Patents

Literature

136results about How to "Improve the efficiency of oil extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

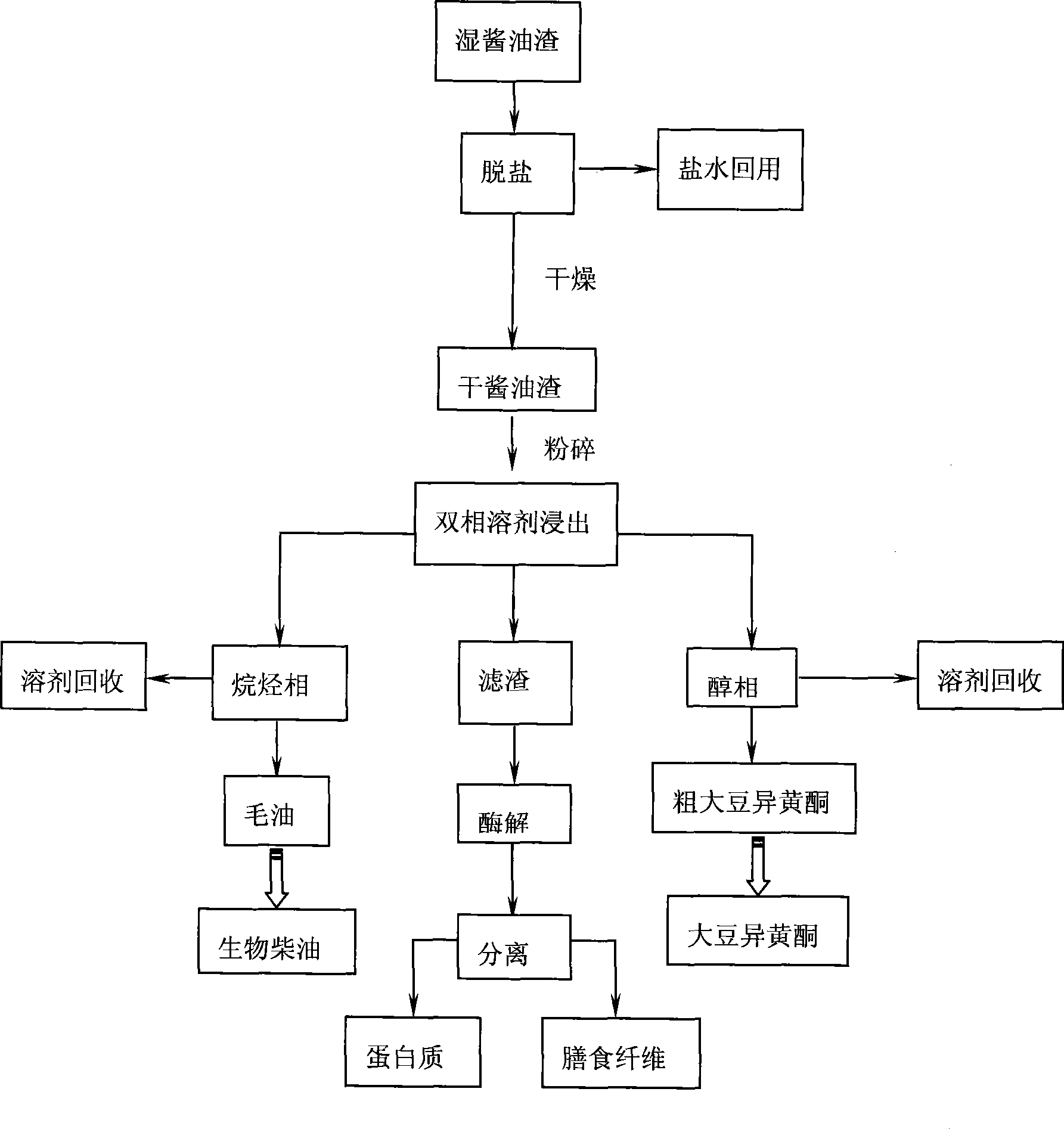

Method for extracting nutritive matter from sauce residue

ActiveCN101385532ASave resourcesThe operation process is simpleFood preparationNutrientDietary fibre

The present invention relates to the field of a sauce residue reclamation application, in particular to a method for extracting nutrient substances, such as grease, protein, dietary fiber, soy isoflavone which has high nutrient value and the like from sauce residue. The present invention uses a advanced two phase solvent extraction technology and an enzymolysis technology to extract the components in the sauce residue, such as the grease, the protein, the dietary fiber, the soy isoflavone which has high nutrient value, etc. The present invention meets the requirement of feed protein of the feed production industry and also obtains additives with high nutrient value, such as the dietary fiber and the soy isoflavone and the grease required by the energy source industry, thus realizing the high value resource conversation of the sauce residue. The present invention not only saves the resource, but also takes effect on protecting the environment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

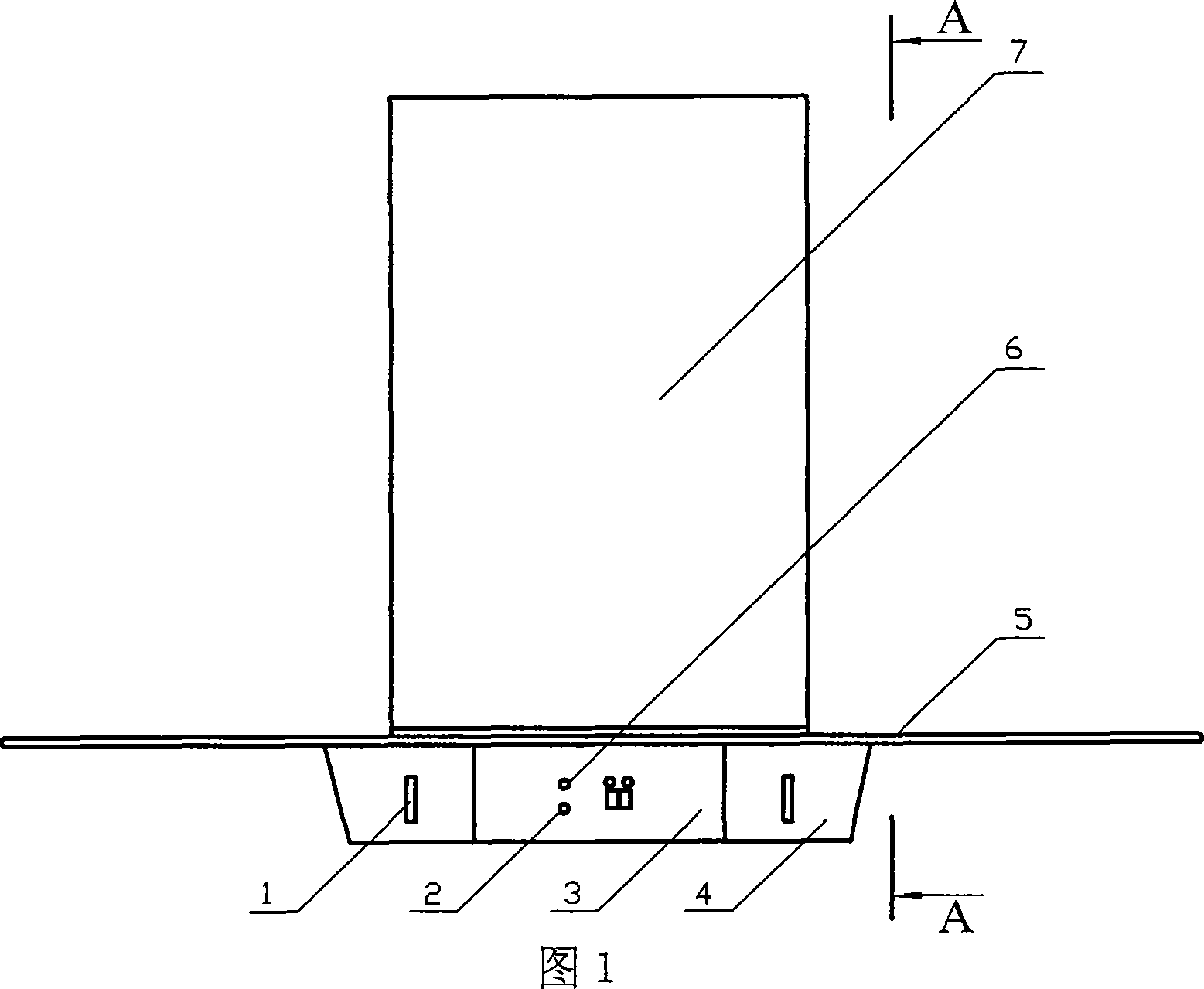

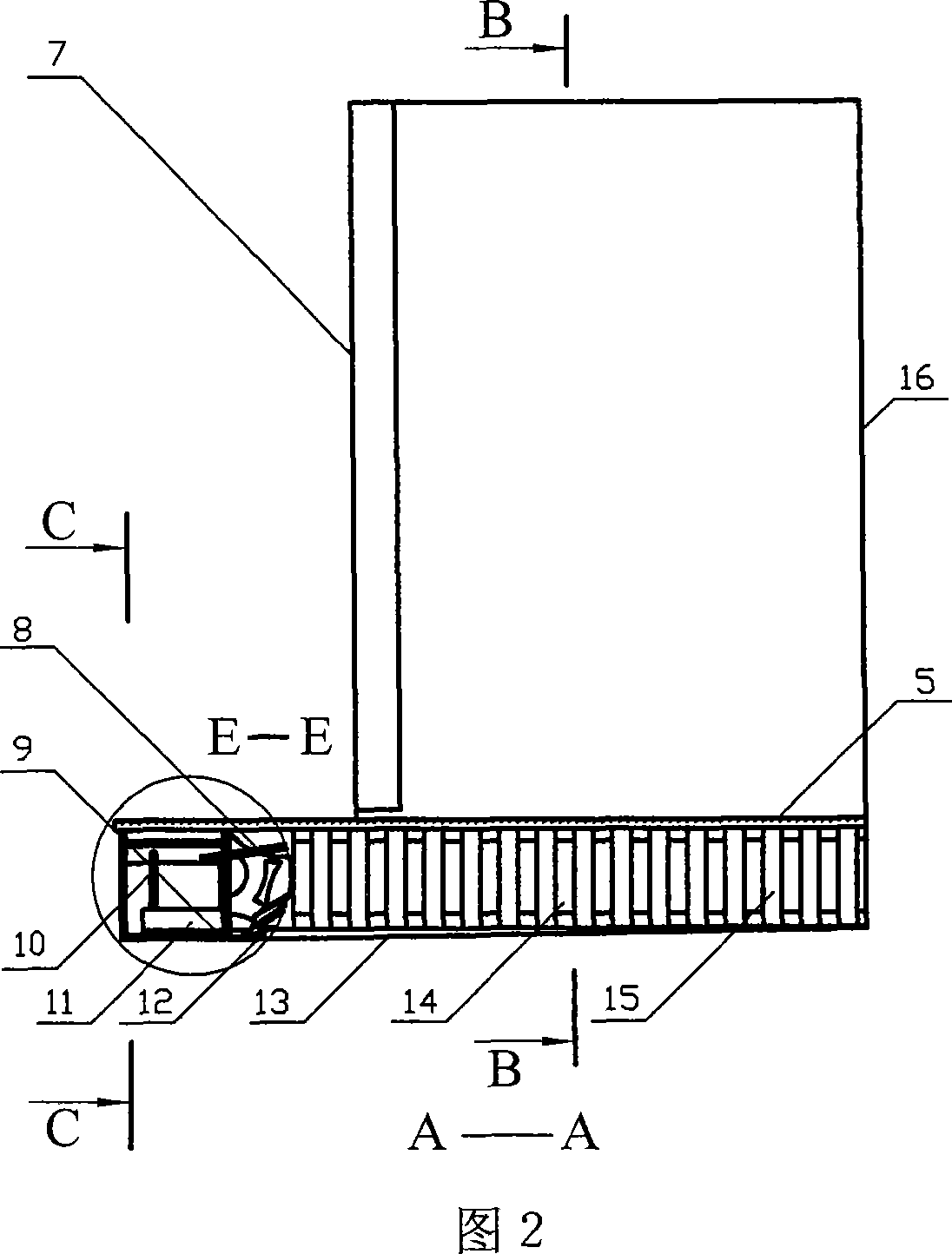

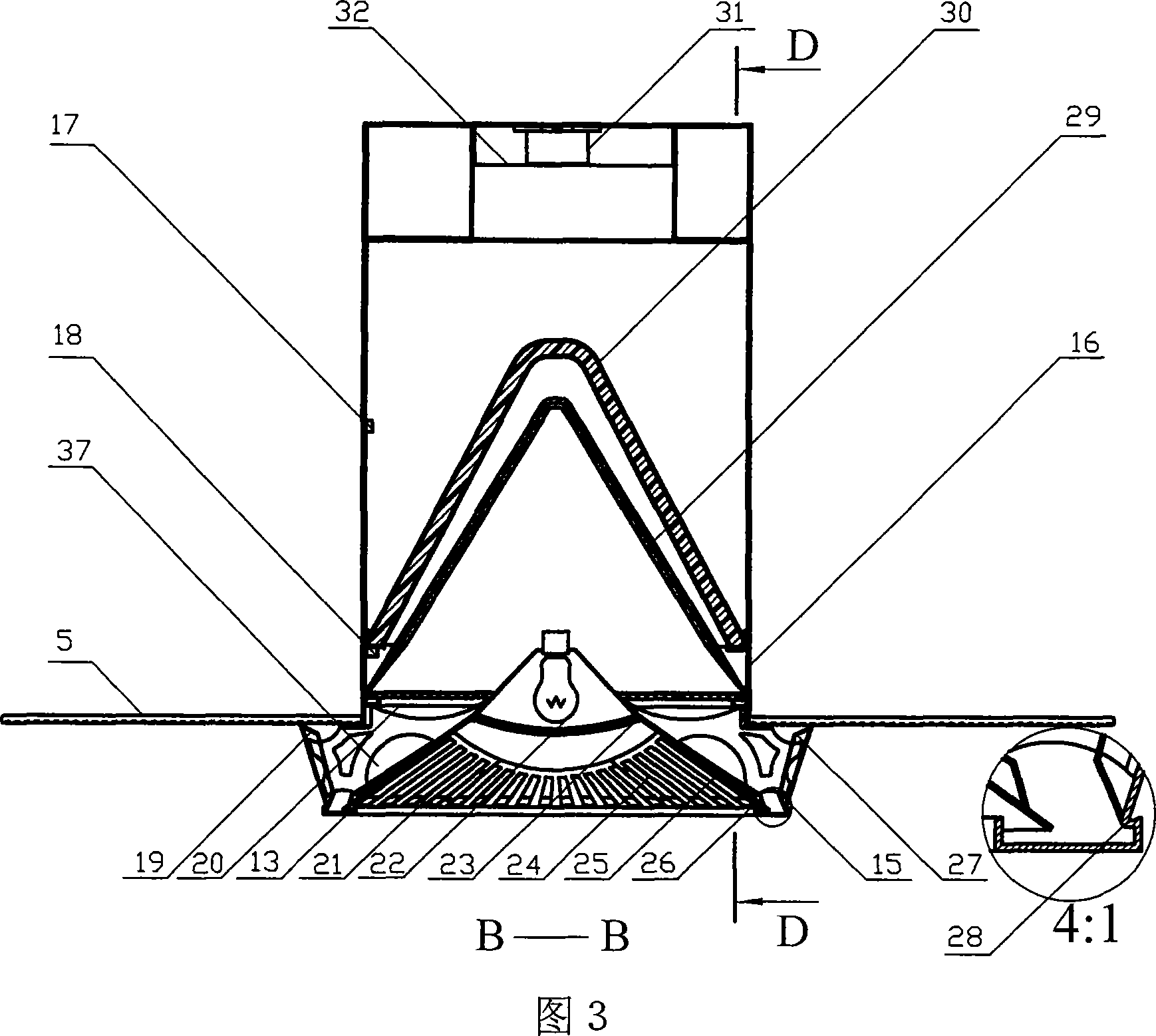

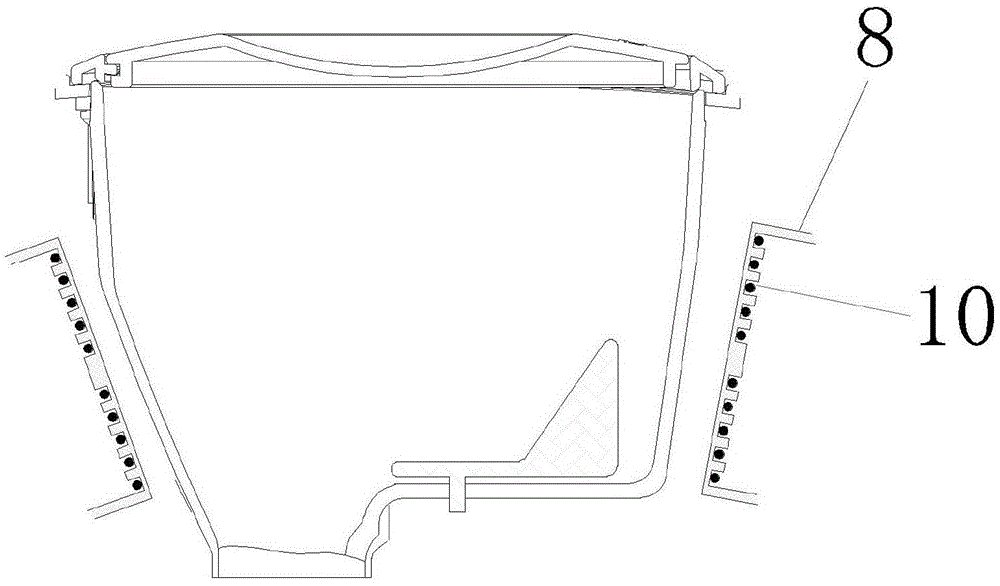

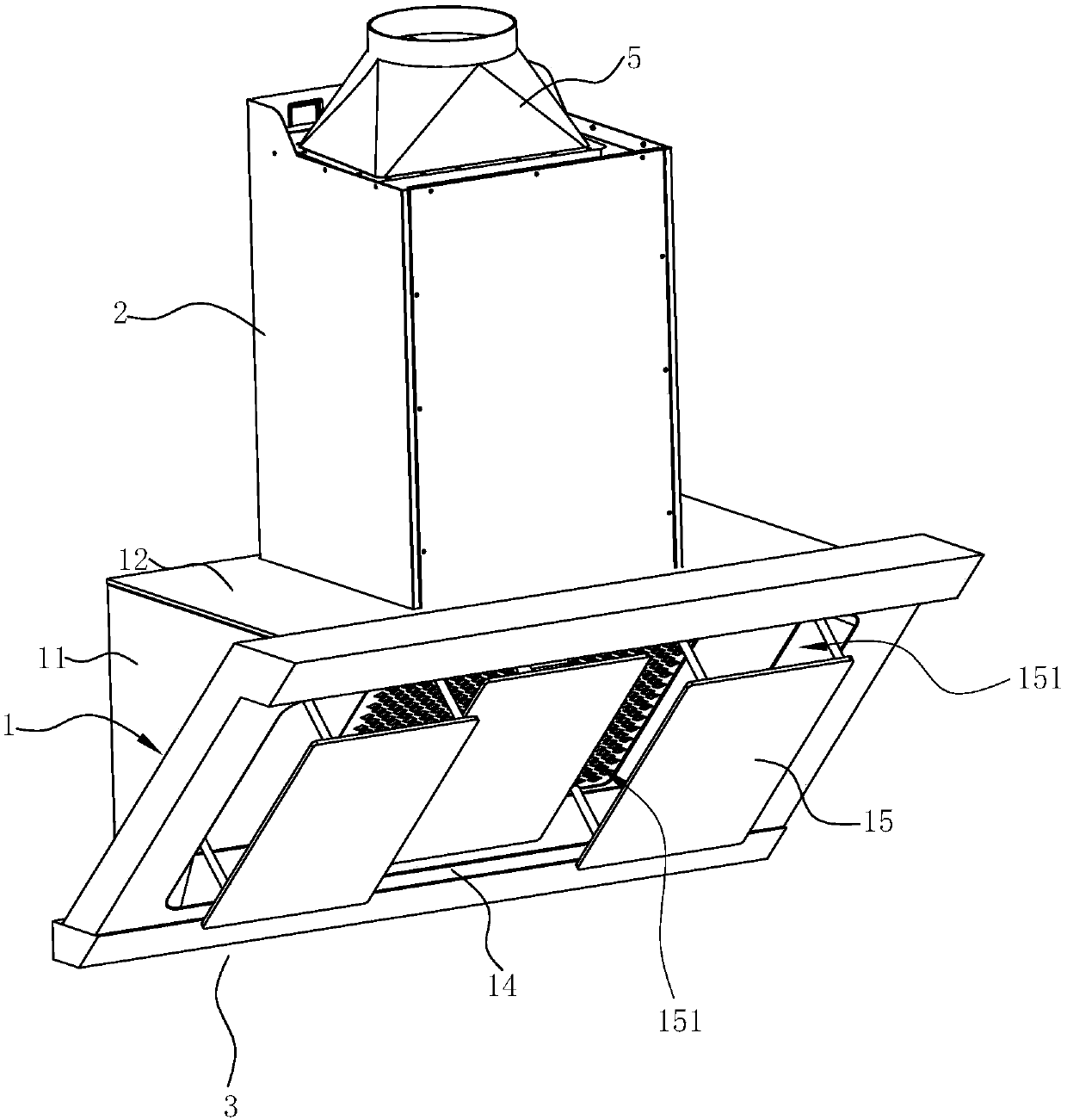

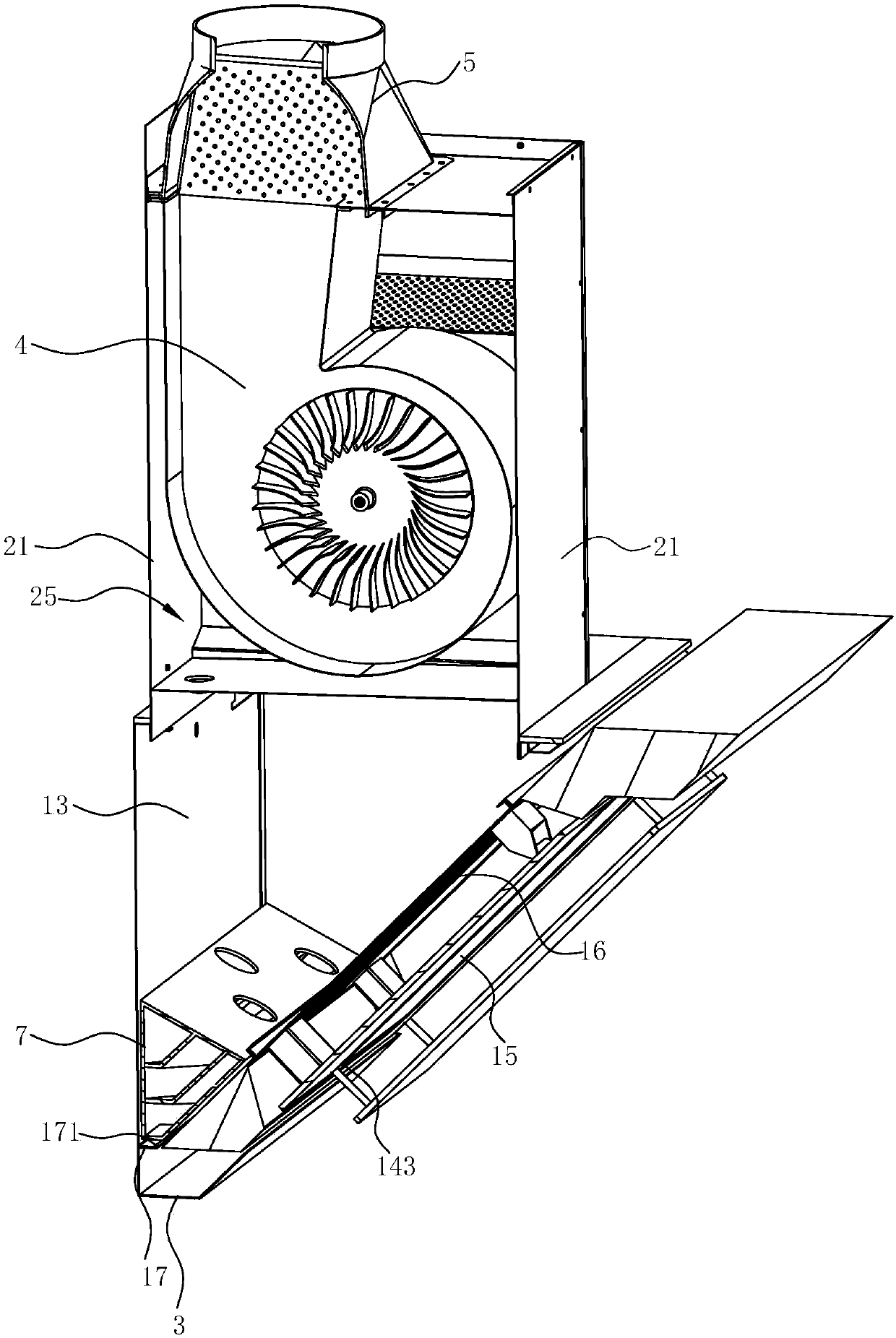

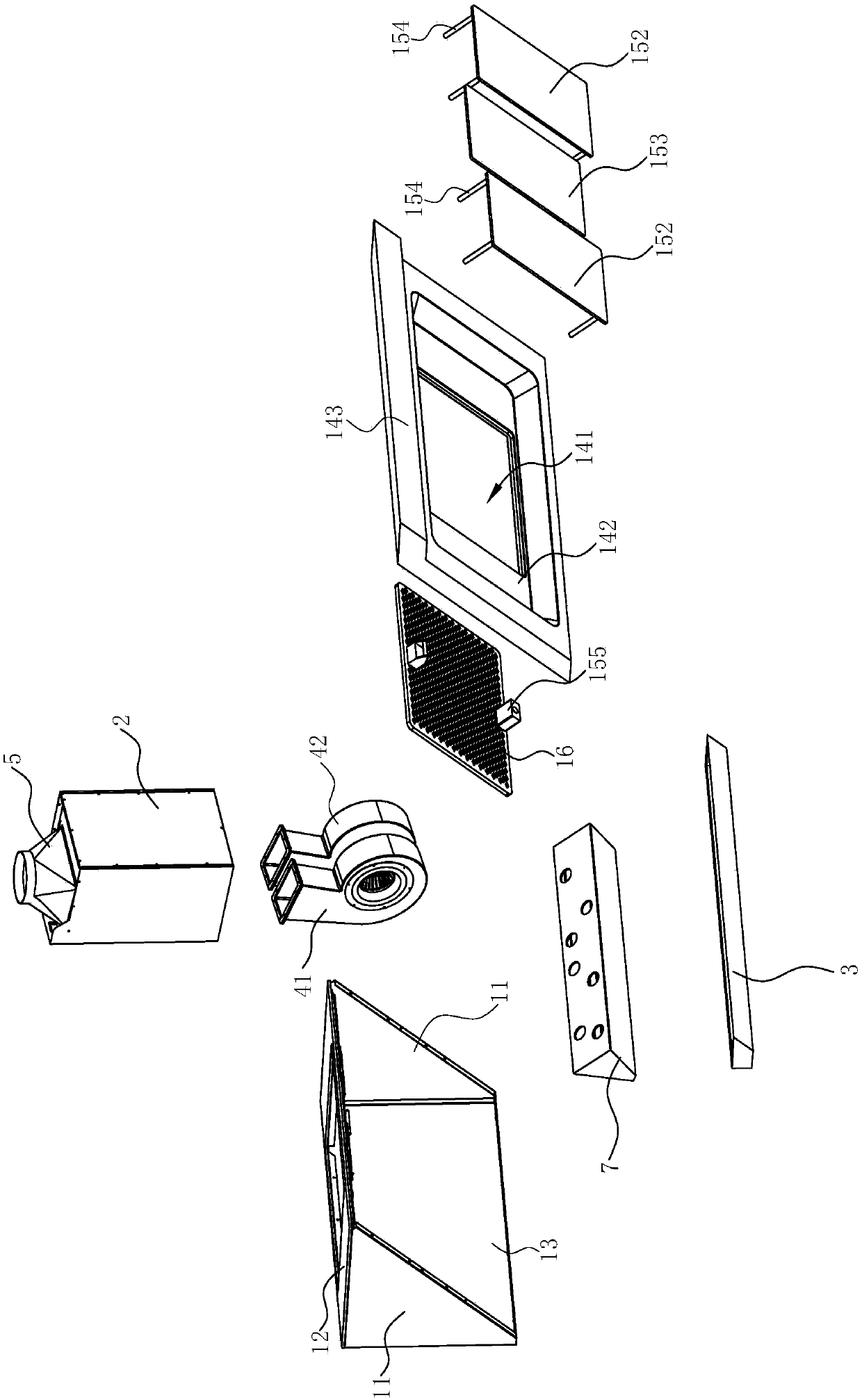

Glass hood cooking fume exhauster with powerful fume sucking function and capacity of exhausting clean air

InactiveCN101046308AReduce entryLower the entranceDomestic stoves or rangesLighting and heating apparatusFilter mediaEngineering

The cooking fume exhauster includes one fume collecting cavity, one side ventilating inner wall, one side air inlet covers, one control box, one blower connected to one motor, one composite filter net, filtering medium, one oil accepting pan, one glass hood, one oil pump and other parts. It features one cloud plate fixed below the fume collecting cavity, two side air inlet covers outside the cloud plate, the ventilating inner wall in the middle part, one oil sump and the control box before the air inlet covers. It has the advantages of high cooking fume sucking efficiency, capacity of purifying air, low power consumption, long service life, etc.

