Bone filler conveying sleeve

A technology of bone filler and delivery tube, which is applied in the direction of catheter, surgery, dilator, etc., can solve the problems of heavy economic burden, long operation time, and many instruments used by patients, so as to reduce the economic burden, reduce pain, and reduce complications. The effect of the incidence of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

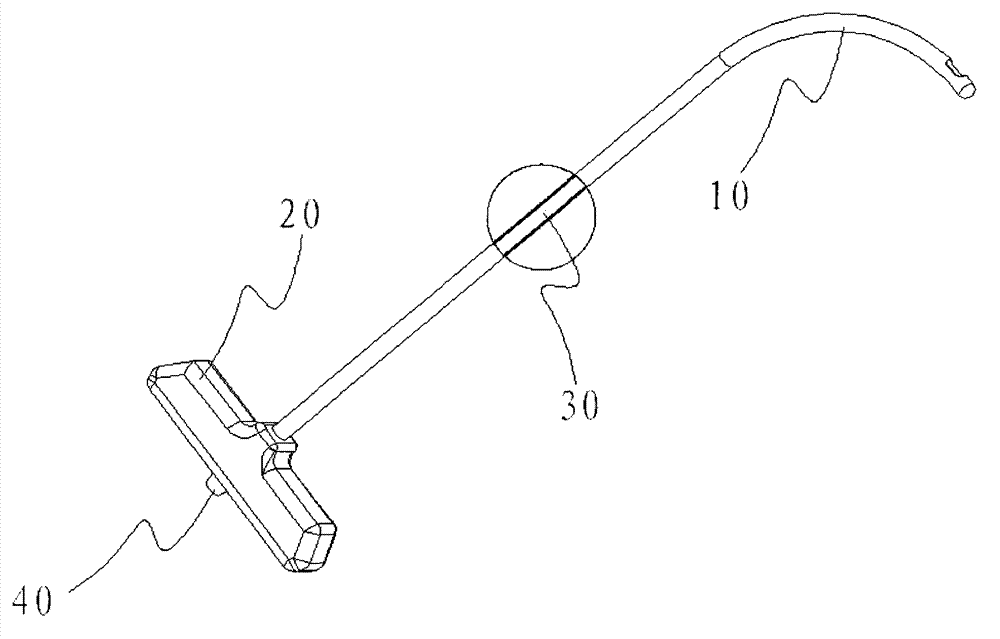

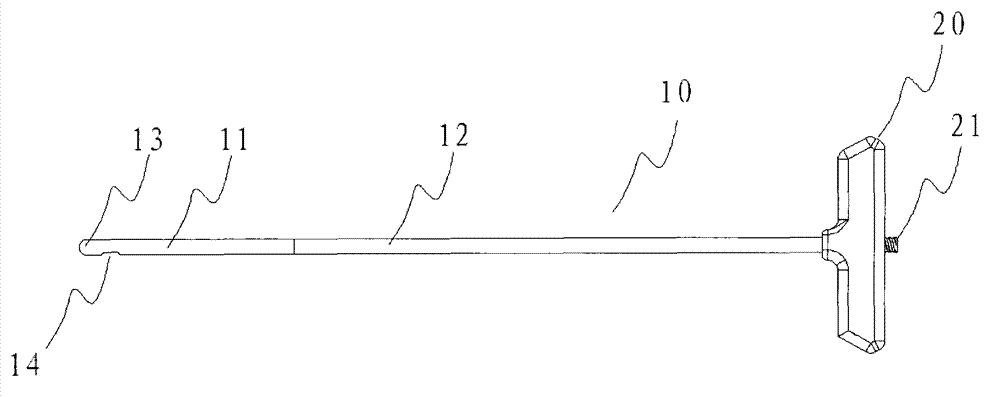

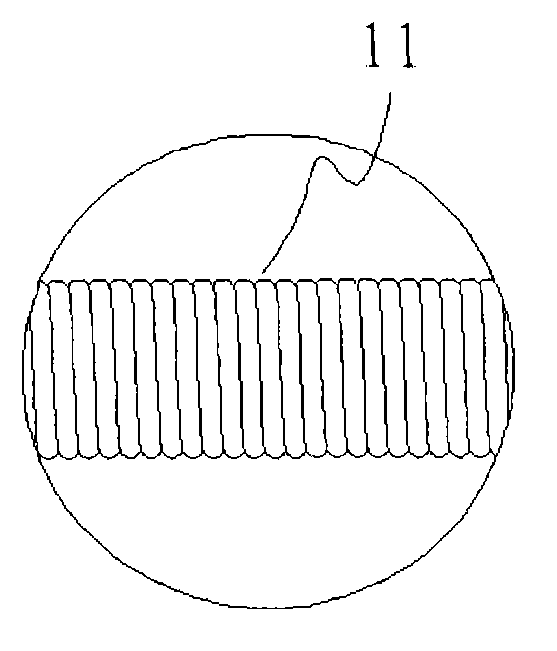

[0038] Such as figure 1 As shown in -3, a bone filler delivery sleeve includes a delivery tube 10 and a delivery handle 20, wherein the distal part of the delivery tube 10 is a flexible tube 11, and the proximal part of the delivery tube 10 is a rigid tube 12. The proximal end of the flexible tube 11 is fixedly connected to the distal end of the rigid tube 12 (such as glued, heat welded, riveted, screwed, etc.), and the proximal end of the rigid tube 12 is connected to the delivery handle 20 Fixed connection, the delivery handle 20 has a Luer connector 21 (for connecting with a bone filler injection device), the end 13 of the delivery tube 10 is closed, and the side wall of the flexible tube 11 has one or more holes 14. The bone filler delivery sleeve further includes a sheath core 30 slidably inserted inside the delivery tube 10, the proximal end 32 of the sheath core 30 is fixedly connected with an adjustment handle 40, and the sheath core 30 The distal end portion is bent ...

Embodiment 2

