a drive motor assembly, a transmission gear set, a ball screw, a steering engine, asteering shaft, an adaptive under-actuated flexible wing framework, a single-sliding block and double-rocker mechanism, and a fixing seat, the drive motor assembly, the ball screw and the fixing seatare connected with an underwater vehicle body separately, the drive motor assembly is composed of a motor, a speed reducer and an encoder, the ball screw is composed of a screw rod, a screw nut and ascrew fixing seat, and an output shaft of the speed reducer is connected with a driving gear of the transmission gear set; a driven gear of the transmission gear set is connected with the screw rod of the ball screw, and the motor drives the screw rod to rotate through the transmission gear set. The bionic underwater vehicle flapping wing propulsion device has the advantages that the integral structure is provided with a front end swing and a rear end swing, the whole device has two degrees of freedom, and propulsion, turning, floating, submergence and other movements of the underwater vehicle can be achieved.

Owner:TIANJIN UNIV

Propeller in magnetic field, and brake and/or power generation device in magnetic field

InactiveCN110719010AStrong external magnetic fieldBig propulsionPropulsion systemsElectrical conductorEngineering

The invention discloses a propeller. The propeller comprises a magnetic field gathering part and a conductor capable of conducting electricity. The magnetic field gathering part is provided with an external magnetic field channel used for enhancing an external magnetic field. The external magnetic field channel comprises an enhancing channel, and the conductor is arranged in the enhancing channel.The propeller has a larger propulsive force.

Owner:SHENZHEN DANMING TECH CO LTD

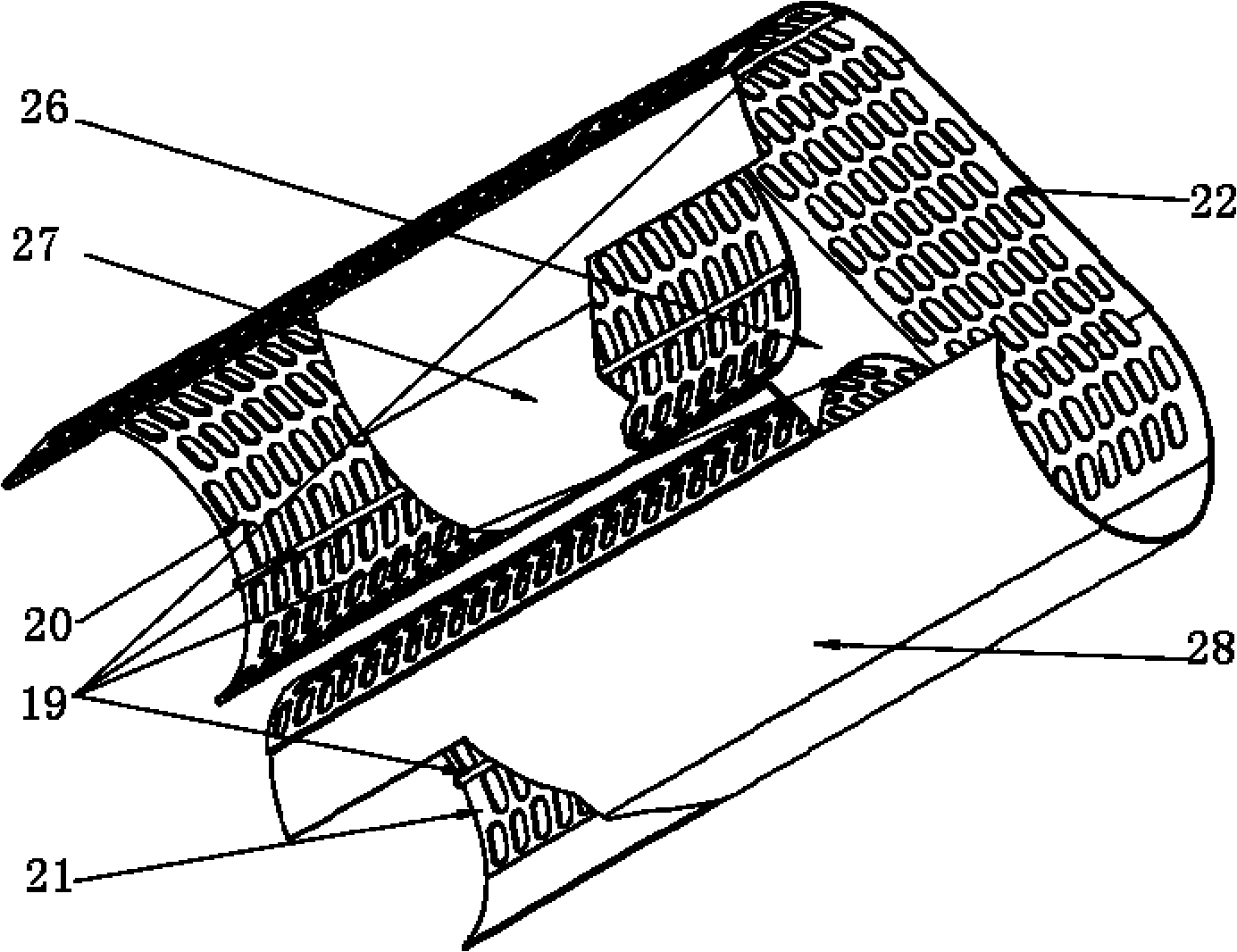

Multi-gyring extruder for 3D printing and control system

ActiveCN105965895AShorten the lengthLittle increase in diameterAdditive manufacturing apparatusGlass shaping apparatusControl systemMiniaturization

The invention discloses a multi-gyring extruder for 3D printing. The multi-gyring extruder for 3D printing comprises a housing and a screw extruding system, wherein a driving system is arranged at one end of the housing; the screw extruding system is arranged in the housing and comprises at least two screws which are correspondingly embedded at the inside and outside; at least one screw is driven through the driving system. According to the multi-gyring extruder, the length is greatly reduced, so that the size of an industrial 3D printer can be further reduced. The multi-gyring extruder for the 3D printing is stable in flow output, high in accuracy, low in energy consumption, high in heat energy utilization rate, light in weight, small in size, high in heating efficiency, novel in design, high in practicability, easy to popularize and apply, and extremely high in economic value.

Owner:浙江光镀智造科技有限公司

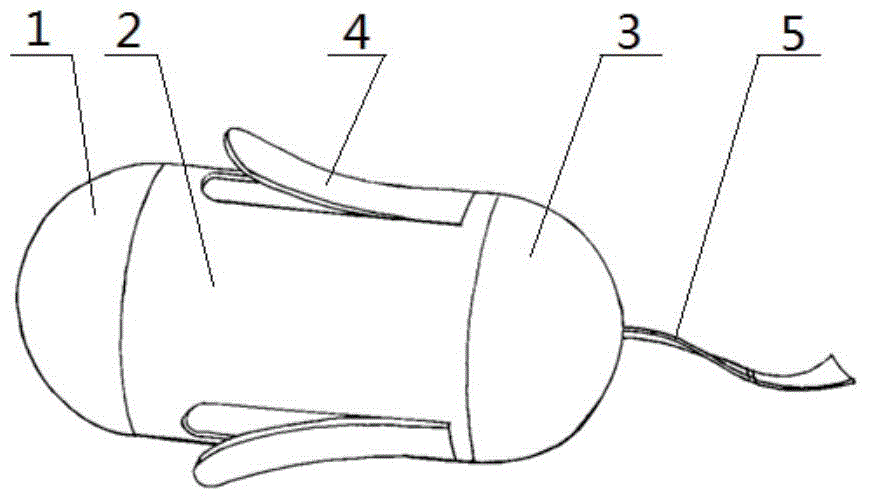

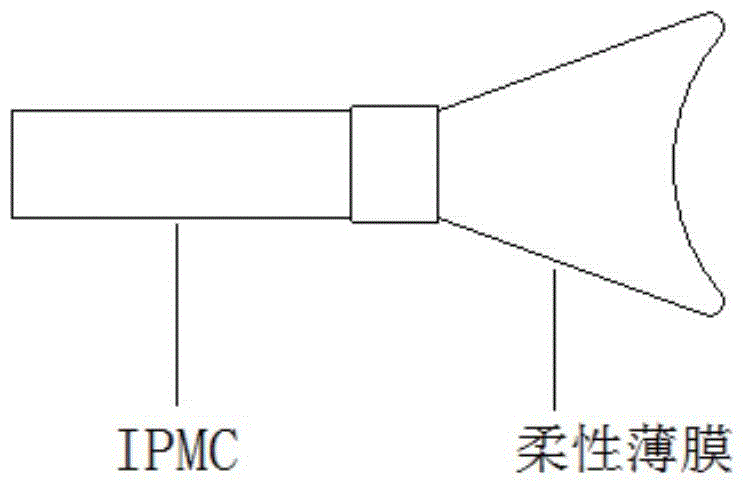

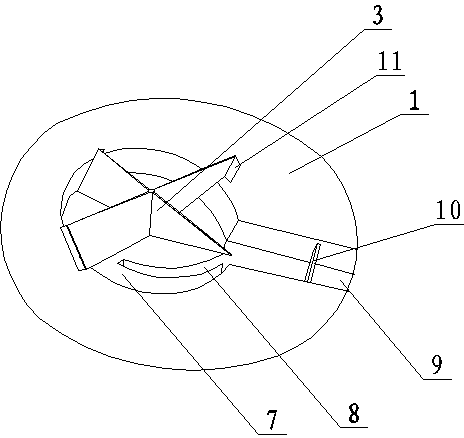

Capsule endoscope based on IPMC (ionic polymer metal composite) driving and driving method thereof

InactiveCN104873166ATo achieve the purpose of losslessEasy to swallowGastroscopesOesophagoscopesIonic polymer–metal compositesAttitude control

The invention relates to a capsule endoscope based on IPMC (ionic polymer metal composite) driving and a driving method thereof. The capsule endoscope based on the IPMC driving comprises a capsule front cover, a capsule main body structure and a capsule tail structure, wherein a plurality of slice IPMCs are arranged on the outer side of the capsule main body structure and on the capsule tail structure along the axial direction of a capsule. Under normal moving status of the capsule endoscope based on the IPMC driving, the slice IPMCs on the outer side of the capsule main body structure can be folded along the capsule, and are unfolded outwards after control signals are applied onto the slice IPMCs on the outer side of the capsule main body structure, and thereby can be used to achieve a deceleration or clamping function. When the slice IPMCs on the outer side of the capsule main body structure are respectively controlled, a posture adjustment for the capsule can be achieved. One or two IPMCs can be installed at the tail end of the capsule, and are used to achieve an active driving function. The capsule endoscope based on the IPMC driving and the driving method thereof use IPMC artificial muscle smart materials good in biocompatibility to achieve movement and posture control of the capsule endoscope based on the IPMC driving in a human body.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

