Simple and efficient hydraulic oil extraction equipment

A high-efficiency hydraulic oil extraction technology, applied in presses, grain processing, manufacturing tools, etc., can solve problems such as single oil extraction method, affecting the efficiency of oil extraction, and difficult to clean residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

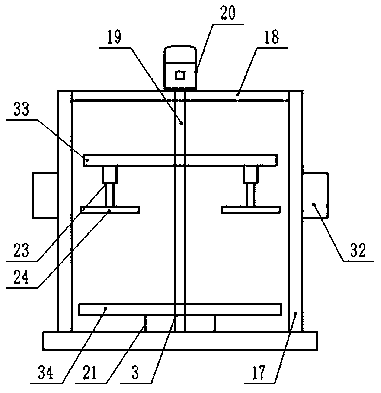

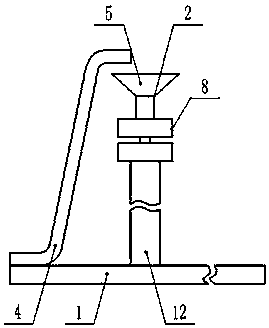

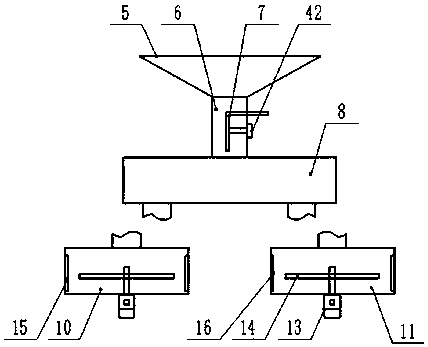

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8As shown, a simple and high-efficiency hydraulic oil pressing equipment includes a base base 1, a feeding device 2 is provided on the front side of the upper end of the base base 1, and a hydraulic oil pressing device 3 is provided on the rear side of the upper end of the base base 1. The feeding device 2 is composed of the inclined conveyor 4 provided above the front end of the base base 1, the feeding funnel 5 provided directly below the discharge end of the inclined conveyor 4, the feeding cylinder 6 provided below the feeding funnel 5, and the feeding The inverted L-shaped volume control plate 7 provided in the cylinder 6, the crushing box 8 connected to the lower end of the feeding cylinder 6, the roller device 9 provided in the crushing box 8, and the left and right sides below the crushing box 8 are respectively equipped with The hot press temperature con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com