Top suction type extractor hood

A range hood, top suction technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of hindering the internal flow of gas, external air disturbance, air pollution, etc., to prevent oil fume from escaping, improving the effect, and improving The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

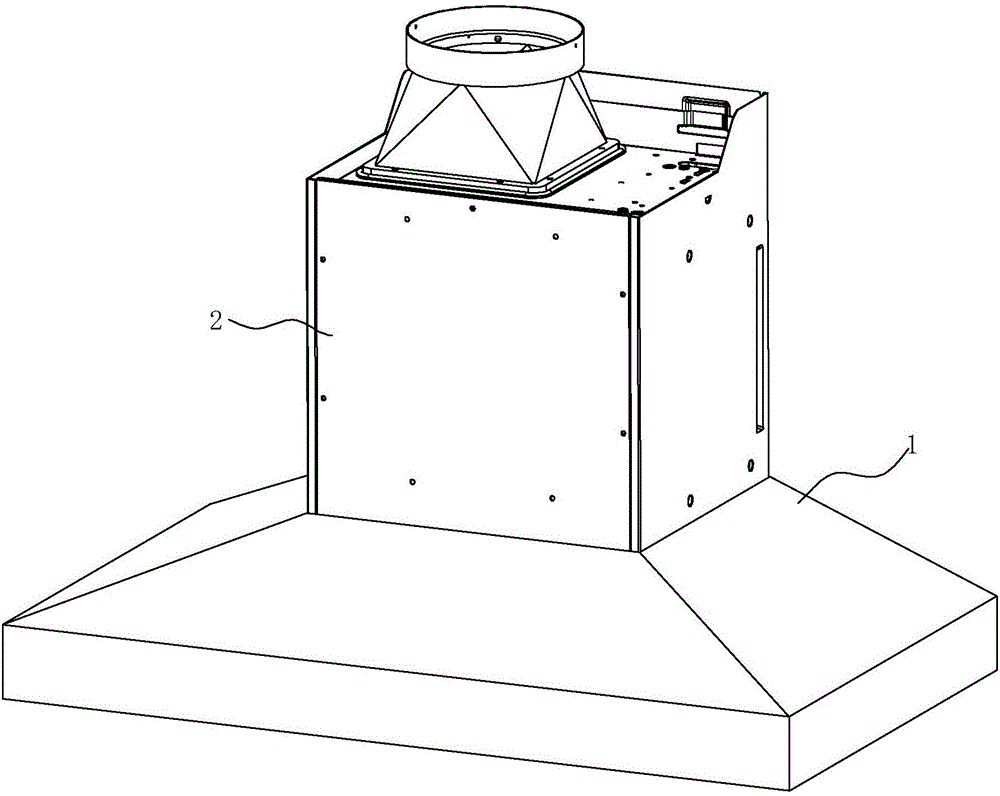

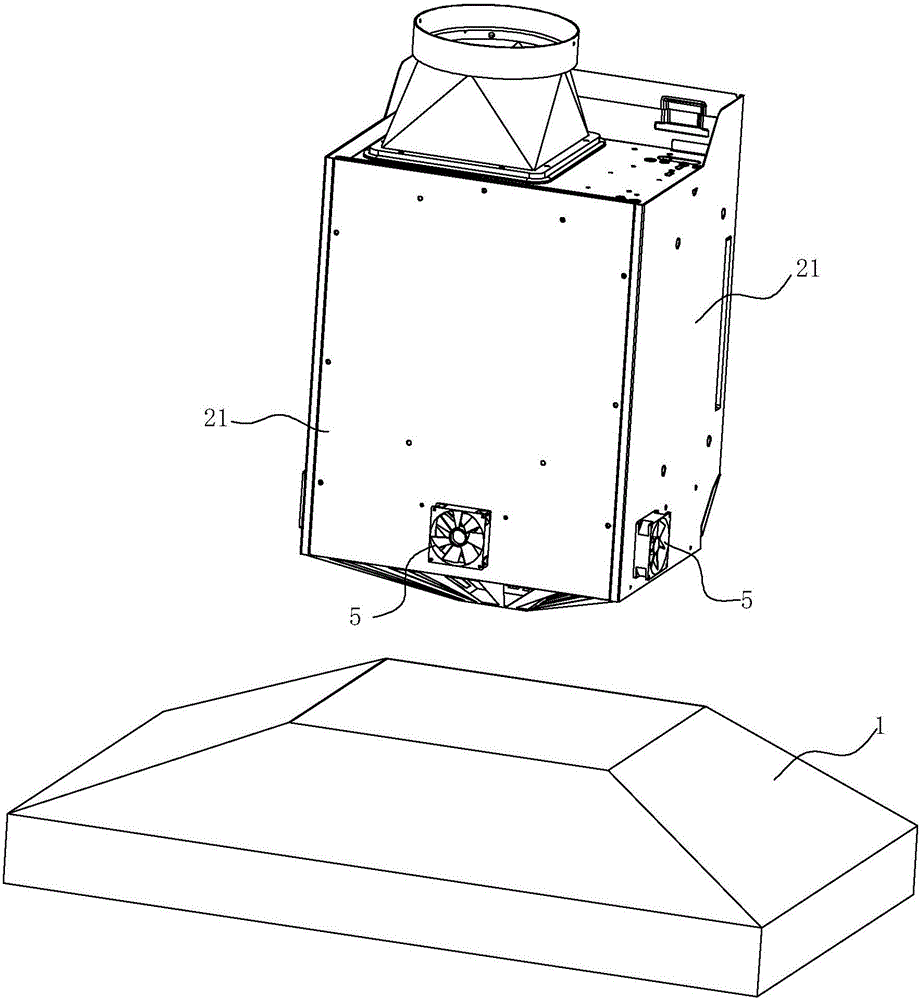

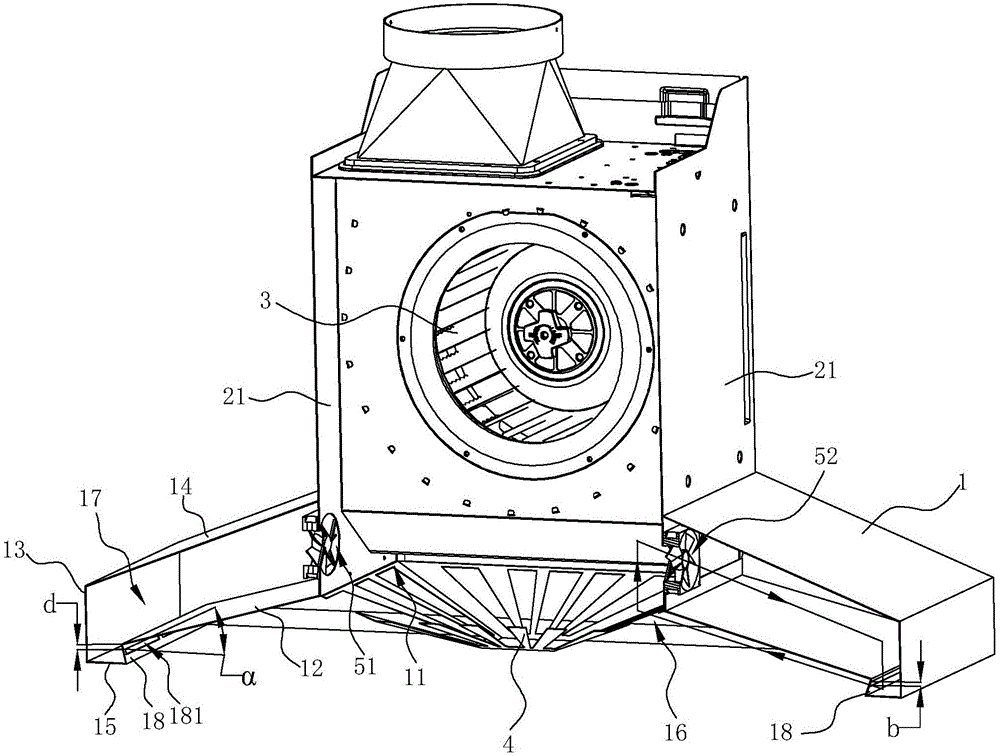

[0027] see Figure 1 ~ Figure 4 , a top-suction range hood, including a smoke collection hood 1, a fan cover 2 arranged above the smoke collection hood 1, and a main fan 3 arranged in the fan cover 2. An air inlet 11 is opened on the fume collecting hood 1, and the fume gas is sucked in from the air inlet 11, and is discharged into the public flue through the main fan 3. The fan cover 2 includes four side walls 21 forming a square fan cover 2 .

[0028] The smoke collecting hood 1 includes a lower cover plate 12, vertical side plates 13, an upper cover plate 14 and a horizontal bottom plate 15. The above-mentioned air inlet 11 is opened in the middle of the lower cover plate 12, and the lower cover plate 12 is upward from the outer edge to the middle. Inclined, thereby forming a smoke collecting cavity 16 under the lower cover plate 12 . The outer edge of the lower cover plate 12 is connected to the inner edge of the bottom plate 15, and the outer edge of the bottom plate 15...

Embodiment 2

[0035] see Figure 5 , in this embodiment, the difference from the first embodiment above is that the auxiliary fan 5 adopts a centrifugal fan instead of a centrifugal fan. At this time, there are two centrifugal fans arranged at the front end, which are respectively close to the left and right sides, and the left centrifugal fan Blow air in the cavity 17 on the left side, while the centrifugal fan on the right side blows air in the cavity 17 on the right; .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com