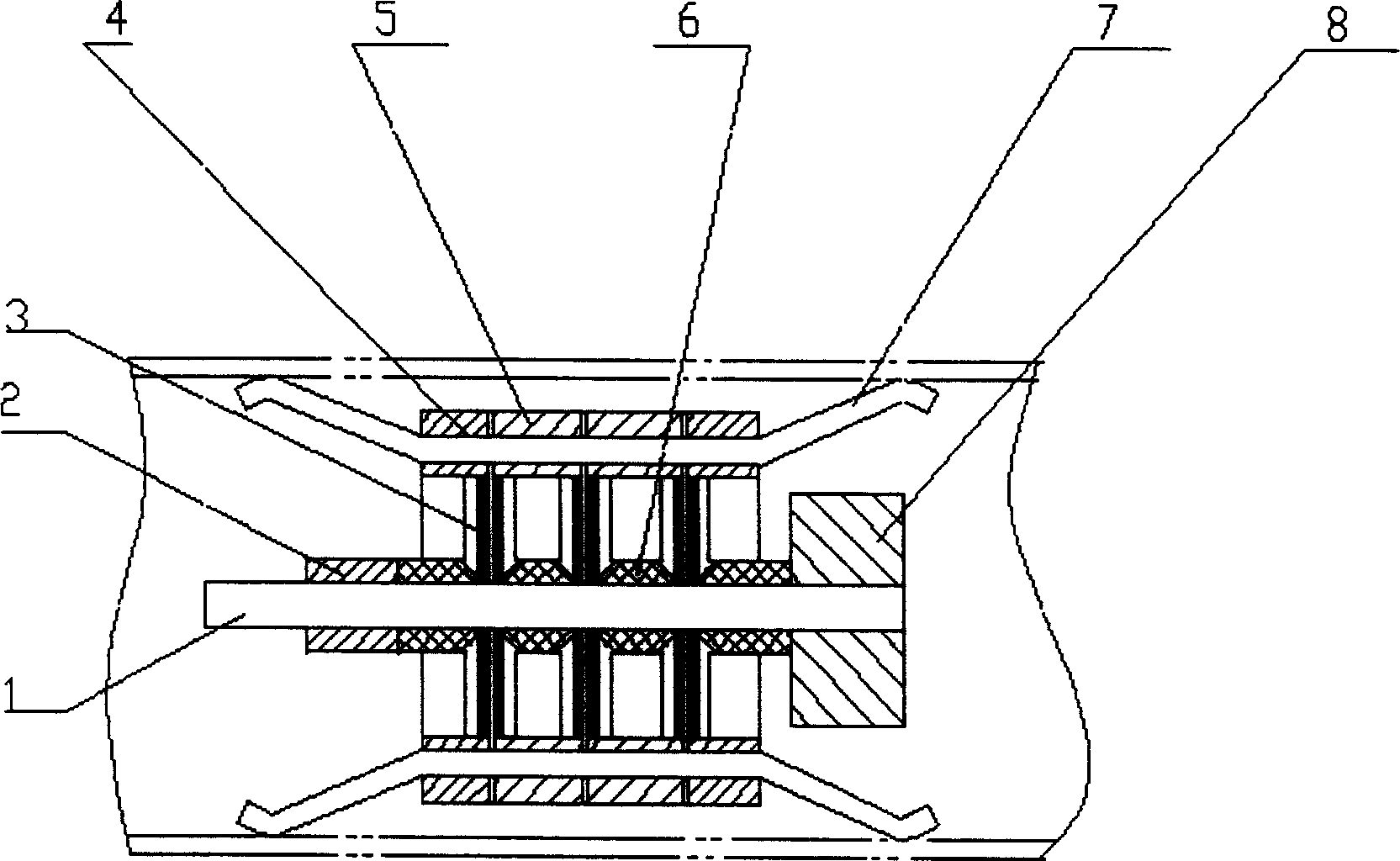

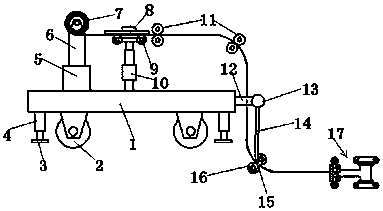

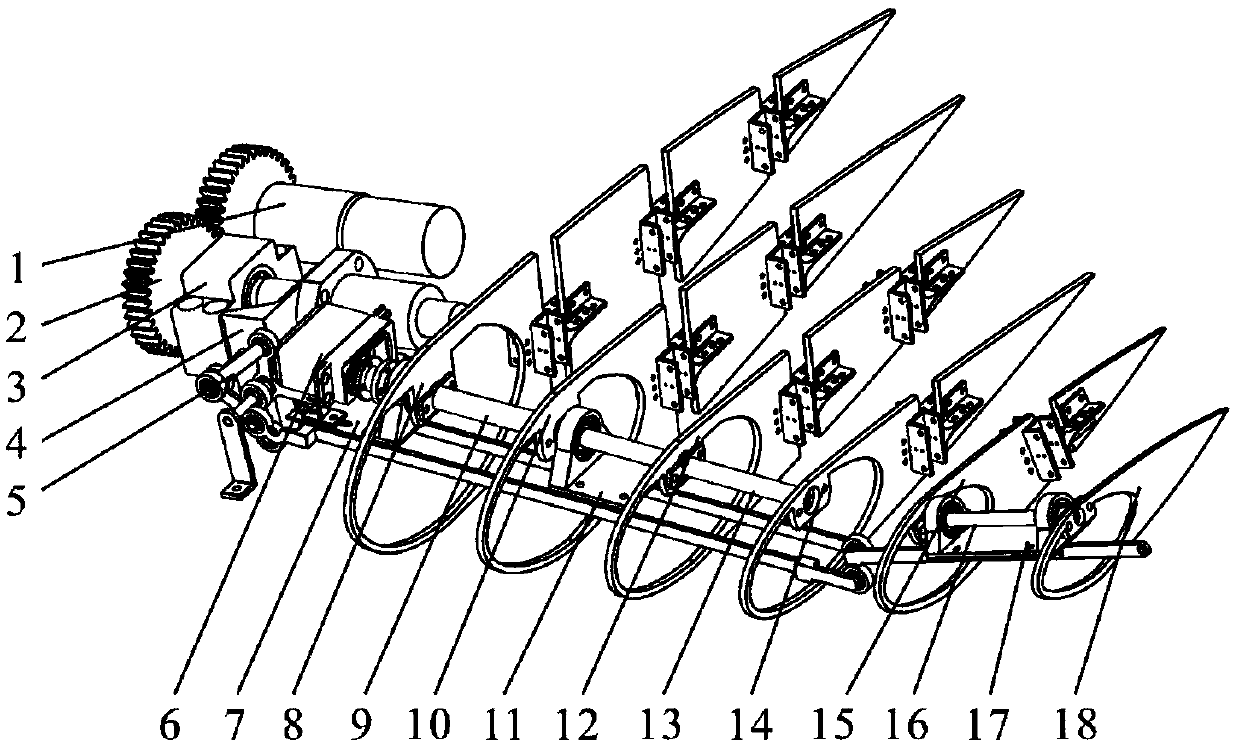

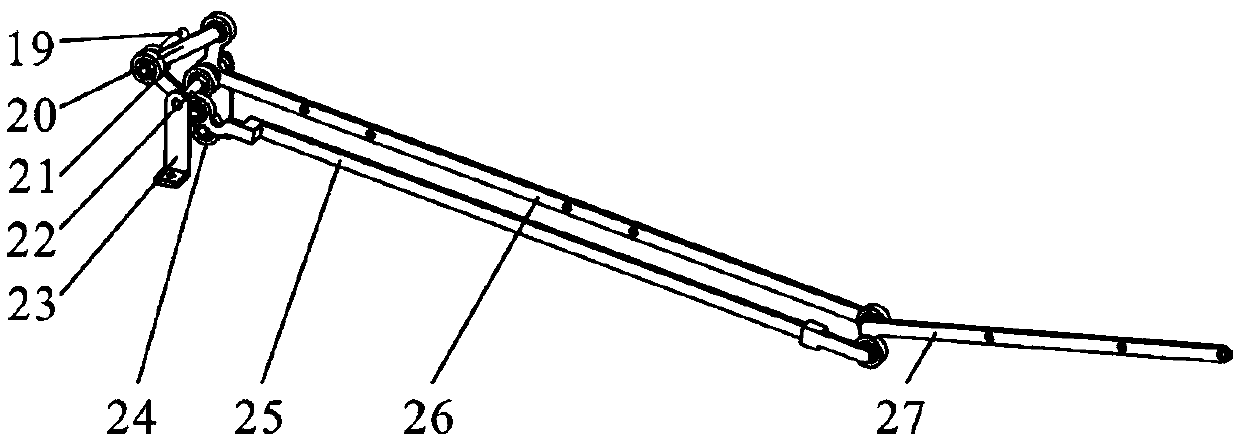

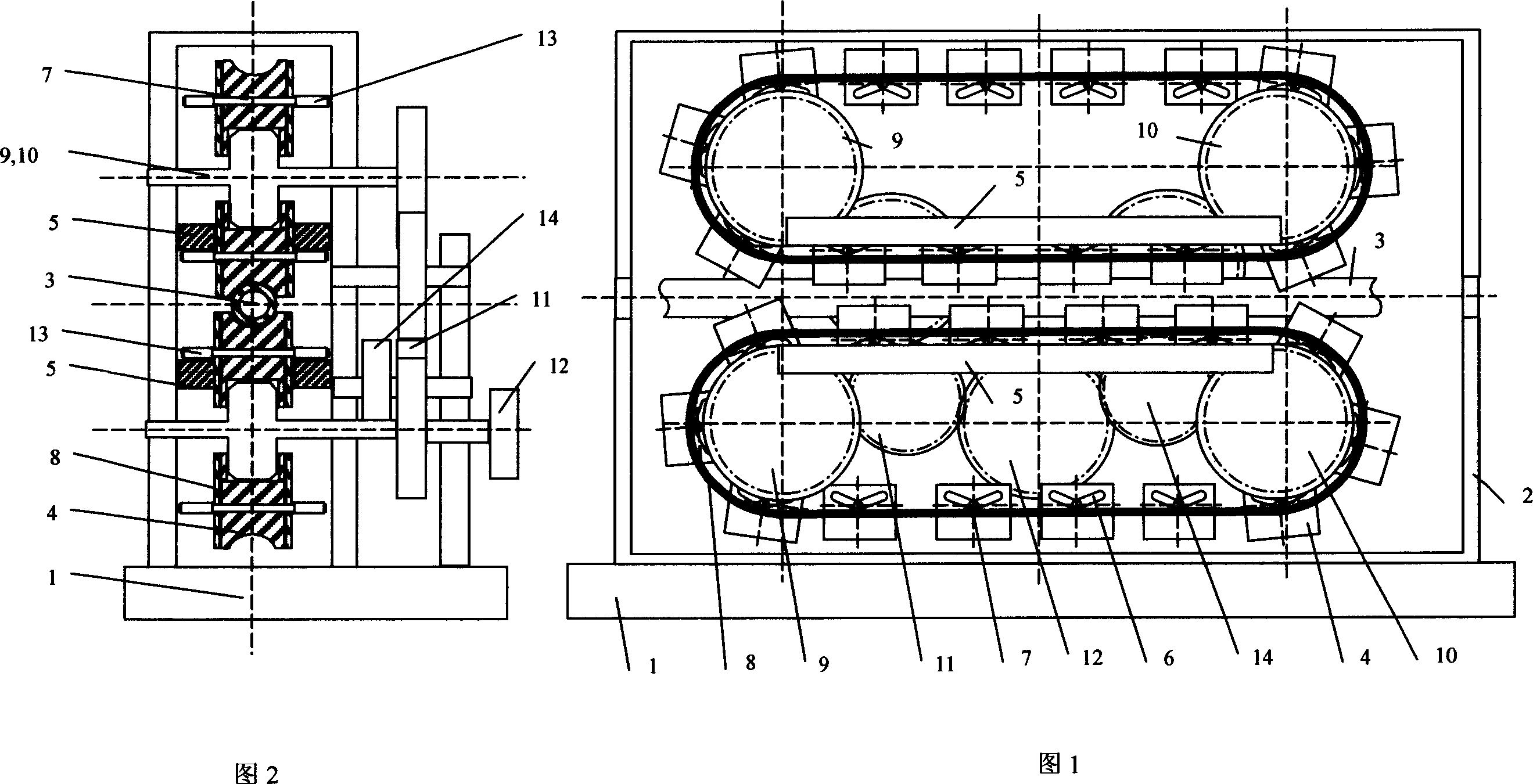

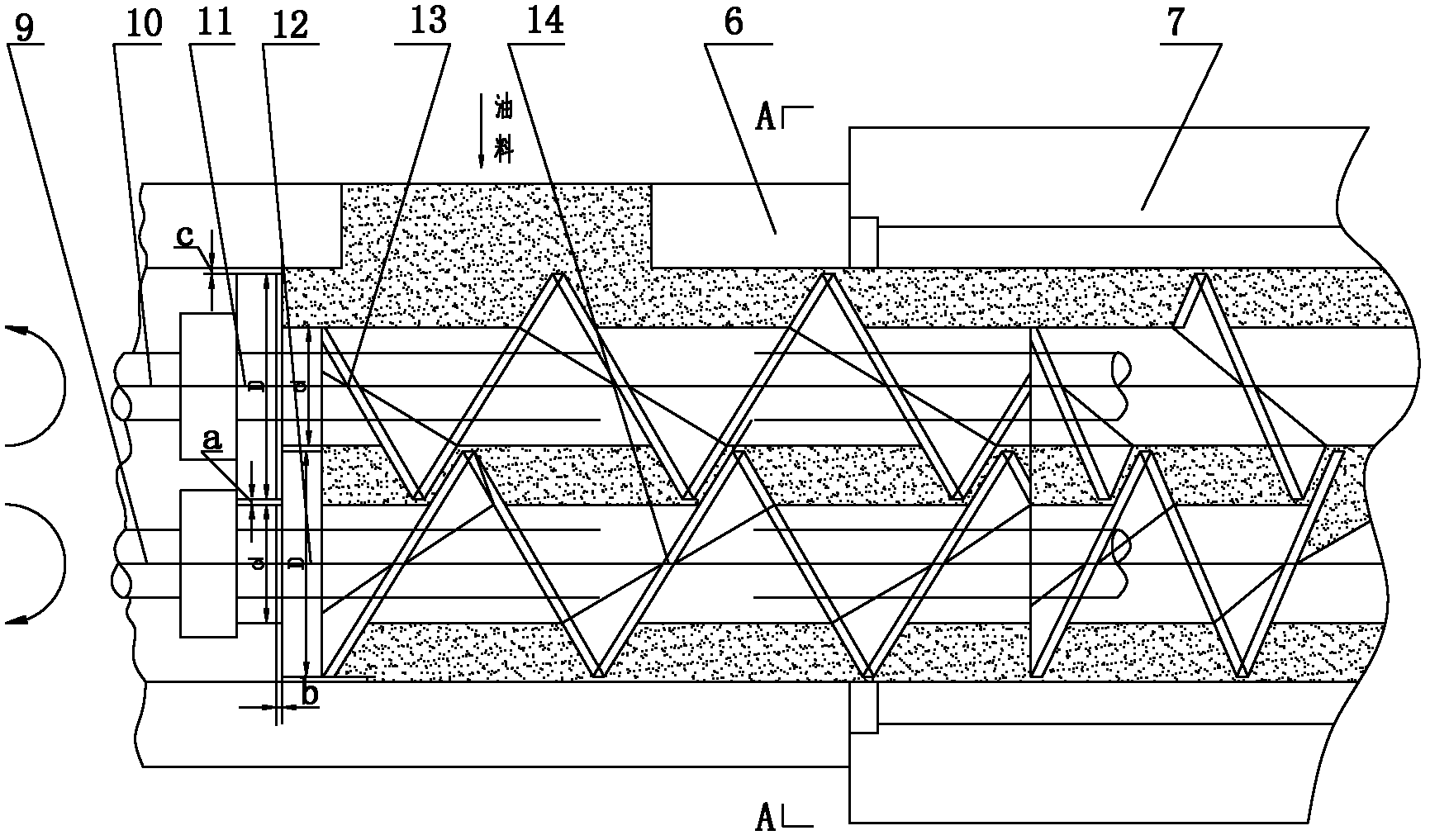

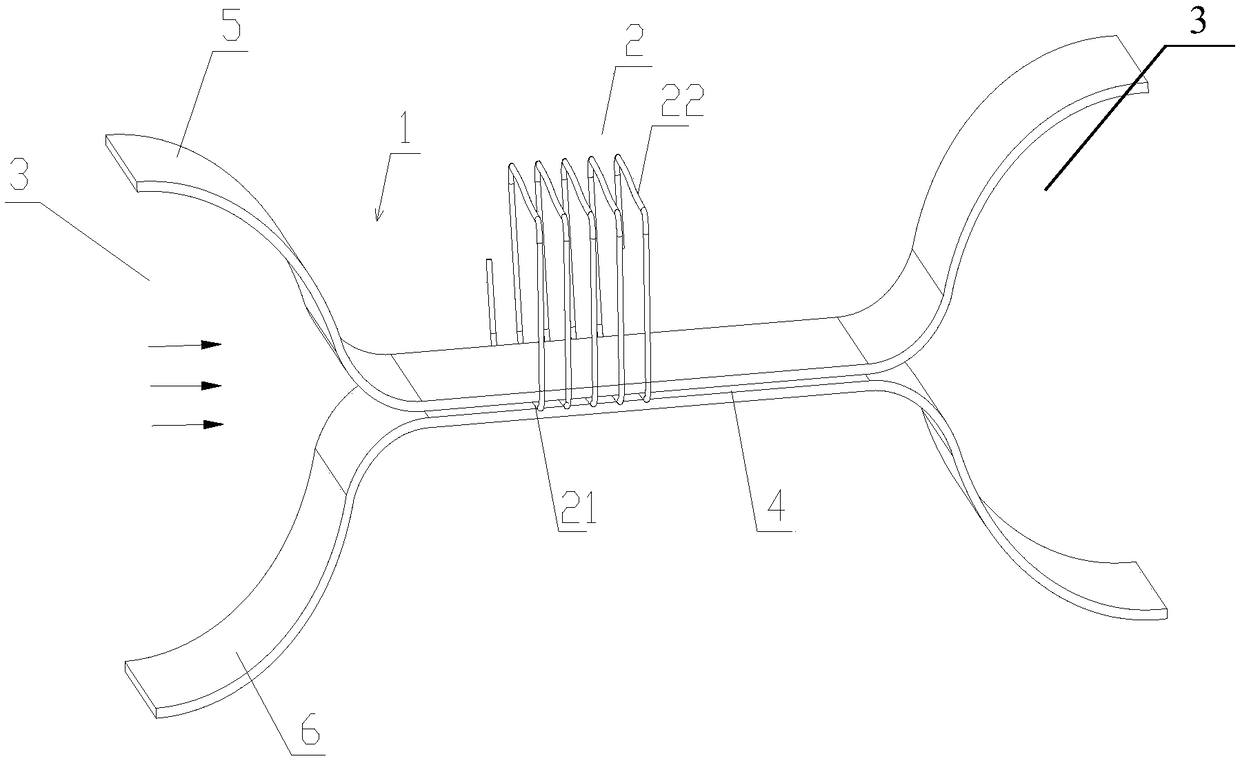

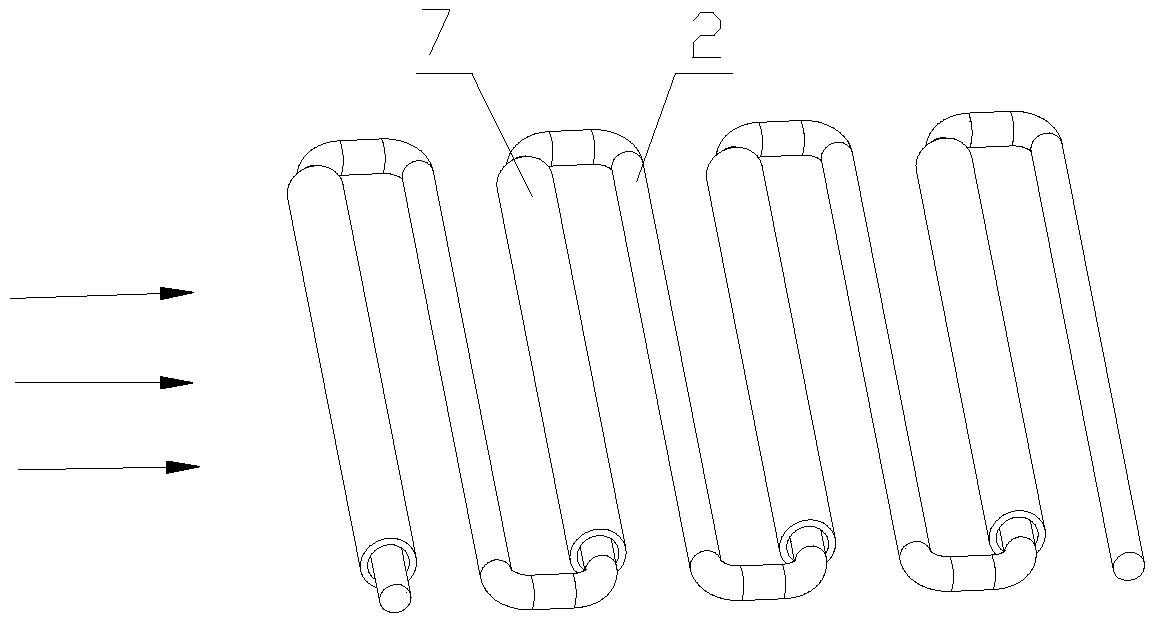

Strong force propulsion plant of continuous tube

InactiveCN1558084ABig propulsionIncrease the propulsion friction surfaceLiquid/gas jet drillingDirectional drillingLine tubingDrive wheel

The powerful control tube driving apparatus is suitable for driving various tubes inside deep hole in mining and geotechnical engineering. The present invention sets fixed friction blocks symmetrically to the transmission chain, and the friction blocks are connected to the transmission chain via shaft pin, are provided with inclined shaft pin rail. The two limiting rails symmetrically over and below the continuous tube are parallel to the continuous tube and made to contact with the roller of the shaft pin, and each transmission chain is driven with one pair of driving wheels. Compared with available technology, the present invention can produce much great continuous driving force to meet the requirement of drilling horizontal drilling over 200 m.

Owner:TAIYUAN UNIV OF TECH

Bionic fishtail structure based on PVC gel artificial muscle driving

ActiveCN111874196AMeet performance requirementsEasy to drivePropulsive elements of non-rotary typeUnderwater equipmentStructural engineeringMechanical engineering

The invention discloses a bionic fishtail structure based on PVC gel artificial muscle driving. The bionic fishtail structure comprises a multi-joint bionic fishtail framework, a plurality of PVC gelartificial muscle driving modules, a tail fin, a tail end, a skin and other accessories. The bionic fishtail framework is composed of a pre-pressing block, a joint shaft and an installation groove. Each PVC gel artificial muscle driving module is composed of a plurality of PVC gel driving units, wherein an anode, a PVC gel film and a cathode form one PVC gel driving unit; the two PVC gel driving modules and the bionic fishtail skeleton form a driving joint. Based on the structure, bending deformation is driven in a left-right alternating mode, and therefore swing is generated.