[0043] Such as Figure 8-1 As shown in 0, a bone filler delivery sleeve includes a delivery tube 10 and a delivery handle 20, wherein the distal part of the delivery tube 10 is a flexible tube 11, and the proximal part of the delivery tube 10 is a rigid tube 12 , the proximal end of the flexible tube 11 is fixedly connected to the distal end of the rigid tube 12 (such as glued, heat welded, riveted, screwed, etc.), and the proximal end of the rigid tube 12 is fixed to the delivery handle 20 The delivery handle 20 has a Luer connector 21 (for connecting with a bone filler injection device), the end 13 of the delivery tube 10 is not closed, and the bone filler delivery sleeve also includes a slidably inserted The sheath core 30 inside the delivery tube 10, the proximal end 32 of the sheath core 30 is fixedly connected to an adjustment handle 40, and the distal part of the sheath core 30 is bent at a fixed angle to form a fixed bending section of the sheath core 30 31, the end 3...

Embodiment 3

[0046] Such as Figure 8-1 As shown in 0, a bone filler delivery sleeve includes a delivery tube 10 and a delivery handle 20, wherein the distal part of the delivery tube 10 is a flexible tube 11, and the proximal part of the delivery tube 10 is a rigid tube 12 , the proximal end of the flexible tube 11 is fixedly connected to the distal end of the rigid tube 12 (such as glued, heat welded, riveted, screwed, etc.), and the proximal end of the rigid tube 12 is fixed to the delivery handle 20 connection, the delivery handle 20 has a luer connector 21 (for connection with a bone filler injection device), the end 13 of the delivery tube 10 is not closed, preferably on the side of the flexible tube section 11 at the distal end of the delivery tube 10 The wall has one or more holes 14, and the bone filler delivery sleeve also includes a sheath core 30 slidably inserted inside the delivery tube 10, and a proximal end 32 of the sheath core 30 is fixedly connected to an adjustment hand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com