Owner:朱钦浩

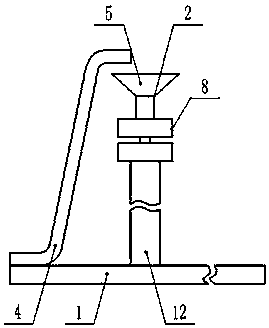

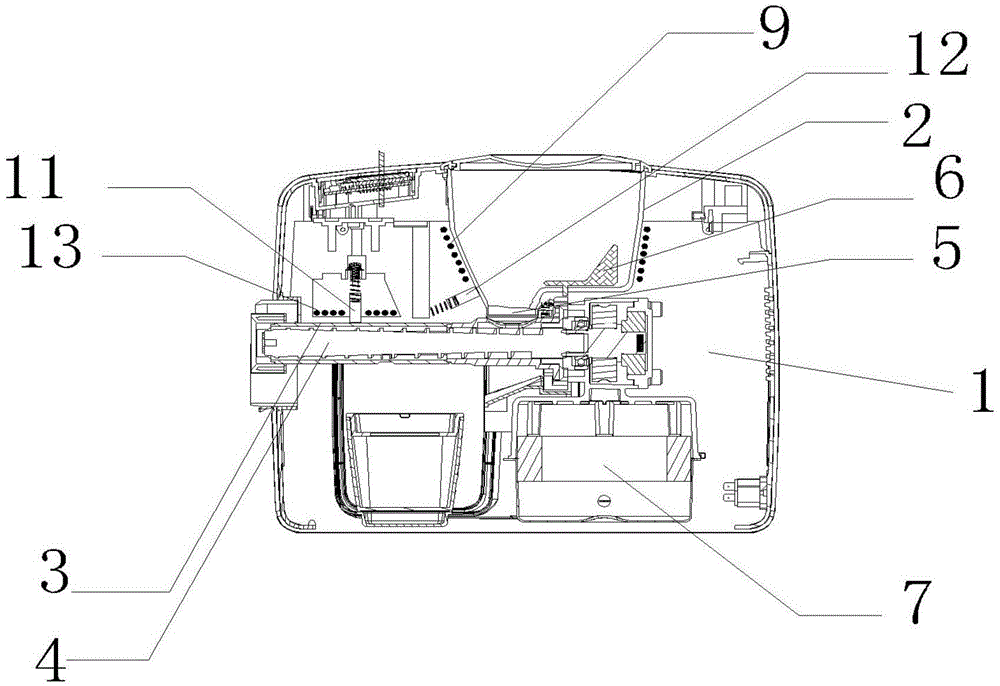

Household oil press

Owner:梁以钱

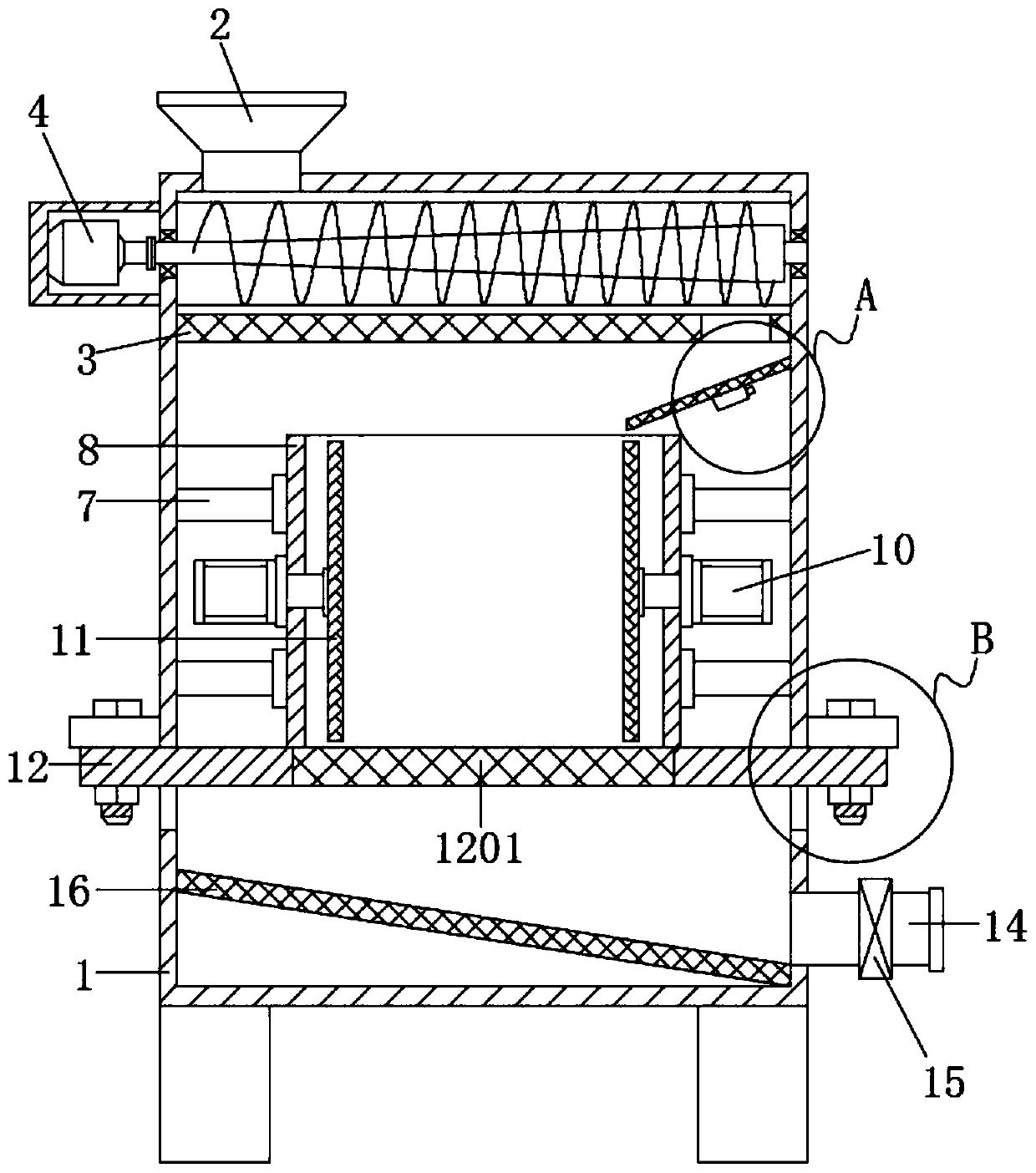

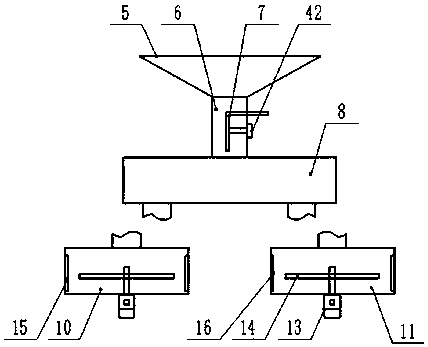

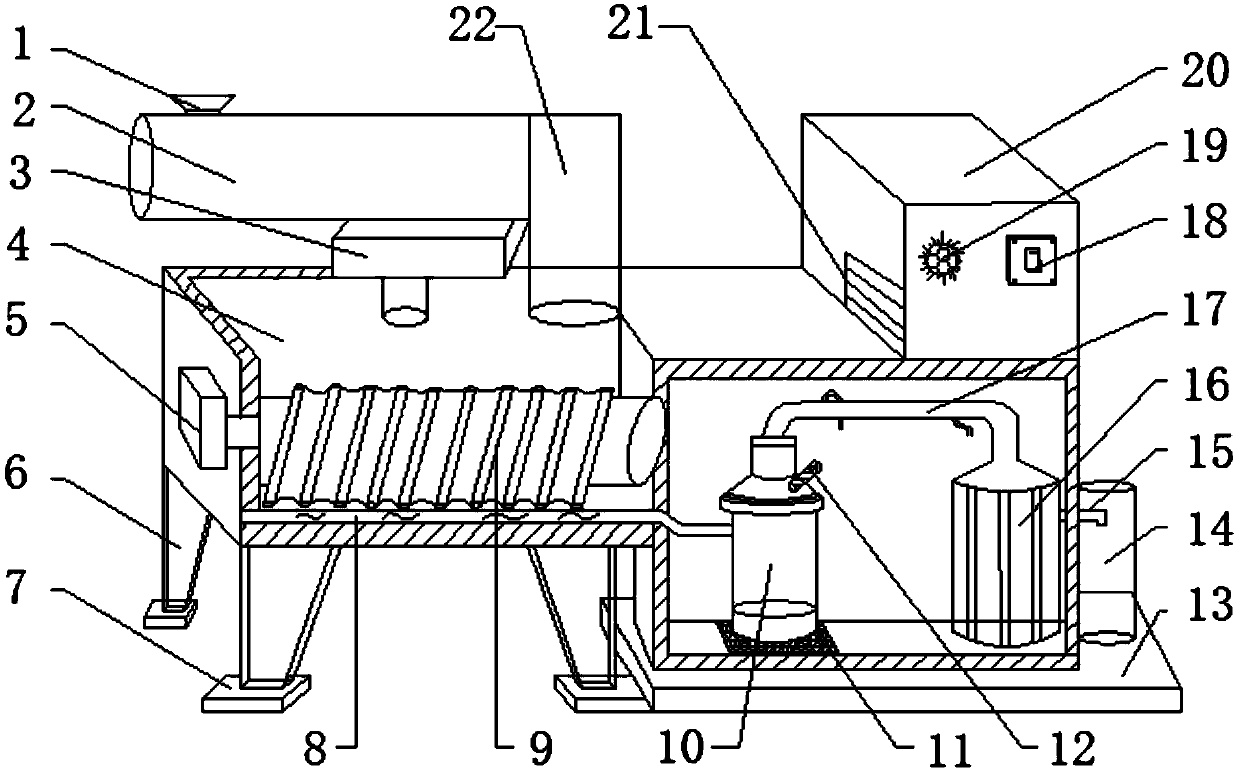

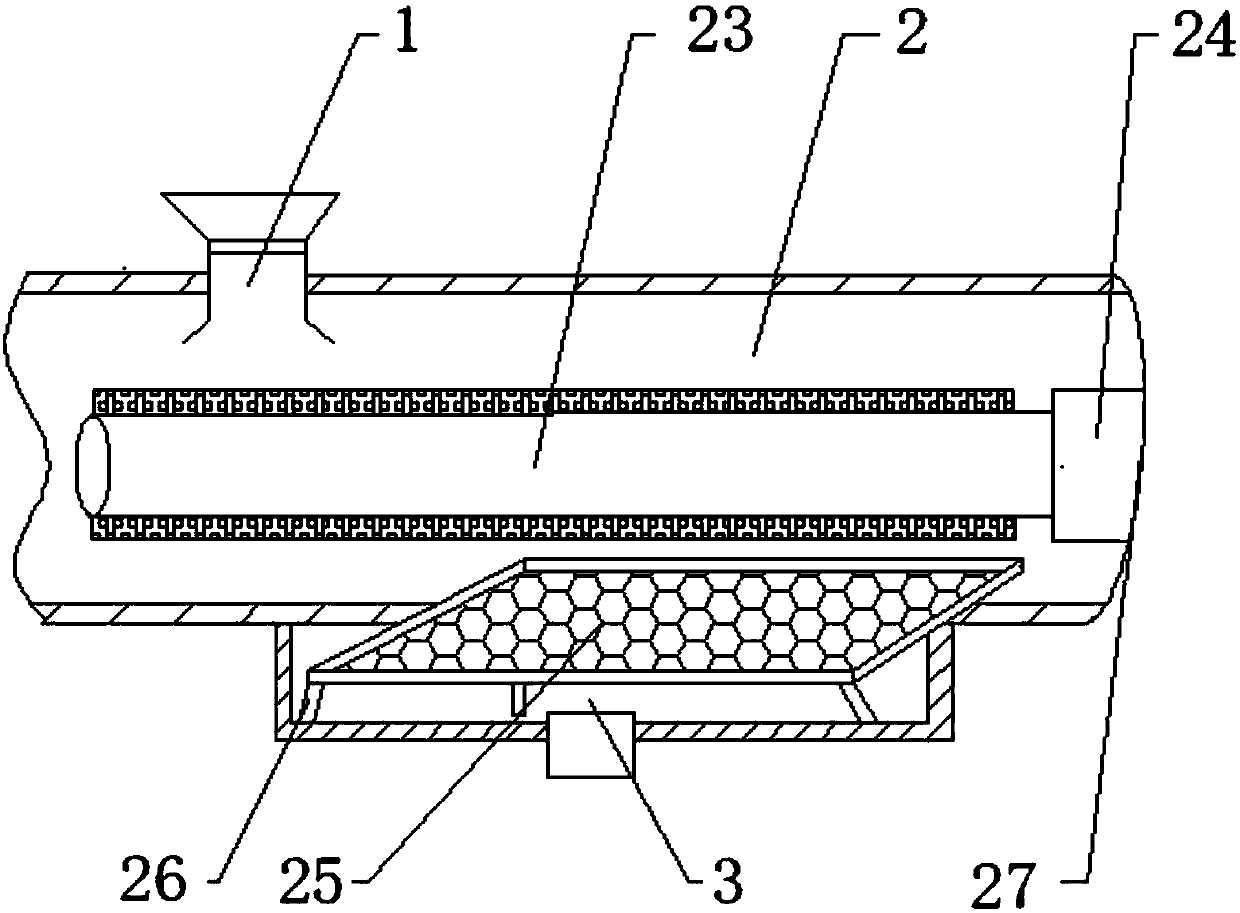

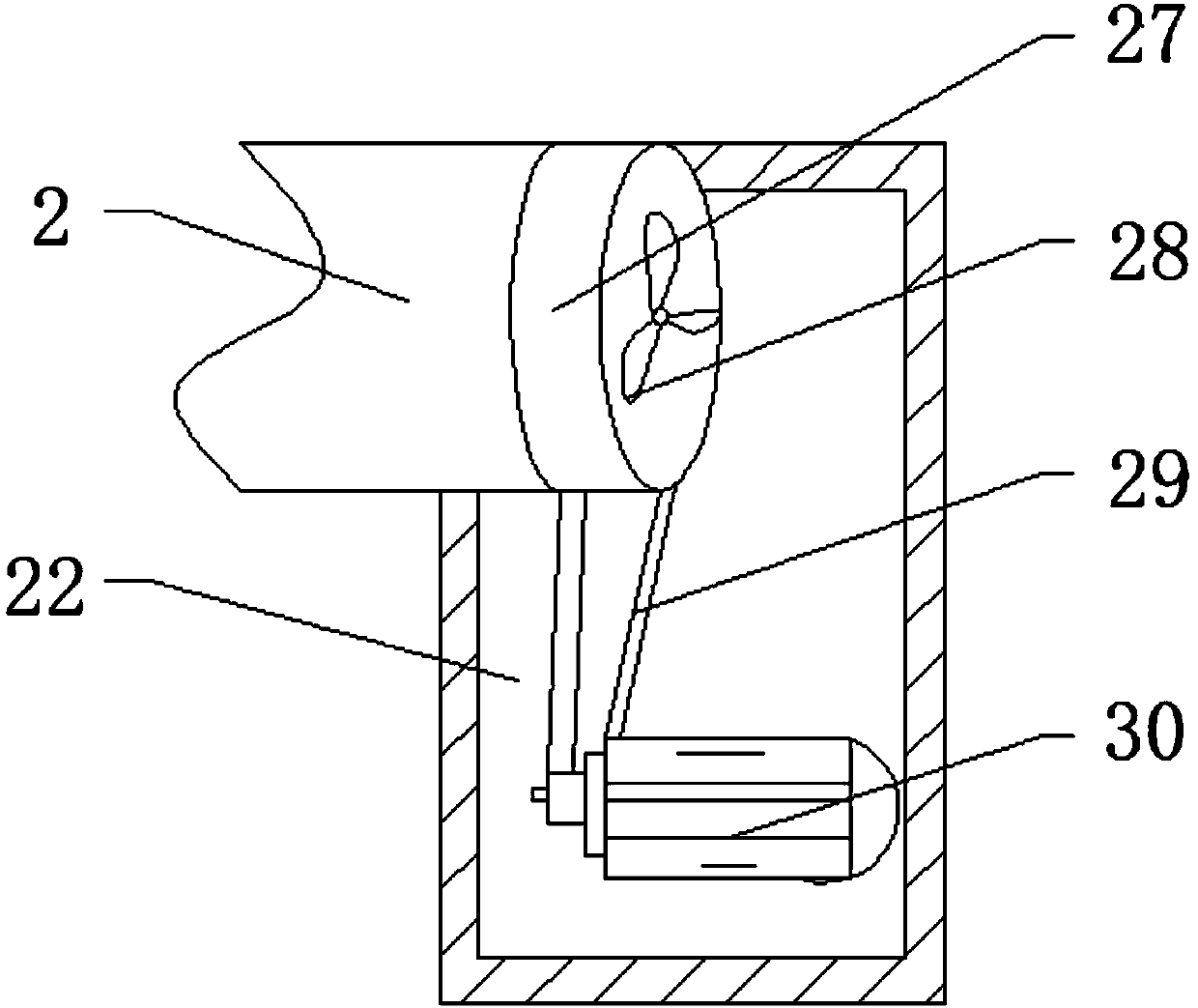

Multi-stage squeezing equipment for sesame oil

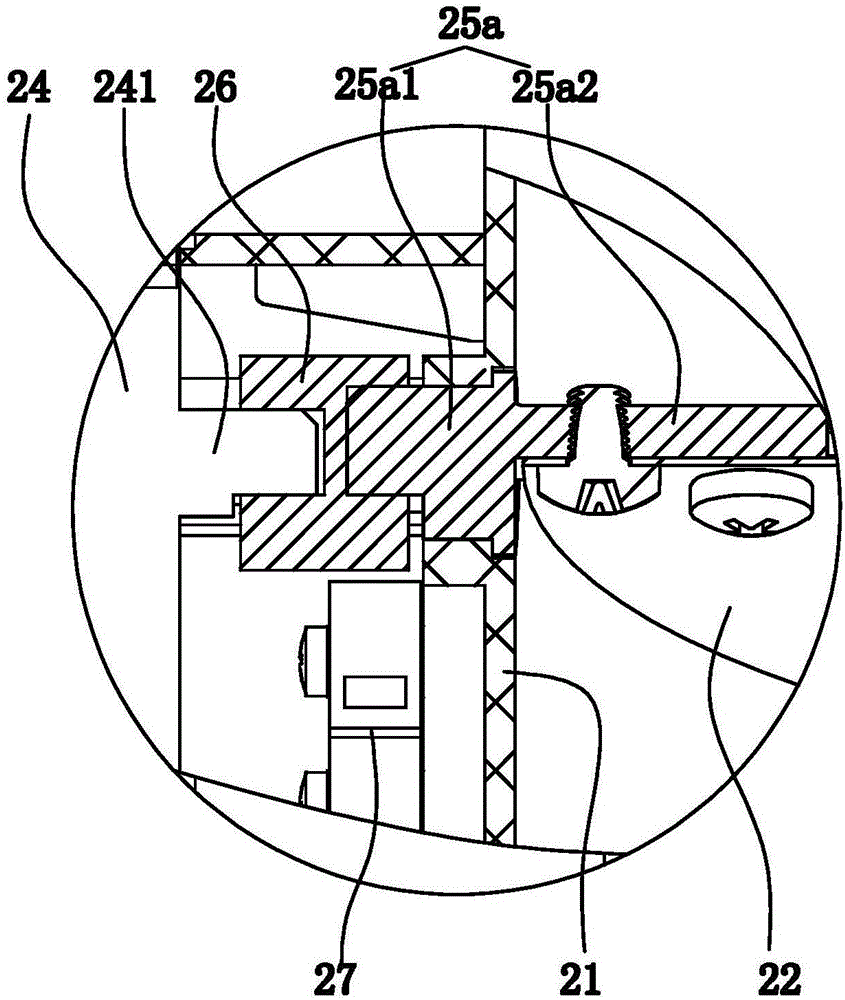

InactiveCN110356029AImprove the efficiency of oil extractionEasy to disassembleFatty-oils/fats productionPressesSesamum orientaleEngineering

The invention discloses multi-stage squeezing equipment for sesame oil, and belongs to the technical field of squeezing equipment. The multi-stage squeezing equipment comprises a shell, wherein a feeding hopper is inserted in the left side of the top of the shell, a baffle is fixedly connected between the side walls of an inner cavity of the shell, a rotating motor is fixedly connected to the leftside wall of the shell, the ends, close to each other, of two fixing rods are fixedly connected with a squeezing cylinder with openings in the top and the bottom, a transition mechanism is arranged on the right side wall of the inner cavity of the shell, reciprocating telescopic motors are symmetrically and fixedly connected to the left side wall and the right side wall of the squeezing cylinder,the telescopic ends of the reciprocating telescopic motors penetrate through the side wall of the squeezing cylinder to be fixedly connected with pressing plates, and the bottom of the squeezing cylinder abuts against a bottom plate. According to the multi-stage squeezing equipment, the squeezing cylinder, the bottom plate, the reciprocating telescopic motors and the pressing plates are arrangedso that primarily-crushed sesame raw materials can be subjected to high-efficiency reciprocating squeezing to obtain oil through the reciprocating telescopic motors and the pressing plates, the squeezed-out sesame oil can flow to the lower portion of the squeezing cylinder through filter screens in the bottom plate and is discharged through a discharging pipe, and the squeezing efficiency of the sesame oil is improved.