Owner:XI AN JIAOTONG UNIV

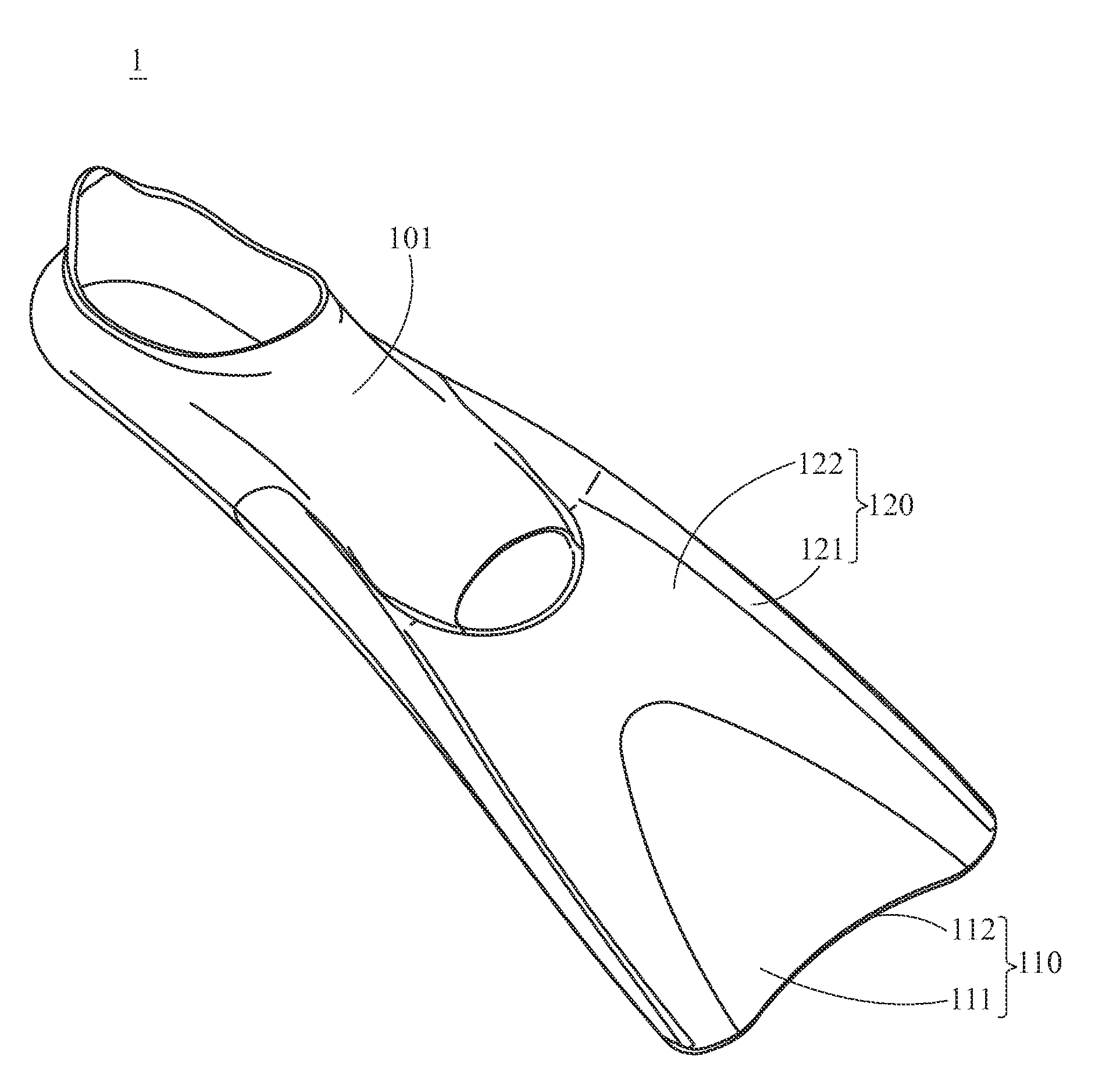

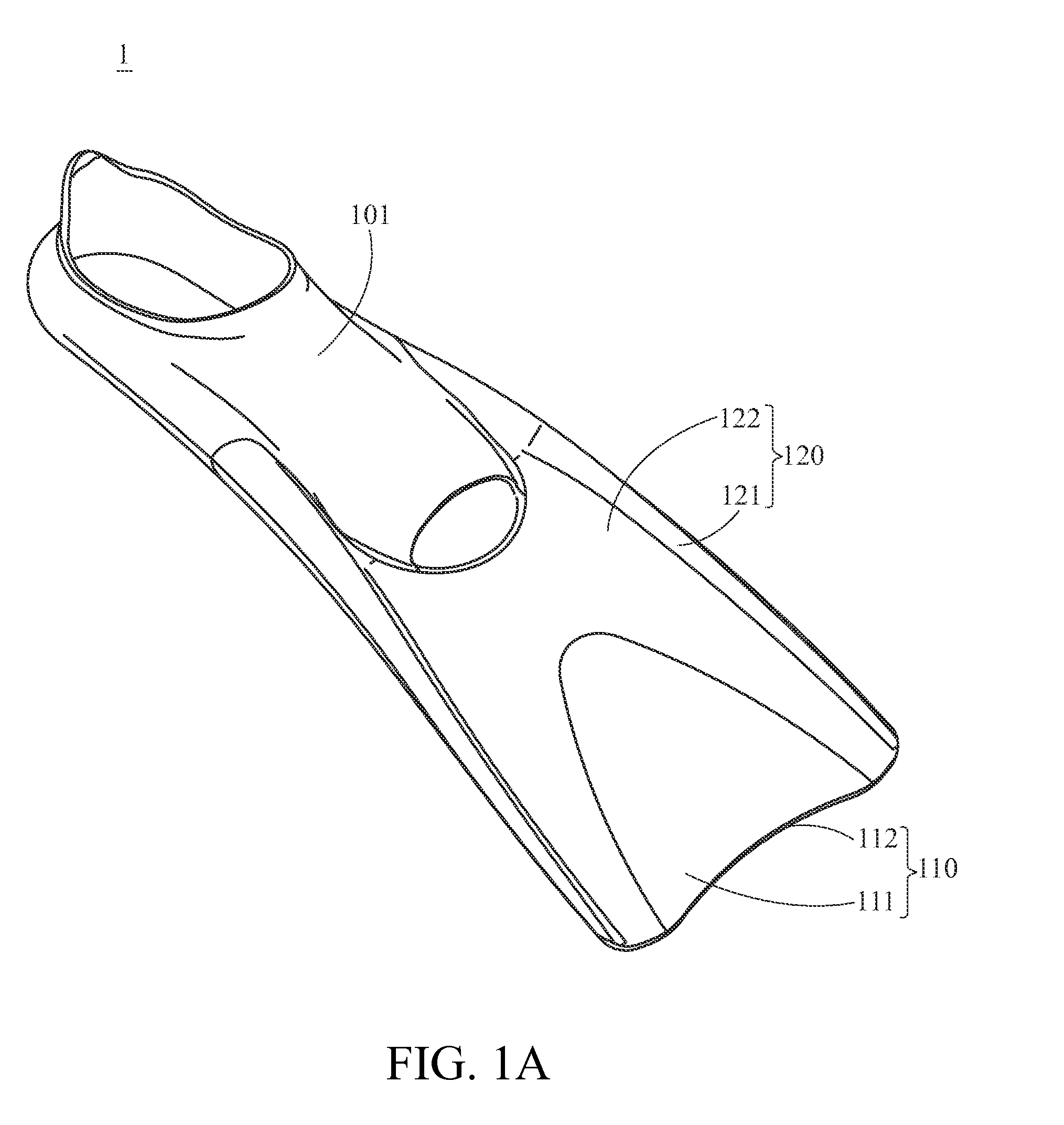

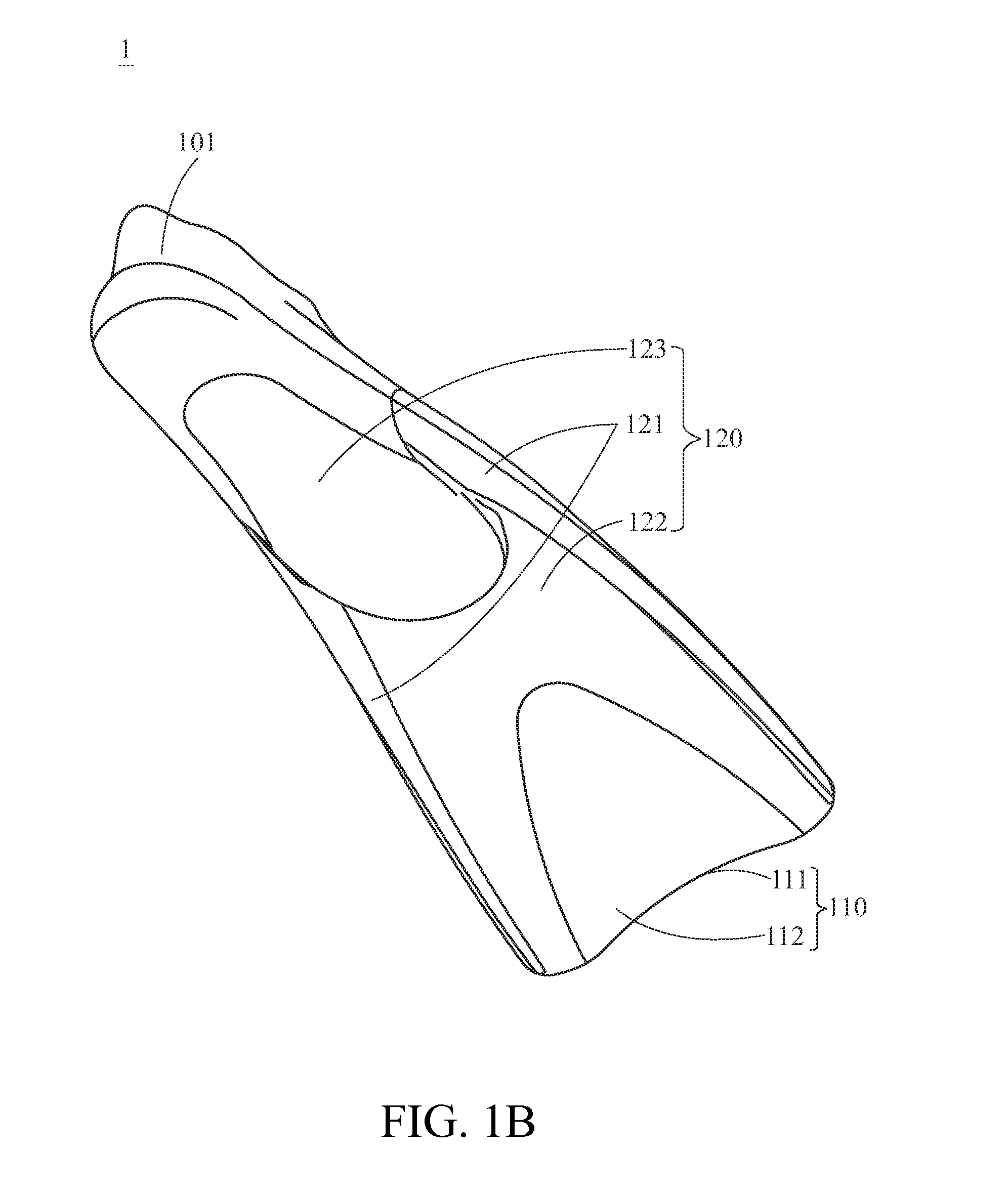

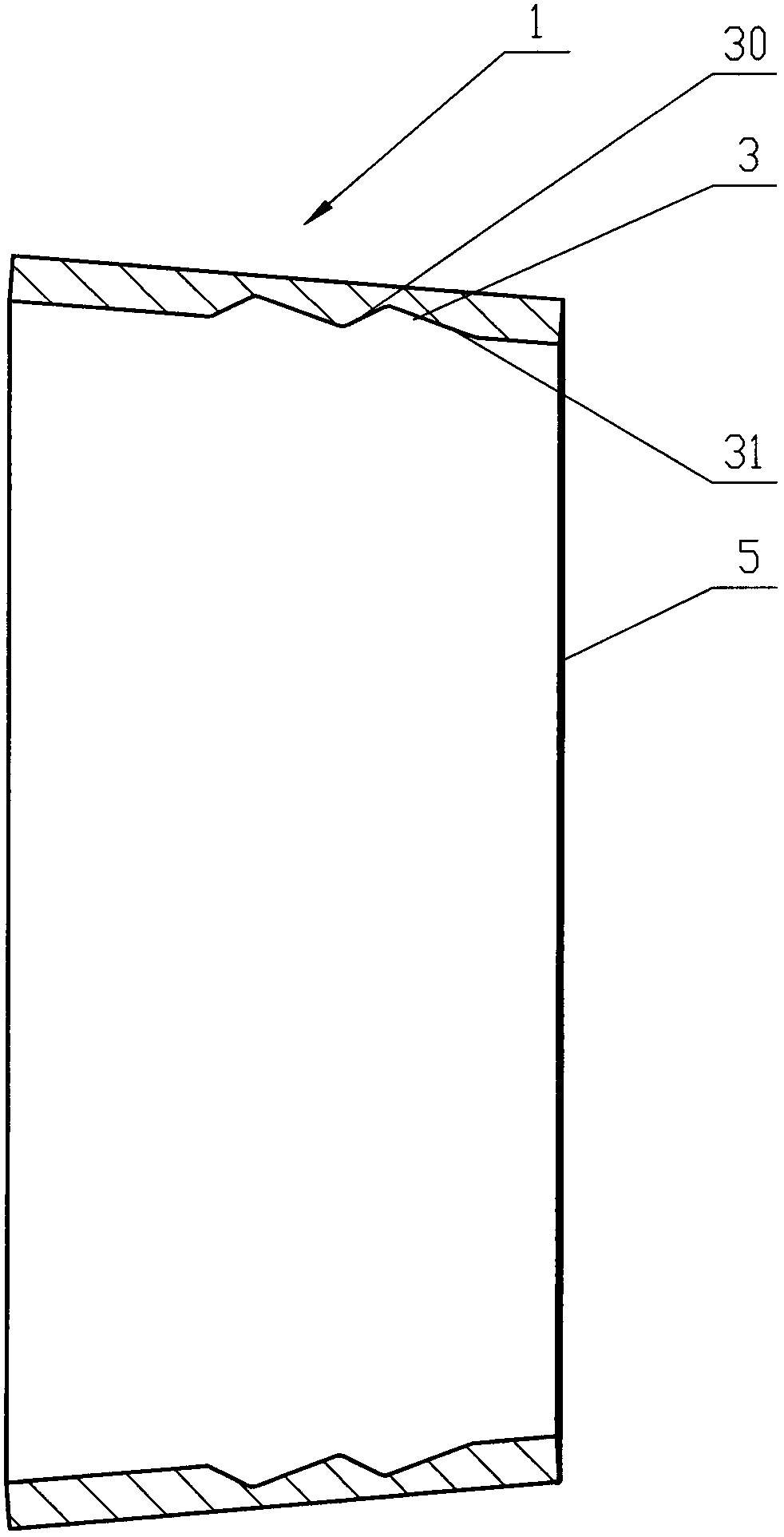

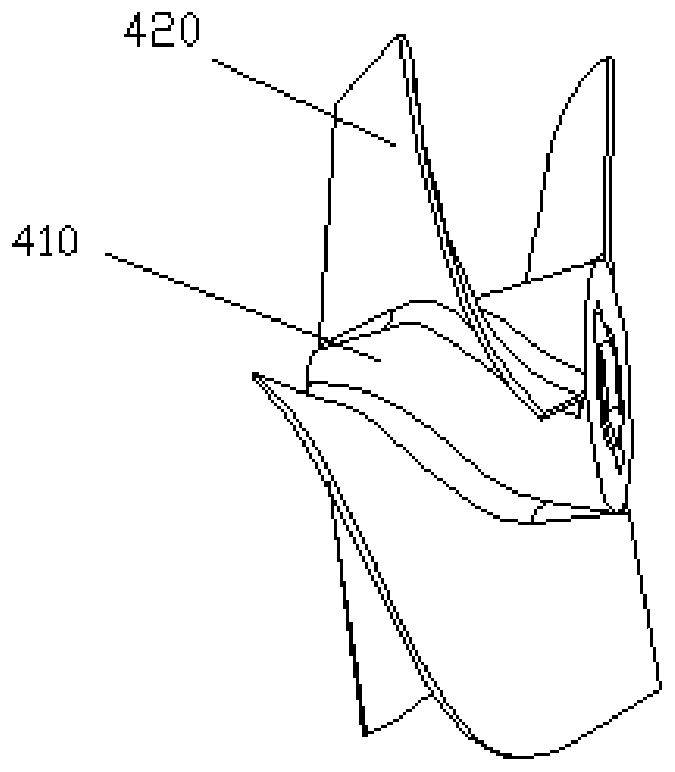

Flipper

A flipper is provided. The flipper includes a pocket, a blade and a strengthening structure. The pocket is for accommodating the foot of the user. The blade extends forwards from the pocket, and the strengthening structure is detachably disposed at the blade and extends to reach the front edge of the blade. The flexural strength of the strengthening structure is larger than that of the blade to constrain the swing angle of the blade relative to the pocket. By using the strengthening structure to constrain the swing angle of the blade, the flipper can not only provide a larger propulsion in the down-kicking state, but also decrease the resistance of water in the up-kicking state.

