Soybean milk grinding machine

A refiner and pulp rolling technology, which is applied in milk substitutes, grain processing, dairy products, etc., can solve the problems of complete rolling, low yield of soybean-rolled soybean milk, and large labor consumption, and achieves increased yield and continuous automation. The effect of high production work and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

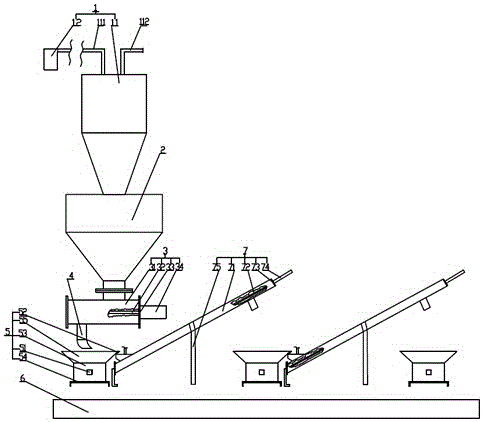

[0027] as attached figure 1 The present embodiment shown comprises air extraction device 1, feeding cylinder 11, air extraction pump 12, material suction pipe 111, water inlet pipe 112, feeding funnel 2, rolling pushing device 3, shell one 31, push rod 32, flange Disk 1 33, driving device 1 34, discharge pipe 4, pulping device 5, pulp outlet 51, slag discharge port 52, pulping device body 53, base 54, sealing cover 55, material receiving trough 6, conveying device 7 , shell two 71, screw conveying rod 72, flange two 73, driving device two 74, support seat 75, by arranging air extraction device 1, soybean is sucked in the feeding cylinder 11, and air extraction device 1 is provided with water inlet pipe 112, the soybeans and water are mixed and enter the feeding funnel 2, the lower end of the feeding funnel 2 is provided with a rolling push device 3, and the soybeans are crushed and pushed to the discharge pipe 4 through the rolling push device 3, and the discharge pipe 4 A pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com