Owner:ANHUI HUAYU FLAVORING FOOD

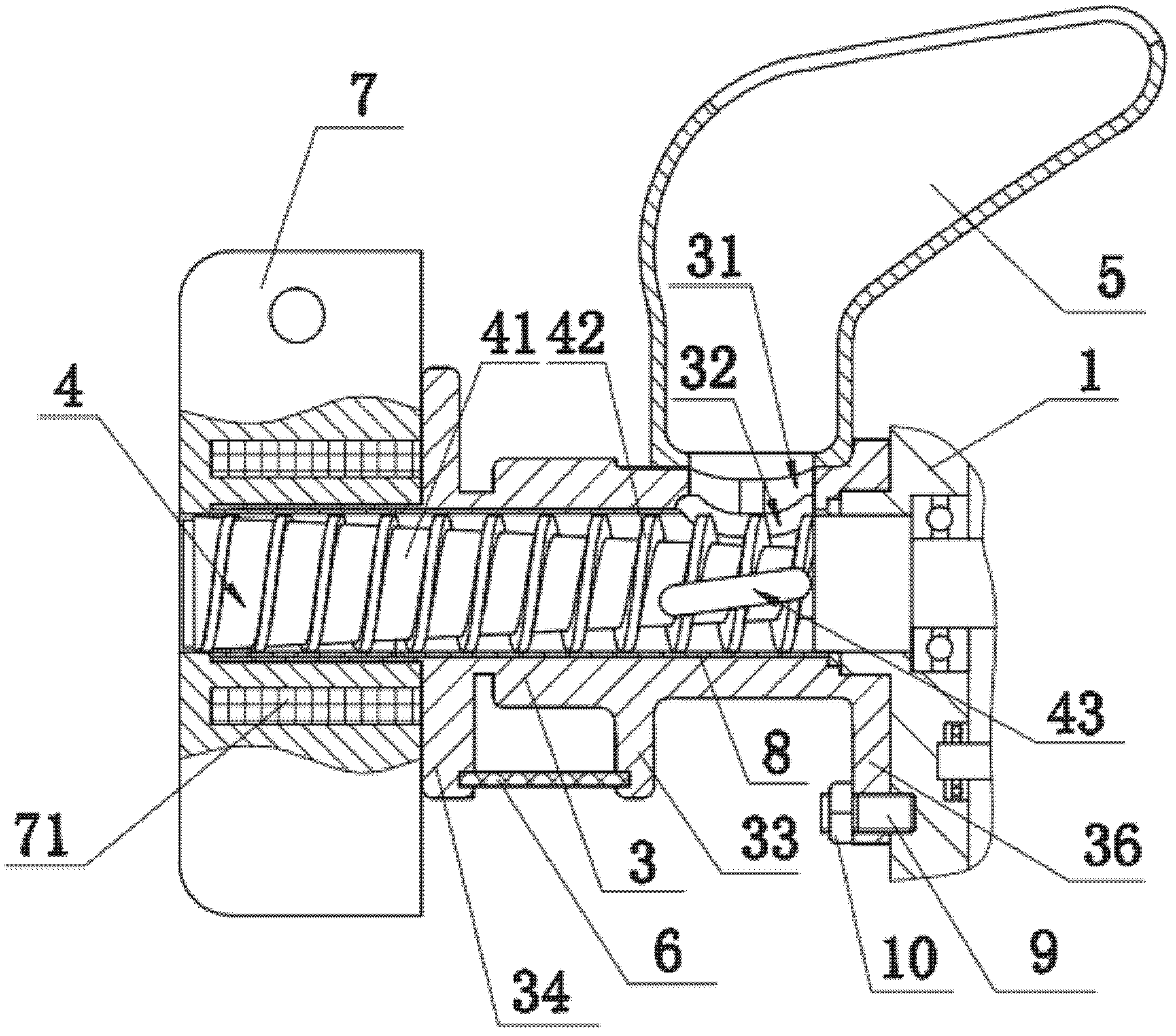

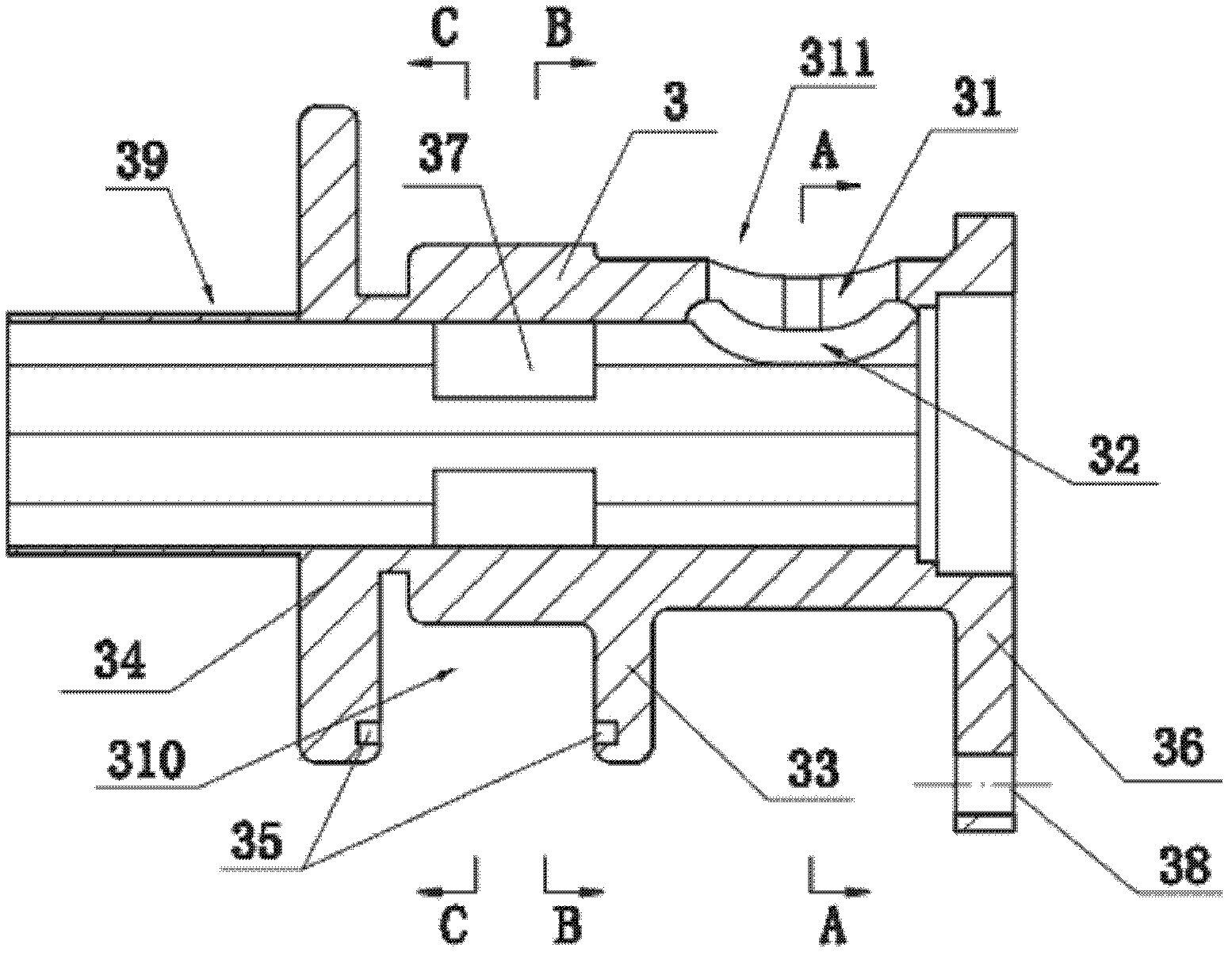

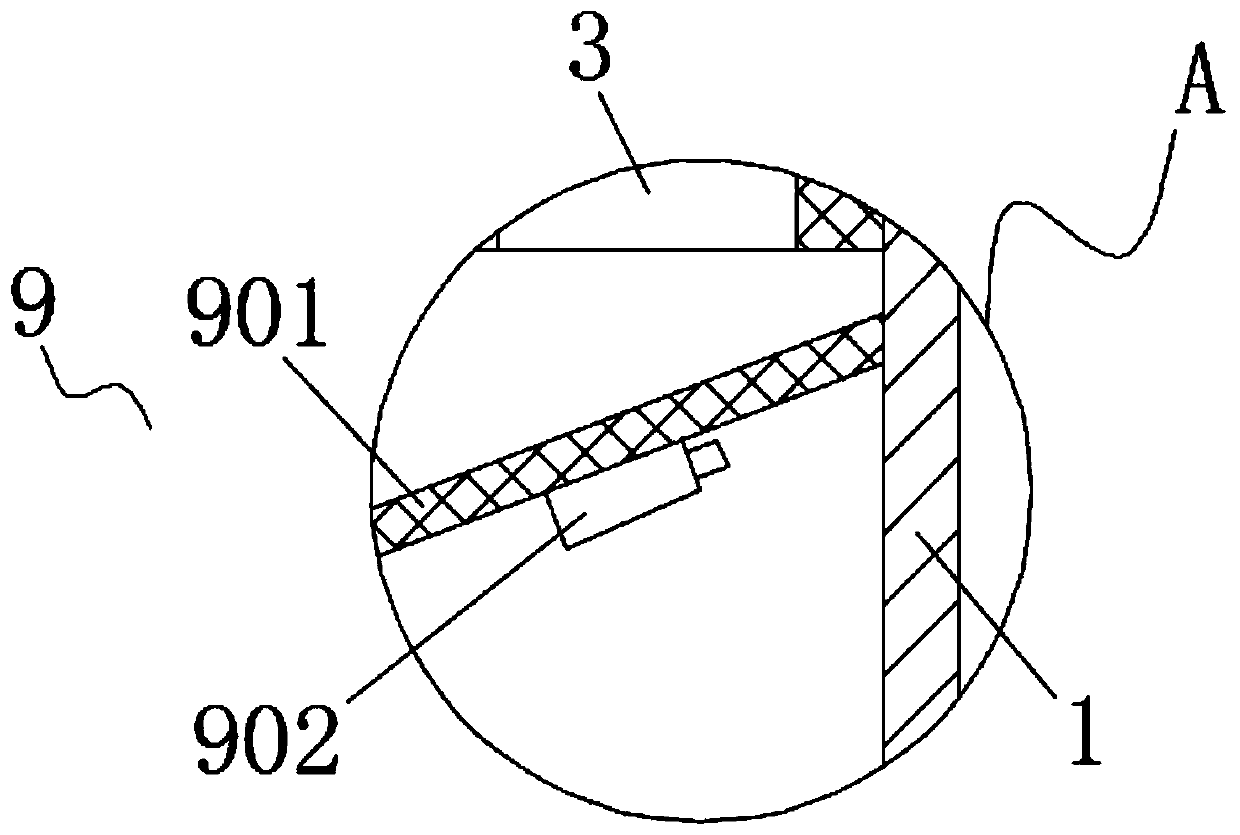

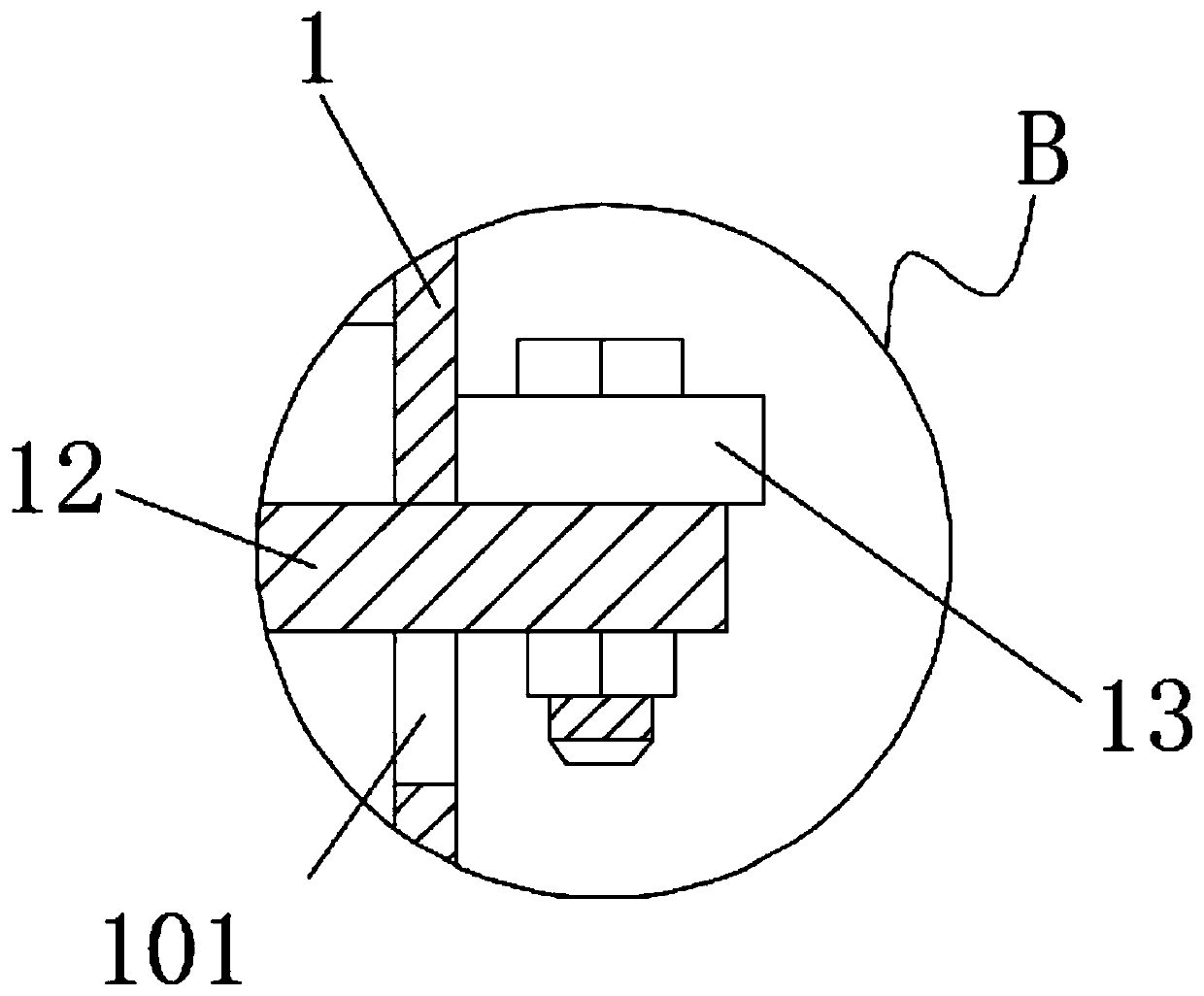

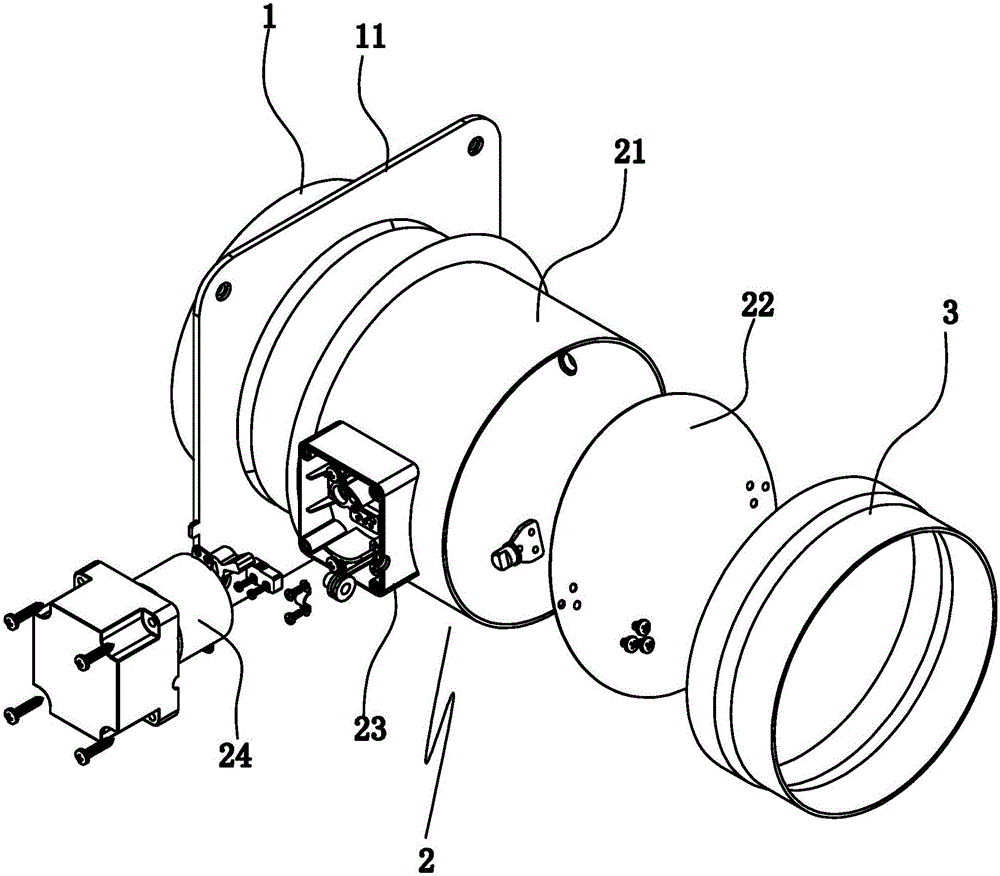

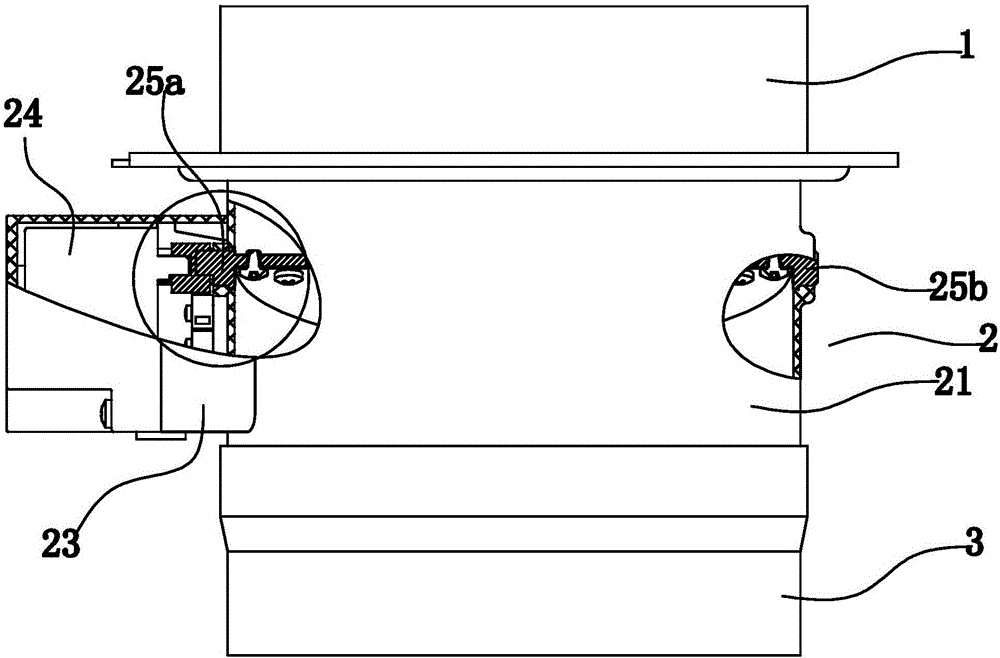

Electric control air-return-resistant check valve for exhaust hood

InactiveCN106382397AImprove stabilityAvoid the problem of air volume lossDomestic stoves or rangesOperating means/releasing devices for valvesAir volumeEngineering

The invention discloses an electric control air-return-resistant check valve for an exhaust hood, and aims to ensure that a valve plate can be opened and closed automatically, effectively solve the problem about air loss of the exhaust hood in an oil fume emission process, and then improve the oil fume suction efficiency. The electric control air-return-resistant check valve comprises a check valve body, wherein the check valve body comprises a check valve main sleeve, the valve plate, a motor seat and a motor; the two ends of the check valve main sleeve are open; the valve plate is arranged in the check valve main sleeve by rotating a valve plate rotation shaft; the motor seat is arranged on the outer side surface of the check valve main sleeve; the motor is arranged on the motor seat; a motor shaft of the motor is connected with the valve plate rotation shaft through a crankshaft, and coaxially arranged with the valve plate rotation shaft; and a micro switch matched with the crankshaft is also arranged on the motor seat.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

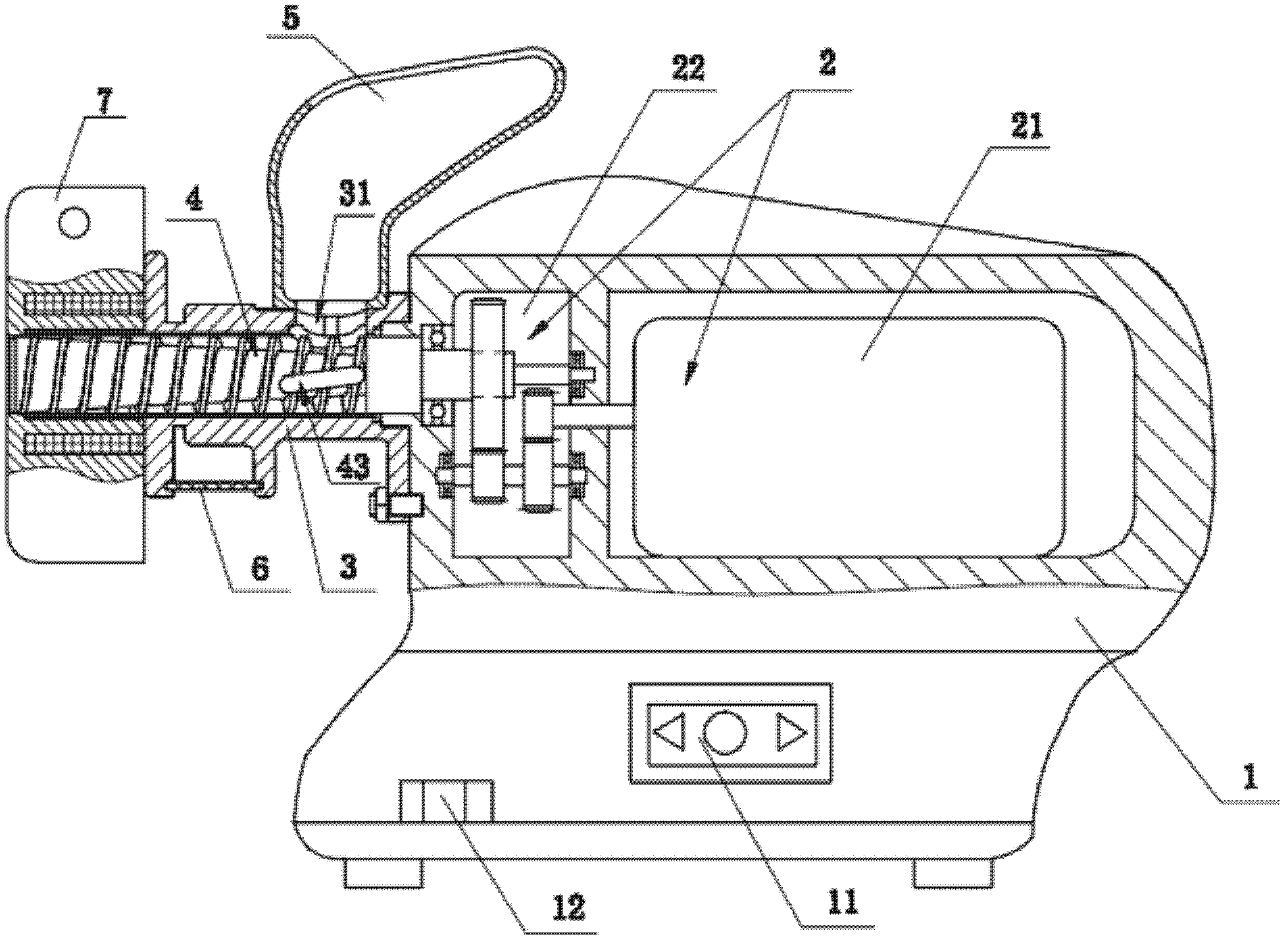

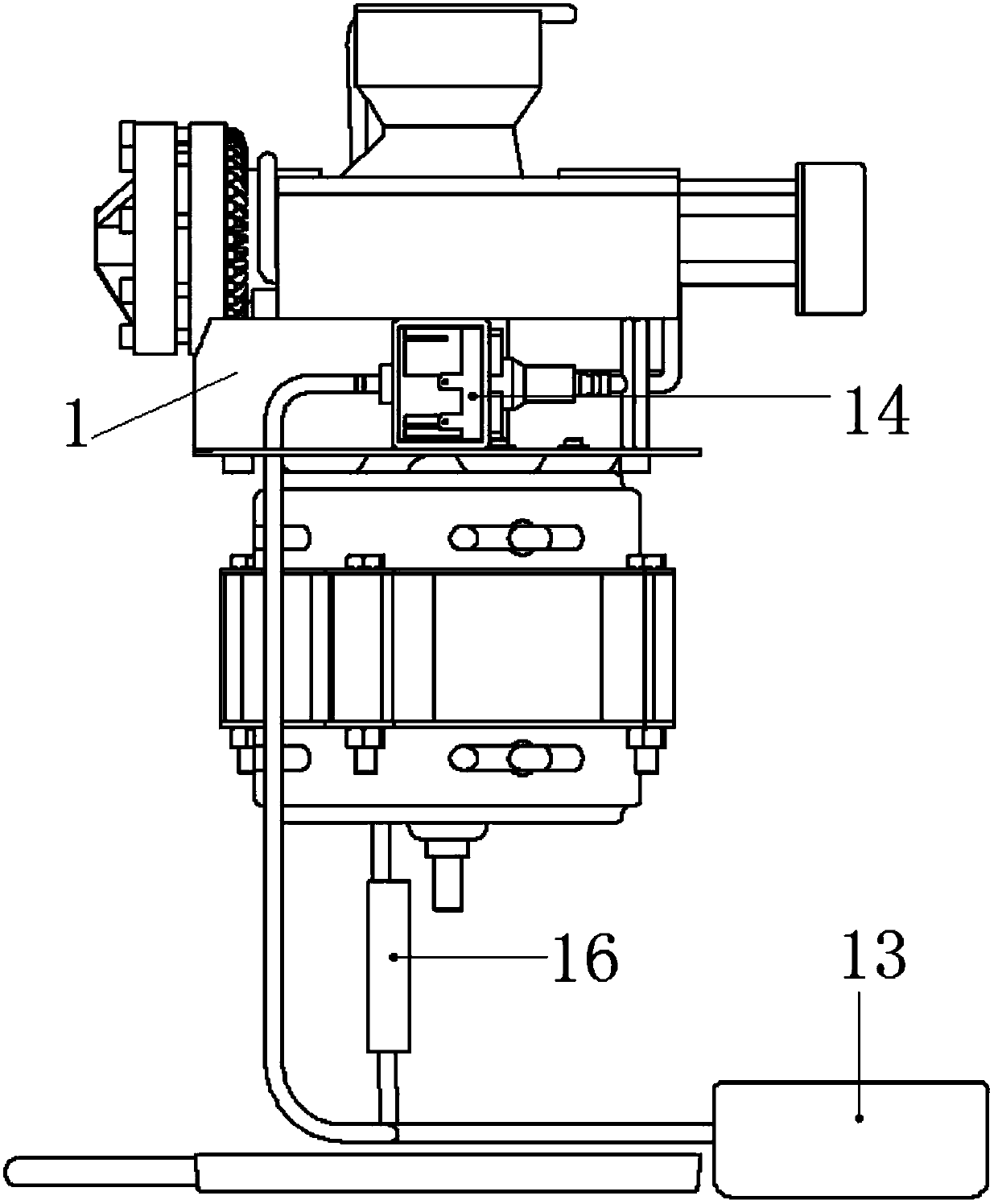

Automatic cleaning oil press

The invention discloses an automatic cleaning oil press. The automatic cleaning oil press comprises a shell, a pressing module, a cleaning device and an opening and closing device; the pressing moduletransversely penetrates through the shell, and consists of a pressing cavity, a screw rod arranged in the pressing cavity, a power connecting mechanism arranged at one end of the screw rod and an unloading mechanism arranged above a middle section of the pressing cavity; a feed opening is formed in the middle section of the pressing cavity; the internal of the unloading mechanism is a funnel cavity; the funnel cavity is provided with an upper end feed port and a lower end opening; the lower end opening is in butt joint with the feed opening; the pressing cavity is divided into an oil pressingsection and an oil return section, which are respectively positioned on the two sides of the feed opening; a slag outlet end is arranged at one end of the pressing cavity, and an oil outlet end is arranged at the other end; a heating device is arranged on the outer side of the pressing cavity; the opening and closing device comprises one or more opening and closing mechanisms; the opening and closing mechanisms are provided with cleaning nozzles; and the cleaning device is connected with cleaning nozzles through pipelines. The automatic cleaning oil press is safe, efficient, time-saved, convenient, free of blocking slag and high in oil pressing efficiency.

Owner:深圳市云匠科技有限公司

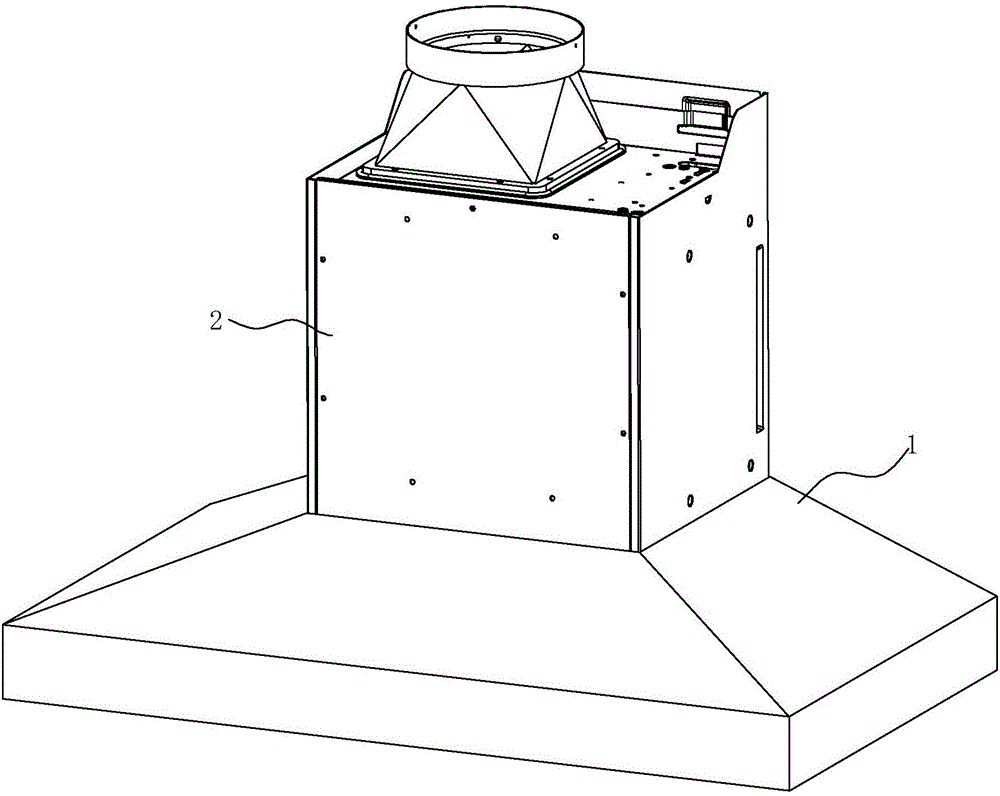

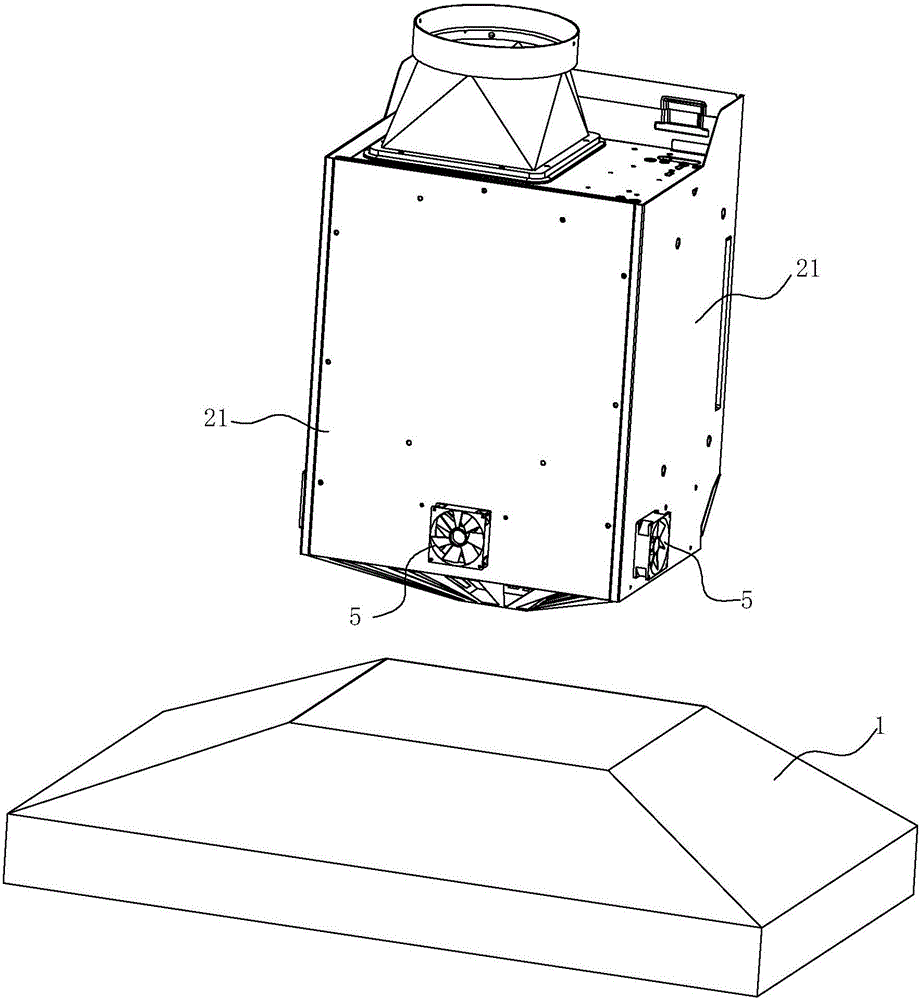

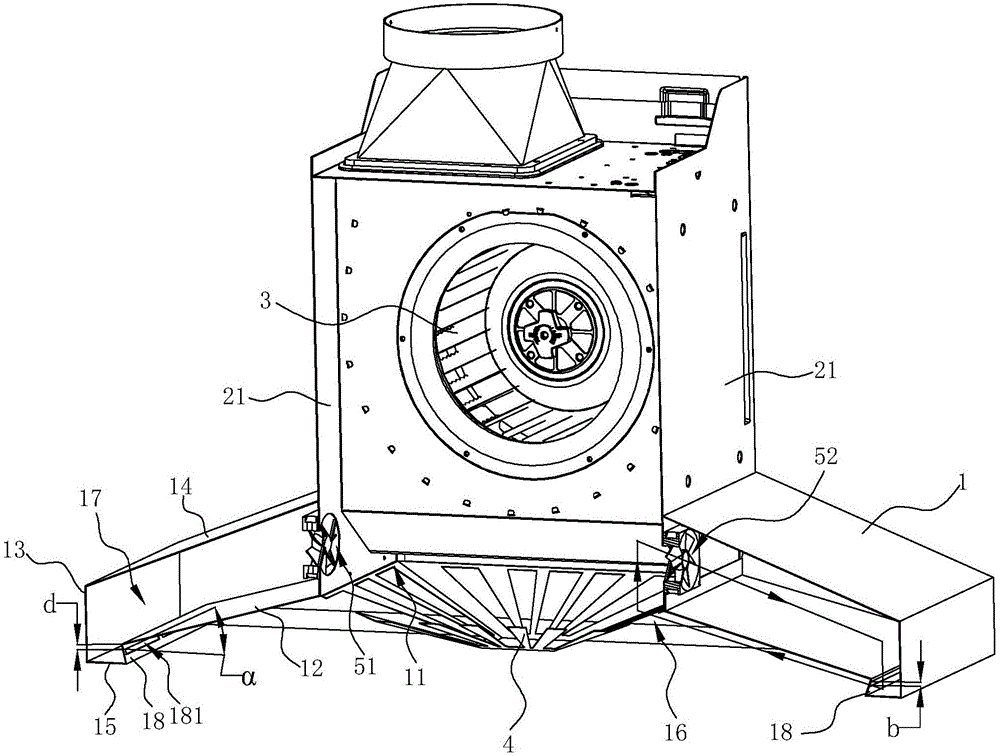

Top suction type extractor hood

ActiveCN106524267APrevent escapeSolve problems that block the flow of air to the range hood inletDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

The invention discloses a top suction type extractor hood which comprises an exhaust fume collecting hood and an auxiliary fan for injection. The exhaust fume collecting hood is concaved upwards to form an exhaust fume collecting cavity. The exhaust fume collecting hood is provided with an air inlet. A cavity is formed around the air inlet in the exhaust fume collecting hood. An air outlet of the auxiliary fan faces towards the interior of the cavity. The bottom of the outer side of the cavity is provided with an injection air outlet which faces towards the air inlet in an upward inclined mode. The top suction type extractor hood is characterized in that the lowest point of the air inlet of the auxiliary fan is not lower than the air inlet of the exhaust fume collecting hood, and sucks gas entering the air inlet of the exhaust fume collecting hood, and the cavity, the injection air outlet, the exhaust fume collecting cavity, the air inlet of the exhaust fume collecting hood and the auxiliary fan form a circulation flow path for gas circulation flow. Gas circularly flows in the circulation flow path, negative pressure is produced, rising exhaust fume is guided to flow and be gathered towards the air inlet of the extractor hood, the exhaust fume collecting effect is greatly improved, and exhaust fume is prevented from being escaping.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method for preparing rapeseed oil in inertia pressurization mode

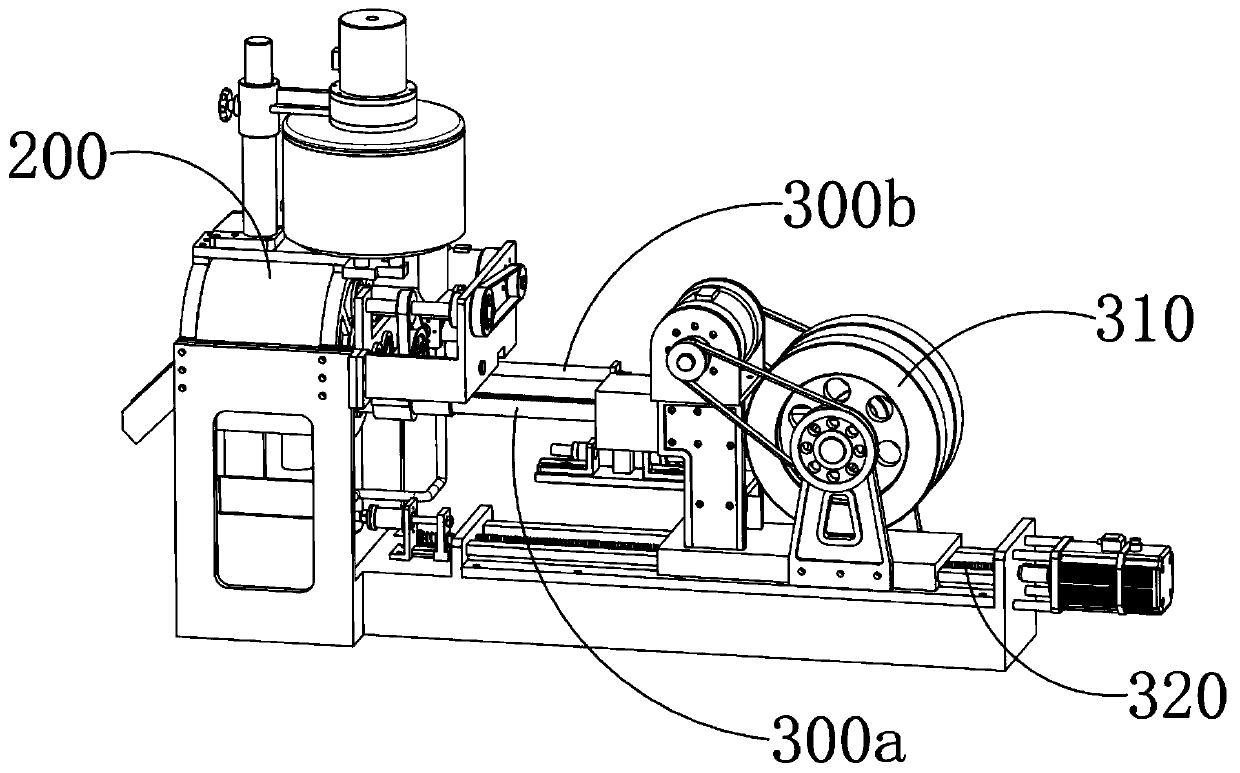

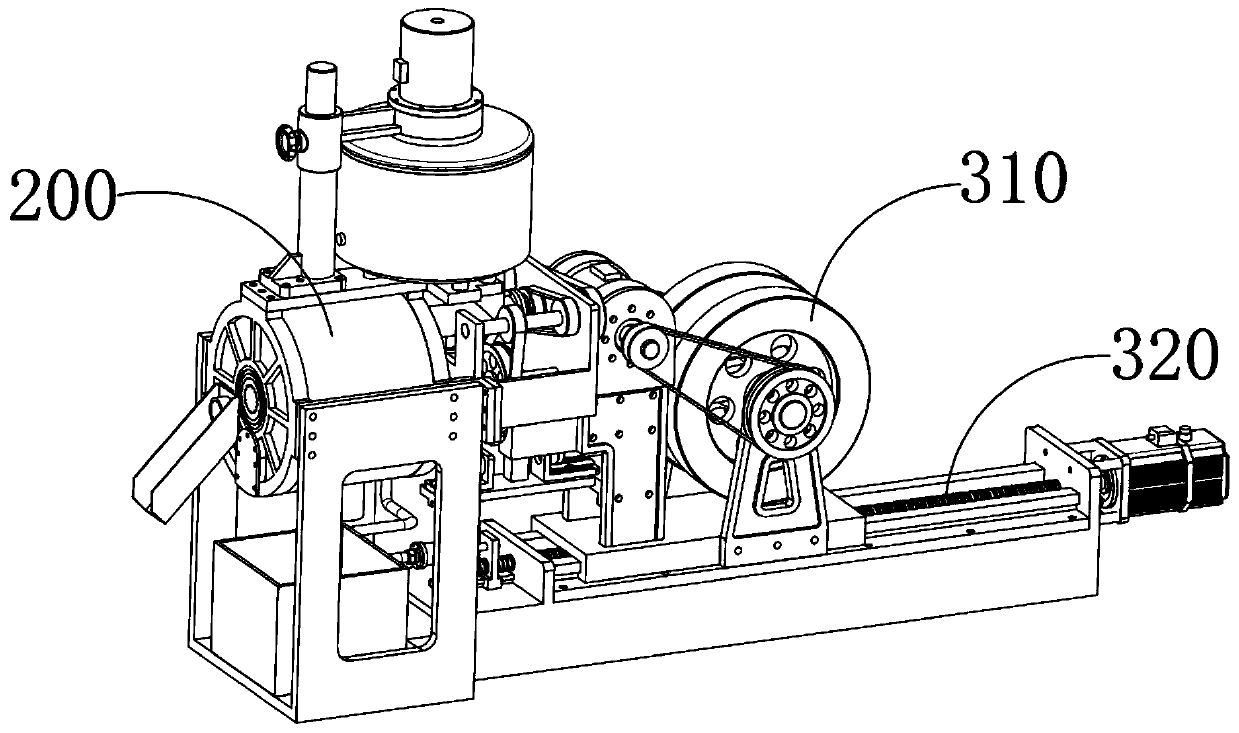

InactiveCN111117765AReduce oil contentIngenious structureFatty-oils/fats productionVegetable oilFeed drive

The invention provides a method for preparing rapeseed oil in an inertia pressurization mode. The method comprises the following steps: 1, a feeding mechanism receives the power of a power driving device and sequentially conveys a stir-fried oil material into a pressing cage in an oil pressing barrel; 2, a flywheel pressurizing mechanism and a feeding driving mechanism are started, the feeding driving mechanism drives the flywheel pressurizing mechanism to move close to a front fixing plate, and the flywheel pressurizing mechanism continuously impacts a pressing push rod and enables the pressing push rod to press the oil material; 3, one part of vegetable oil pressed from the oil material enters a fixed outer cylinder through an oil outlet hole and a through hole, and the other part of thevegetable oil enters the fixed outer cylinder through a filter screen and a connecting channel and then is downwards discharged into a collecting container through the oil outlet pipe; and 4, in theprocess of step 2 and step 3, when the pressing cage containing the oil residues rotates to be aligned with the discharging push rod, the discharging push rod is inserted into the pressing cage, and the oil residues in the pressing cage are discharged outwards through a discharging pipe and a discharging channel.