Owner:QBAS CO LTD

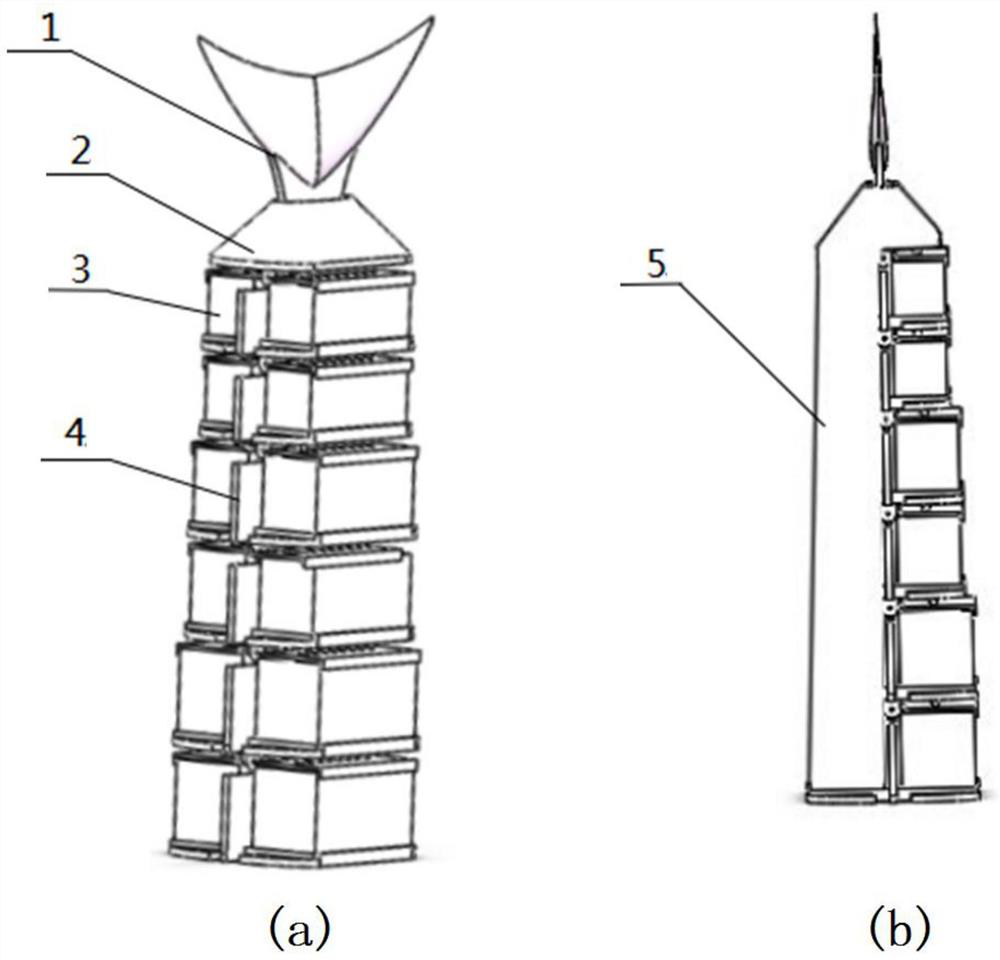

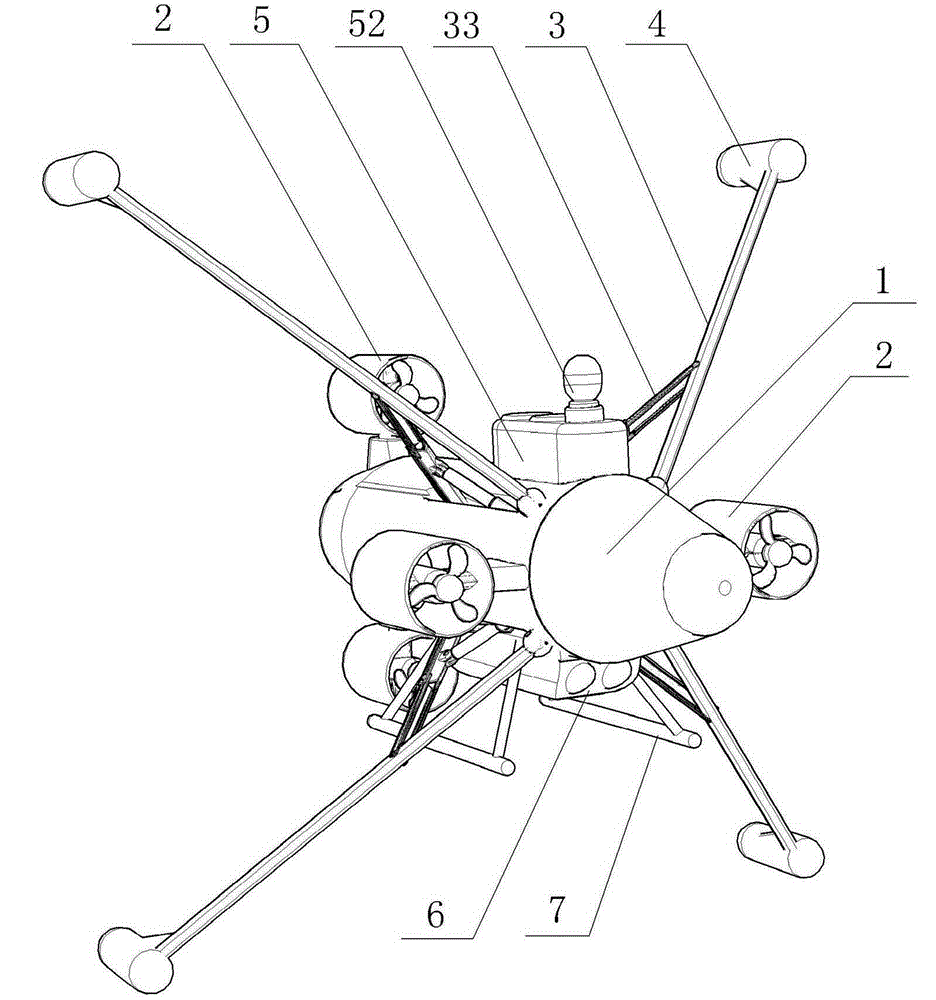

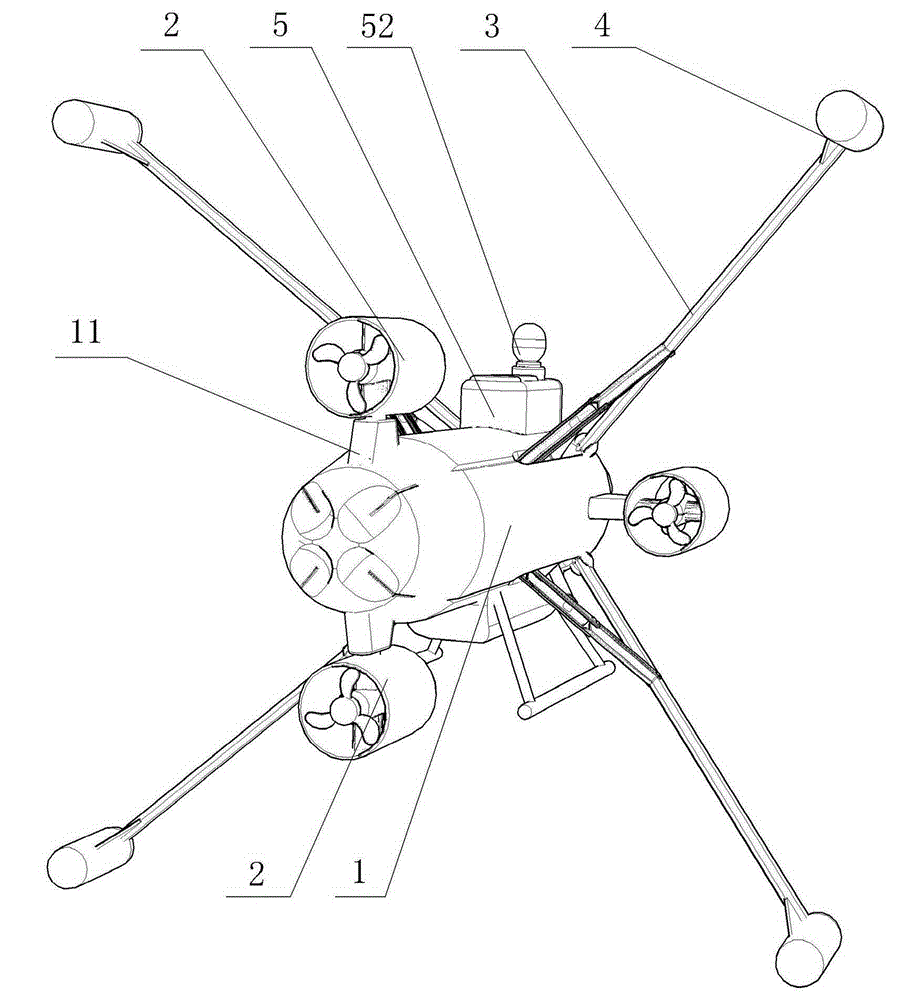

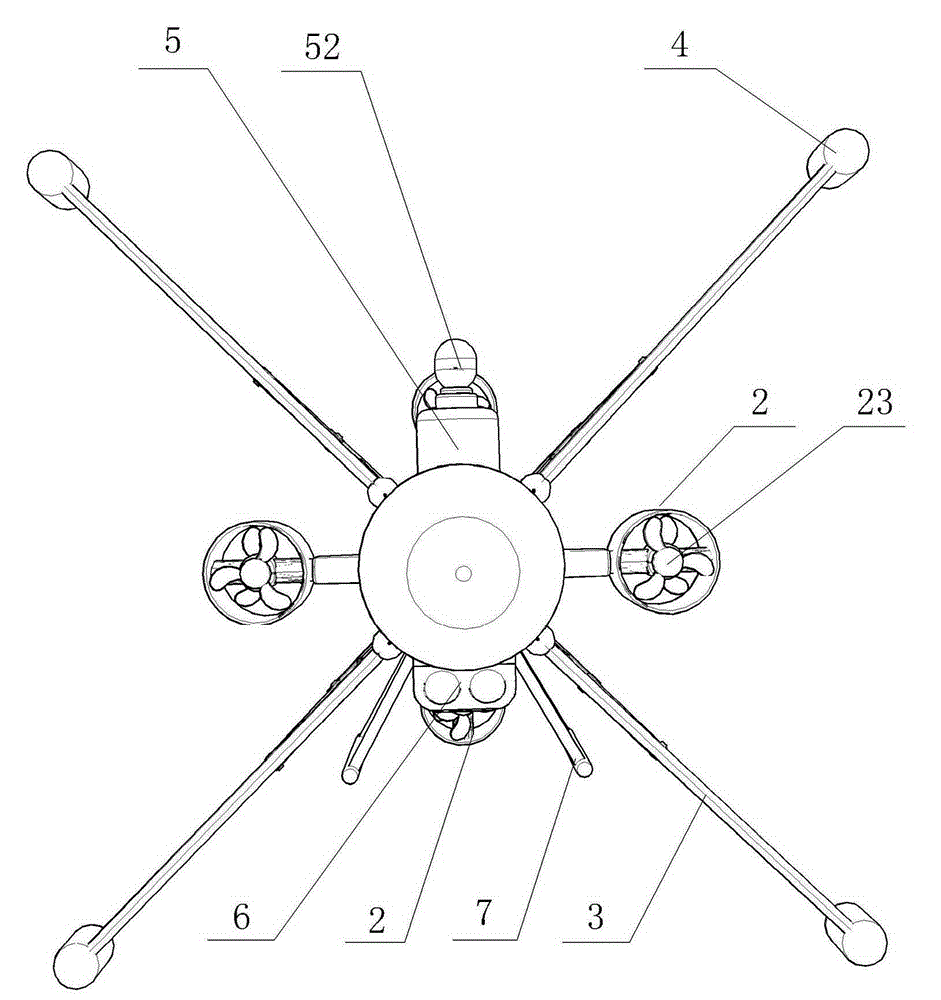

Submersible folding type sonar equipment

InactiveCN105223577ABig propulsionLarge thrustPosition/course control in three dimensionsAcoustic wave reradiationSonarPropeller

The invention discloses submersible folding type sonar equipment, which comprises a hull body, double-acting twin-screw propellers, and a plurality of sonar detectors. The periphery of the front end of the hull body is provided with a plurality of hemispherical coupled base blocks. The hemispherical coupled base blocks are in coupled connection with sonar folding arms. The outer ends of the sonar folding arms are fixedly provided with sonar acoustic protection tubes and the sonar detectors are arranged inside the sonar acoustic protection tubes. The hull body is in coupled connection with a hydraulic extendable conveyor belt A and folding power arms. The upper end of the hydraulic extendable conveyor belt A is in coupled connection with the middle-upper end of the folding power arms. The upper ends of the folding power arms are in coupled connection with folding connection arms. The folding connection arms are in coupled connection with the sonar folding arms. The two sides of the front end of the hull body are respectively provided with a plurality of double-acting twin-screw propellers. The upper and lower parts of the rear end of the hull body are respectively provided with a plurality of double-acting twin-screw propellers. According to the technical scheme of the invention, the influence of submersible noises on the folding type sonar equipment during the detection process is reduced to a minimum level, so that clearer and more accurate data can be obtained. During the retracting process, the navigational speed and the maneuverability of the submersible are not influenced at all.

Owner:嘉善联睿电子科技有限公司

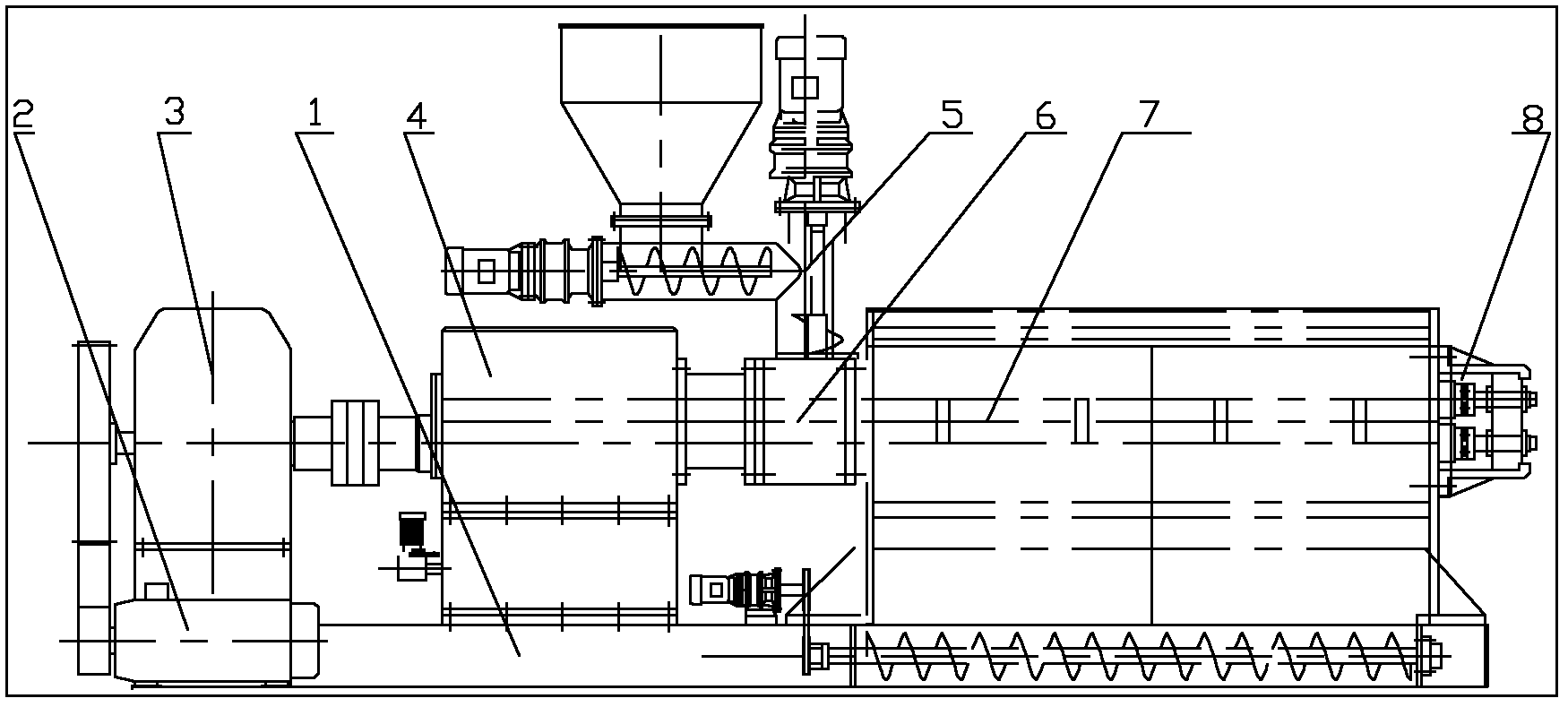

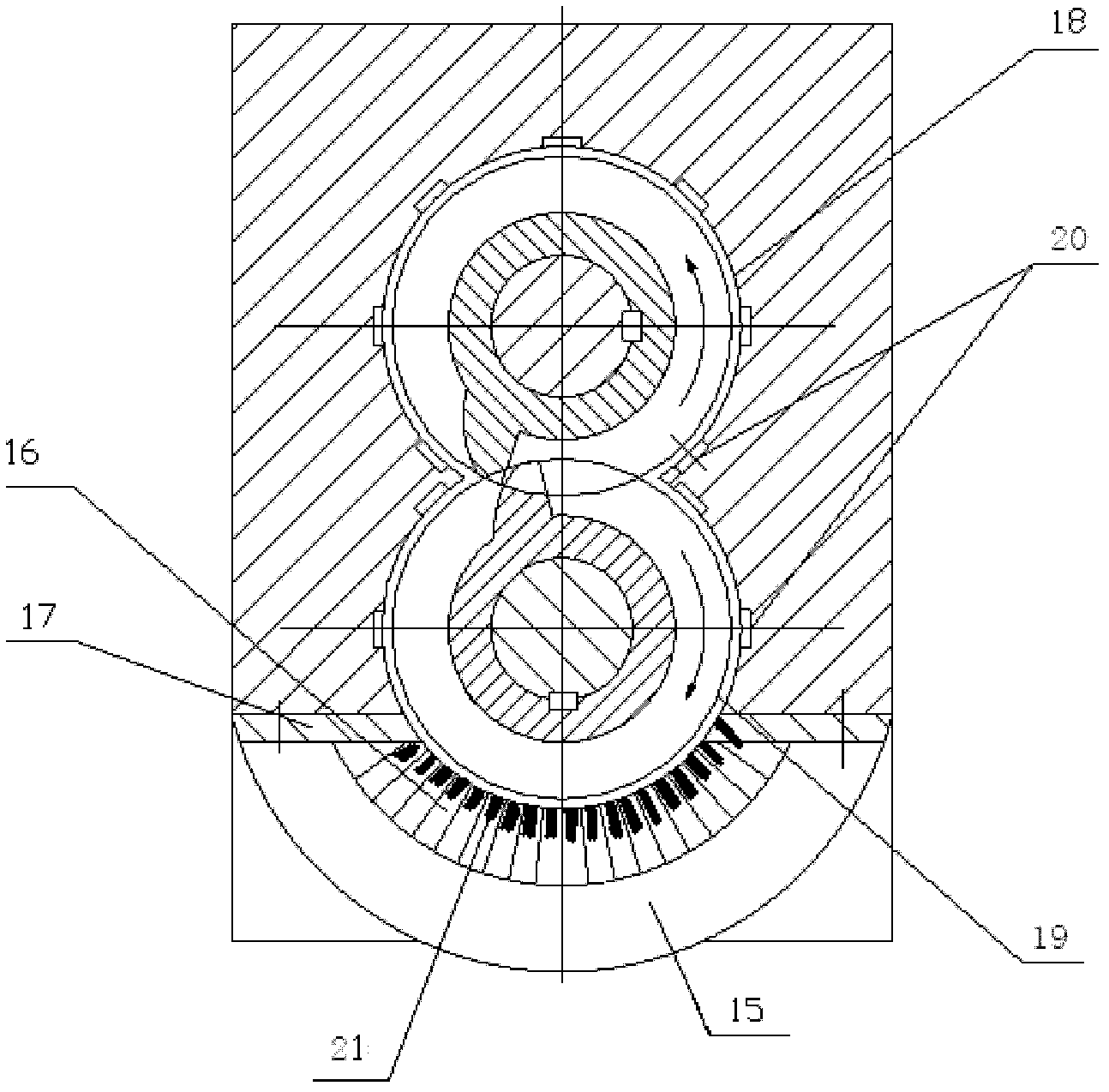

Double worm oil press capable of preventing oil materials from sliding out of chamber

The invention relates to a double worm oil press capable of preventing oil materials from sliding out of a chamber, comprising a frame base, a driving motor, a reduction gear, a torque distributor, a feeding base, a feeding device, a double worm oil pressing device and a residual cake discharging mechanism, wherein the driving motor and the reduction gear are connected to the frame base; the torque distributor is connected to the output end of the reduction gear; the feeding base is connected to the output end of the torque distributor; the feeding device is arranged on the feeding base; the double worm oil pressing device is connected to the feeding base; the residual cake discharging mechanism is positioned on the tail end of the double worm oil pressing device; the feeding base comprises a first material sending hole and a second material sending hole and a first mandrel and a second mandrel; the first and second mandrels are respectively sleeved with a first left spiral worm and a first right spiral worm and respectively positioned in the first material sending hole and the second material sending hole; and a plurality of slide-proof grooves are arranged on the inner walls of the first and second material sending holes in the direction of a generatrix. The double worm oil press disclosed by the invention solves the problem that the oil material may slide out of the chamber, improves the sealing property of the feeding end of the first pressing chamber, effectively prevents the oil material from flowing out of the double worm oil pressing device and has the advantages of high oil yield and high production efficiency.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI +1

