Multi-cylinder circulating pressing method of rapeseed oil

A kind of rapeseed oil, cylinder type technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of low automation, time-consuming and labor-intensive, low oil extraction efficiency, etc., and achieve high automation, simple principle, and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

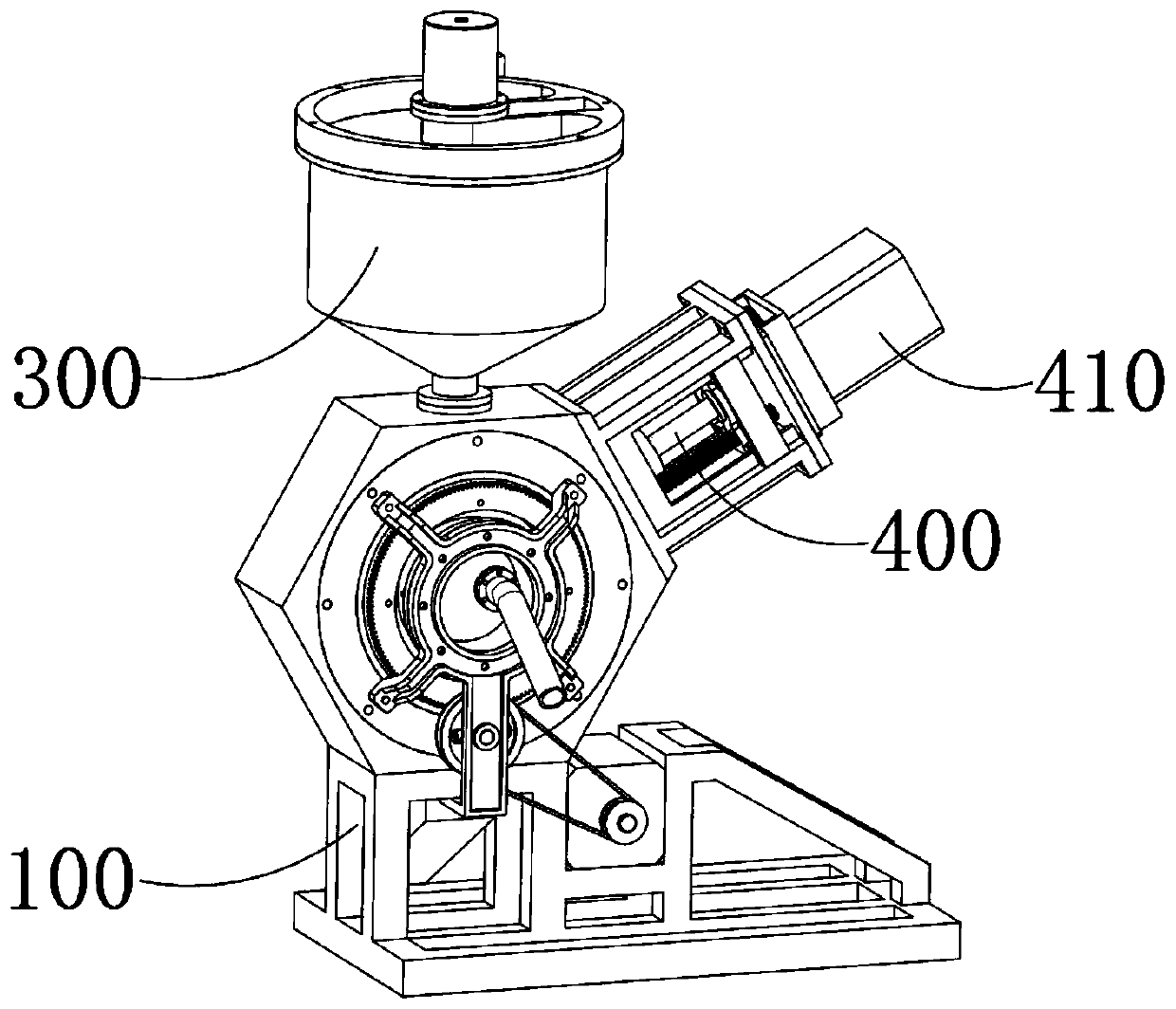

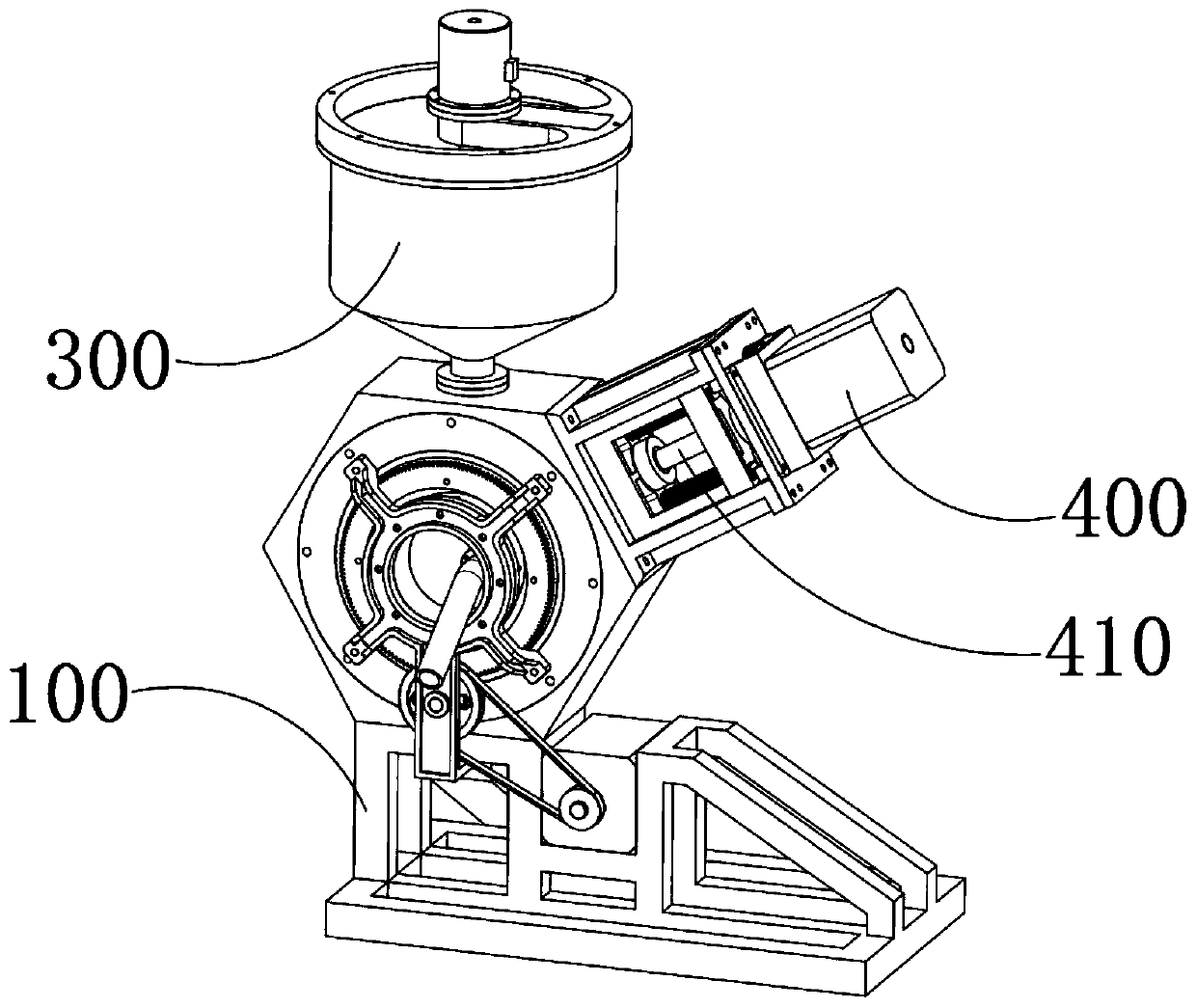

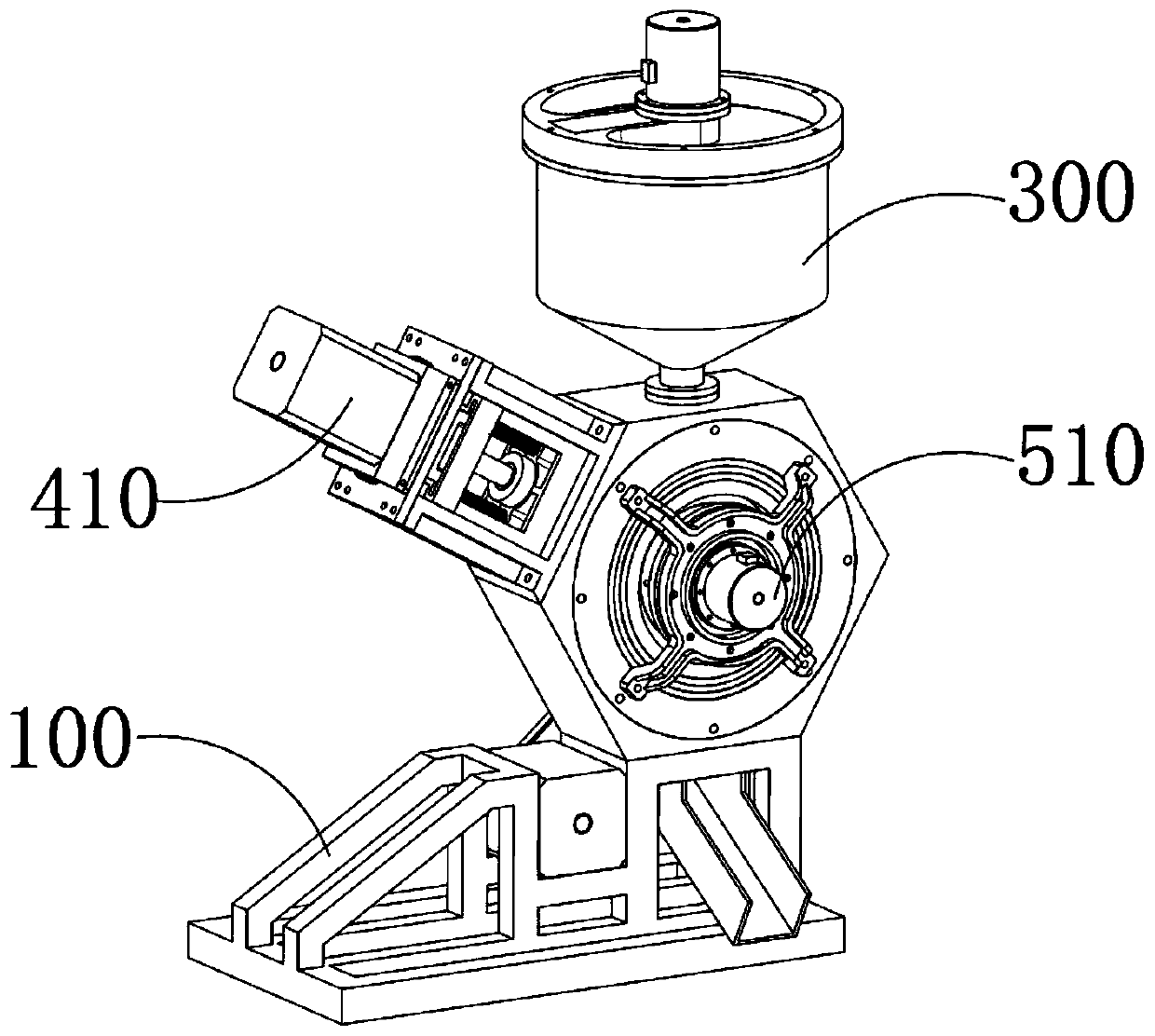

[0064] The method for extracting rapeseed oil in a multi-drum cycle, the steps are as follows:

[0065] (1) Feeding stage;

[0066] S1: The user puts the steamed / fried oil in the feeding mechanism 300, and the rotating drive mechanism 130 drives the intermediate cylinder 106 to rotate clockwise at 60 degrees around its own axis, and the oil extraction cylinder 200 will follow the The oil extractor 200 moves synchronously, and when the oil extractor 200 rotates to align with the feeding port 101a, the feeding mechanism 300 transports the oil inside it into the oil extractor 200;

[0067] There are multiple oil extractors 200, and the plurality of oil extractors 200 are movably arranged on the installation base 100 and arranged in an array around the circumferential direction. In addition to pressing and boring, the feeding mechanism 300 is used to sequentially supply steamed / fried oil to the oil extraction cylinder 200, and the pressing rod 400 can be driven by the pressing dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com