Owner:六安七茗道机电科技有限公司

Method for extracting microbial oil

ActiveCN101985637BEfficient extractionHigh extraction rateMicroorganism based processesFermentationOil and greaseMicrobial oil

The invention provides a method for extracting microbial oil, which comprises the following steps: (1) allowing an oil-producing microbial strain to ferment and obtaining fermentation liquor; (2) regulating the pH value of the fermentation liquor obtained by the step (1) to 3.5 to 4.5, and allowing microbes to autolyze; (3) extracting by adding an extracting solvent into the fermentation liquor obtained by the step (2), and collecting upper mixed oil; (4) extracting again by adding the extracting solvent into the lower solution obtained by the extraction and separation in the step (3), and collecting upper mixed oil; and (5) mixing the upper mixed oil obtained by the step (3) and the upper mixed oil obtained by the step (4), distilling, recovering the extracting solvent and obtaining the microbial oil product. The method can extract the oil in the cells of microbes effectively, has high oil extraction rate and high oil extraction efficiency, makes process simple and is favorable for large-scale production.

Owner:CABIO BIOTECH WUHAN CO LTD

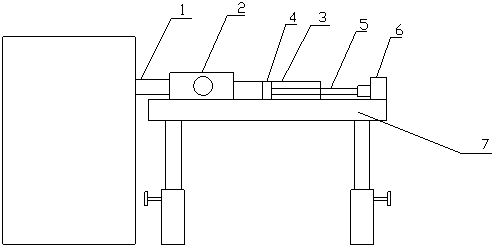

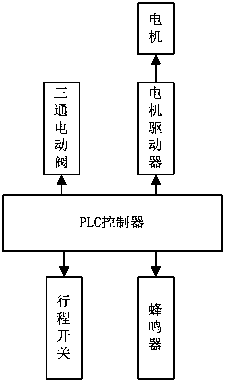

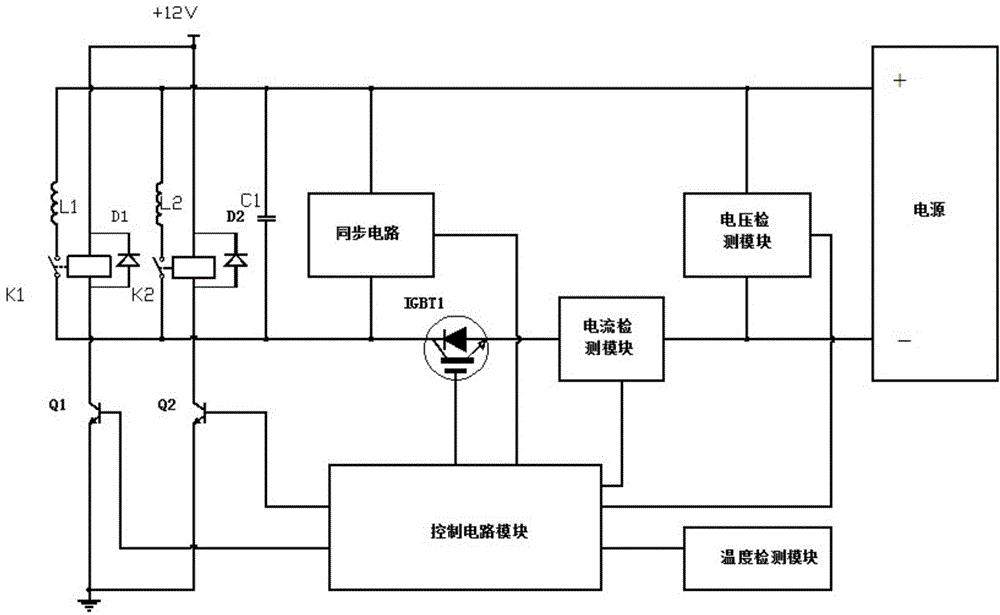

An automatic oil sampling device for oil and gas charging and an oil sampling method thereof

InactiveCN107702945AImprove oil extraction efficiencyImprove the efficiency of oil extractionWithdrawing sample devicesElectricityAutomatic control

The invention relates to an automatic oil sampling device for oil and gas charging and an oil sampling method thereof. The device includes a tee-joint electrically operated valve. A first end port ofthe tee-joint electrically operated valve is in threaded connection with an oil sampling port, a second end port of the tee-joint electrically operated valve is communicated with an outlet end of an oil sample pipe, and a third end port of the tee-joint electrically operated valve is an oil discharging port. A piston extends into the inlet end of the oil sample pipe, and is connected to a motor through a screw so that the piston is driven to move along the length direction of the oil sample pipe. The inlet end and the outlet end of the oil sample pipe are provided with a travel switch respectively. The travel switches, the tee-joint electrically operated valve and the motor are electrically connected to a PLC controller. Beneficial effects of the device and the method are that an oil discharging path is controlled by the tee-joint electrically operated valve, the motor drives the screw to drive the piston to move in the oil sample pipe so as to extract an oil sample, automatic controlled oil sampling is achieved through control by the PLC controller, and the oil sampling efficiency is increased.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

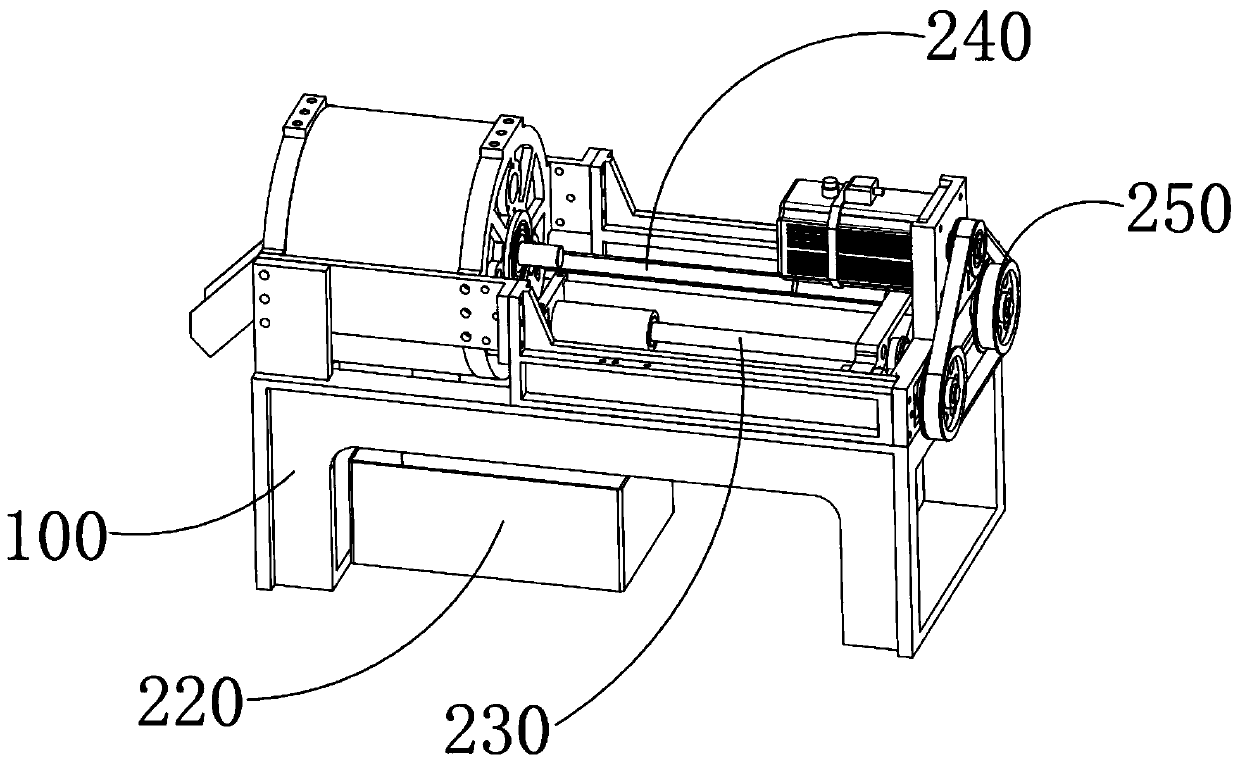

Multi-cylinder circulating pressing method of rapeseed oil

InactiveCN111117764AHigh degree of automationIngenious structureFatty-oils/fats productionOil and greaseRapeseed

The invention provides a multi-cylinder circulating pressing method of rapeseed oil. The method comprises the following steps: a user places steamed / fried oil materials into a feeding mechanism, a rotary driving mechanism drives oil pressing cylinders to do 60 DEG clockwise step-by-step rotary motion around the axis of the oil pressing cylinders around a middle barrel, and when each oil pressing cylinder rotates to be aligned to and communicated with a feeding opening, the feeding mechanism conveys the oil material in the feeding mechanism into the oil pressing cylinder; then, when each oil pressing cylinder rotates to be aligned to and communicated with a plunger opening, a pressing driving mechanism drives a pressing rod to be inserted into the oil pressing cylinder from the plunger opening and extrudes and presses oil in the oil pressing cylinder; then, the oil material is converted into oil and oil residues, and the oil is discharged outwards through an oil discharging pipe; and finally, when each oil pressing cylinder rotates to be aligned to and communicated with a residue discharging opening, a residue discharging driving mechanism drives a residue discharging block to movevertically downwards and slide into the residue discharging opening from the second opening of the oil pressing cylinder, and the oil residues are ejected outwards from the residue discharging opening, fall into the residue discharging pipe and then are discharged outwards from the residue discharging pipe.

Owner:六安七茗道机电科技有限公司

Simple and efficient hydraulic oil extraction equipment

InactiveCN108263010AImprove crushing rateImprove the efficiency of oil extractionGrain treatmentsPressesCircular discTemperature control

The invention discloses simple and efficient hydraulic oil extraction equipment, which comprises a basic base, wherein a feeding device is arranged at the front side of the upper end of the basic base; a hydraulic oil extraction device is arranged at the back side of the upper end of the basic base; the feeding device consists of an inclination angle conveyor, a feeding funnel, a feeding tube, a reverse L-shaped quantity control plate, a crushing box body, a roller device, a heat extraction temperature control box, a cold extraction temperature control box and a vertical support frame; the hydraulic oil extraction device consists of a vertical fixing frame, a horizontal connecting frame, a lead screw, a second rotating motor, a crossed rotating frame, a tubular support frame, a circular disc-shaped rotating frame, an oil extraction barrel, a compression air cylinder, a press plate, a third rotating motor and a driving gear; the oil extraction barrel is separated into an inner barrel body and an outer tube body; an oil storage cavity is formed between the inner barrel body and the outer tube body. The simple and efficient hydraulic oil extraction equipment has the beneficial effectsthat the structure is simple; the practicability is high.

Owner:湖北双明粮棉油有限公司

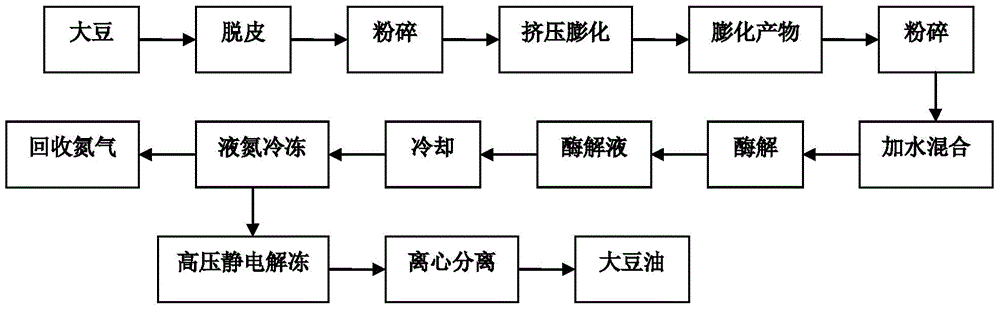

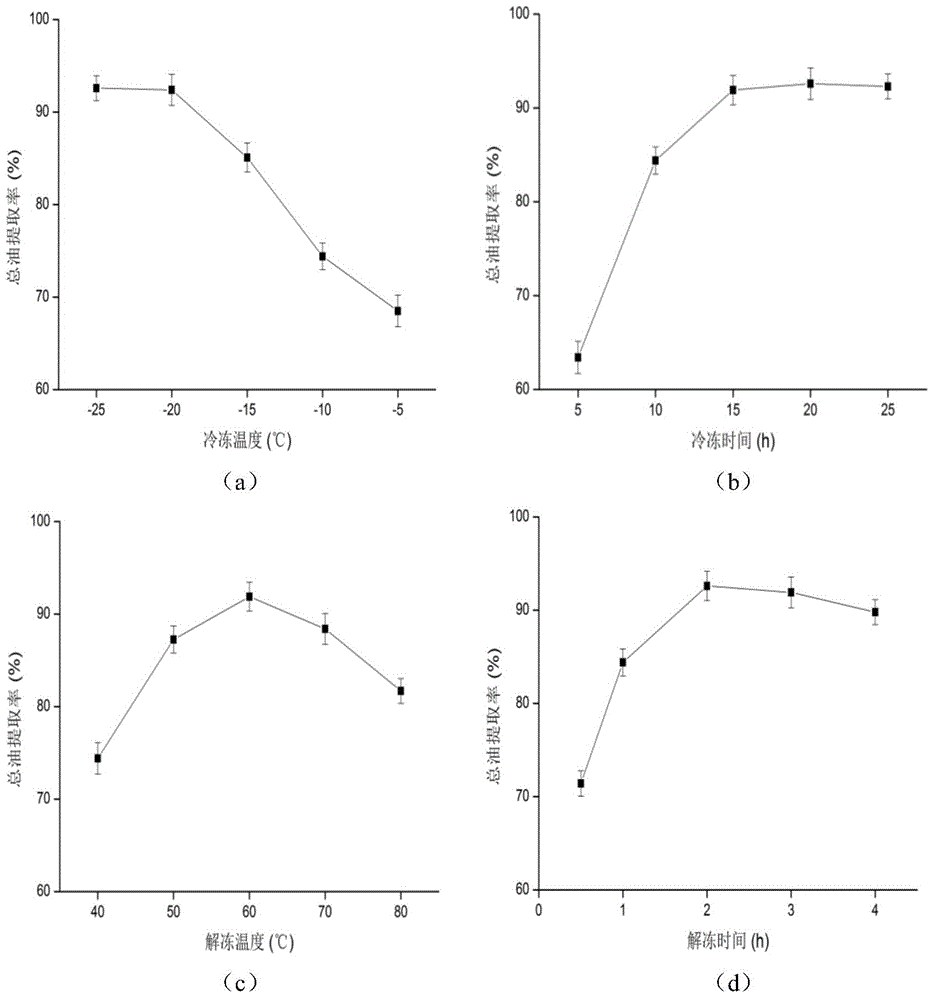

Method for preparing soybean oil by aqueous enzymatic method and application thereof

ActiveCN104450154ALow peroxide valueImprove antioxidant capacityFatty-oils/fats refiningFatty-oils/fats productionAlkaline proteaseHydrolysate

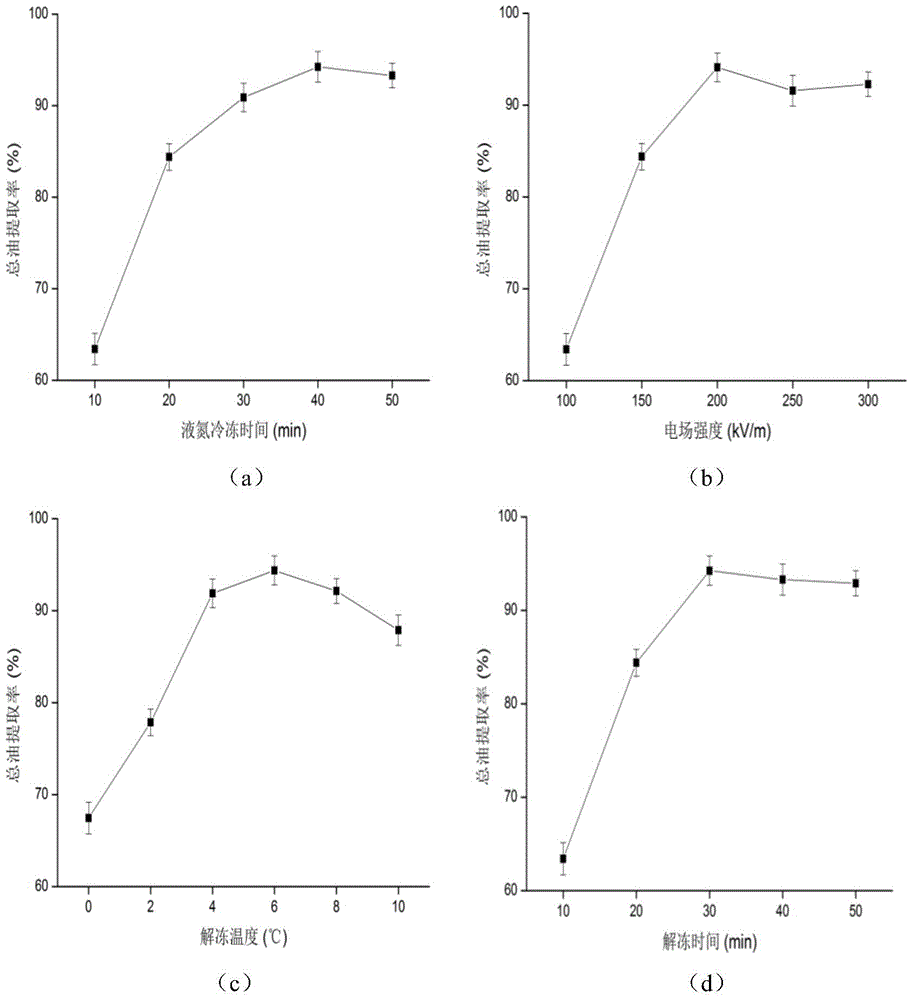

The invention discloses a method for preparing soybean oil by an aqueous enzymatic method and an application thereof, belonging to the technical field of plant oil extraction and processing. The method disclosed by the invention comprises the following steps: after cleaning and peeling soybeans, crushing the soybeans; then, extruding the crushed soybeans; after extrusion, crushing a puffed product; then, hydrolyzing the puffed product by using alkaline protease; freezing the hydrolysate by using a liquid nitrogen refrigeration method after hydrolysis; and finally unfreezing by virtue of a high voltage electrostatic method and carrying out centrifugal separation and unfreezing to obtain the soybean oil. The method disclosed by the invention has the characteristics of being short in oil extraction time and high in total oil extraction rate. Just in the freezing and unfreezing links, 93.1% of time in the method provided by the invention can be saved and the total oil extraction rate can reach 95.36%. Meanwhile, the extracted soybean oil has relatively low peroxide value, p-fennel value and TOTOX value, and the quality of the extracted oil is better.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

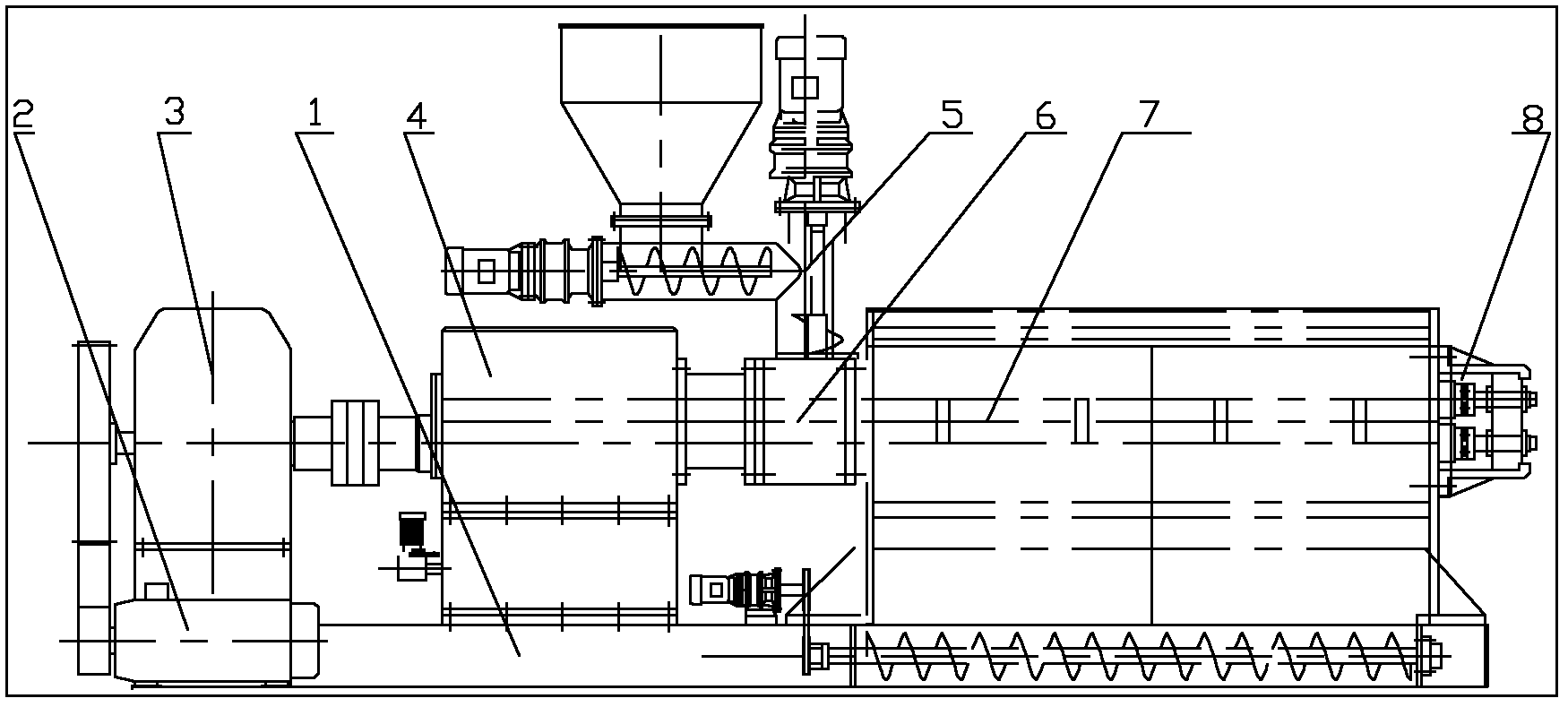

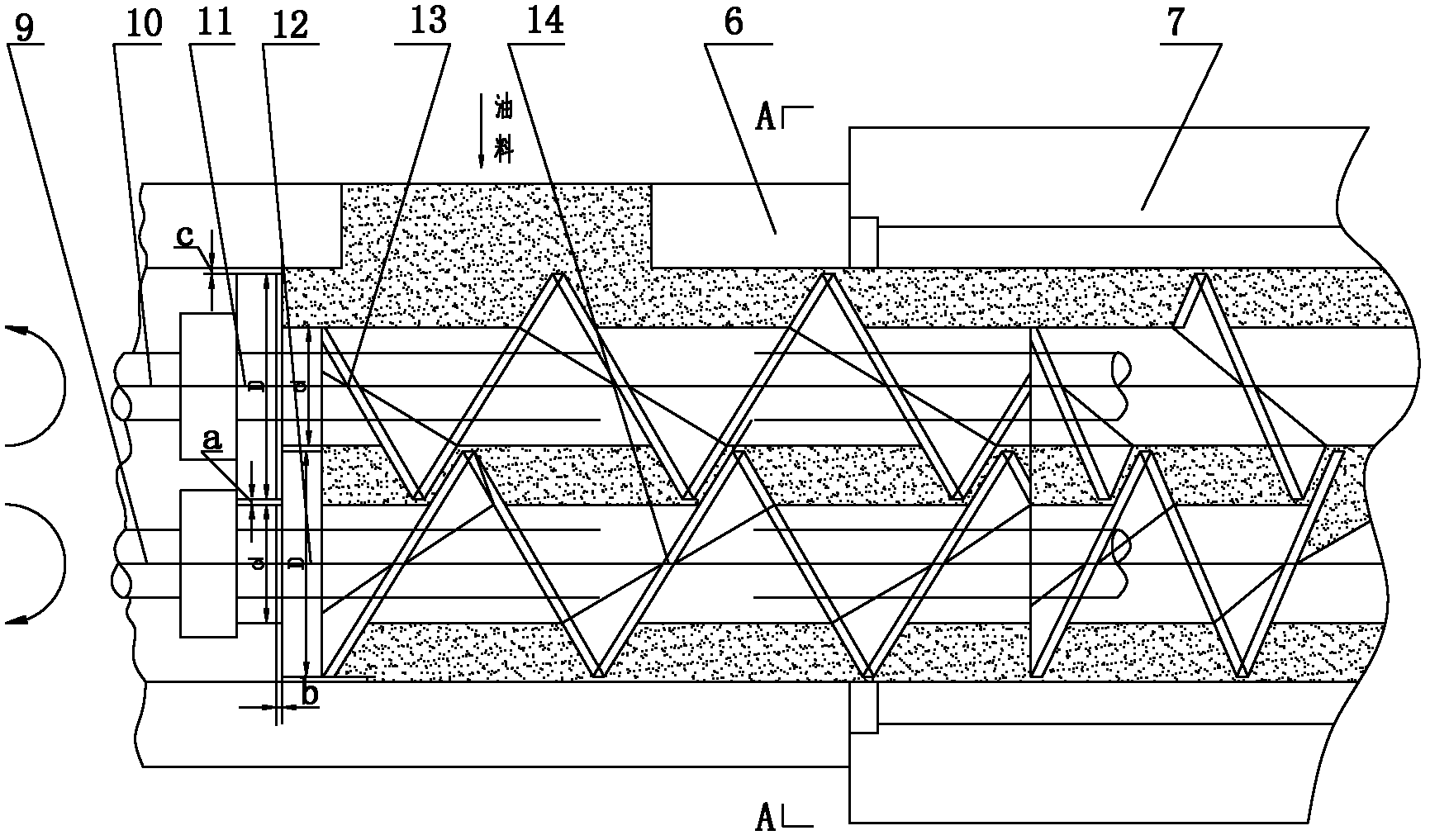

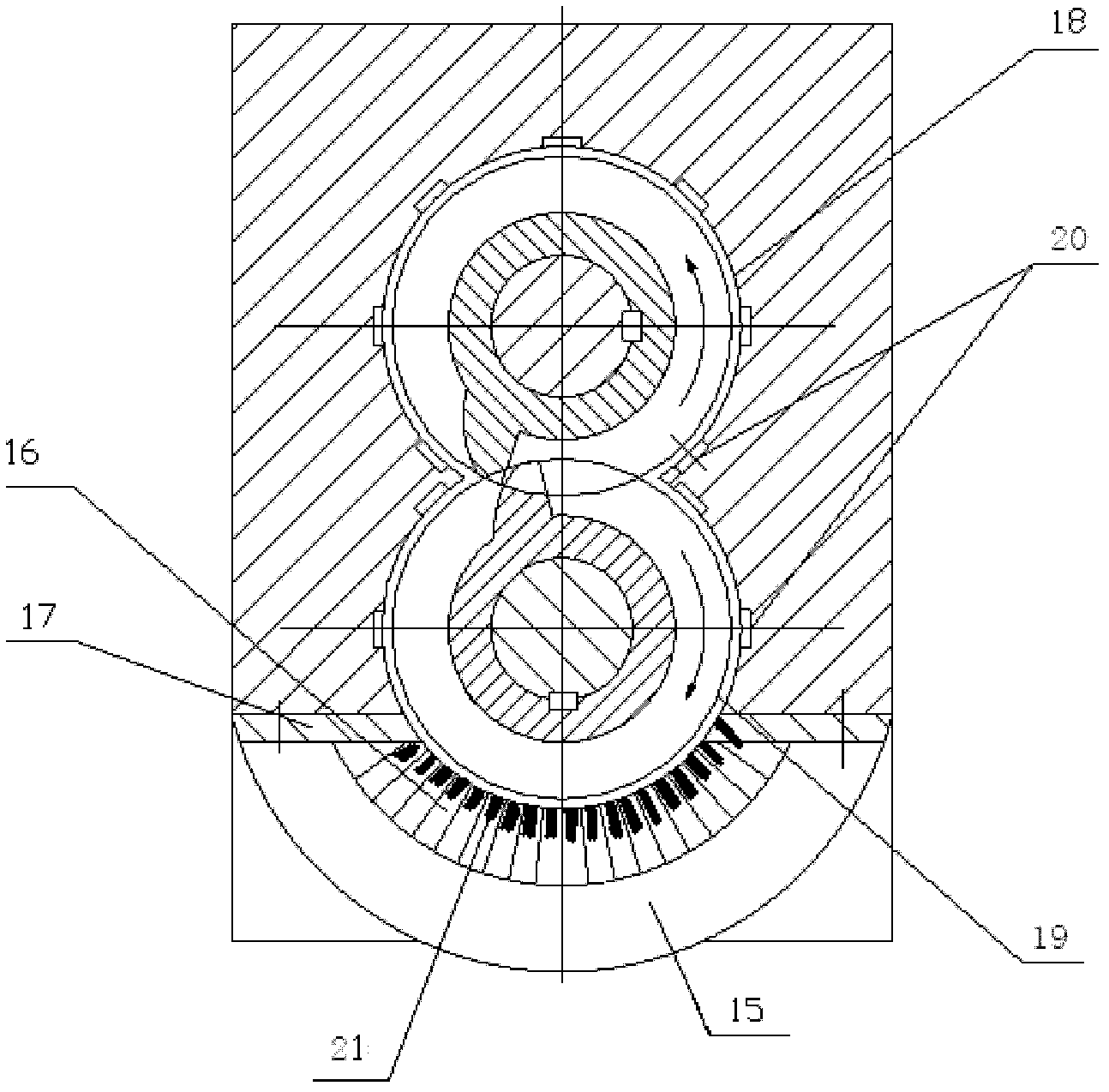

Double worm oil press capable of preventing oil materials from sliding out of chamber