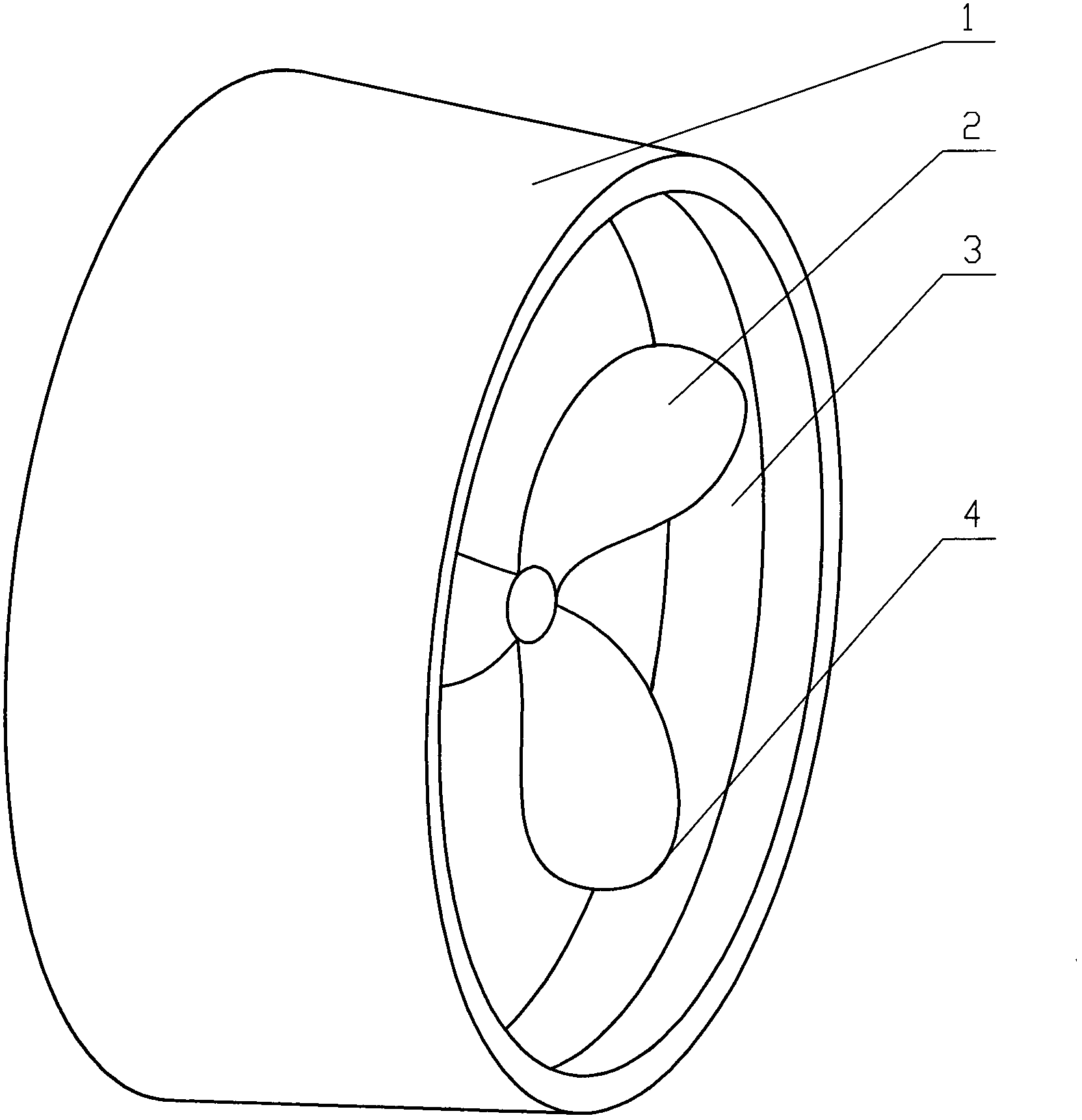

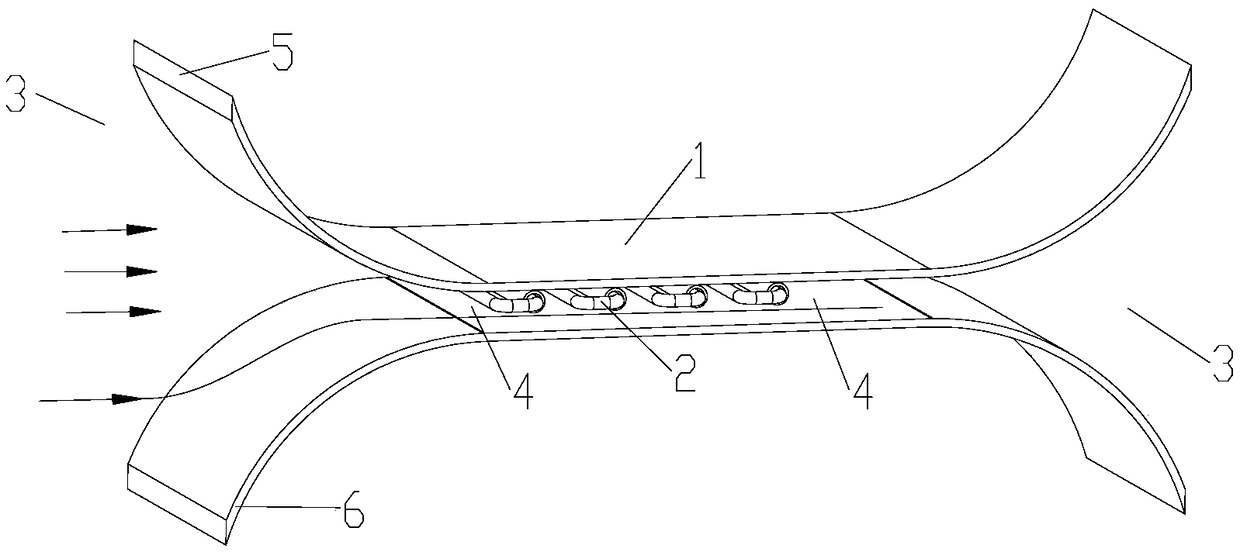

Efficient ducted propeller

InactiveCN103507934ABig propulsionImprove work efficiencyPropulsive elementsEngineeringDucted propeller

The invention relates to an efficient ducted propeller which comprises a duct and paddles. The efficient ducted propeller is characterized in that a groove is formed in the inner surface of the duct, and the position of the groove corresponds to the periphery positions of the tail ends of the paddles. Compared with an existing ducted propeller, according to the efficient ducted propeller, due to the fact that the gaps between the tail ends of the paddles and the inner wall of the duct are enlarged, the groove with a certain gradient is formed, the probability that sundries are clamped between the duct and the paddles is reduced, the propulsive force of the propeller is enlarged, and therefore the working efficiency of the propeller is improved.

Owner:WUXI TONGCHUANG FIBERGLASS BOAT FACTORY

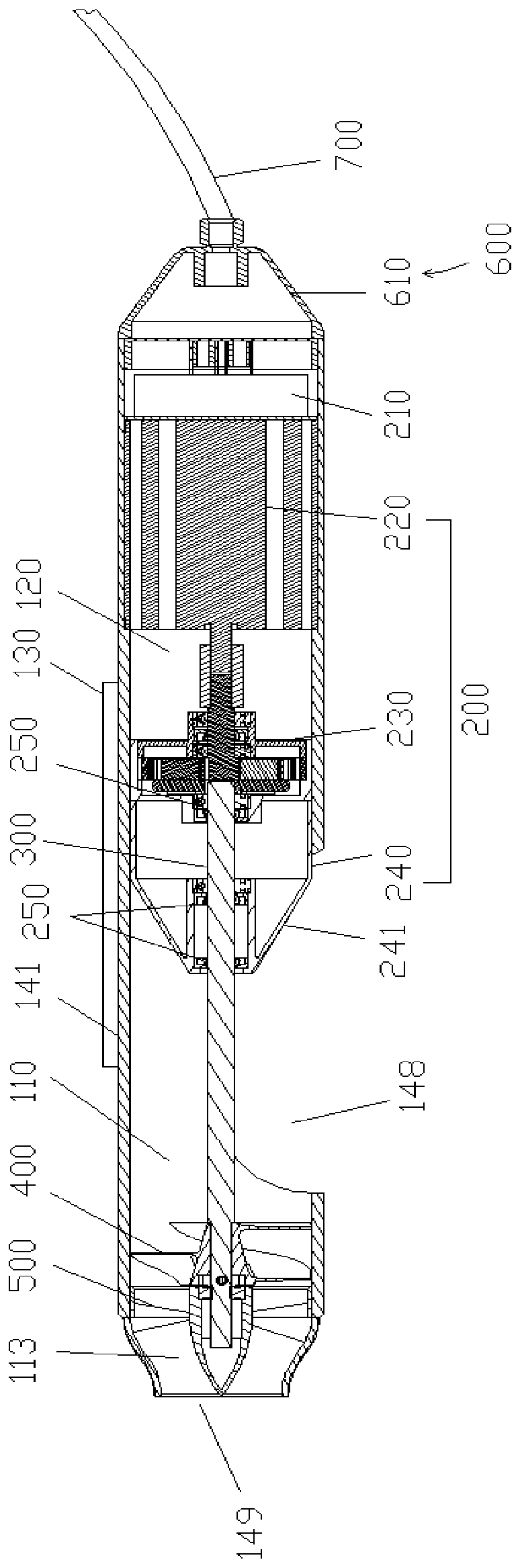

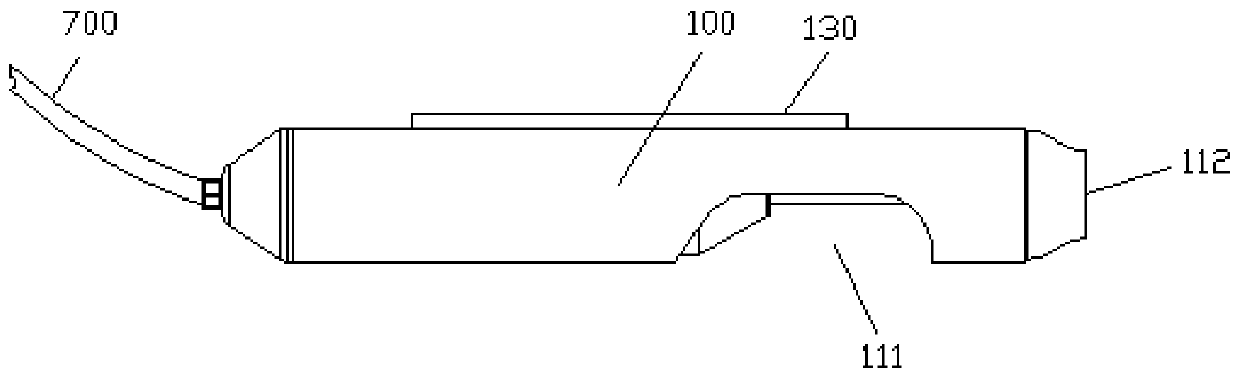

Underwater propeller

PendingCN110203367ABig propulsionIncrease propulsionCharging stationsPropulsion power plantsPropellerImpeller

The invention provides an underwater propeller, and belongs to the field of underwater power propelling equipment. The underwater propeller comprises a shell, a driving component, a driving shaft, a first impeller and a second impeller; a fluid channel and a containing cavity are arranged in the shell, the fluid channel comprises a water inlet and a water outlet; a pressurization area is arrangedin the fluid channel, and the inner diameter of the pressurization area is decreased in the drainage direction; the driving shaft is connected with the driving component; the driving component is arranged in the containing cavity; the first impeller is fixedly connected to the driving shaft, the second impeller is rotatably connected to the driving shaft, the first impeller is located at the upstream position of the second impeller, and the second impeller is located in the pressurization area. The driving component drives the first impeller to rotate through the driving shaft, and the first impeller enables the water flow to be pushed into the pressurization area; the second impeller located in the pressurization area accelerates water flow and sprays the water flow out of the water outlet, so that the propelling power is increased, the propelling power of the underwater propeller is improved, and the driving effect is improved.

