Double worm oil press capable of preventing oil materials from sliding out of chamber

A double-screw oil press, double-screw technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of difficult to achieve oil smoothbore failure, reduced deformation resistance, high oil yield, etc., to improve oil extraction efficiency and increase sealing. performance, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

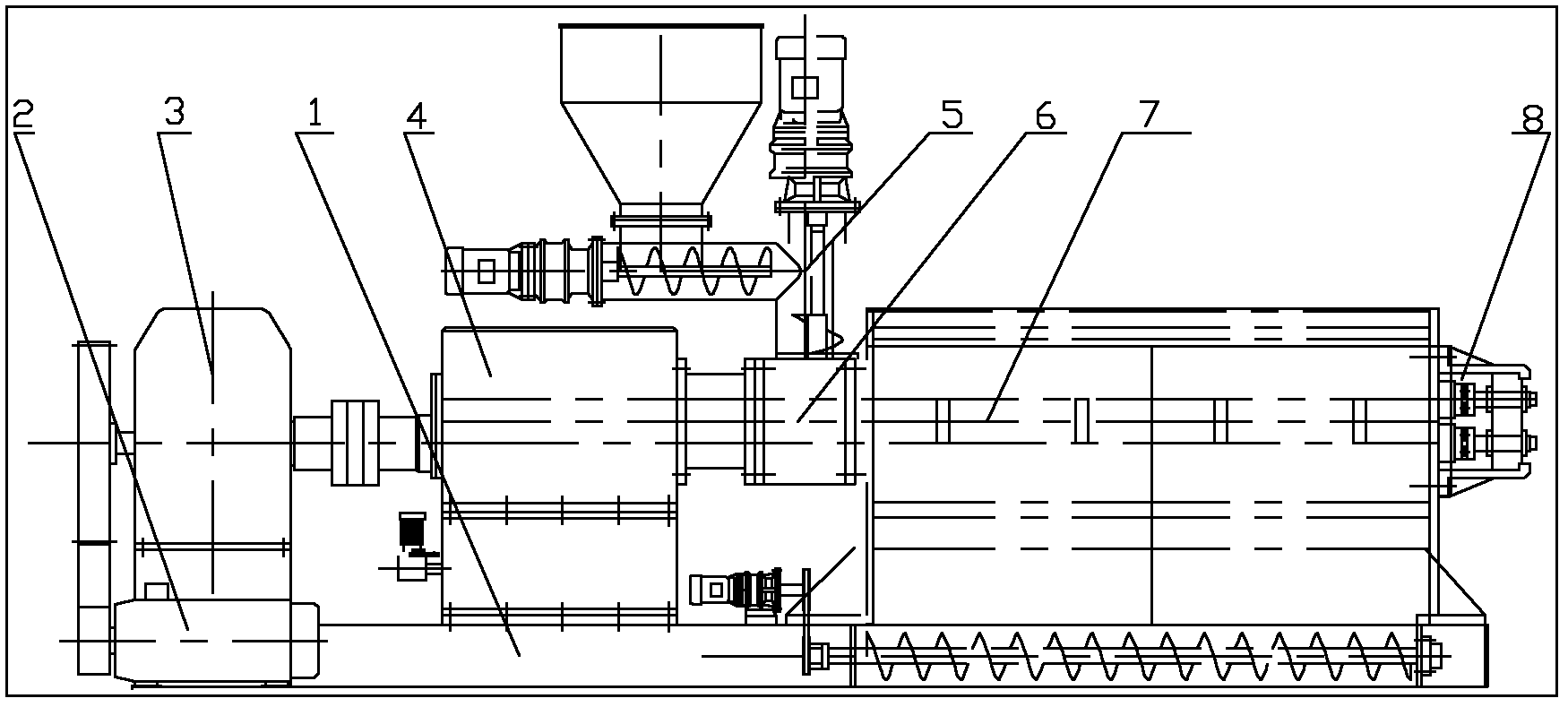

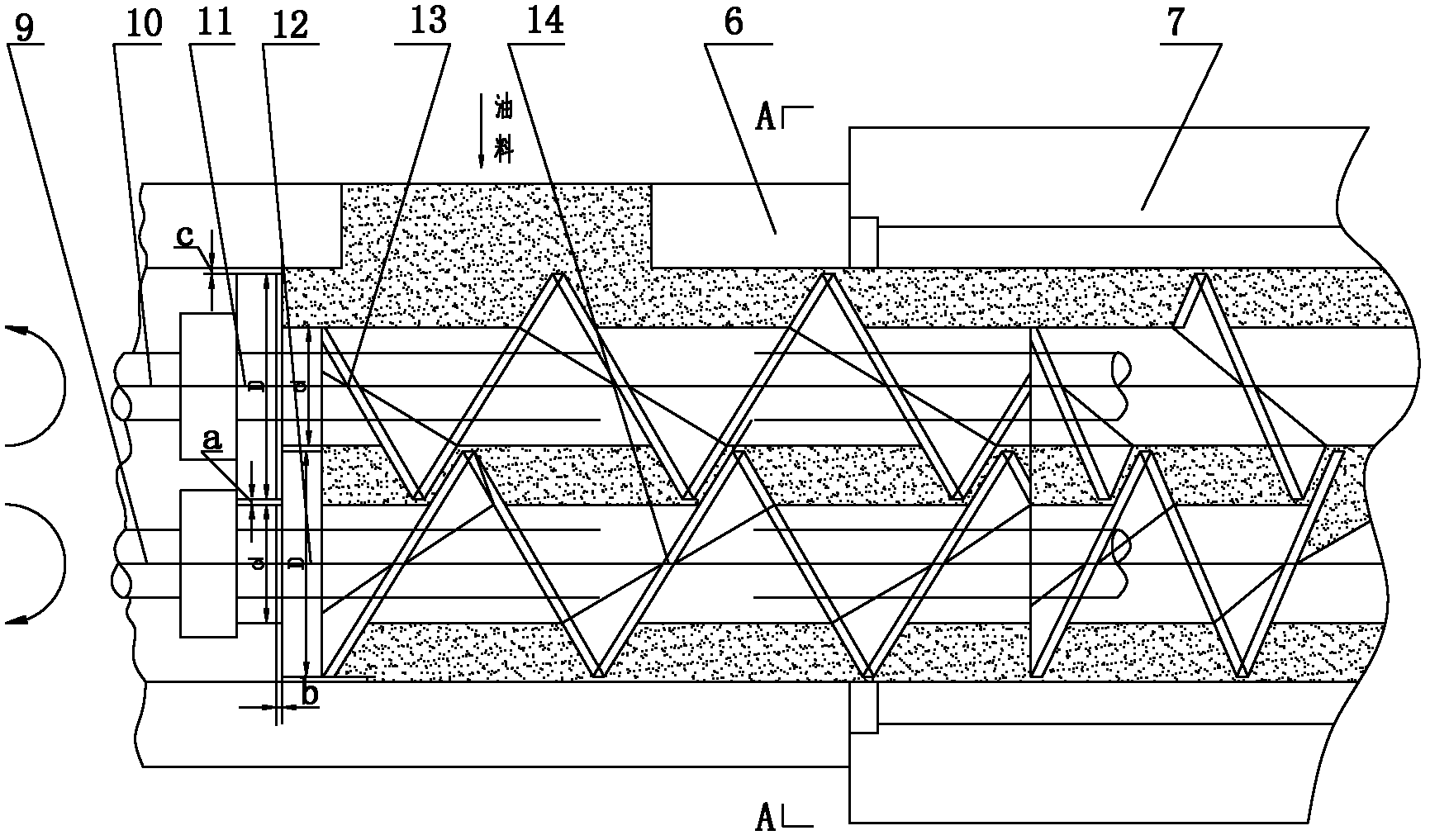

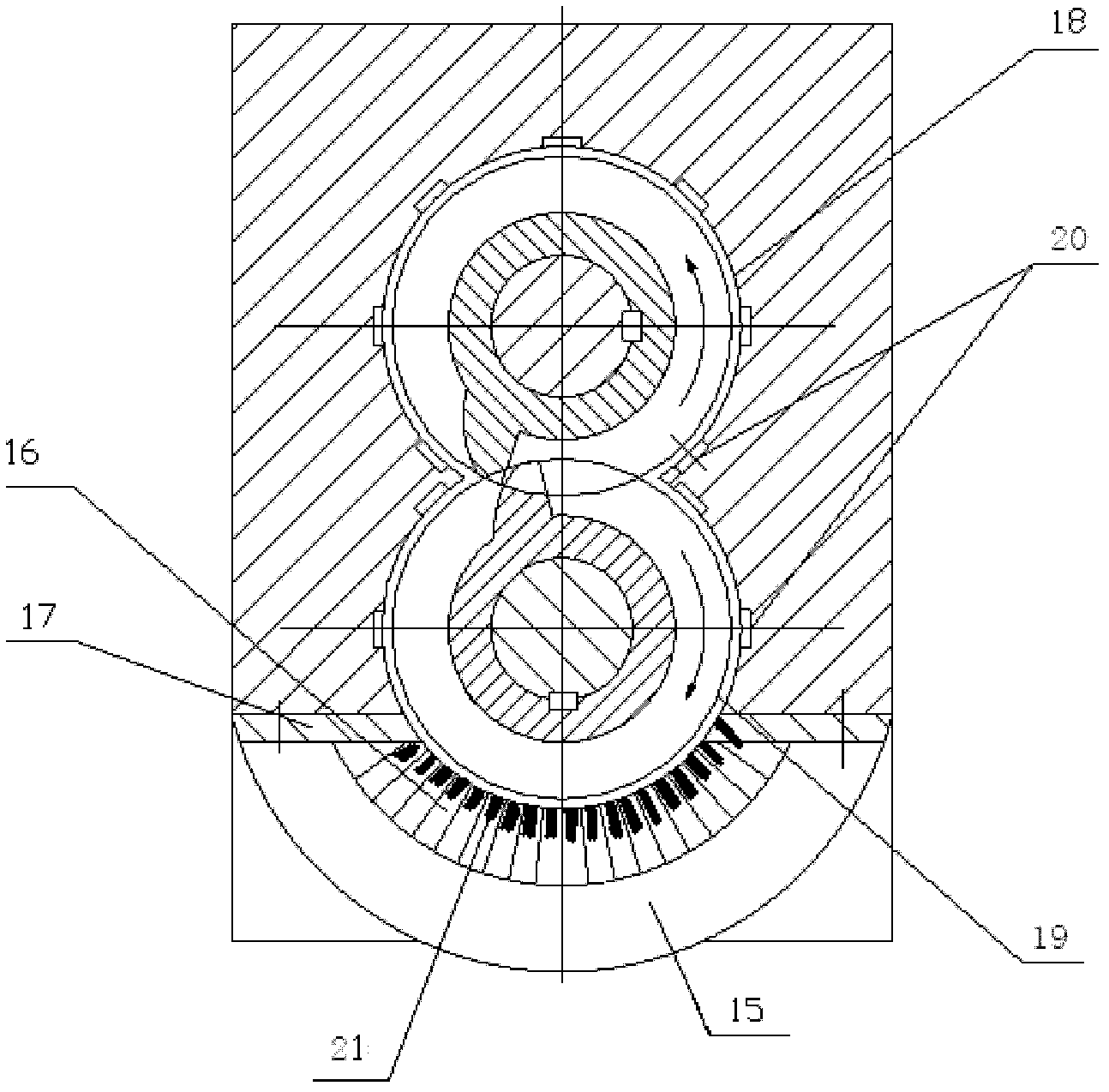

[0026] Such as figure 1 The double-screw oil press shown to prevent oil smoothbore includes a frame base 1, a drive motor 2 connected to the frame base 1, a reduction device 3, a torque distributor 4 connected to the output end of the reduction device 3, and a torque distribution device. The feeding base 6 connected to