The invention relates to a double worm oil press capable of preventing oil materials from sliding out of a chamber, comprising a frame base, a driving motor, a reduction gear, a torque distributor, a feeding base, a feeding device, a double worm oil pressing device and a residual cake discharging mechanism, wherein the driving motor and the reduction gear are connected to the frame base; the torque distributor is connected to the output end of the reduction gear; the feeding base is connected to the output end of the torque distributor; the feeding device is arranged on the feeding base; the double worm oil pressing device is connected to the feeding base; the residual cake discharging mechanism is positioned on the tail end of the double worm oil pressing device; the feeding base comprises a first material sending hole and a second material sending hole and a first mandrel and a second mandrel; the first and second mandrels are respectively sleeved with a first left spiral worm and a first right spiral worm and respectively positioned in the first material sending hole and the second material sending hole; and a plurality of slide-proof grooves are arranged on the inner walls of the first and second material sending holes in the direction of a generatrix. The double worm oil press disclosed by the invention solves the problem that the oil material may slide out of the chamber, improves the sealing property of the feeding end of the first pressing chamber, effectively prevents the oil material from flowing out of the double worm oil pressing device and has the advantages of high oil yield and high production efficiency.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI +1

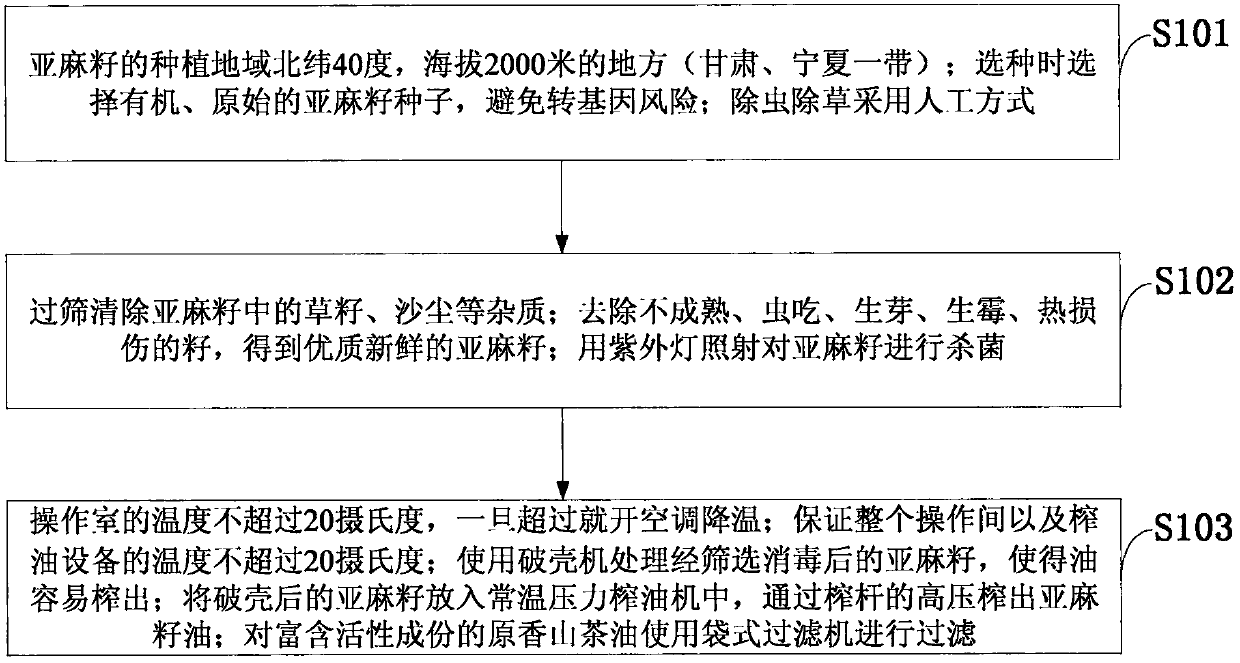

Organic original-fragrance linseed oil rich in active ingredients and preparation method thereof

InactiveCN108624397AThe method flow is simpleLow requirements for process conditionsFatty-oils/fats refiningBakery productsFlavorLinseed oil

The invention belongs to the technical field of herbaceous plant oil production, and discloses organic original-fragrance linseed oil rich in active ingredients and a preparation method thereof. The method comprises the steps that impurities in linseed is removed through sieving, and an ultraviolet lamp is used for irradiating the linseed for sterilization; and the temperature of an operation chamber does not exceed 20 DEG C, a hull breaking machine is used for treating the screened and disinfected linseed, the linseed subjected to hull breaking treatment is put into a normal-temperature pressure oil press, the linseed oil is pressed out through high pressure of a press rod, and the original-fragrance linseed oil rich in active ingredients is filtered by a bag type filter. According to thelinseed oil, the content of alpha-linolenic acid is 56g / 100g-58g / 100g, and the content of linoleic acid is 16g / 100-18g / 100 g. The linseed oil has the advantages that the original fragrance of naturallinseed oil can be retained, no high temperature is needed in the whole process, no chemical additive is needed, the flavor substances can be well retained, and the original fragrance of the naturallinseed oil is rich.

Owner:高艳

Domestic oil pressing machine and oil pressing method

The invention discloses a domestic oil pressing machine and an oil pressing method. The oil pressing method at least comprises the stages of material drying, preheating, material feeding and crushing for oil extraction; the stages of material drying and preheating can be carried out in a step-by-step mode or simultaneously; the two parts, namely a material hopper and a pressing barrel, are heated, and thus material drying and water evaporation before material feeding are realized; during the squeezing and crushing process, due to the heat conduction of the pressing barrel, the materials are crushed more thoroughly under the effect of high temperature, and thus the oil extraction rate is improved, residue and oil separation is better realized, a residue outlet is unlikely to block by residues, and the oil is strong in fragrance.

Owner:JOYOUNG CO LTD

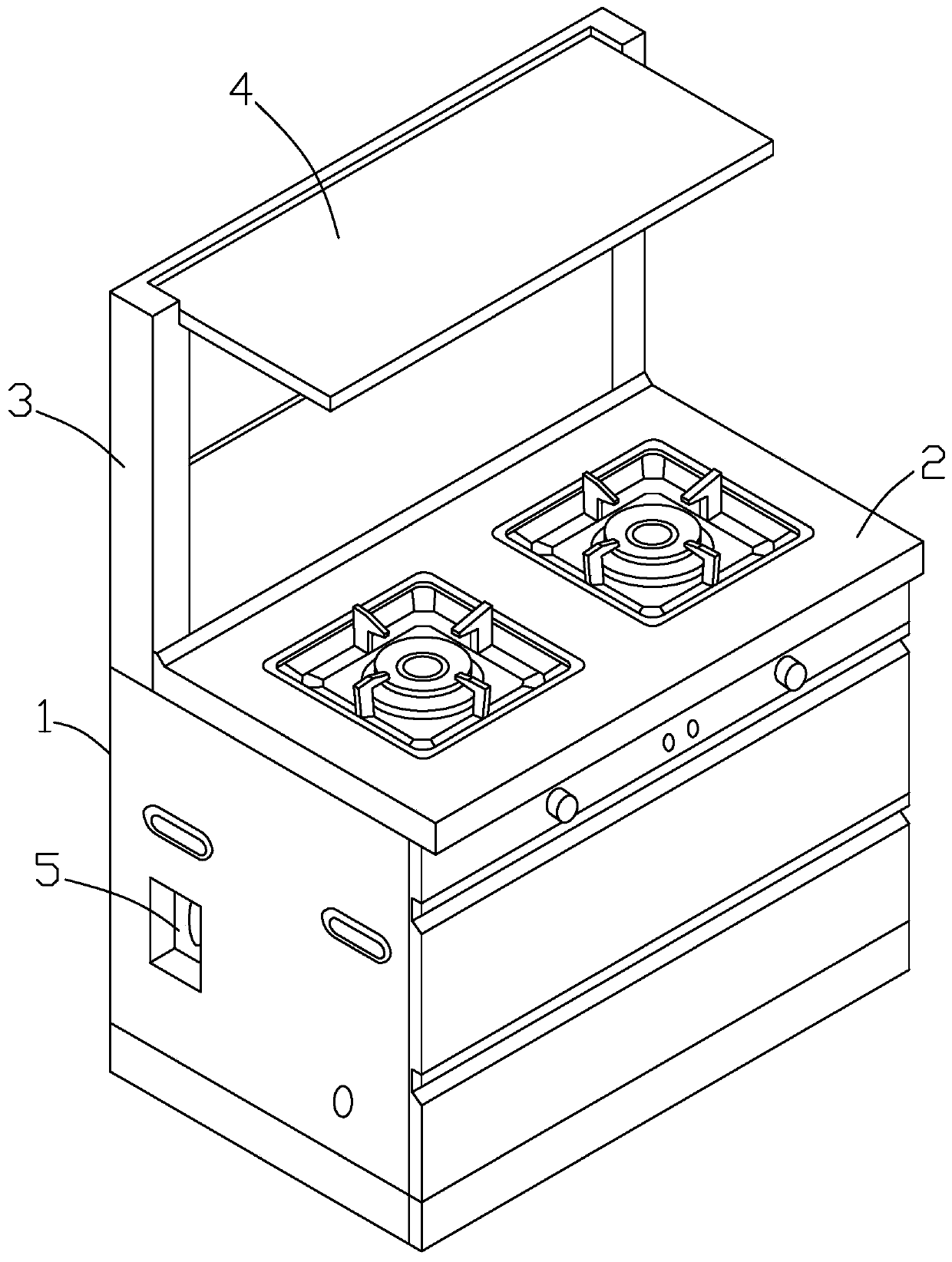

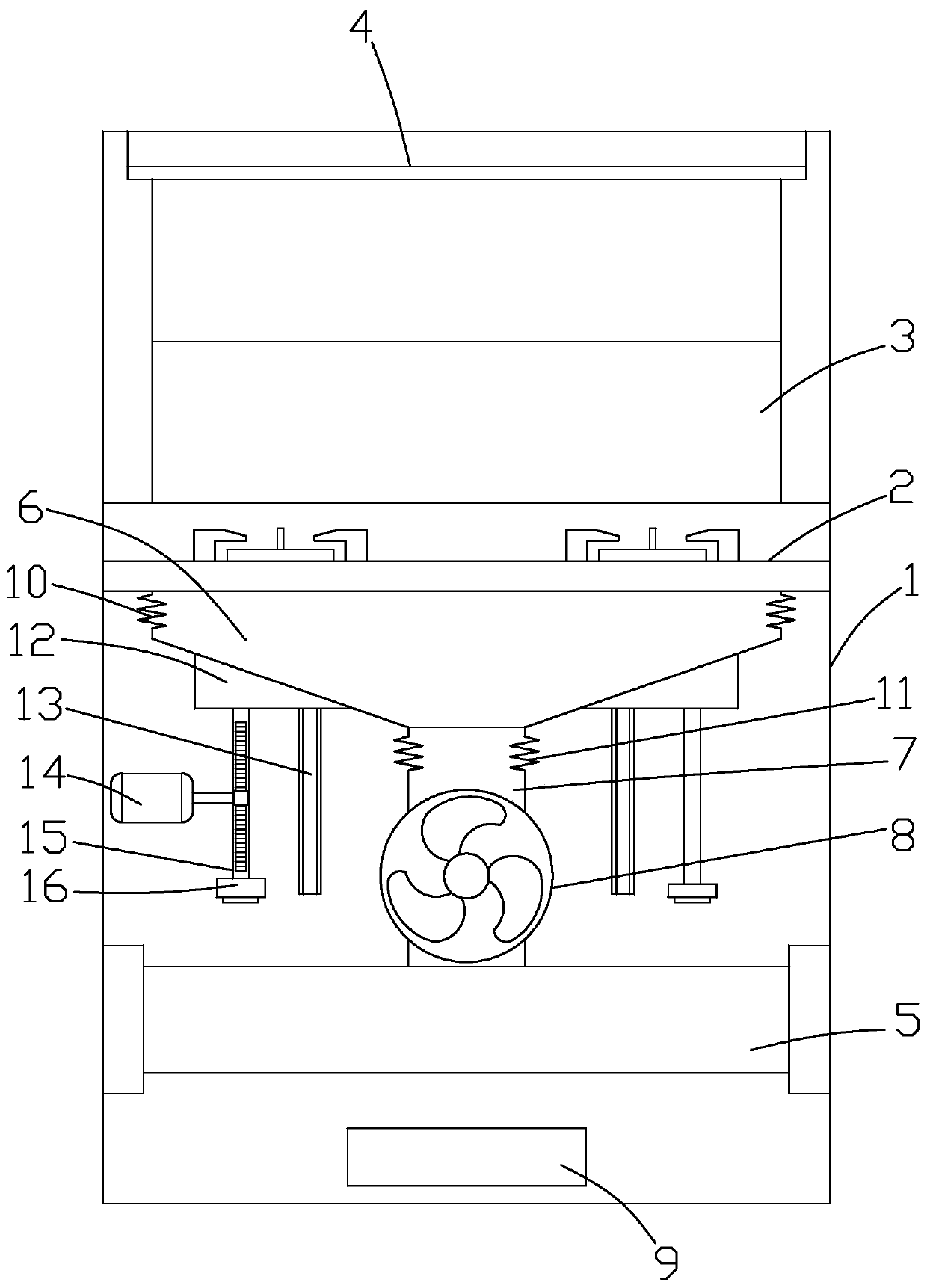

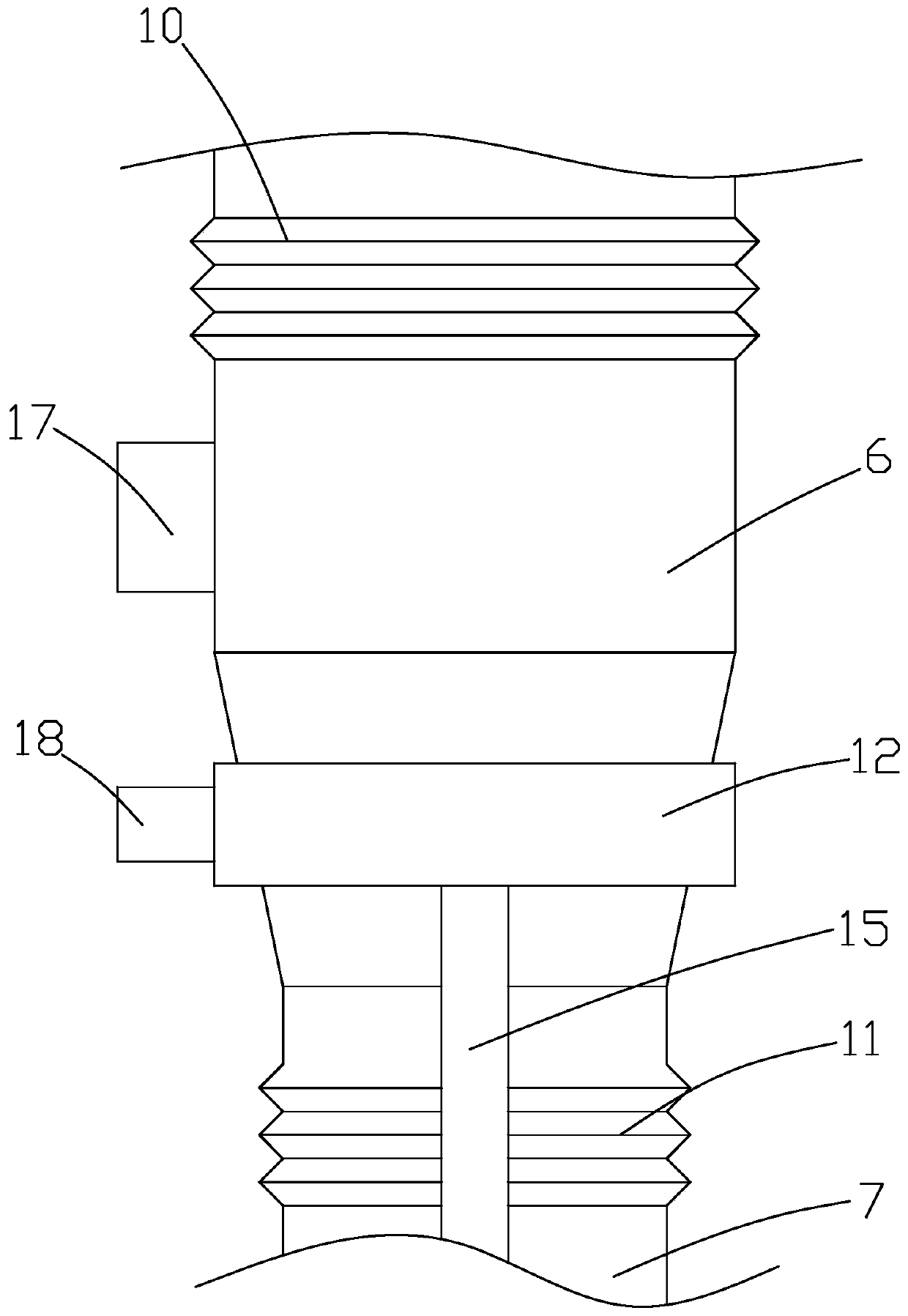

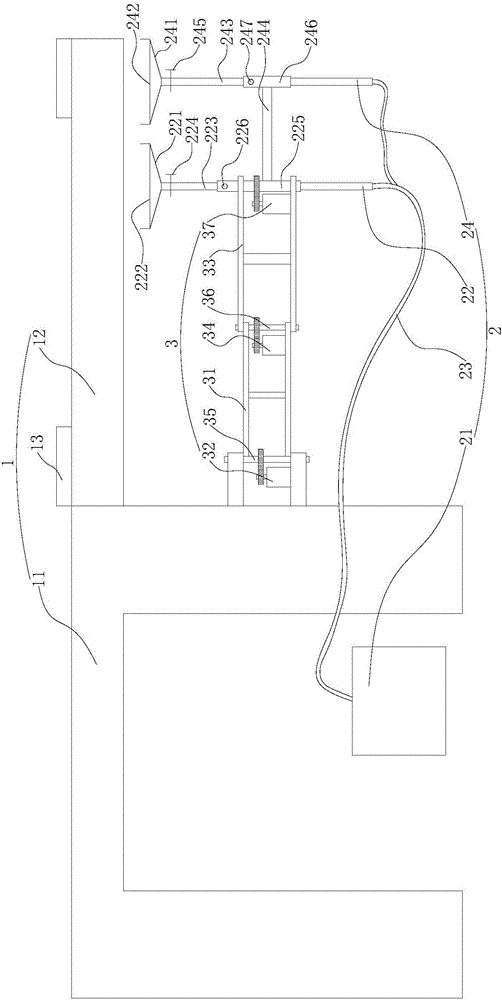

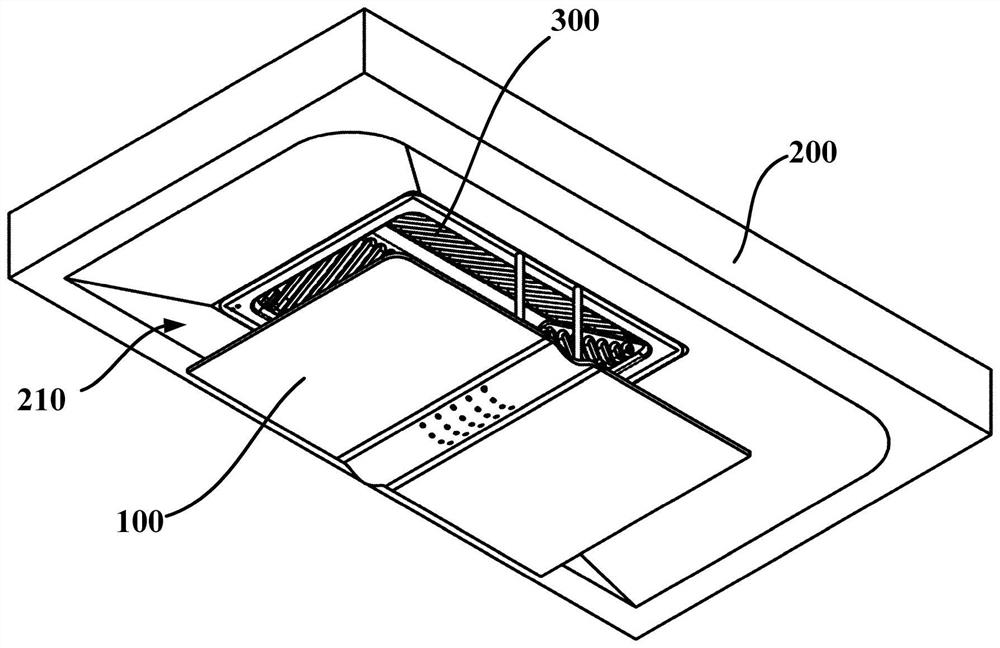

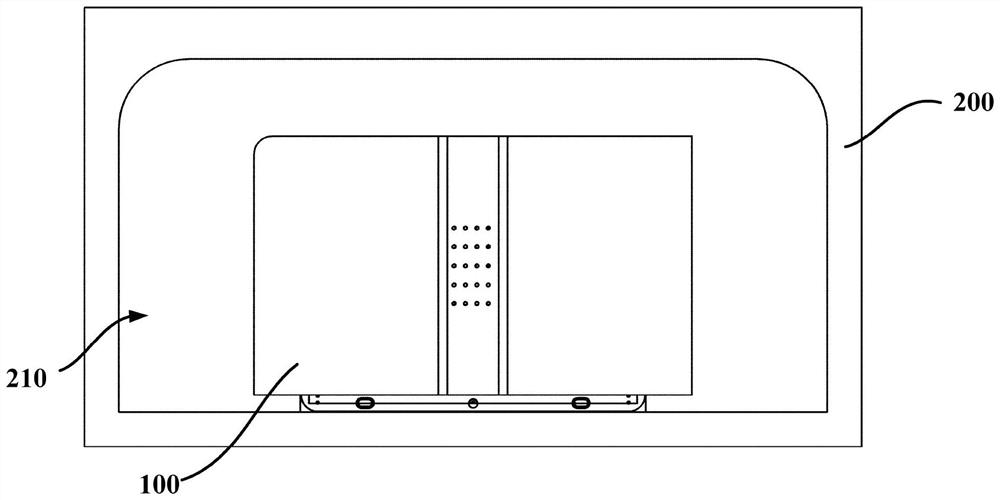

Integration cooker capable of adjusting volume of smoke collection cavity and making method of integration cooker

PendingCN110726164AAdjustable spacingImprove sealingDomestic stoves or rangesPump componentsProcess engineeringWind power

The invention discloses an integration cooker capable of adjusting the volume of a smoke collection cavity and a making method of the integration cooker. The integration cooker comprises an integration cooker body and the adjustable smoke collection cavity, the top of the adjustable smoke collection cavity is communicated with a cooking fume suction groove in the top face of the integration cookerbody, and a supporting mechanism is arranged on the side face of the adjustable smoke collection cavity, and connected with a lifting driving mechanism and a limiting sliding mechanism. The making method of the integration cooker comprises the steps of machining the integration cooker body, machining and installing the adjustable smoke collection cavity, machining and installing the supporting mechanism, installing the lifting driving mechanism, installing the limiting sliding mechanism, and conducting pilot running on the integration cooker. According to the integration cooker, through the design of the adjustable smoke collection cavity, the smoke collection cavity is close to or away from a draught fan, flexible adjustment of wind power in the shifting process of the draught fan is satisfied, and it is avoided that the wind power is suddenly increased or decreased; moreover, up-down floating adjustment on wind power can be made when the draught fan is at different gear positions, the adjustment on the wind power of the integration cooker is diversified, air flow is smoother, and the noise is lowered.

Owner:浙江蓝炬星电器有限公司

Automobile waste oil recycling platform

InactiveCN106515908AEasy to get oilEasy to operateVehicle dissasembly recoverySolid waste disposalMotor driveFuel tank

The invention discloses an automobile waste oil recycling platform which comprises a containing table, a recycling mechanism and a telescopic drive mechanism. The containing table comprises a fixed frame and two supporting rods formed by the fixed frame in an extending manner. The recycling mechanism comprises an oil storage tank, a first oil extraction assembly arranged below the supporting rods and an oil conveying pipe connecting the first oil extraction assembly with the oil storage tank. The telescopic drive mechanism comprises a first telescopic part with one end pivoted to the middle portion of the fixed frame, a first stepping motor driving the first telescopic part to rotate relative to the fixed frame, a second telescopic part with one end hinged to the free end of the first telescopic part and the other end connected with the first oil extraction assembly, and a second stepping motor driving the second telescopic part to rotate relative to the free end of the first telescopic part. By the adoption of the automobile waste oil recycling platform, a waste automobile can be placed on the two supporting rods, the first telescopic part and the second telescopic part are driven to rotate by an angle through the cooperation of the first stepping motor and the second stepping motor, and the first oil extraction assembly is driven to move to the position below an oil tank of the waste automobile to extract oil conveniently. The automobile waste oil recycling platform is easy and convenient to operate, and the oil extraction efficiency is improved.