Owner:CYCLEAGLE INTELLIGENT EQUIP (WEIHAI) CO LTD

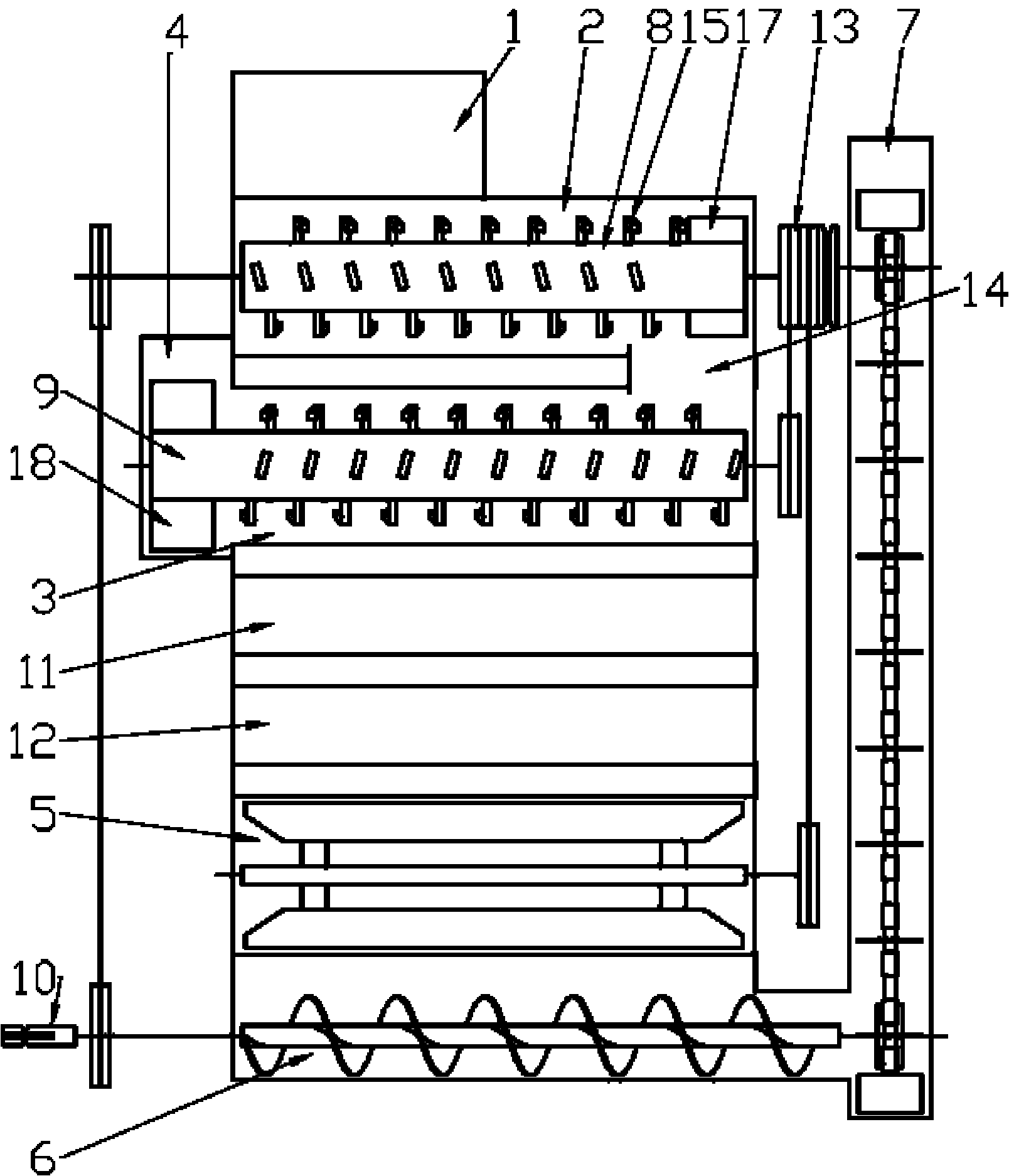

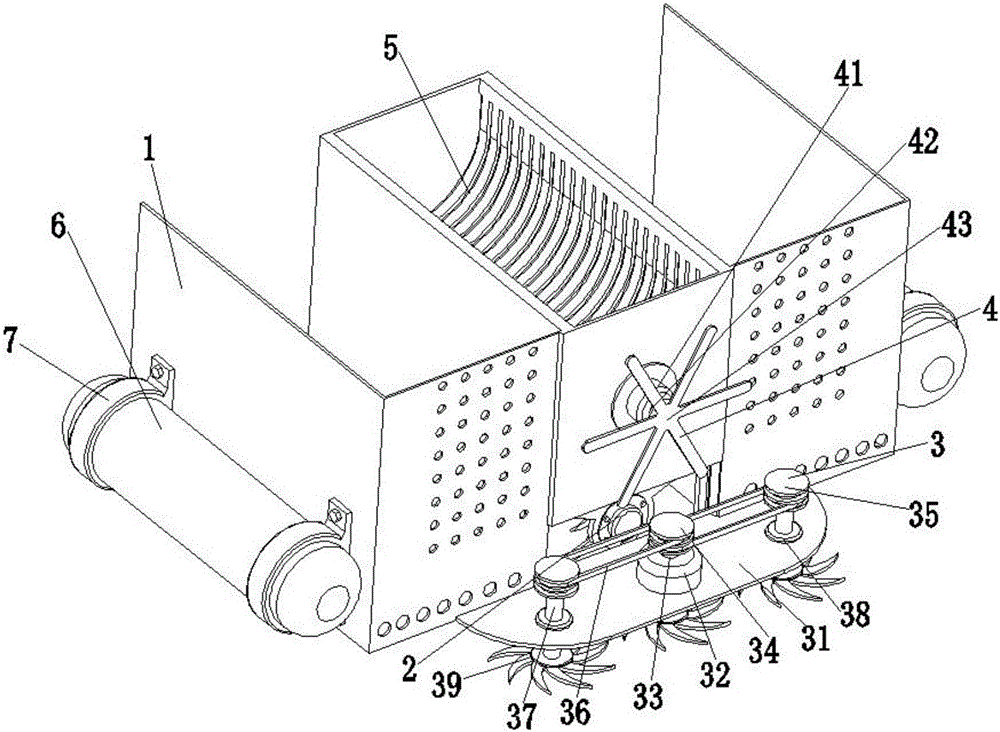

Design method and device of corn sheller

The invention relates to agricultural machinery, in particular to a design method and a device applicable to a corn sheller; the device comprises five parts, i.e. power transmission mechanisms, a threshing mechanism, a conveying mechanism, an impurity removing mechanism and a frame, and is characterized in that a drum of the threshing mechanism is provided with a screen hole, and the longitudinal direction of the screen hole is longer than the horizontal direction thereof; the power transmission mechanisms are arranged on both sides of the frame; the conveying mechanism comprises a pushing device and an elevating device, the pushing device is arranged on the lower side of the frame, the elevating device is arranged on one side of the frame, and the threshing mechanism and the impurity removing mechanism are fixed on the frame; each power transmission mechanism comprises a power access shaft head and a power access wheel; and when the power access shaft head serves as a power access point, the power access shaft head is connected with a power output PTO, a diesel engine or a motor in a transmission way. The invention not only has high efficiency and high purification to dry corn with skin or wet corn with skin, but also has simple structure, and can be combined with any power source.

Owner:袁毅

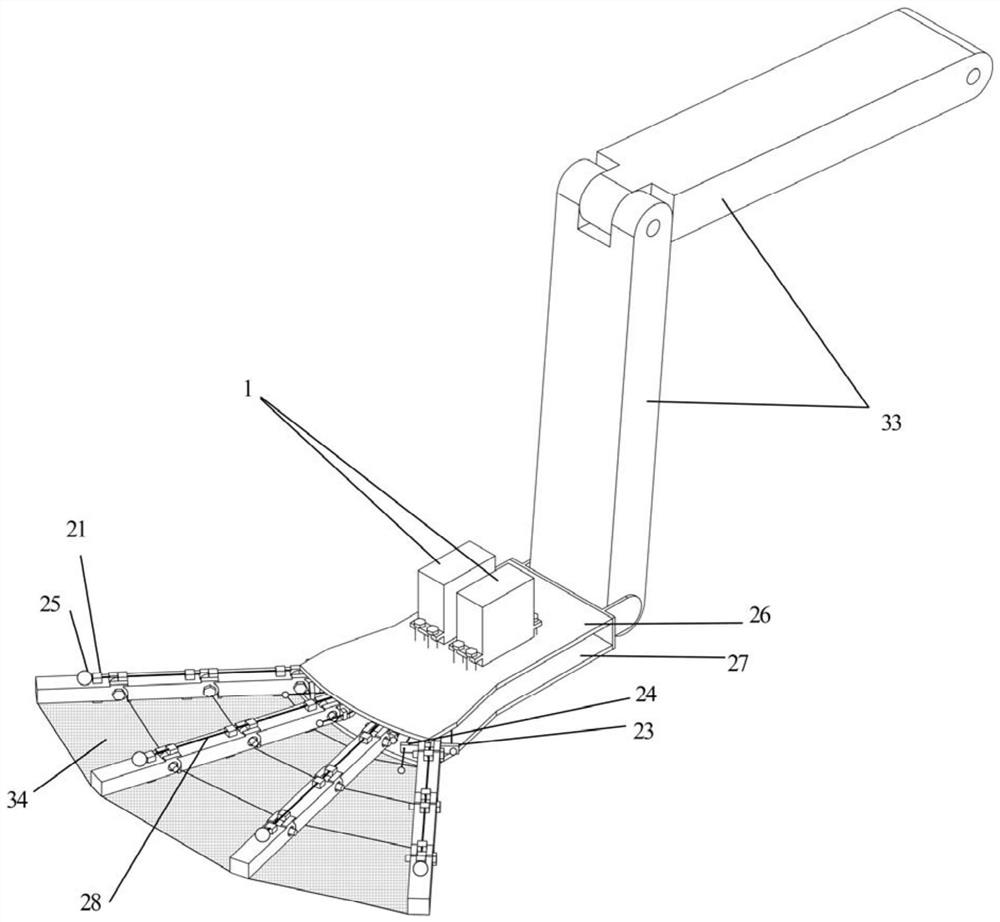

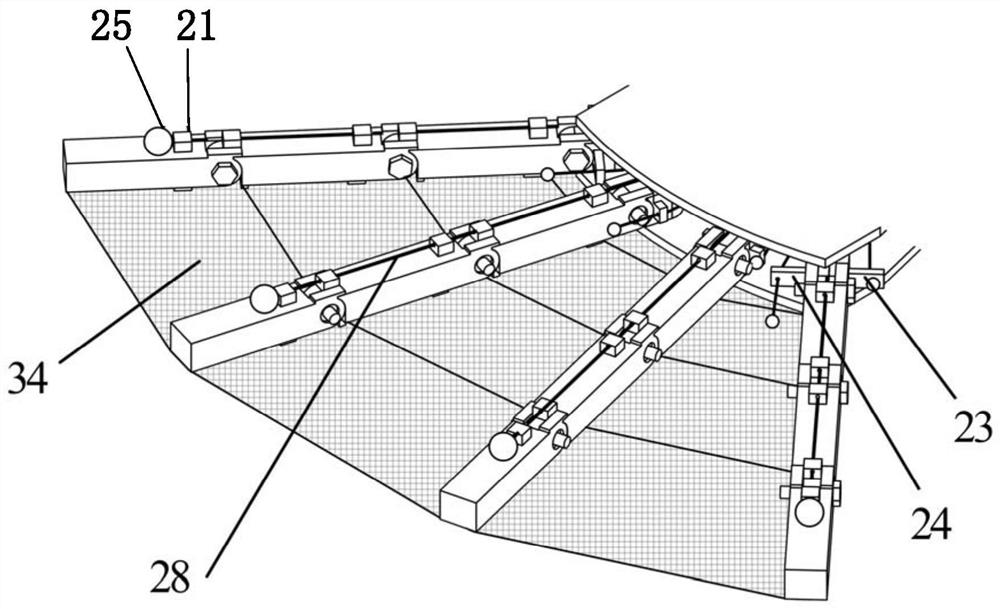

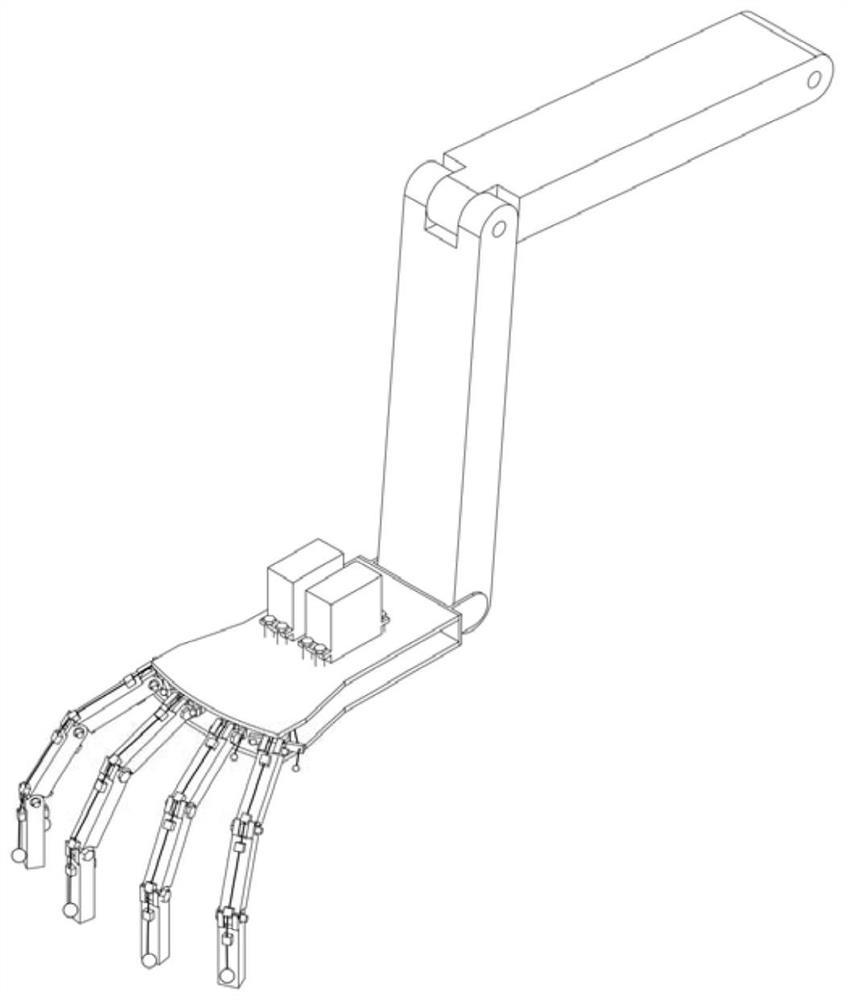

Flipper propelling device imitating posterior limbs of beaver

ActiveCN112109868AReduce weightSimple structurePropulsive elements of non-rotary typePhysical medicine and rehabilitationPhysical therapy

The invention belongs to the technical field of robots, and aims to provide a flipper device imitating posterior limbs of a beaver. The device has the advantages of being simple in structure and highin propelling efficiency. According to the technical scheme, the flipper device imitating the posterior limbs of the beaver is characterized by comprising a connecting rod mechanism and a flipper hinged to the connecting rod mechanism, wherein the flipper comprises two steering engines, a flipper support for the steering engines to be fixed, four toe assemblies which are the same in structure andcan be hinged to the flipper support in a swinging mode, and a thin film connected with the four toe assemblies so as to facilitate paddling.

Owner:ZHEJIANG SCI-TECH UNIV

Special travelling device for water surface pollution floater cleaning robot

The present invention relates to a special travelling device for a water surface pollution floater cleaning robot. The special travelling device comprises a frame, a spiral propelling device, a steering device, a power supplementary device, a filter screen, inflators and fixing buckles. The spiral propelling device is positioned at the bottom of the middle of the frame, the spiral propelling device is simple and convenient to control, propelling force is large, and the propelling effect is good. The steering device is positioned at the rear side end of the frame, the steering effect of the steering device is achieved due to the fact that three steering pawls rotate in the same direction, and steering is fast and flexible. The power supplementary device is positioned right above the steering device, and when the weight of water surface pollution floaters born by the special travelling device is too large or movement power is insufficient, the effect of secondary supplementation of the movement forward power can be achieved by the power supplementary device. The filter screen is installed inside an upper layer of a semi-cylindrical housing structure of the frame, the inflators are symmetrically positioned at left and right sides of the frame respectively, and the inflators and the frame are connected through the fixing buckles.

Owner:枣庄市顺翔科技发展有限公司

Boat propelling system

ActiveUS8831802B2Sure easyQuicker increase in the target pivot angleSpeed controllerElectric devicesSteering angleSteering linkage

A boat propelling system capable of determining an abnormality regarding steering of a propelling system main body includes an outboard engine main body, a steering section arranged to steer the outboard engine main body, a steering angle sensor arranged to detect a steering angle of the steering section, a pivot sensor arranged to detect an actual pivot angle of the outboard engine main body, and an ECU. The ECU calculates a target pivot angle change amount based on a target pivot angle derived from the steering angle and a baseline target pivot angle, calculates an actual pivot angle change amount based on the actual pivot angle and a baseline actual pivot angle, and obtains a gap amount between the target pivot angle change amount and the actual pivot angle change amount. Then, the ECU determines an abnormality regarding steering of the outboard engine main body based on a result of comparison between the gap amount and the first threshold value. Setting of the baseline target pivot angle and the baseline actual pivot angle is based on a result of a comparison between the gap amount and a second threshold value.