the output end of the device 4, the feeding device 5 located above the feeding base 6, the double-screw oil pressing device 7 connected to the feeding base 6, and the cake output mechanism located at the tail end of the double-screw oil pressing device 7 8, wherein the feeding base 6 includes a first feeding hole 18, a second feeding hole 19, a first section of left-handed screw 13, a first section of right-handed screw 14, a first mandrel 9 and a second core Axis 10, as in figure 2 As shown, the first section of left-handed pressing screw 13 and the first section of right-handed pressing screw 14 are respectively sleeved on the first mandrel 9 and the second ...

Embodiment 2

[0029] A double-screw oil press machine that prevents oil smoothbore, including a frame base 1, a drive motor 2 connected to the frame base 1 and a reduction device 3, a torque distributor 4 connected to the output end of the reduction device 3, and an output of the torque distributor 4 end-connected feeding base 6, a feeding device 5 positioned above the feeding base 6, a double-screw oil press device 7 connected to the feed base 6, and a cake-discharging mechanism 8 positioned at the tail end of the double-screw oil press device 7, wherein , the feeding base 6 includes a first feeding hole 18, a second feeding hole 19, a first section of left-handed screw 13, a first section of right-handed screw 14, a first mandrel 9 and a second mandrel arranged horizontally. 10. The first section of left-handed pressing screw 13 and the first section of right-handed pressing screw 14 are set on the first mandrel 9 and the second mandrel 10 respectively, and the first mandrel 9 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com