Owner:GEM WUHAN URBAN MINE RECYCLING IND PARK DEV +3

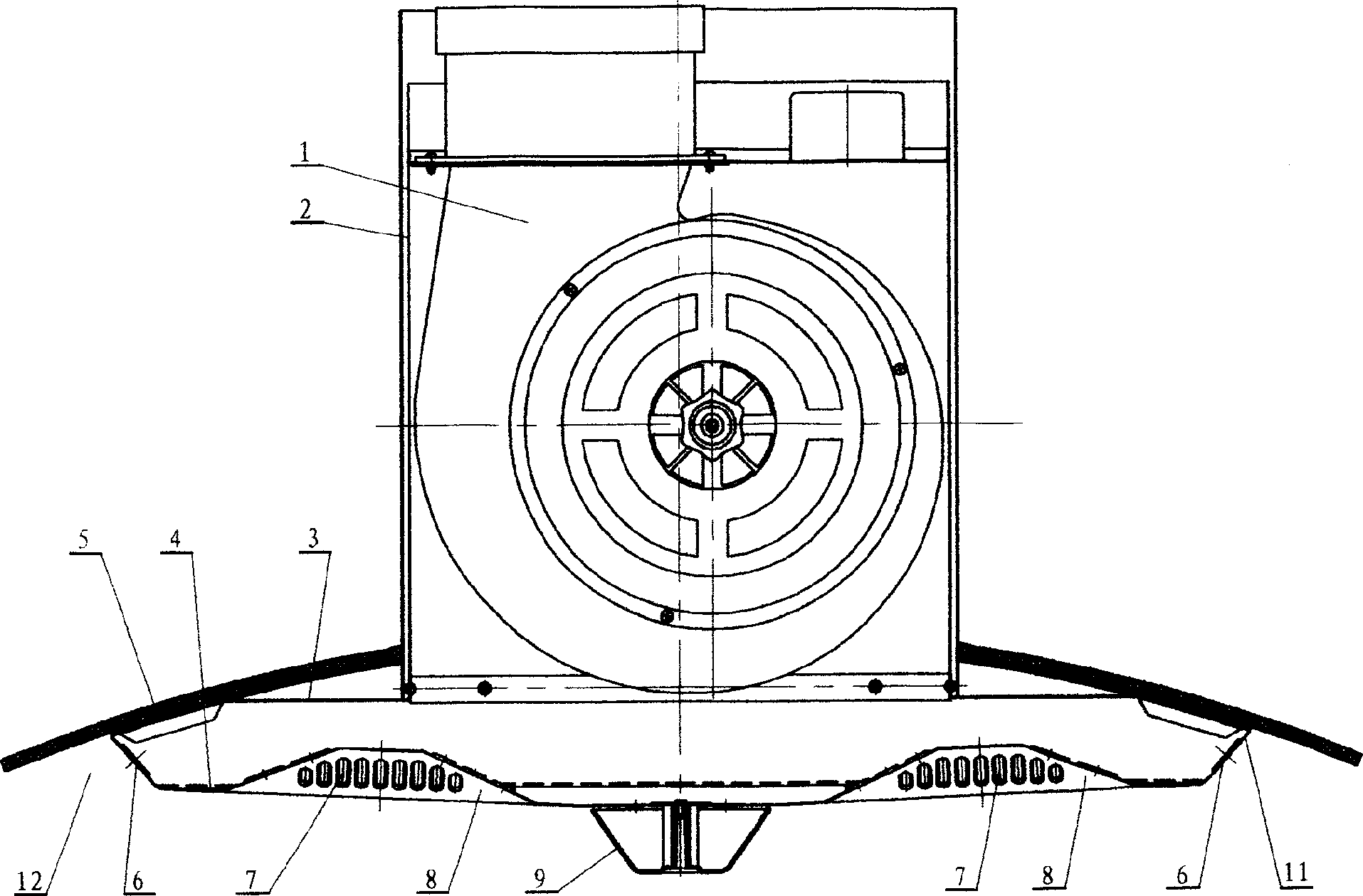

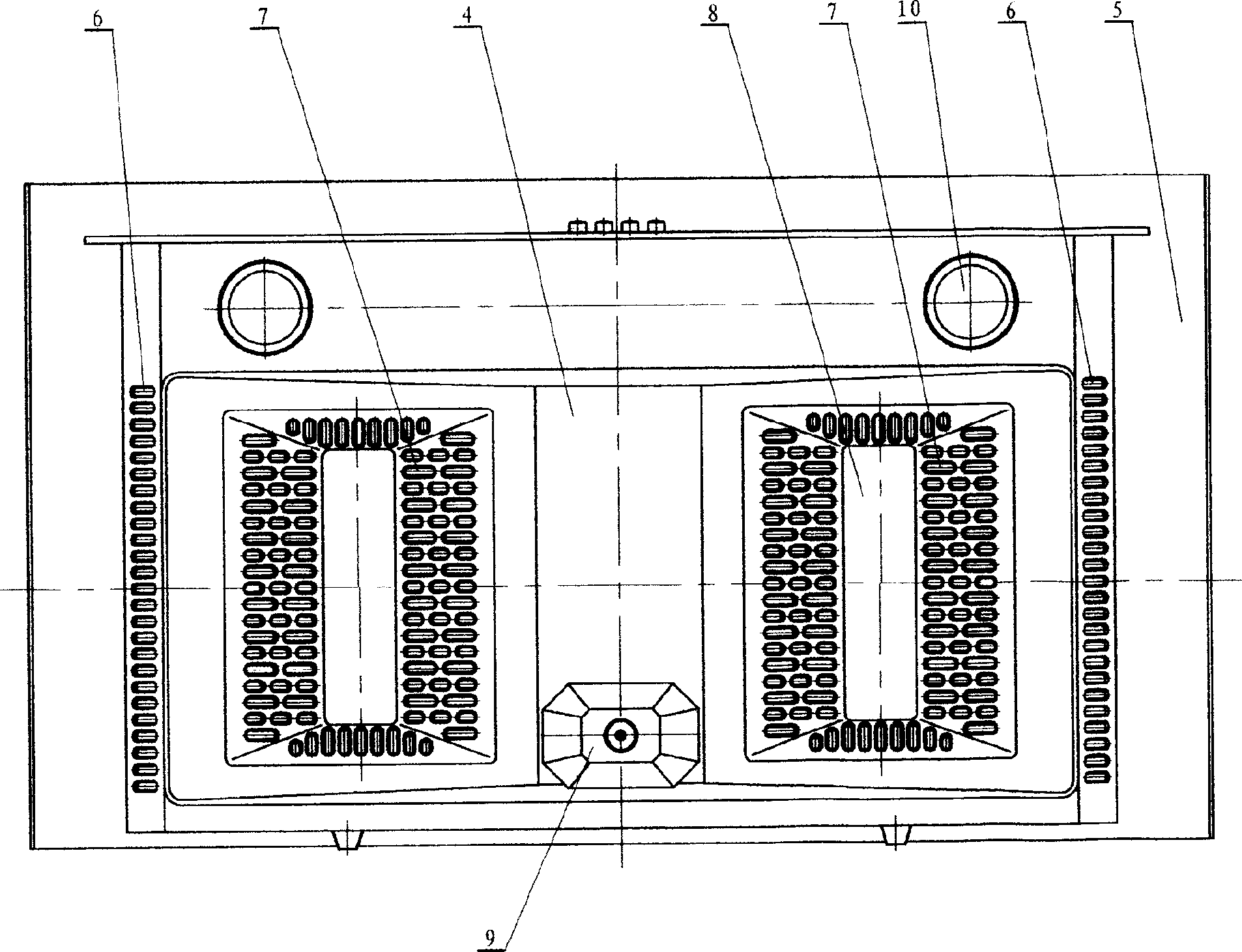

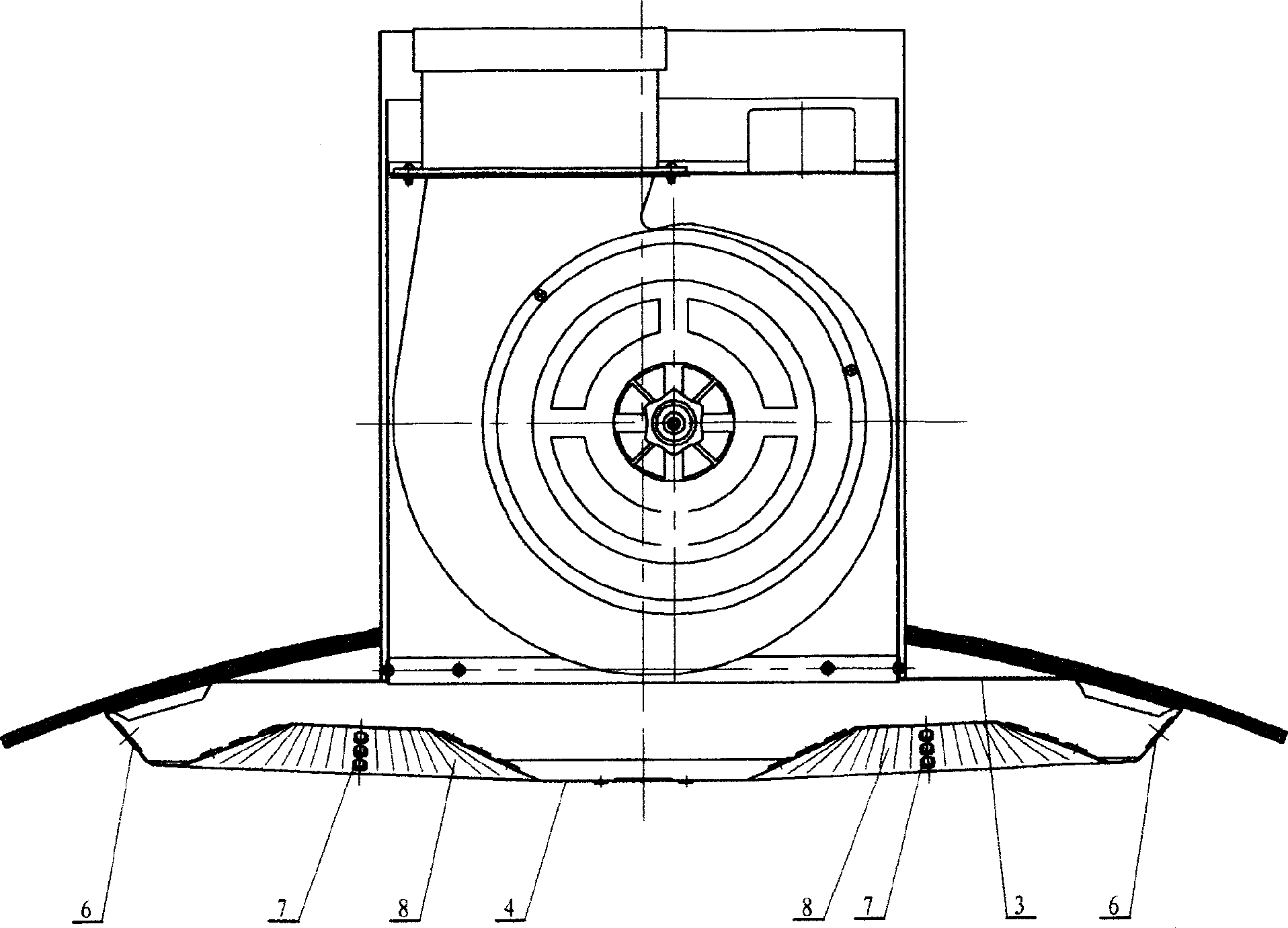

Fume exhaust fan of fume focusing cover with air inlet concave chamber

InactiveCN1900605AImprove the efficiency of oil extractionImprove suction effectDomestic stoves or rangesLighting and heating apparatusOn boardEngineering

Blower fan is installed inside chassis. Inner shell body of fume-collecting hood is installed at low end of chassis. External fume-collecting hood is joined and fixed on inner shell body. There are concave cavities of main air inlet on board of the fume-collecting hood. Multiple main air inlets are made on perisporium of concave cavity. Multiple secondary air inlets are prepared on side plates up bent from two ends of fume-collecting hood. Concave type cavities of secondary air inlets are formed between extended part of external fume-collecting hood and side plates up bent from two ends of fume-collecting hood. When apparatus of sucking oil fume is in use, concave cavities of main air inlets, and concave cavities of secondary air inlets form zone of negative pressure of sucking oil fume. Advantages are: simple structure, goodly outline, and good effect of sucking oil fume. The disclosed cover is suitable to apparatus of sucking oil fume for common people.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

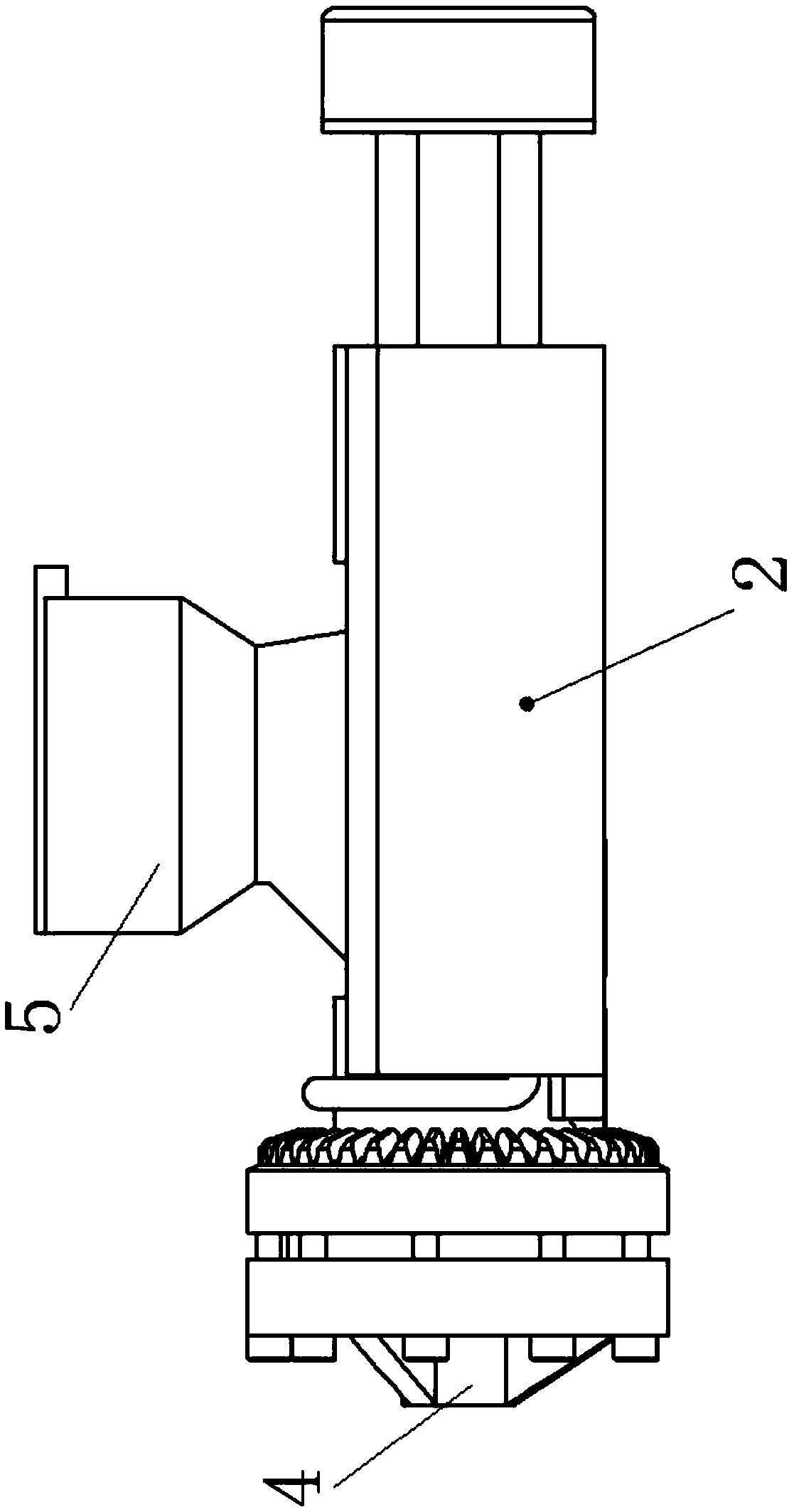

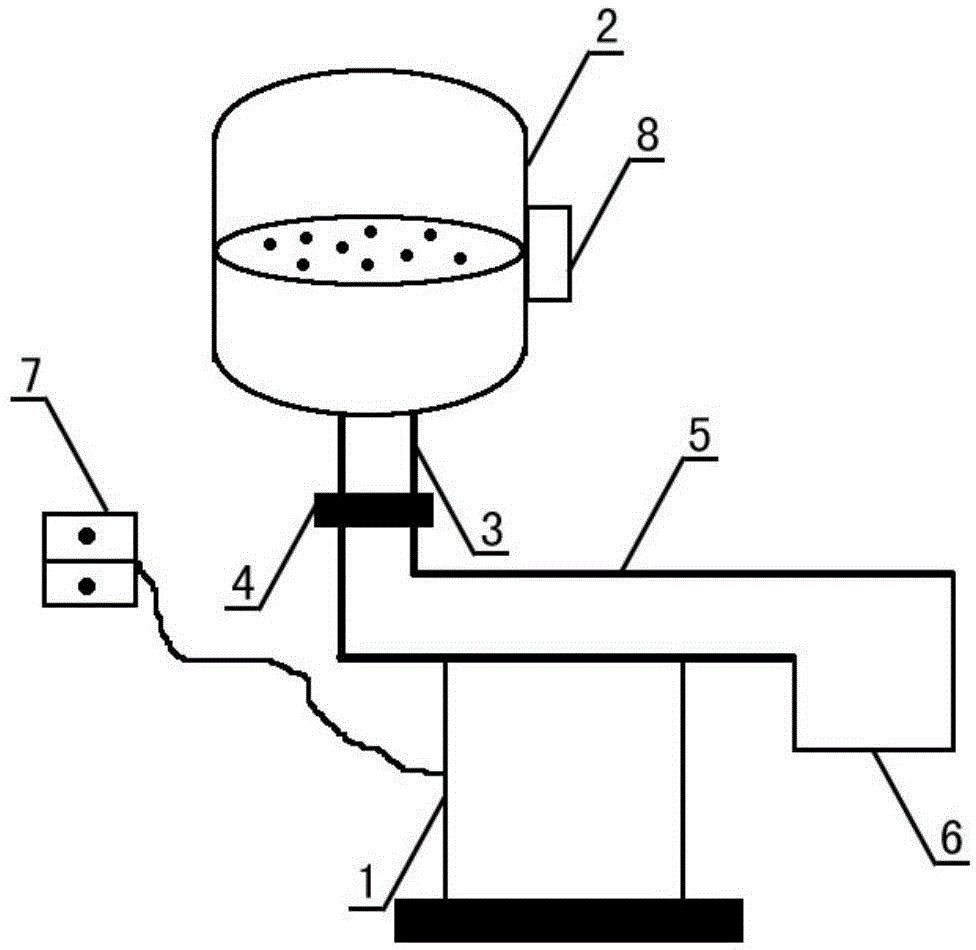

Small oil squeezing device

A small oil squeezing device comprises a rack (1), wherein a feed barrel (2) is arranged on the rack; a dense screen is arranged at the middle section of the feed barrel (2); a squeezing device (3) is arranged at the bottom end of the feed barrel (2); a motor (4) is arranged at the middle section of the squeezing device (3); an oil outlet pipeline (5) is arranged on the squeezing device (3); an oil collecting basket (6) is arranged at the tail end of the oil outlet pipeline; during usage, rapeseeds are evenly poured into the feed barrel (2), the screen filters out redundant impurities, the motor (4) runs to perform preheating from the temperature of the squeezing device (3) for rotating and inward pressing, and oil is discharged via the oil outlet pipeline (5) and flows to the oil collecting basket (6); a power plug (7) is arranged on the rack (1), and low-voltage and direct-current type power supply is adopted for working; a control panel (8) is arranged for setting of the squeezing time and rate; a user can squeeze rapeseed oil at home directly and conveniently, carrying is not required, time and labor are saved during squeezing, the noise hazard is reduced, and the oil squeezing efficiency can be effectively improved.

Owner:ANHUI HAICHENG DECHANG ELECTRONICS TECH

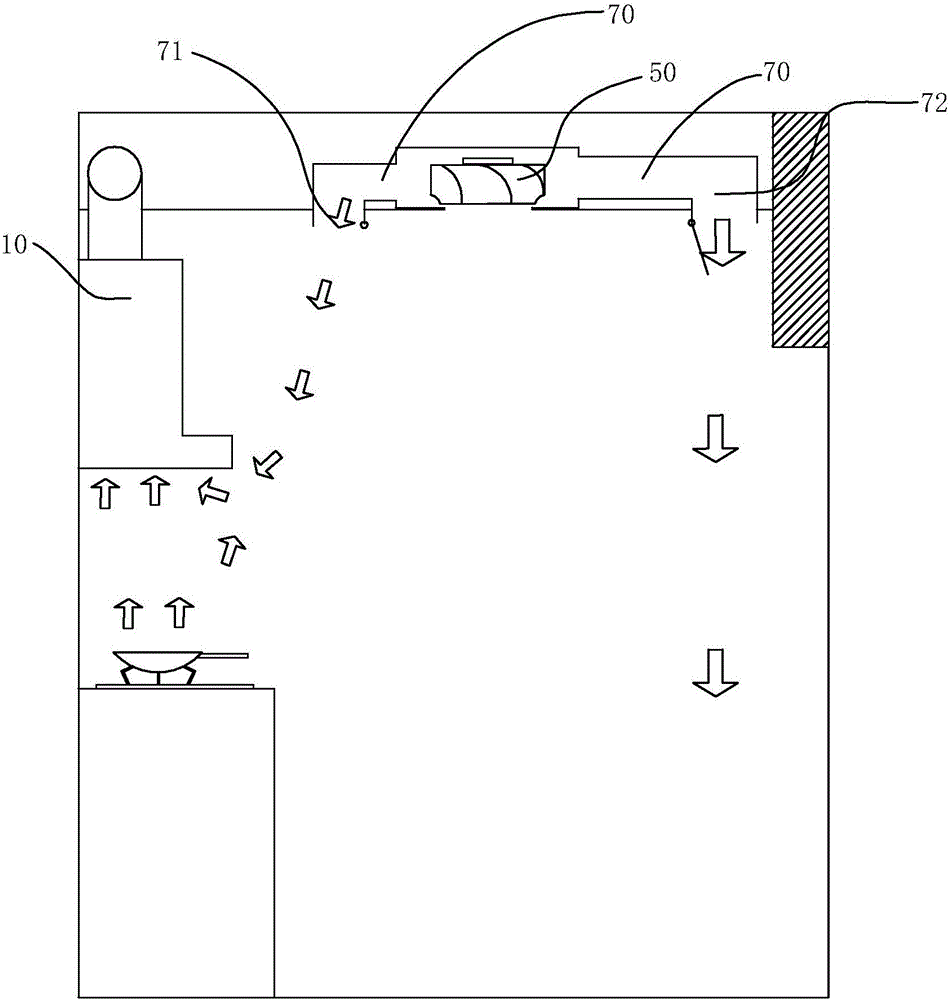

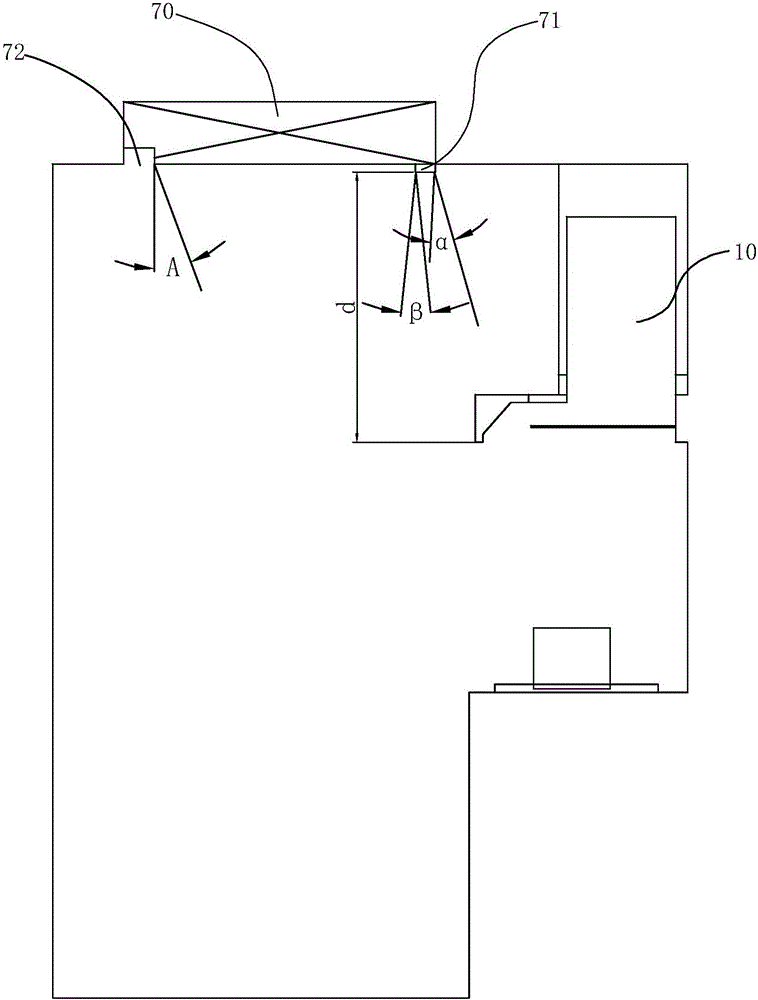

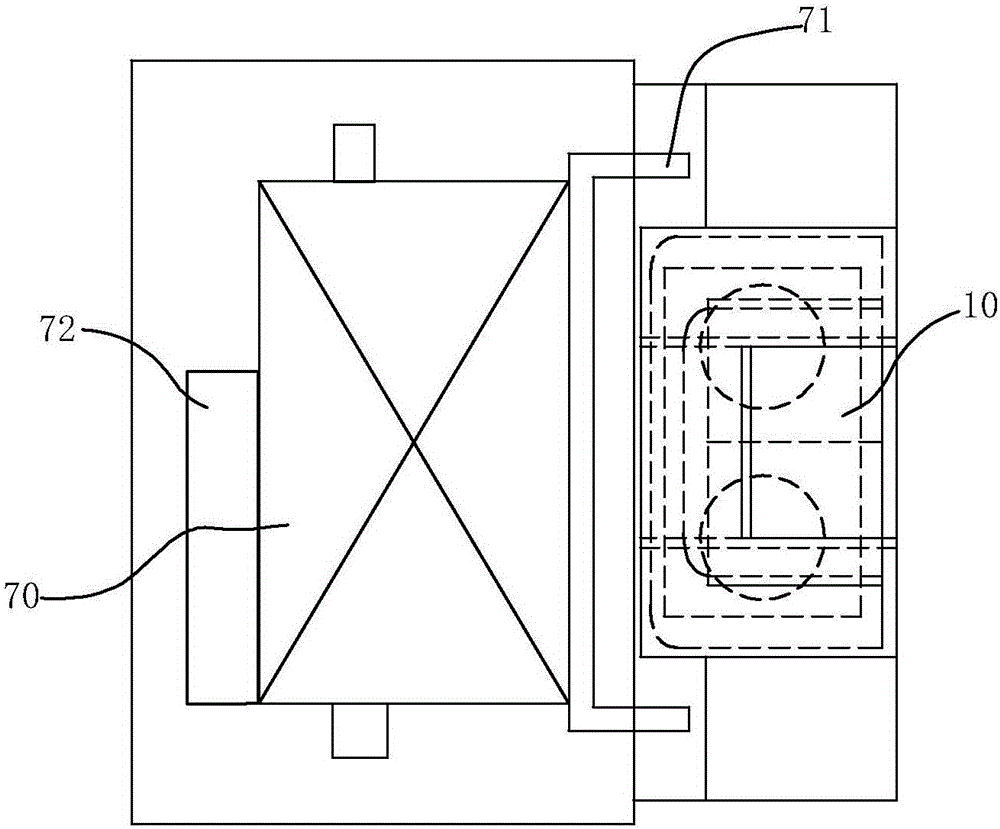

Air curtain system for preventing oil-smoke from escaping

ActiveCN107435964APrevent fumes from escapingImprove the efficiency of oil extractionDomestic stoves or rangesLighting and heating apparatusEngineeringEnvironmental geology

The invention discloses an air curtain system for preventing oil-smoke from escaping. The air curtain system comprises a range hood and an air curtain mechanism located on the top of a kitchen, and is characterized in that the air curtain mechanism comprises an auxiliary air outlet formed in the top of the doorway of the kitchen, the air flow blown out of the auxiliary air outlet flows towards the inner side of the kitchen to guide the air flow to the range hood, so that the air flow flows towards the direction of the range hood, and the oil-smoke air is prone to discharge. The air curtain system for preventing the oil-smoke from escaping comprises the air outlet, formed in the top of the doorway of the kitchen, of the air curtain mechanism, so that the oil-smoke can be prevented from escaping from the top of the kitchen door, the air curtain system further comprises the range hood and the air curtain mechanism, wherein the range hood is used for absorbing the oil-smoke, the air curtain mechanism is positioned on the front side of the range hood to form an air curtain, so that the oil-smoke can be prevented from escaping, and the oil absorption efficiency of the range hood can be improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Device for efficiently extracting amino acid in peanuts

InactiveCN108043730AQuick extractionEasy to removeSievingGas current separationEngineeringAmino acid

The invention discloses a device for efficiently extracting amino acid in peanuts. The device comprises a peeling device; a feeding opening is fixedly installed at the upper left of the peeling device; a protective shell is fixedly installed at the right side of the peeling device; a roller is movably installed inside the peeling device; a connecting shaft is fixedly installed at the right side ofthe roller; a rolling wheel is fixedly installed at the outer surface of the connecting shaft; a fan is fixedly installed at the right side inside the peeling device; a motor is fixedly installed atthe internal lower portion of the protective shell; the upper portion of the motor is movably connected with a belt; a screening device is fixedly installed below the peeling device; a screening gridis fixedly installed at the internal upper portion of the screening device; connecting rods are movably installed at the lower portion of the screening grid; a machine box is fixedly installed below the screening device; supporting frames are fixedly installed at the lower portion of the machine box; and each pedestal plate is fixedly installed below the corresponding supporting frame. The devicedisclosed by the invention is simple in structure, convenient, practical, stable in structure and capable of rapidly extracting lots of amino acid.

