Method for extracting nutritive matter from sauce residue

A technology of soy sauce residue and extractor, which is applied in the field of nutrients to achieve the effects of improving solubility, high economic benefits, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

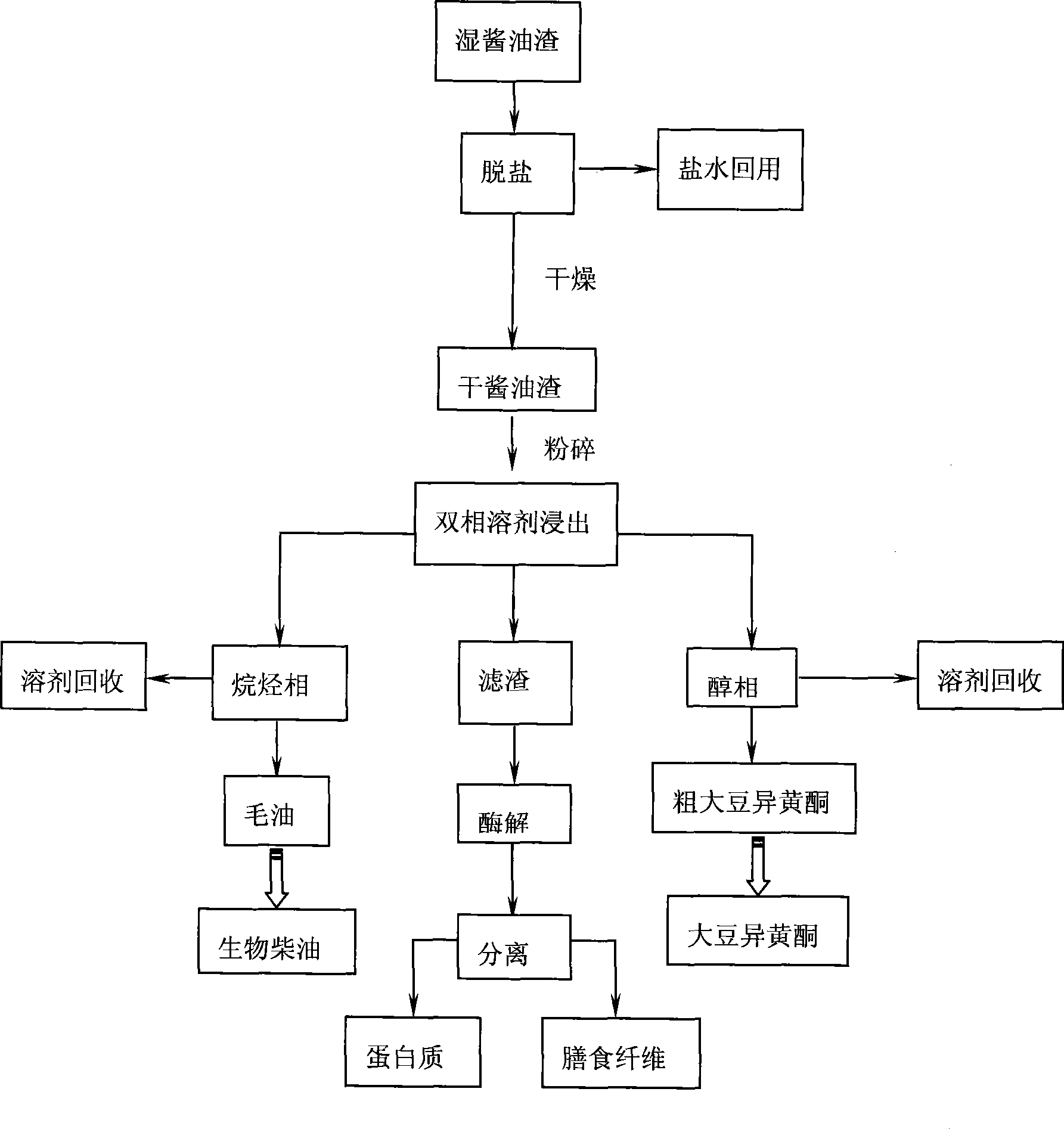

[0026] See figure 1 .

[0027] Add the desalted, dried and pulverized soy sauce residue into the two-liquid phase extractor, and then simultaneously add n-hexane and ethanol solution with a concentration of 75% by volume, wherein the weight ratio of soy sauce residue to n-hexane is 1:8, The weight ratio of soy sauce residue to ethanol solution is 1:8; extract the soy sauce residue at a temperature of 60°C, reflux and stir for 2 hours, and obtain the extraction mixture after the extraction is completed; add the extraction mixture to the filtration separation device, The filter residue is defatted soy sauce residue powder, and the filtrate is divided into upper and lower phases. The two-phase filtrate after liquid separation is subjected to vacuum distillation to recover the solvent. The extraction rate of the obtained crude oil is 97.9%, and the extraction amount of soybean isoflavones is 0.520mg / lg Dry soy sauce residue (calculated as daidzein and genistein), with a purity of...

Embodiment 2

[0030] See figure 1 .

[0031] Add the desalted, dried and pulverized soy sauce residue into the two-liquid phase extractor, and then add n-hexane and an ethanol solution with a concentration of 80% by weight at the same time, wherein the weight ratio of soy sauce residue to n-hexane is 1:6, The weight ratio of soy sauce residue to ethanol solution is 1:4. Extract the soy sauce residue at a temperature of 60°C, reflux and stir for 4 hours. After the extraction is completed, the extraction mixture is obtained; the extraction mixture is added to the filtration separation device, The filter residue is defatted soy sauce residue powder, and the filtrate is divided into upper and lower phases. The two-phase filtrate after liquid separation is subjected to vacuum distillation to recover the solvent. The extraction rate of the obtained crude oil is 92.9%, and the extraction amount of soybean isoflavones is 0.508mg / lg Dry soy sauce residue (calculated as daidzein and genistein), with...

Embodiment 3

[0034] See figure 1 .

[0035] Add the desalted, dried and pulverized soy sauce residue into the two-liquid phase extractor, and then add n-hexane and ethanol solution with a concentration of 75% by weight at the same time, wherein the weight ratio of soy sauce residue to n-hexane is 1:8, The weight ratio of soy sauce residue to ethanol solution is 1:8. Extract the soy sauce residue at a temperature of 50°C, reflux and stir for 2 hours. After the extraction is completed, the extraction mixture is obtained; the extraction mixture is added to the filtration separation device, The filter residue is defatted soy sauce residue powder, and the filtrate is divided into upper and lower phases. The two-phase filtrate after liquid separation is subjected to vacuum distillation to recover the solvent. The extraction rate of the obtained crude oil is 95.4%, and the extraction amount of soybean isoflavones is 0.529mg / lg Dry soy sauce residue (calculated as daidzein and genistein), with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com