Owner:SIEMENS ENERGY INC +1

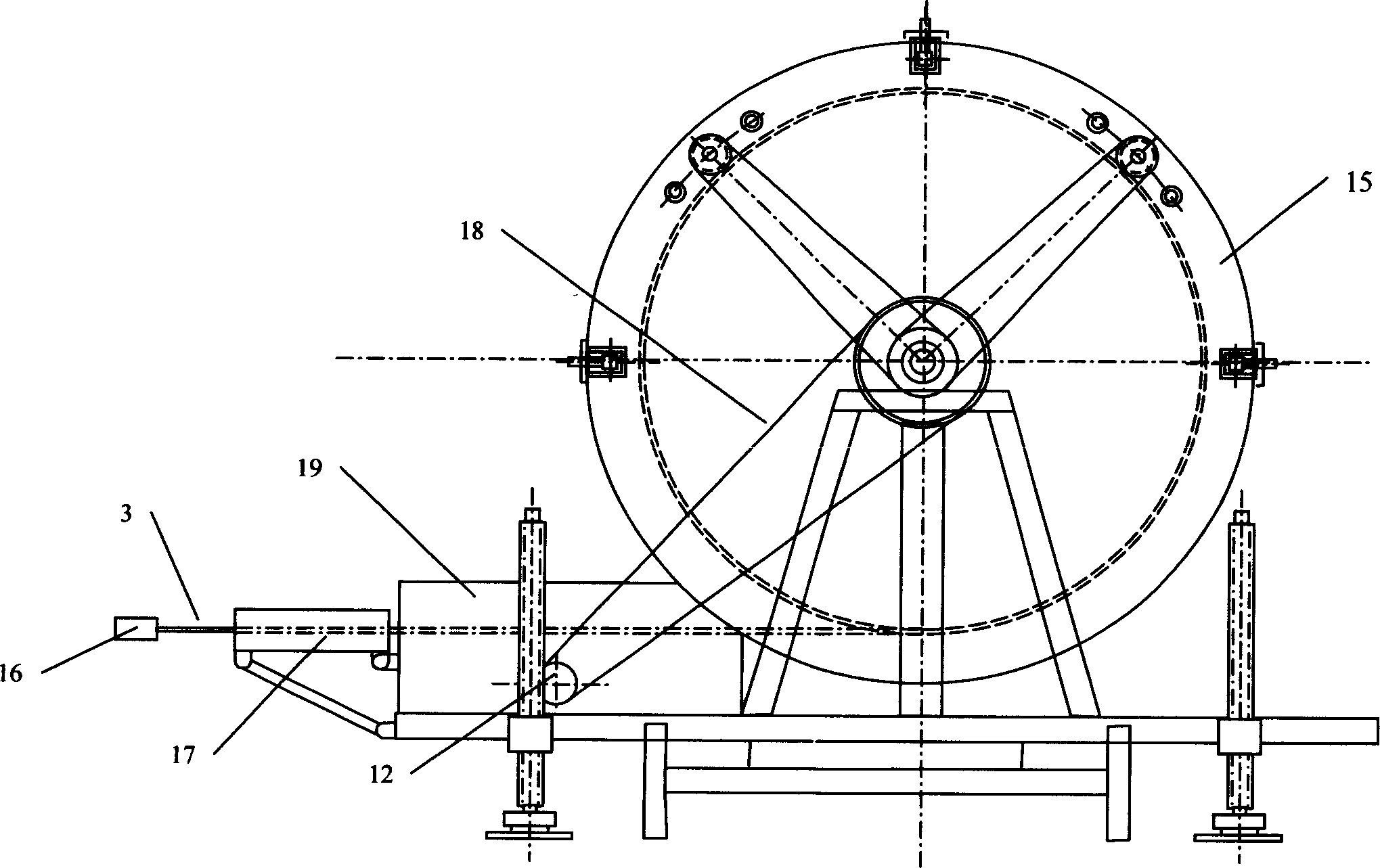

Soft seabed mud spiral propulsion vehicle and traveling method thereof

InactiveCN106428478AAvoid resistanceBig propulsionPropulsive elements of rotary typeUnderwater equipmentOcean bottomVehicle frame

The invention discloses a soft seabed mud spiral propulsion vehicle and a traveling method thereof. A novel propulsion device capable of traveling in soft seabed mud is required. According to the invention, four spiral propellers are arranged at the left front, right front, left rear and right rear positions of the bottom of a frame; the spiral propellers comprise spiral blades, propeller shells, motors, planetary reducers and shaft sealing elements; one end of each propeller shell and a supporting shaft fixed on the end face of a motor seat form a revolute pair, the other end of the propeller shell and a motor output shaft form a revolute pair, and the supporting shaft is fixed with the frame; the propeller shells are driven by the motors; a generator supplies power to the motors by umbilical cables; a control cabinet transmits a control signal to the motors by virtue of the umbilical cables; the spiral blades are fixed outside the propeller shells; the shaft sealing elements are arranged between the supporting shaft fixed on the end face of the motor seat and the frame and between the motor output shaft and the frame. The vehicle disclosed by the invention is capable of overcoming widely distributed seabed mud resistance, freely moving forwards, retreating, steering, and transversely traveling to the left and the right.

Owner:HANGZHOU DIANZI UNIV

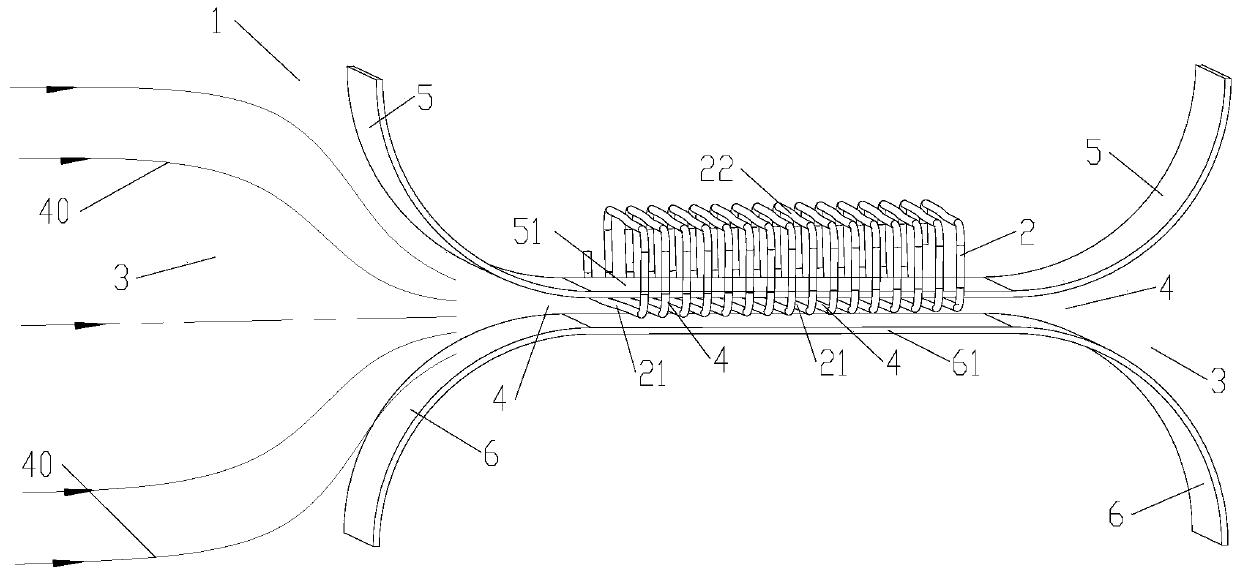

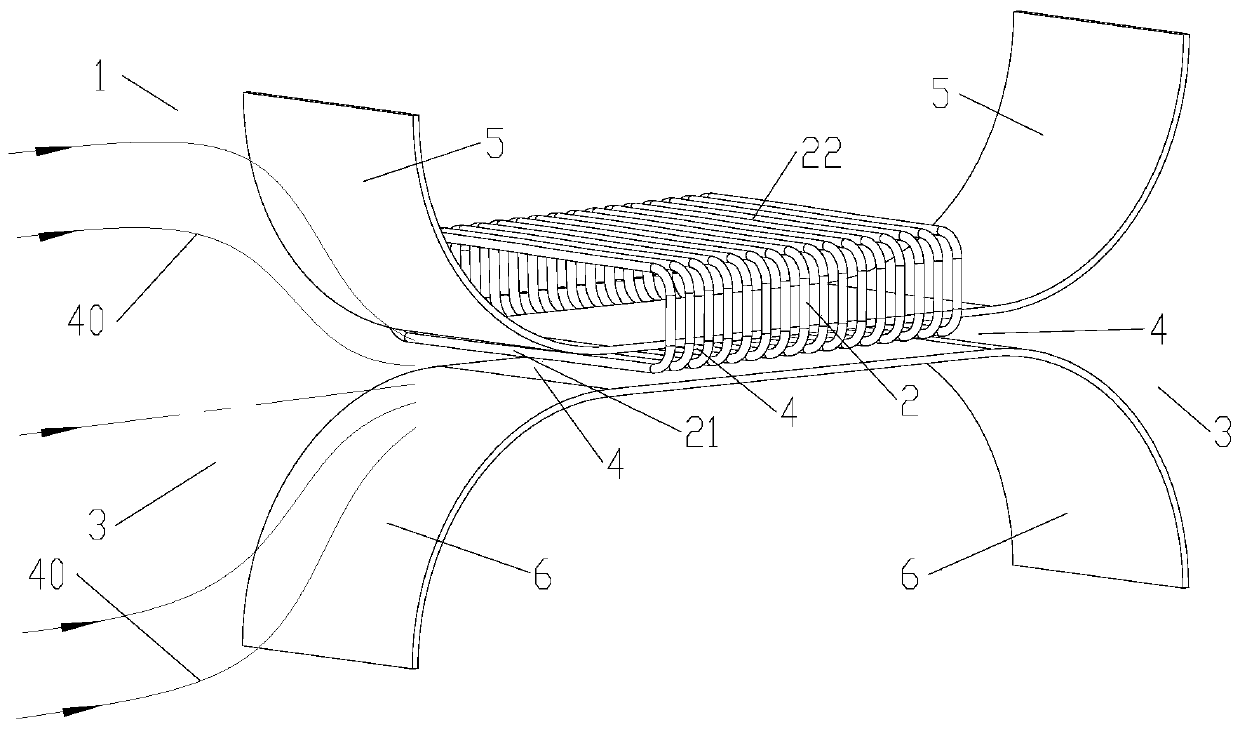

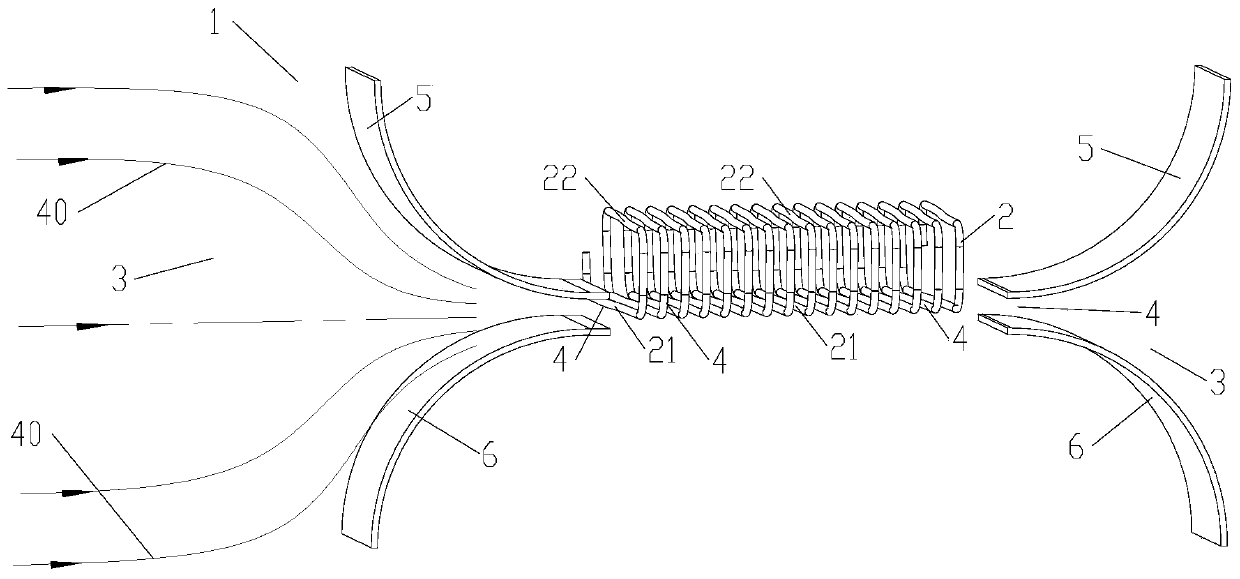

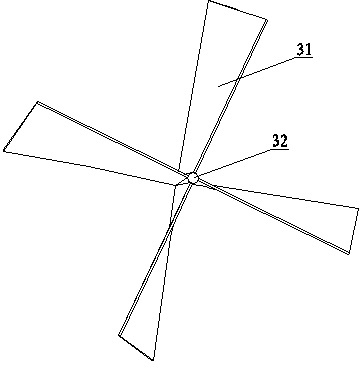

Air flow orientating propelling system

InactiveCN103410752ABig propulsionStrong airflow guidancePump componentsPump installationsAir compressionDrive shaft

The invention discloses an air flow orientating propelling system and belongs to the technical field of power devices. The air flow orientating propelling system aims at solving the problem that the existing air flow orientating propelling system is small in propelling force and poor in guiding property and cannot fix the air flow direction. A paddle torque propeller of the air flow orientating propelling system is installed above a propeller main body, a transmission shaft of the paddle torque propeller is connected with a power system arranged at the bottom of the propeller main body, an air flow dredging vent is arranged at the tail of the propeller main body, a round air compression chamber is arranged at the top of the propeller main body, the blade torque propeller is arranged above the round air compression chamber which is communicated with the air flow dredging vent, a plurality of paddle blades are arrayed on the outer wall of the transmission shaft annularly, the connection end face of each paddle blade is in a 45-degree frontward inclining state, and the paddle blades is bent in the connection ends and transits to be in a vertical state in the tail ends. The air flow orientating propelling system supplies propelling force for mechanical systems and has large propelling force and good air flow orientation property.

Owner:哈尔滨市奇正水稻种植专业合作社

Thrusters in the magnetic field, braking and/or power generation devices in the magnetic field

InactiveCN109039000AStrong external magnetic fieldBig propulsionMagnetic circuit shape/form/constructionPropulsion systemsElectrical conductorMagnetic field

A thruster includes a magnetic field collecting member and an electrically energizable conductor, characterized by, the magnetic field collecting member is provided with a left-right penetrating external magnetic field passage for enhancing the external magnetic field, The external magnetic field path comprises at least a retraction path and an enhancement path, wherein the retraction path is narrowed directly or spatially from above and / or between the lower direction, the retraction path is narrowed from one end to the other end, and the enhancement path is a path after the retraction path isnarrowed or a postponement path after the retraction path is narrowed. The thruster has greater propulsion force, and can be in various forms, the structure is simple, and can effectively overcome the shortcomings of the existing thrusters.

Owner:SHENZHEN DANMING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com