Owner:陈俞英

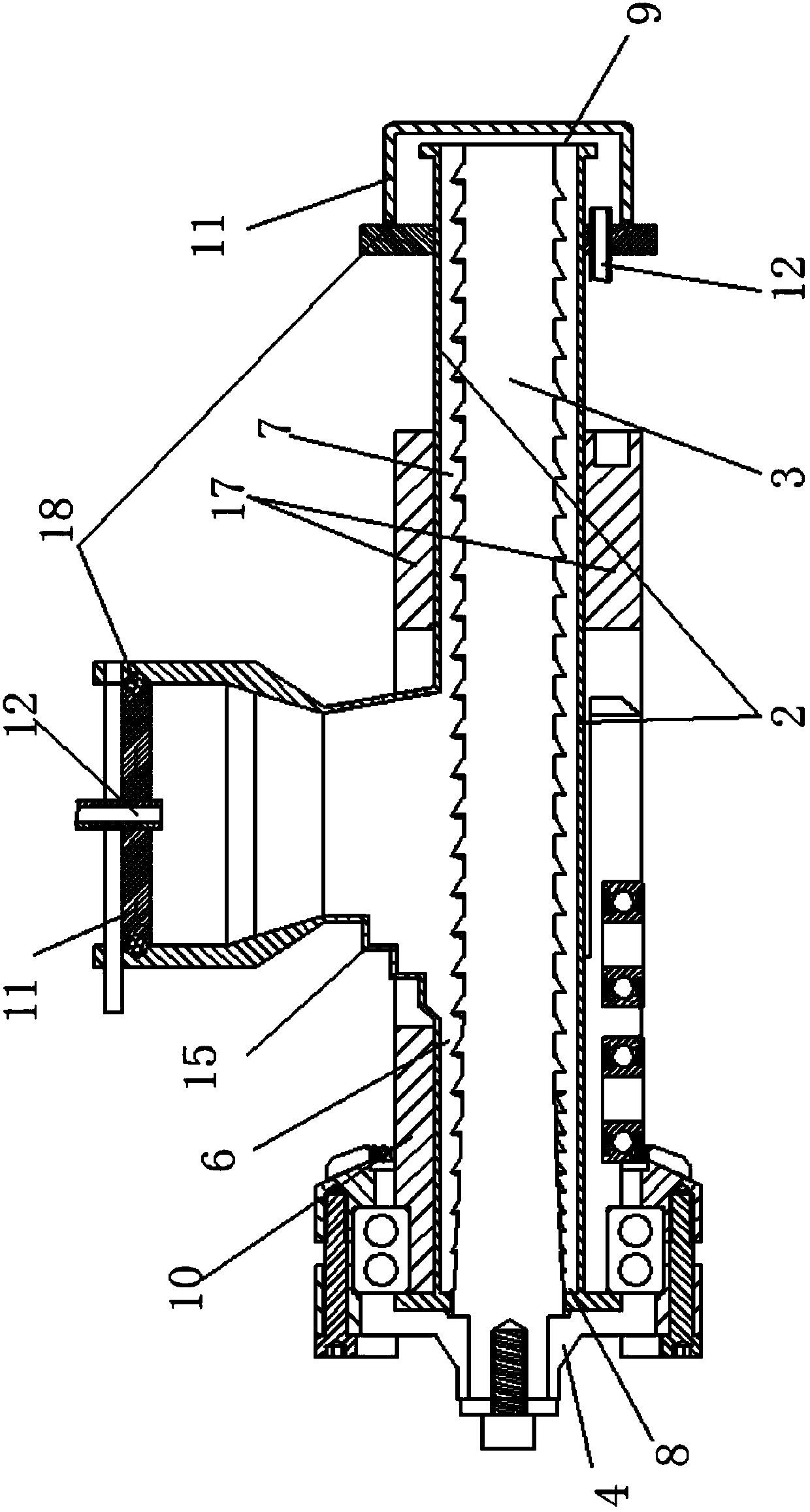

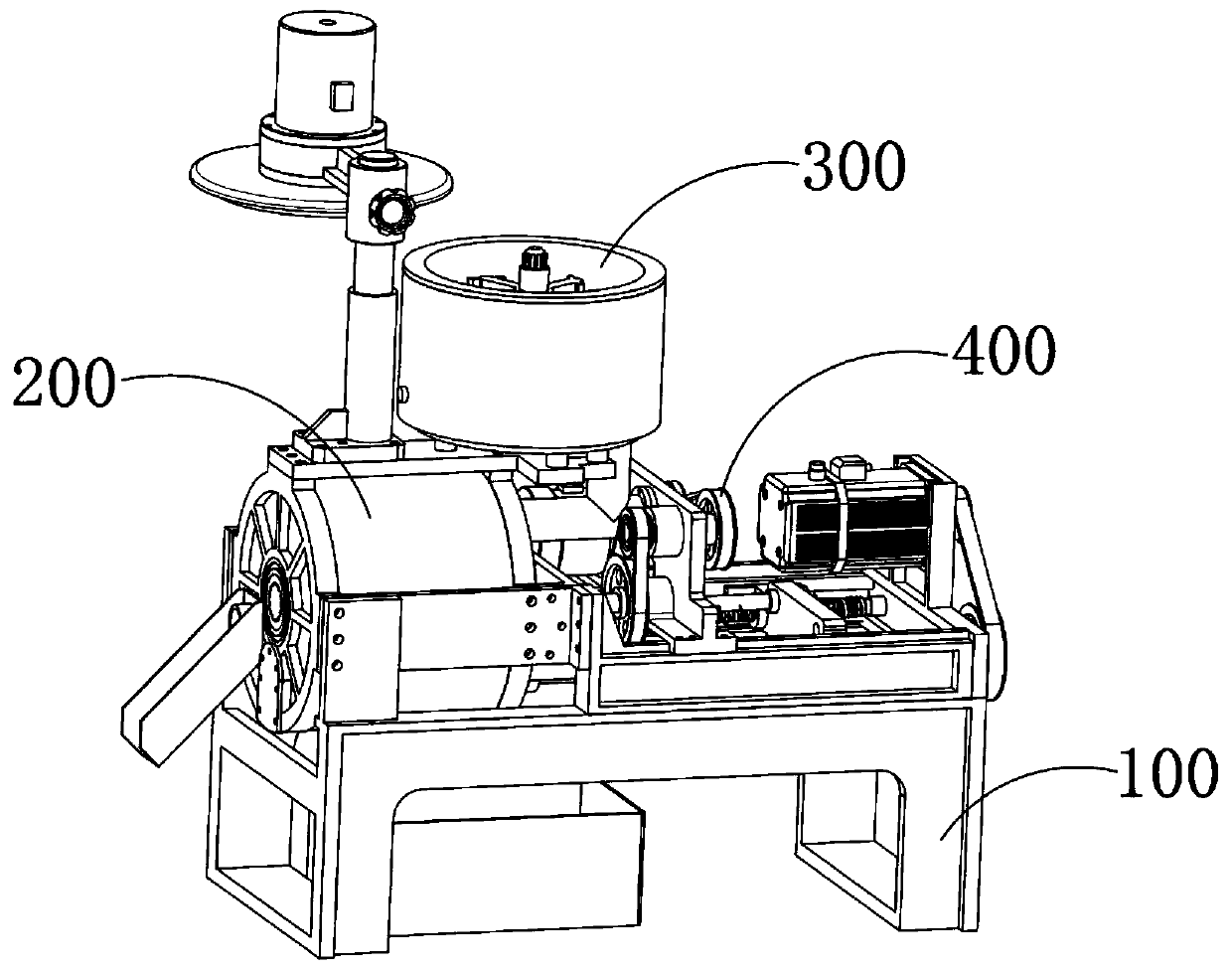

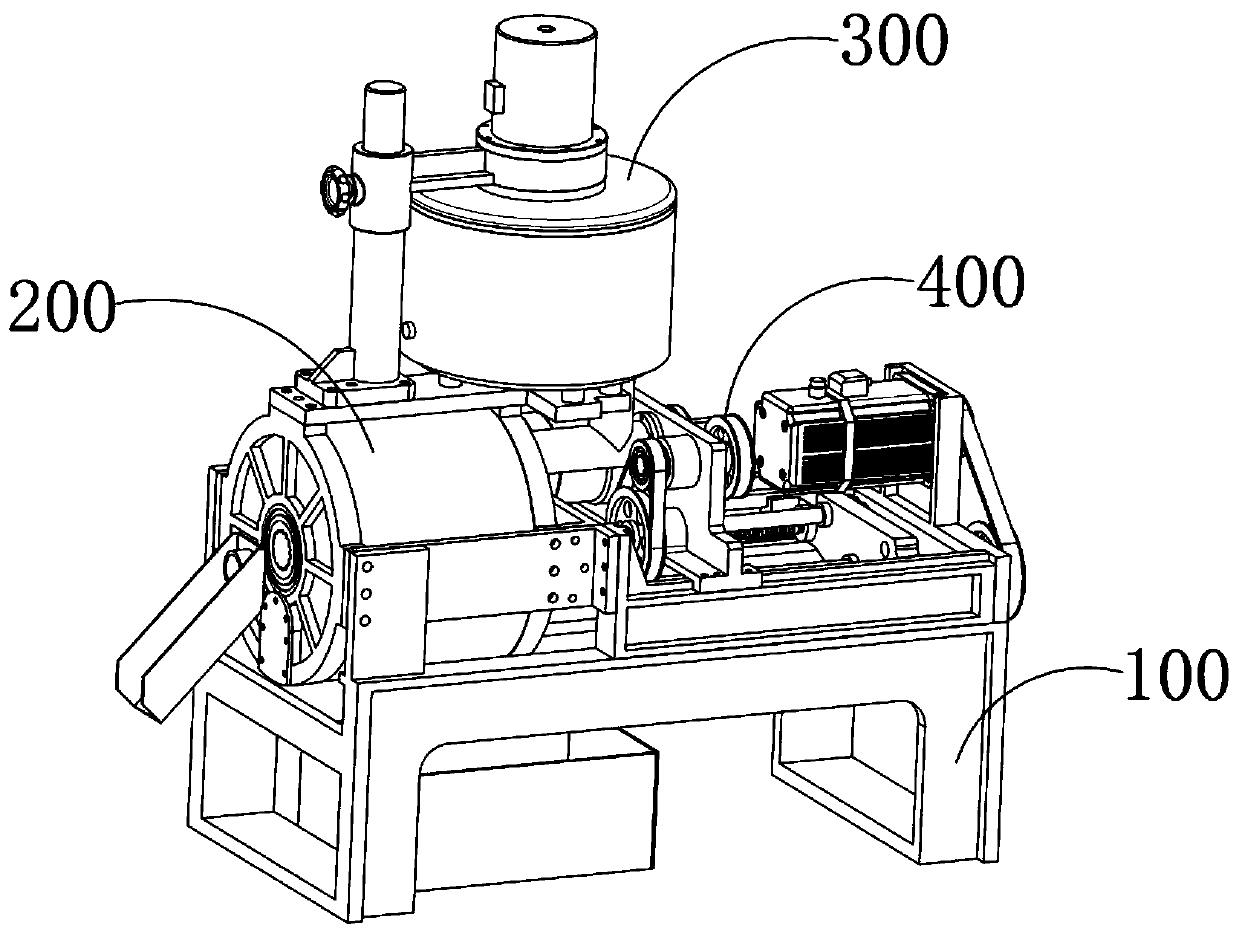

Efficient oil press for extracting oil from peanuts or soybeans

InactiveCN111169069AHigh degree of automationIngenious structureFatty-oils/fats productionPressesVegetable oilFeed drive

The invention provides an efficient oil press for extracting oil from peanuts or soybeans. The efficient oil press comprises a mounting rack, an oil pressing device, a feeding device and a power driving device; the feeding device is used for heating, stir-frying and cooking oil materials and conveying and adding the oil materials into the oil pressing device, and the oil pressing device comprisesa plurality of oil pressing cylinders, an oil receiving tank, a pressing rod, a residue discharging rod and a feeding driving mechanism, wherein the oil pressing cylinders can be circularly and sequentially in butt joint with the feeding device and receive the oil materials conveyed by the feeding device, the oil receiving tank is used for collecting pressed vegetable oil, the feeding driving mechanism can drive the pressing rod to insert the pressing rod into the corresponding oil pressing cylinder and extrude and press the oil materials in the corresponding oil pressing cylinder, meanwhile,the feeding driving mechanism can drive the residue discharging rod to insert the residue discharging rod into the corresponding oil pressing cylinder and eject out the pressed oil in the corresponding oil pressing cylinder, the oil pressing cylinders are communicated with the feeding device to receive the oil materials conveyed by the feeding device, the oil pressing cylinders are matched with the pressing rod to extrude and press the oil materials, the oil pressing cylinders are matched with the residue discharging rod to eject the pressed oil inside the oil pressing cylinders outwards, andoperation is sequentially, continuously and circularly carried out.

Owner:六安七茗道机电科技有限公司

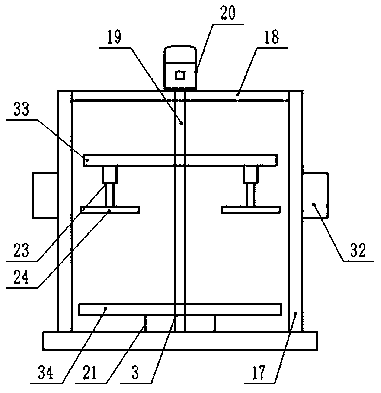

Full-automatic oil press for soybean oil preparation

InactiveCN111169065AFor automatic dischargeIngenious structureFatty-oils/fats productionPressesEngineeringCooking oil

The invention provides a full-automatic oil press for soybean oil preparation. The full-automatic oil press for soybean oil preparation comprises an oil pressing device and a material adding device; the oil pressing device comprises an installing base, a cylinder arranging mechanism comprising multiple oil pressing cylinders and an abut-pushing mechanism; the abut-pushing mechanism comprises pressing pushing rods and residue discharging pushing rods, the pressing pushing rods can be inserted into the oil pressing cylinders from top to bottom to press oil materials in the oil pressing cylindersto extract edible oil, and the residue discharging pushing rods can be inserted into the oil pressing cylinders from top to bottom to downwards eject and discharge oil residues in the oil pressing cylinders; the multiple oil pressing cylinders are arranged at intervals in the linear direction, the linear direction is the feeding direction of the oil pressing cylinders, the oil pressing cylindersmove step by step in the feeding advancing direction and are sequentially aligned with the pressing pushing rods and the residue discharging pushing rods of the abut-pushing mechanism, and the pressing pushing rods and the residue discharging pushing rods of the abut-pushing mechanism complete pressurizing pressing on the oil materials and ejecting and discharging on the oil residues in the step-by-step moving time interval of the oil pressing cylinders; and the material adding device is used for stir-frying the oil materials and adding the oil materials into the oil pressing cylinders.

Owner:六安七茗道机电科技有限公司

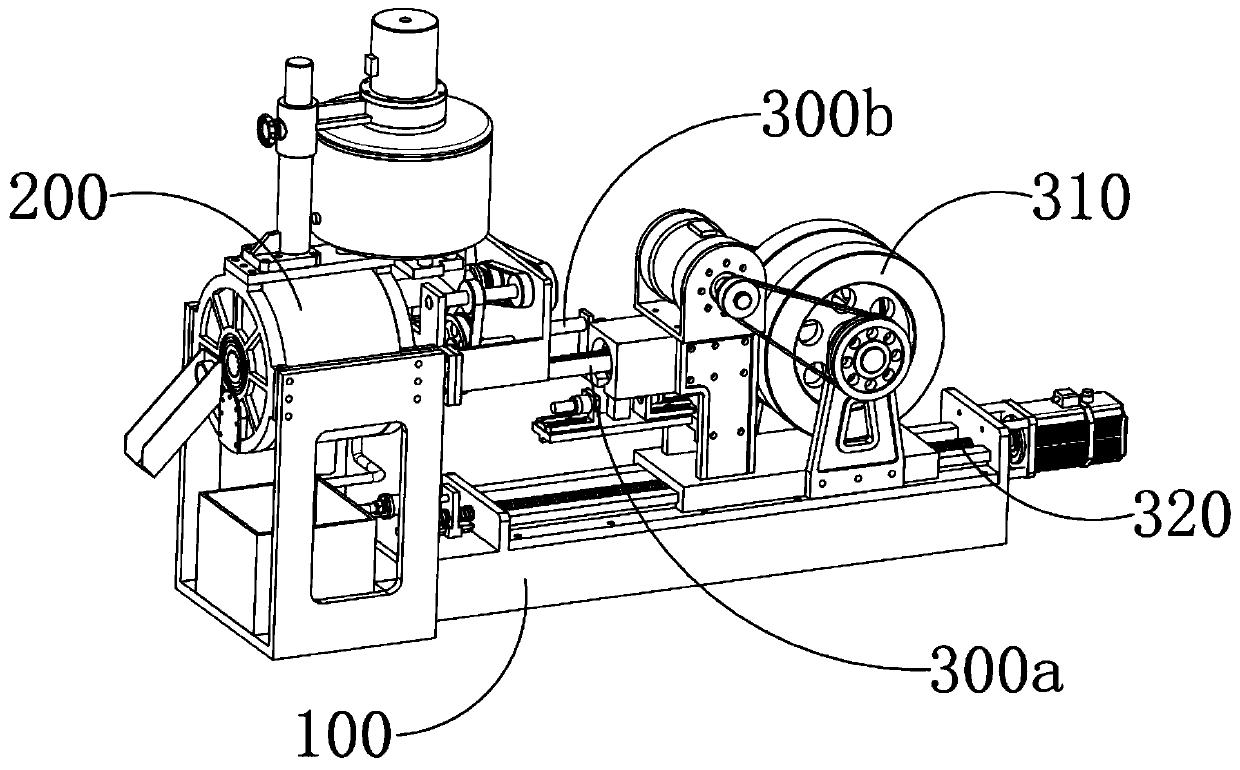

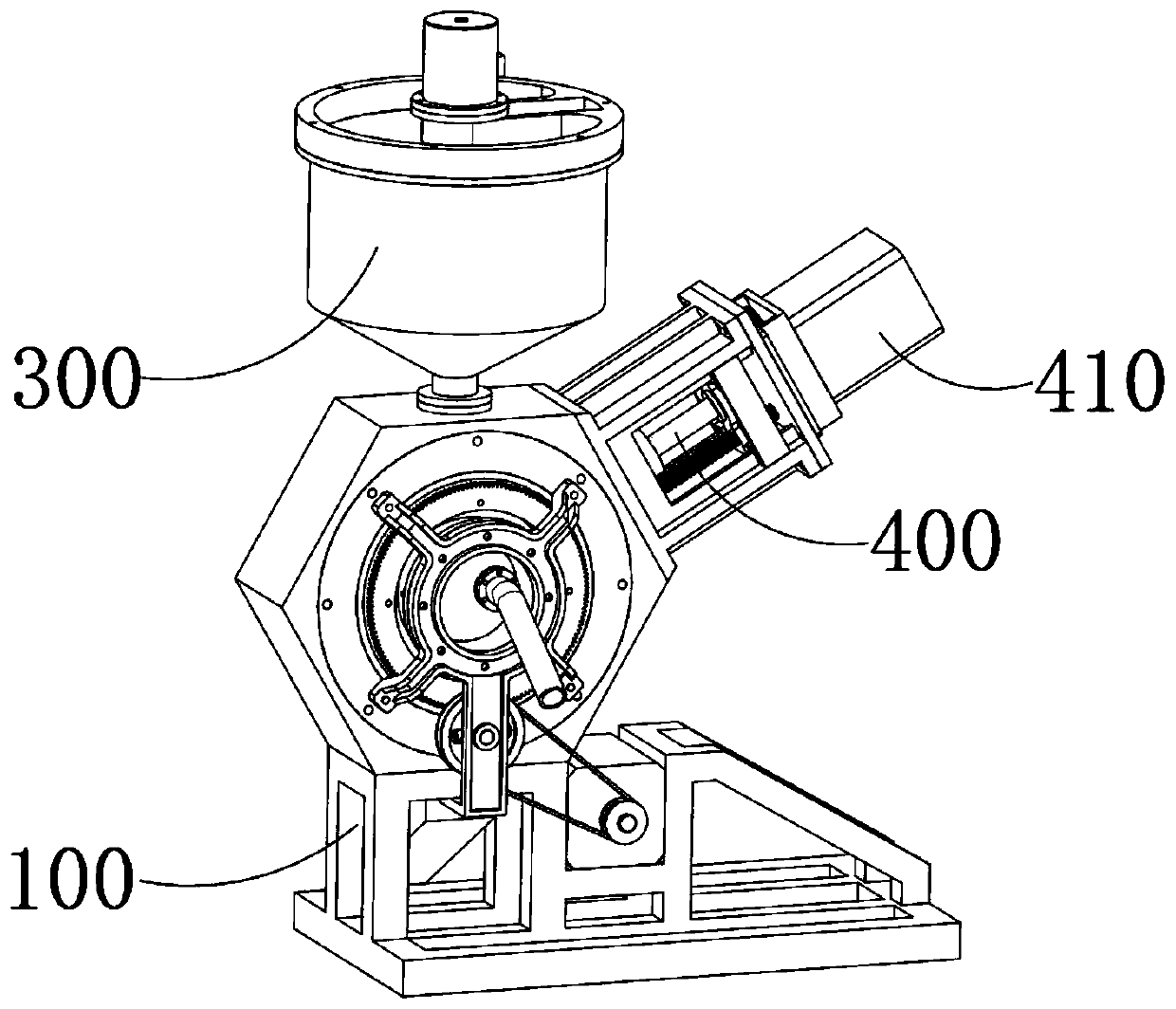

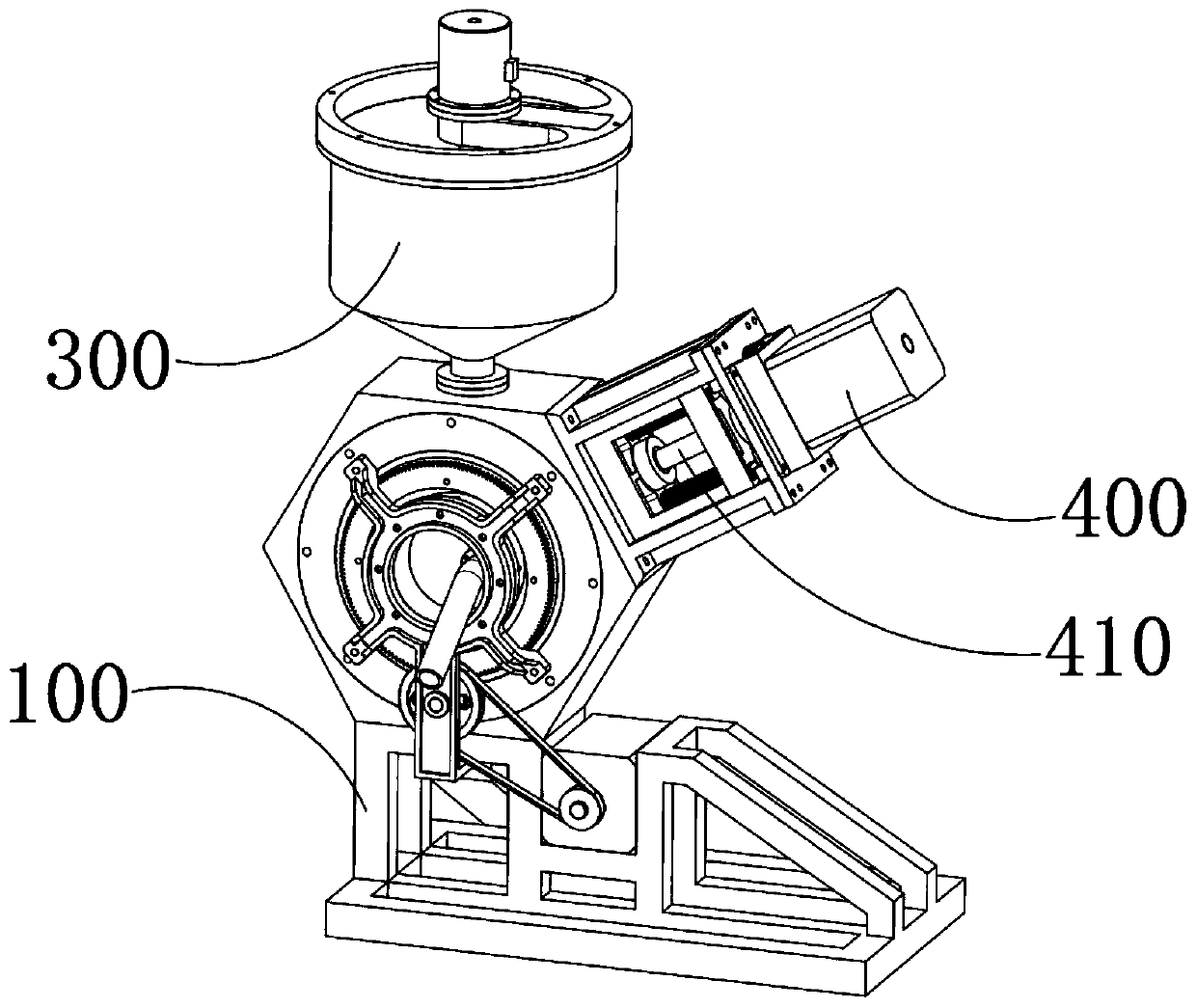

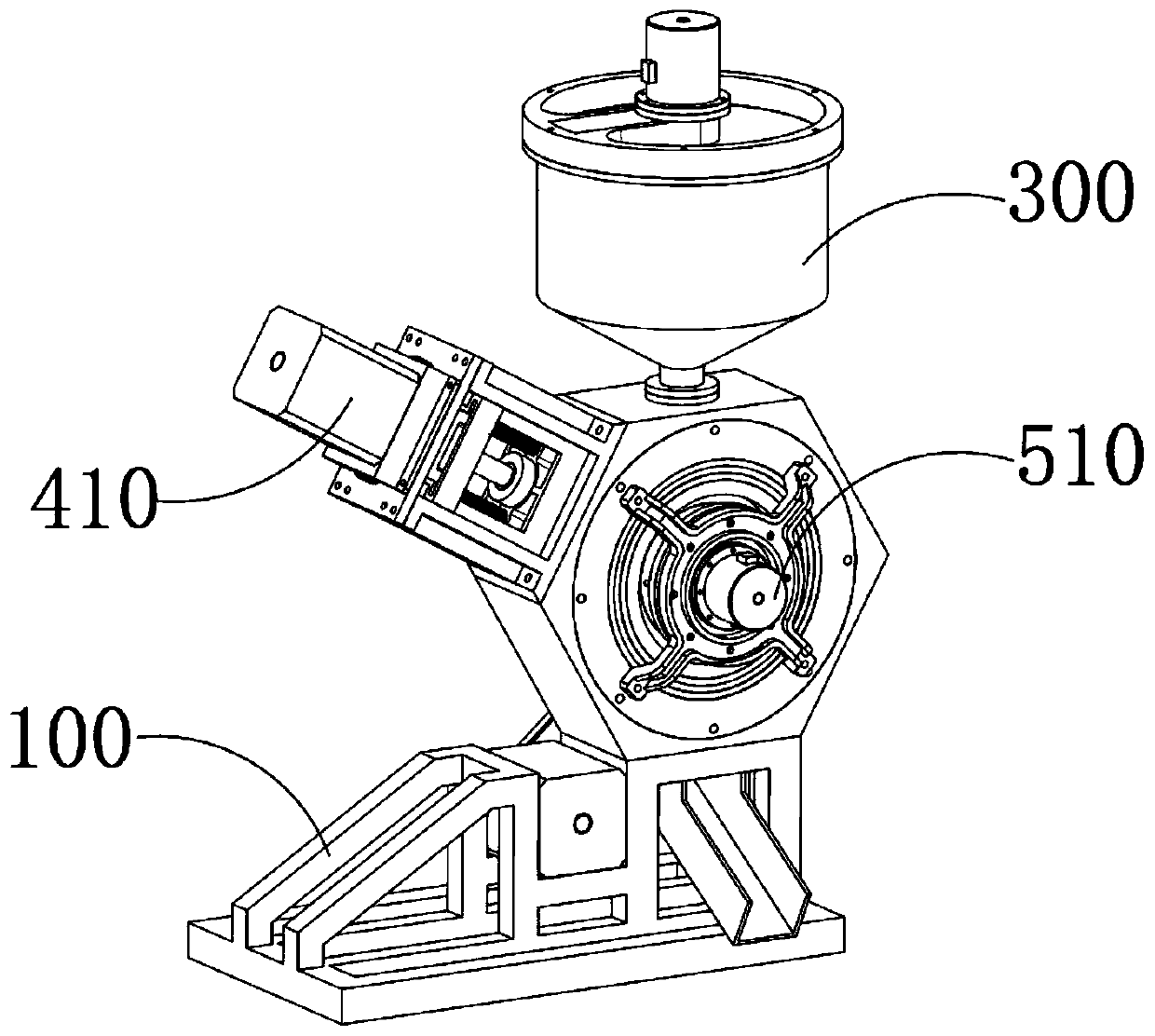

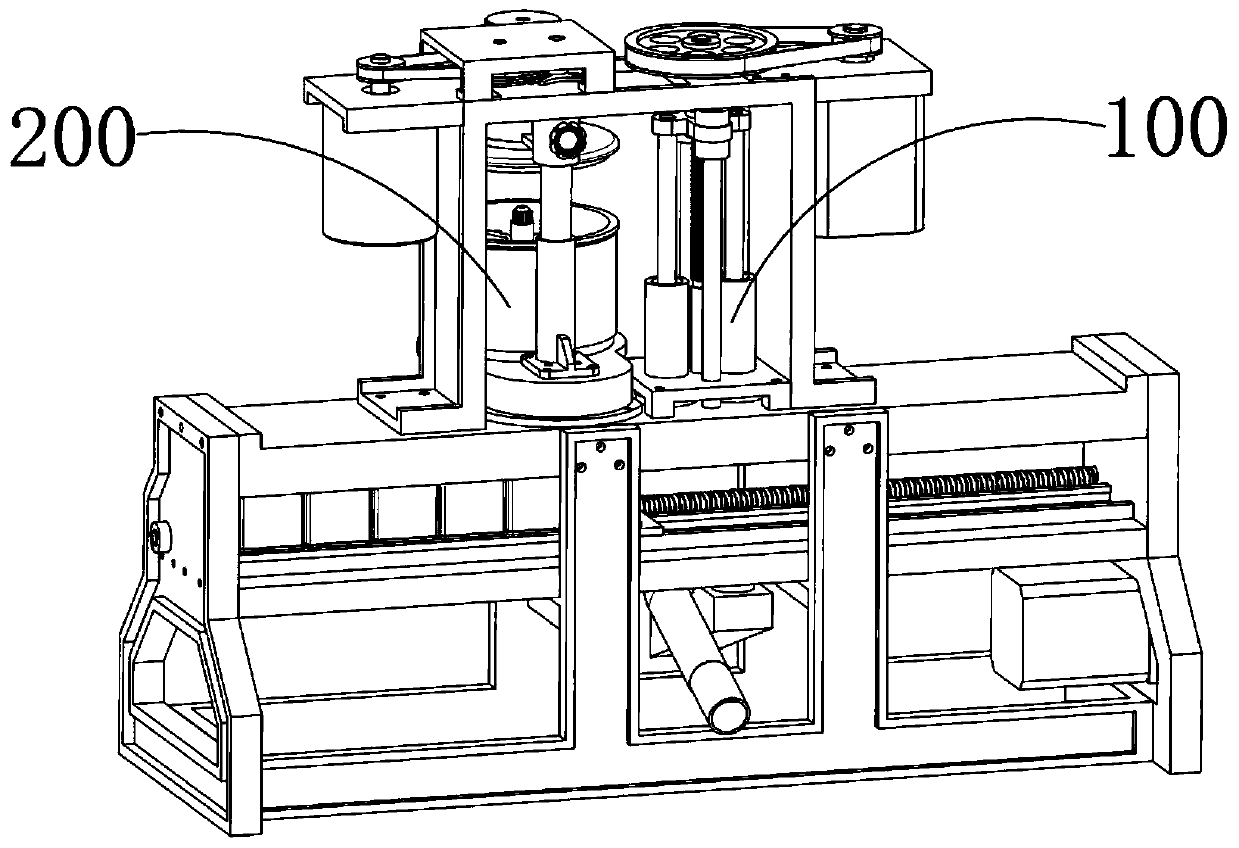

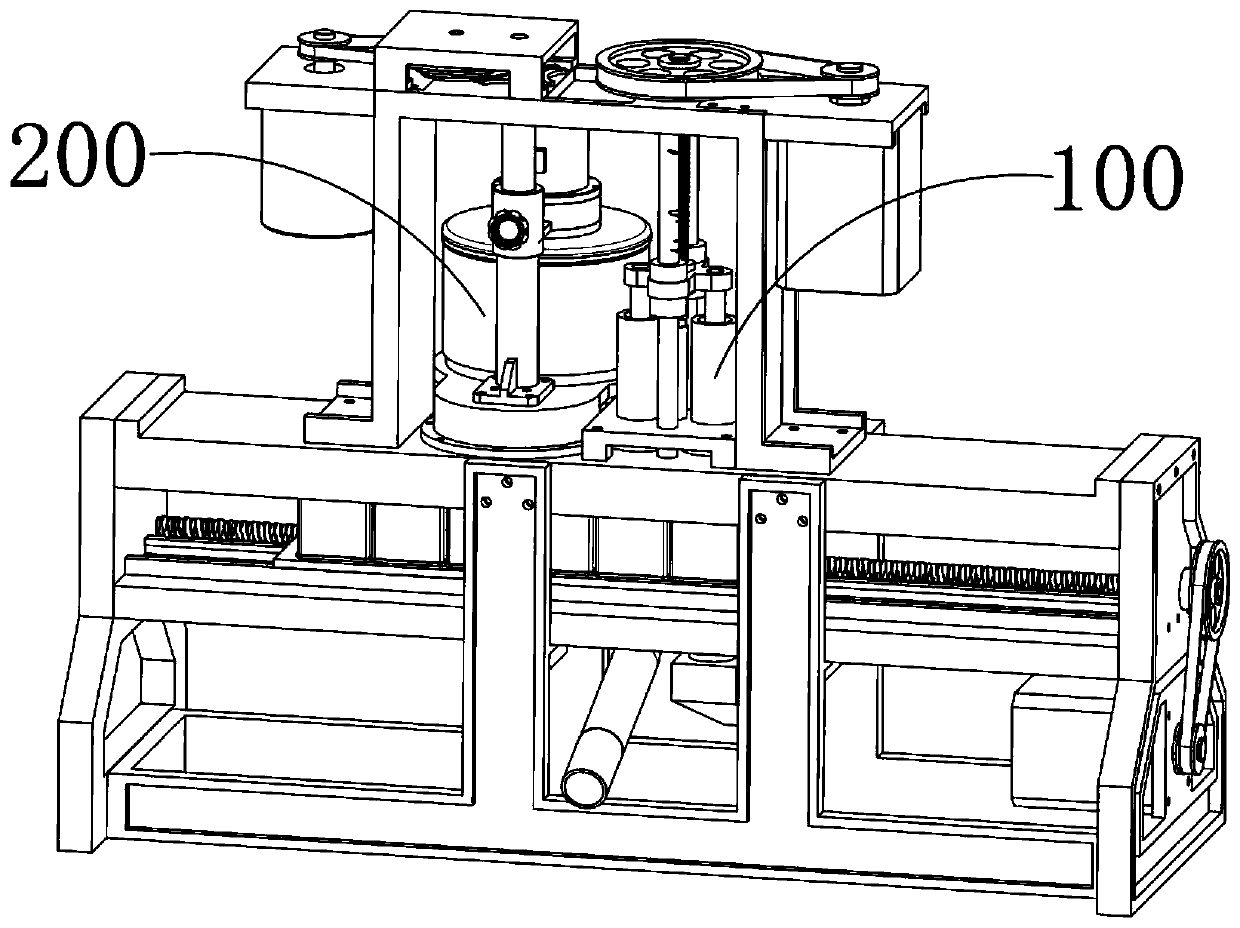

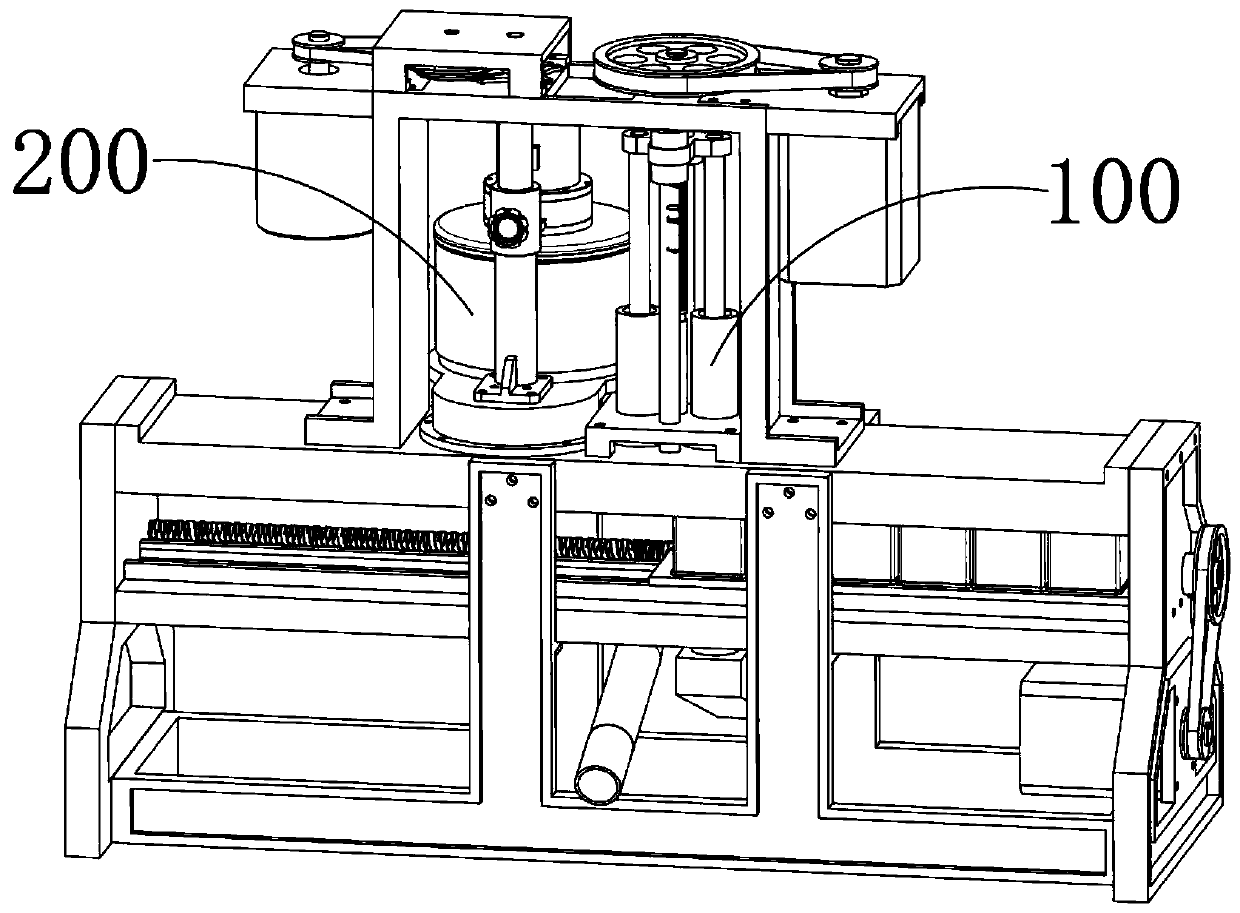

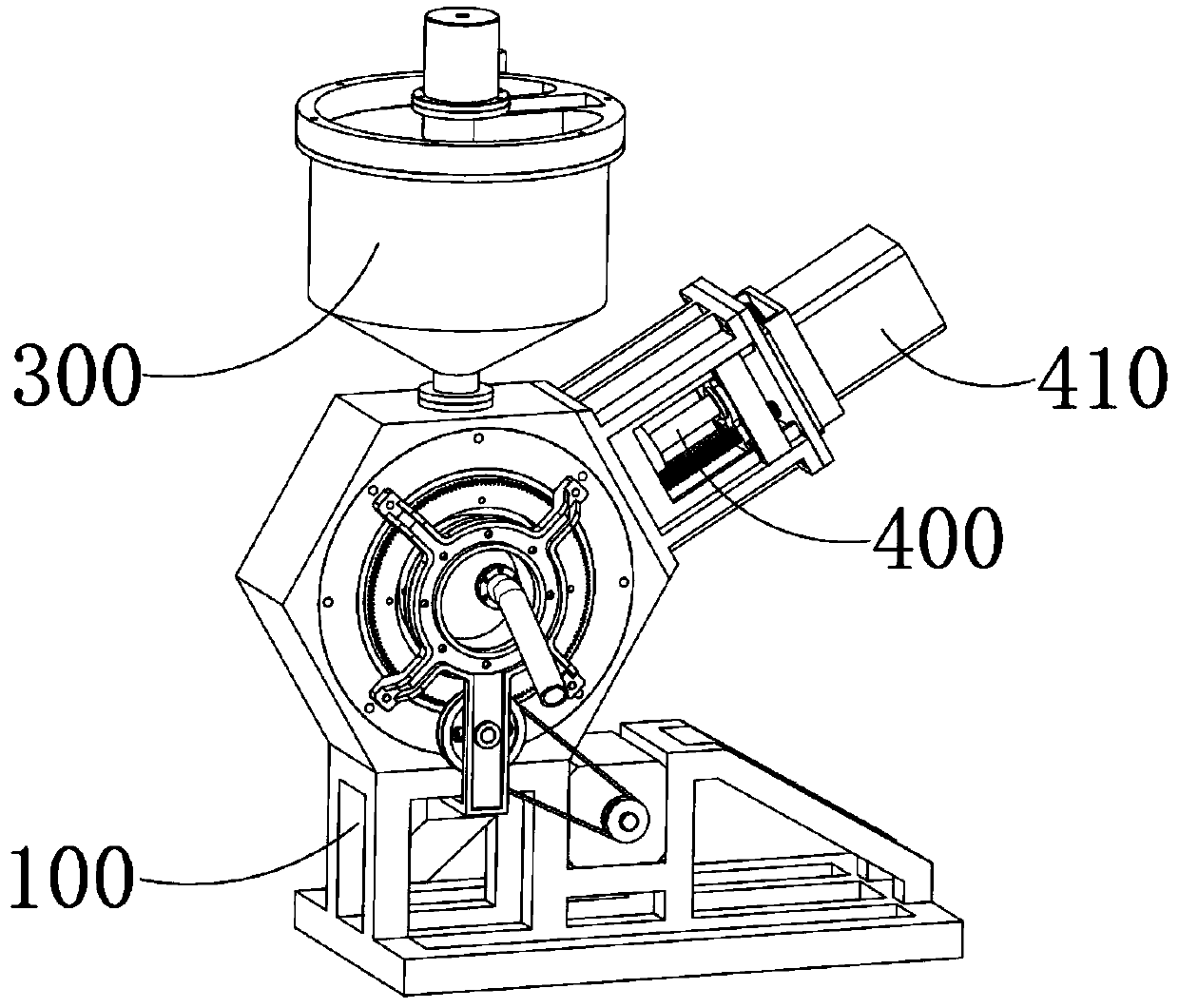

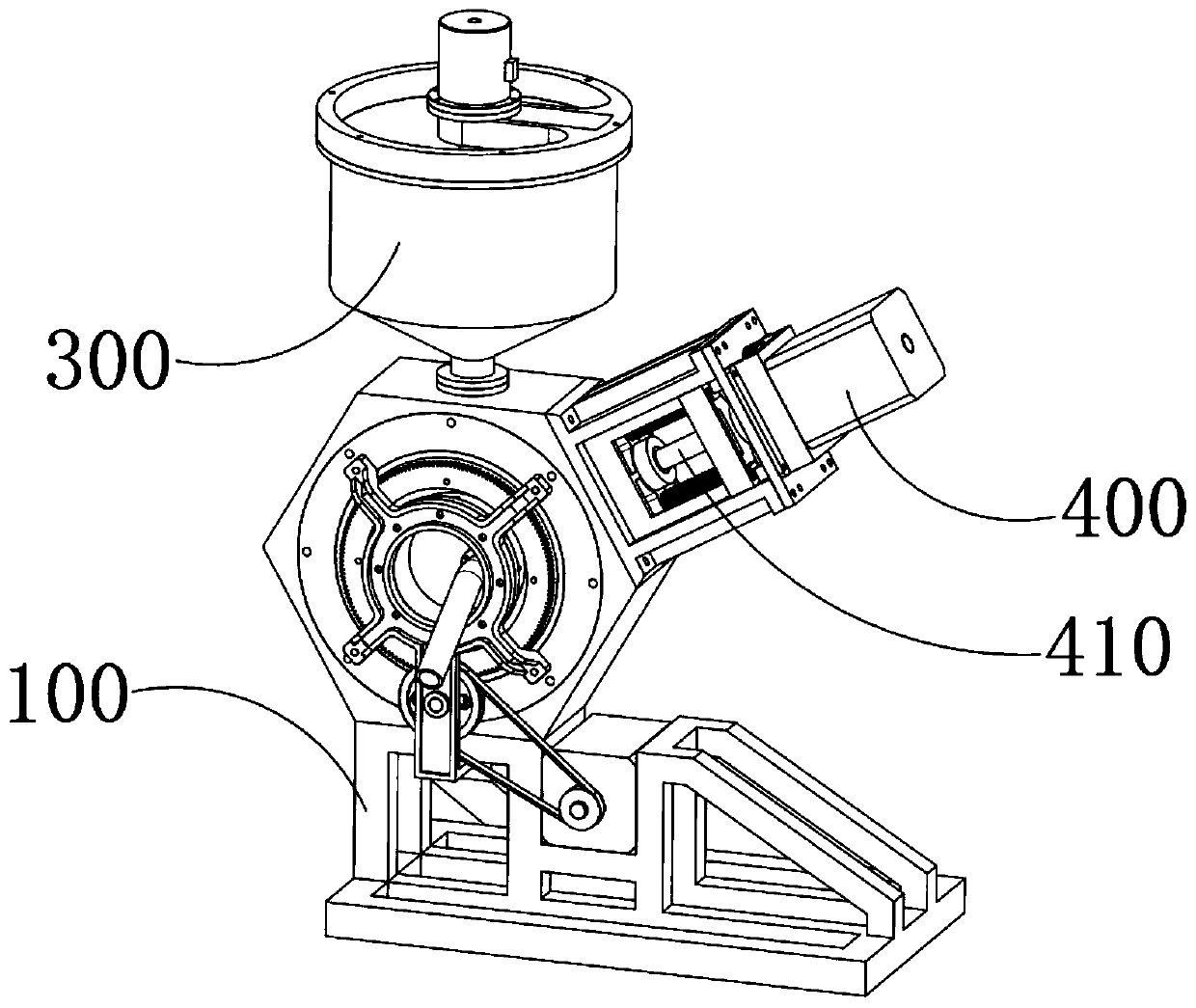

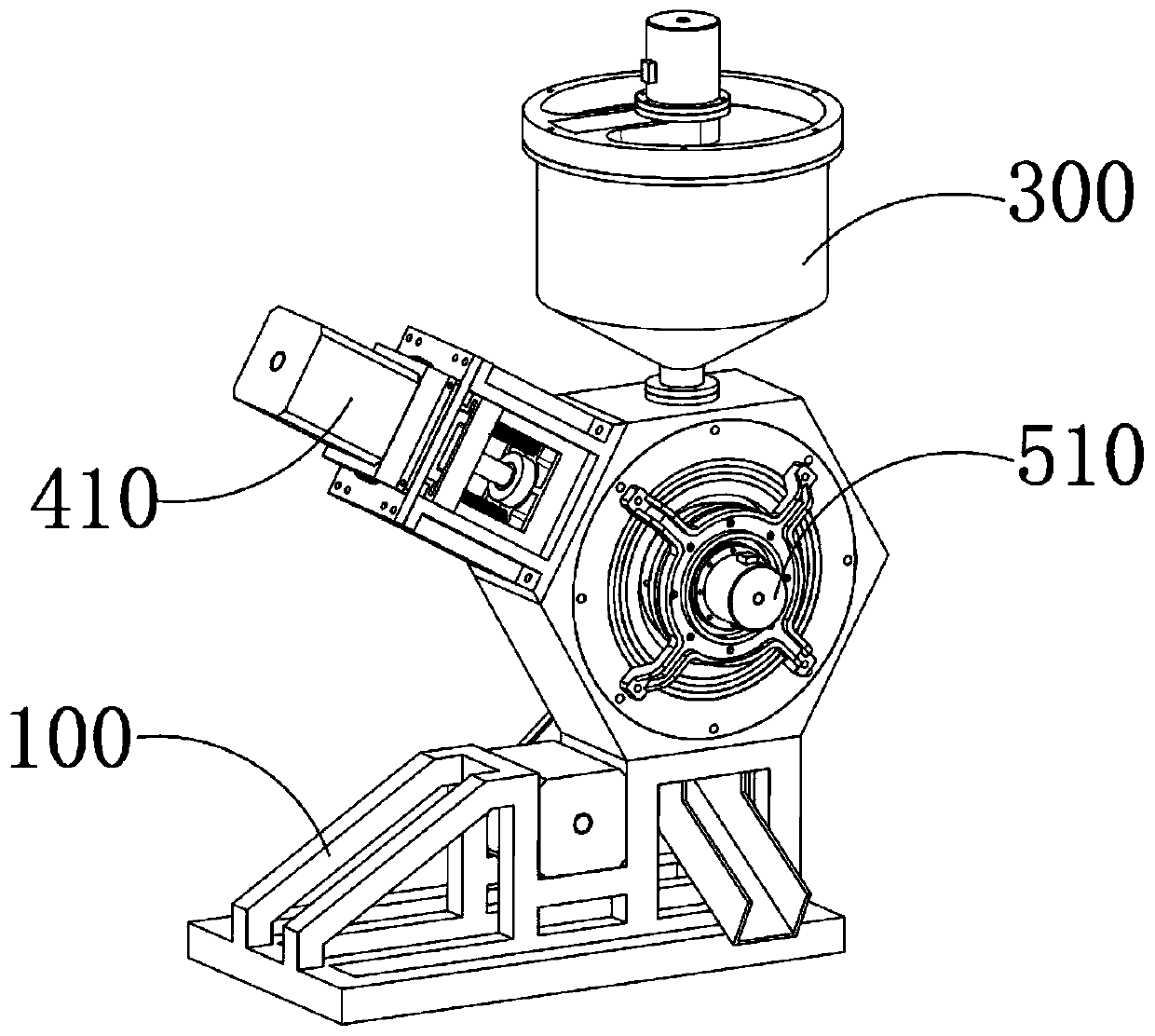

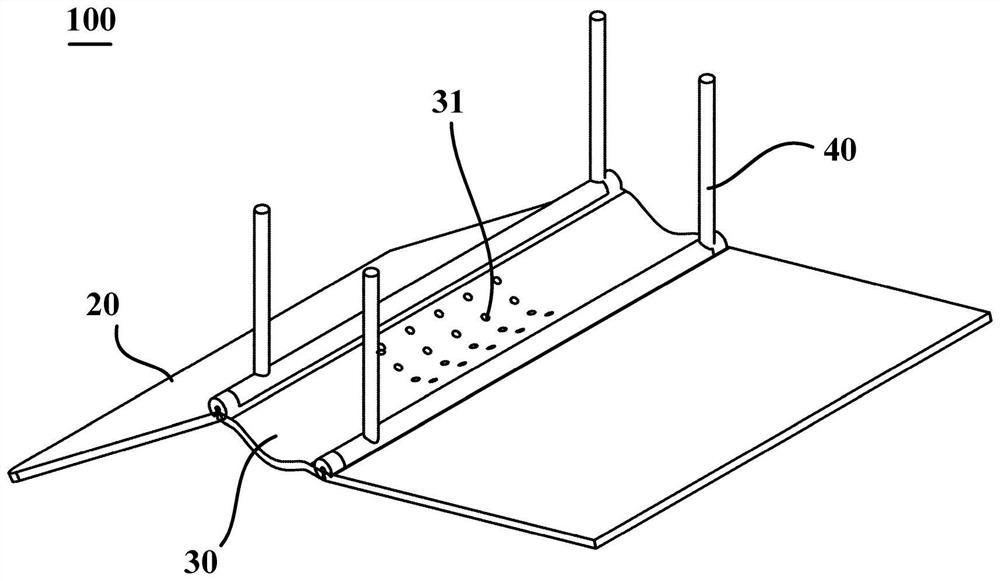

Multi-cylinder rotary oil pressing component for pressing rapeseeds to prepare rapeseed oil

InactiveCN111117763AIngenious structureThe principle is simpleFatty-oils/fats productionOil and greaseStructural engineering

The invention provides a multi-cylinder rotary oil pressing component for pressing rapeseeds to prepare rapeseed oil. The multi-cylinder rotary oil pressing component comprises a mounting base (100),a plurality of oil pressing cylinders (200), a pressing rod (400) and a residue discharging block (500), the plurality of oil pressing cylinders (200) are movably arranged on the mounting base (100) and are arranged in an array around the circumferential direction, the oil pressing barrel (200) is of a barrel structure with openings formed in the two ends, and a pressing bore is formed in the oilpressing cylinders (200), the pressing rod (400) can be sequentially inserted into the oil pressing cylinders (200) filled with oil plants and is used for pressing the oil plants in the oil pressing cylinders (200) to extract oil, the residue discharging block (500) can be sequentially inserted into the oil pressing cylinders (200) after extracted oil is received, and ejects and discharges oil residues in the oil pressing cylinders (200), and the oil pressing cylinders (200) sequentially rotate gradually around the circumferential direction of the array of the oil pressing cylinders, and sequentially cooperate with a plant supply mechanism (300), the pressing rod (400) and the residue discharging block (50). The oil pressing component has the following advantages: the multiple oil pressingcylinders are driven to conduct feeding, pressing and residue discdharging circularly, the automation degree of oil pressing is high, and the oil pressing efficiency is greatly improved.

Owner:六安七茗道机电科技有限公司

Near-suction range hood

PendingCN109595639AImprove smoke exhaust effectSmoke exhaust effect is easyDomestic stoves or rangesLighting and heating apparatusInlet channelEngineering

The invention discloses a near-suction range hood. The near-suction range hood comprises a shell, a cabinet and a fan system, wherein the cabinet and the fan system are located above the shell. The shell comprises a panel which is located at the front end and is inclined to the horizontal direction. The near-suction range hood is characterized in that the fan system comprises a first three-elementfan and a second three-element fan which are arranged in parallel; the fan system is arranged in the cabinet, at least two smoke guide plates are arranged on the front side of the panel, and the smoke guide plates are arranged on the front side of the panel and are arranged side by side in the left-right direction at intervals; an air inlet channel is formed by gaps between the smoke guide platesand the panel and gaps between adjacent smoke guide plates; and at least one of the smoke guide plates can stretch relative to the panel so as to be close to the panel to close the air inlet channelor be away from the panel to open the air inlet channel. At least two smoke guide plates which are arranged side by side and are arranged at intervals are arranged on the front side of the panel, so that airflow passing through an outer rectifying layer can be effectively segmented, rectified and guided, turbulent flow and turbulence in the airflow are reduced, and smooth airflow is formed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Condensation type oil-water separation method

InactiveCN109095551ANovel structureImprove the efficiency of oil extractionFatty/oily/floating substances removal devicesLiquid separationOil waterFreezing point

The invention discloses a condensation type oil-water separation method. The method is characterized in that high-efficiency oil-water separation is realized in a temperature range where oil reaches the freezing point but water does not reach the freezing point on the basis of the difference of the freezing points of oil and water. Therefore, the method has the advantages of novel structure, highoil extraction efficiency, high outlet oil purity and the like.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

Method for manufacturing oil from rapeseed by means of cold pressing

PendingCN109082340AIncrease oil production rateImprove qualityFatty-oils/fats refiningFatty-oils/fats productionWarm waterFreeze and thaw

The invention relates to the technical field of rapeseed processing, in particular to a method for manufacturing oil from rapeseed by means of cold pressing. The method for manufacturing the oil fromthe rapeseed by means of cold pressing includes 5 main oil manufacturing processes of rapeseed cleaning, rapeseed drying, rapeseed cold drying, rapeseed hulling and oil manufacturing and rapeseed oilpurification treatment. The method has the advantages that impurities and abortive rapeseed can be removed by the aid of repeated cleaning procedures, and accordingly the oil manufacturing efficiencycan be effectively improved; the rapeseed is soaked in warm water and then is dried, accordingly, tissues inside the rapeseed can be germinated and activated, and the oil yield of the rapeseed can beeffectively increased; oil is separately manufactured from rapeseed kernels and rapeseed hulls by the aid of rapeseed hulling technologies, impurities in primary rapeseed oil further can be removed bythe aid of freezing and thawing purification treatment, accordingly, the purpose of purifying rapeseed oil can be achieved, the quality of finished rapeseed oil can be improved, and squeezed rapeseedkernel oil and squeezed rapeseed hull oil can be applied to different fields.

Owner:望谟县布依王油脂有限公司

Smoke gathering plate for range hood and range hood

PendingCN112484106AIncrease the areaImprove the efficiency of oil extractionDomestic stoves or rangesLighting and heating apparatusAir velocityEngineering

The invention relates to a smoke gathering plate for a range hood and the range hood. The smoke gathering plate comprises two side baffles which are sequentially arranged in the transverse direction,and each side baffle is located on one side below a smoke inlet of the range hood; each side baffle is provided with a first side and a second side which are sequentially arranged in the transverse direction, and the second sides are close to the middle of the smoke inlet; and each side baffle is arranged in a rotatable mode so that the first side of the side baffle can rotate upwards to a presetposition and is used for preventing airflow from flowing into the smoke inlet from the outside of the first side of the side baffle. For a gas appliance using a double-end stove, when cooking areas onthe two sides are opened, the downward turning angles of the two side baffles can be adjusted to control the smoke inlet area, and therefore the air inlet pressure and the air speed are adjusted; andwhen the single-side cooking area is used, the side baffle on the other side can be adjusted to turn over upwards and abut against the inner side of a smoke cavity, so that a semi-closed cavity is formed to shield inlet air in the direction of the other side, the overall air pressure of the side of the range hood is increased, and the working efficiency of the range hood is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +2

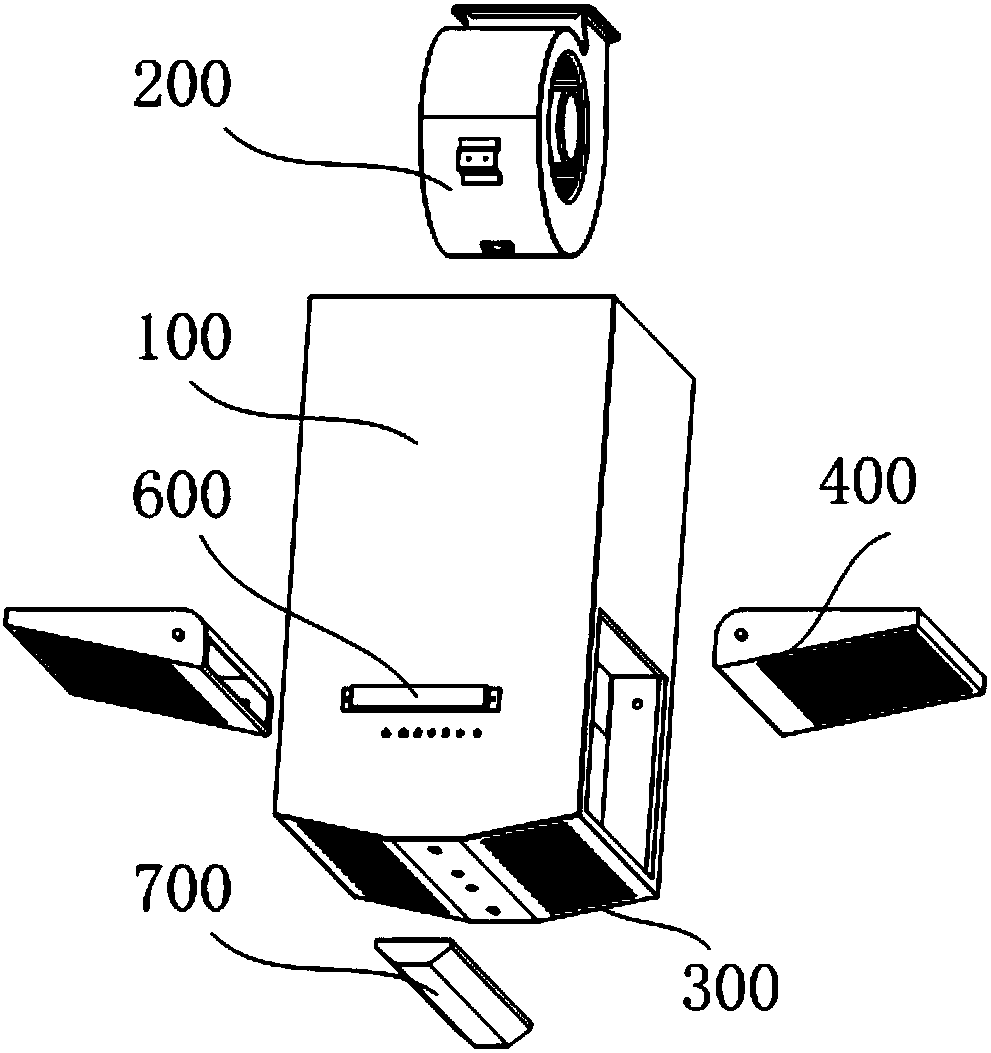

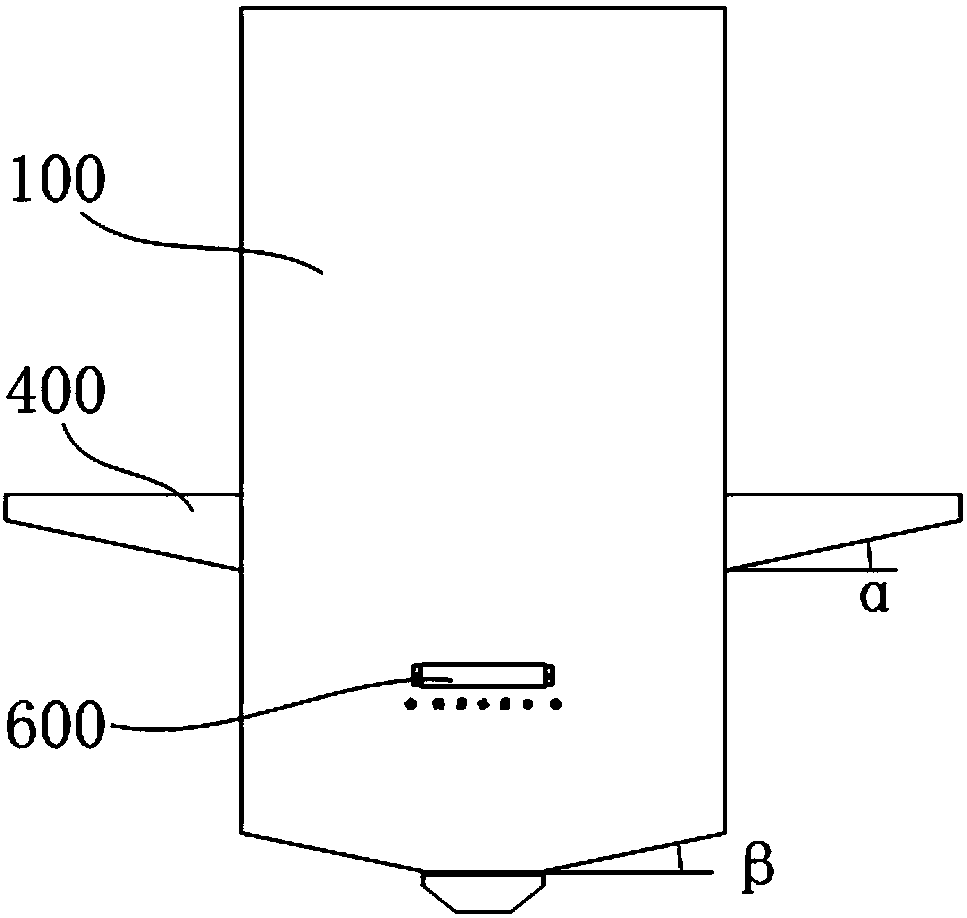

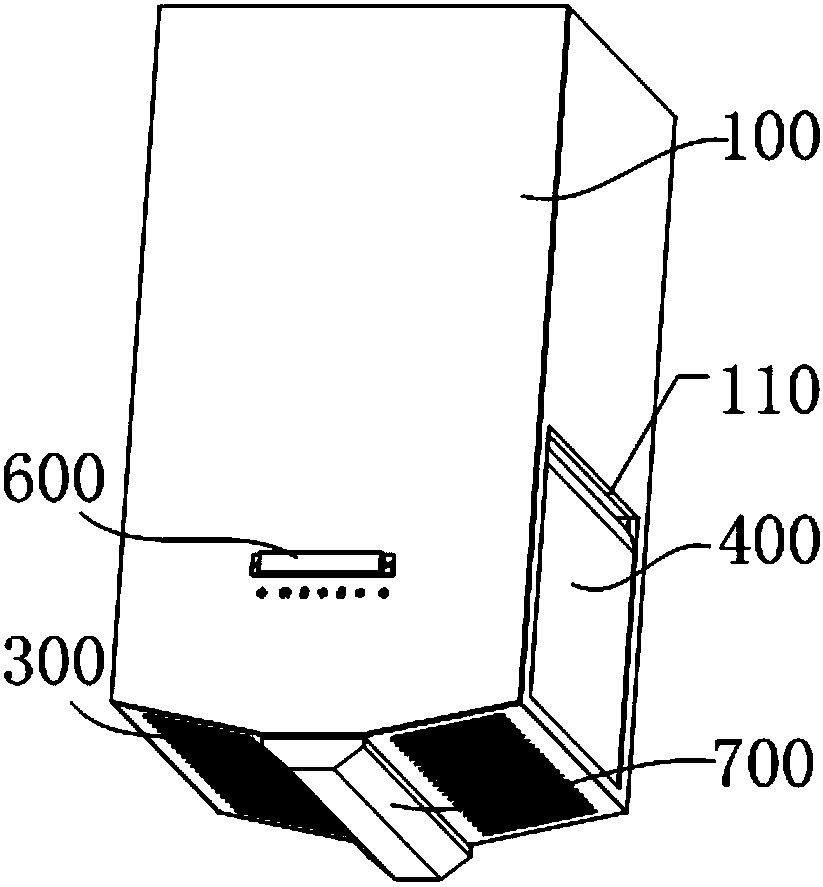

Range hood with multi-smoke vent and top suction type range hood

PendingCN108266775AAffect physical and mental healthComprehensive adsorptionDomestic stoves or rangesLighting and heating apparatusEngineeringClosest relatives

The invention provides a range hood with multi-smoke vent and a top suction type range hood, and belongs to the technical field of range hoods. The range hood with multi-smoke vent at least comprisesa shell device, a bottom exhausting device and a side exhausting device, wherein the side exhausting device is arranged on at least one side of the shell device and can be opened or closed relative tothe shell device; when the side exhausting device is opened, the side exhausting device is matched with the bottom exhausting device to suck the smoke into the shell device and then exhaust; when theside exhausting device is closed, the side exhausting device can be folded into the shell device. The top suction type range hood comprises the range hood with the multi-smoke vent. The invention solves the problem of worse smoke sucking effect caused by the fact that fume generated by cookware does not correspond to the smoke vent in the prior art.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com