Fume exhaust fan of fume focusing cover with air inlet concave chamber

The technology of a range hood and a fume collecting hood is applied in the field of range hoods, which can solve the problems of poor range hood, unsightly appearance, complicated structure, etc., and achieves high range hood efficiency, good range hood effect and good operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

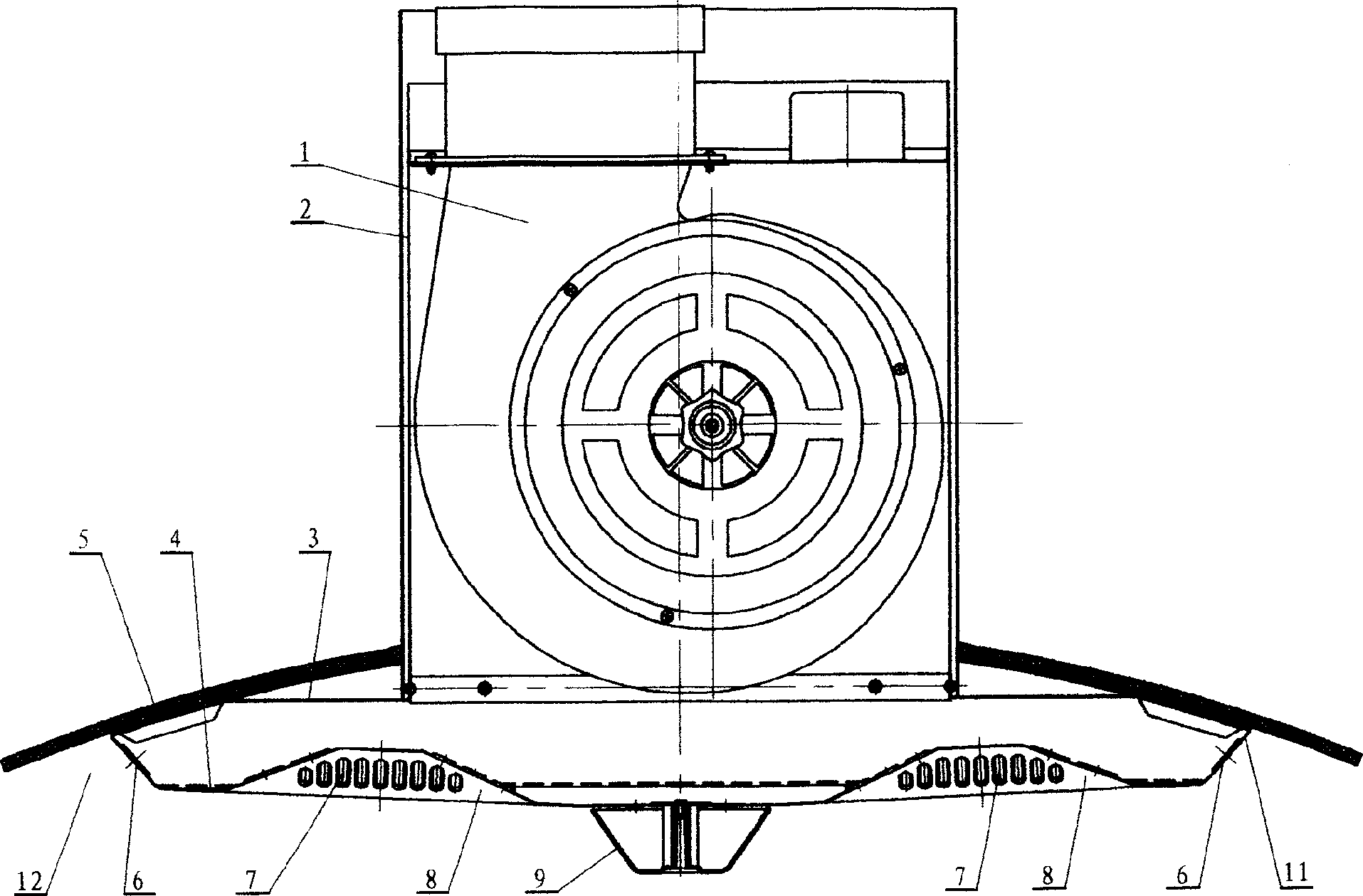

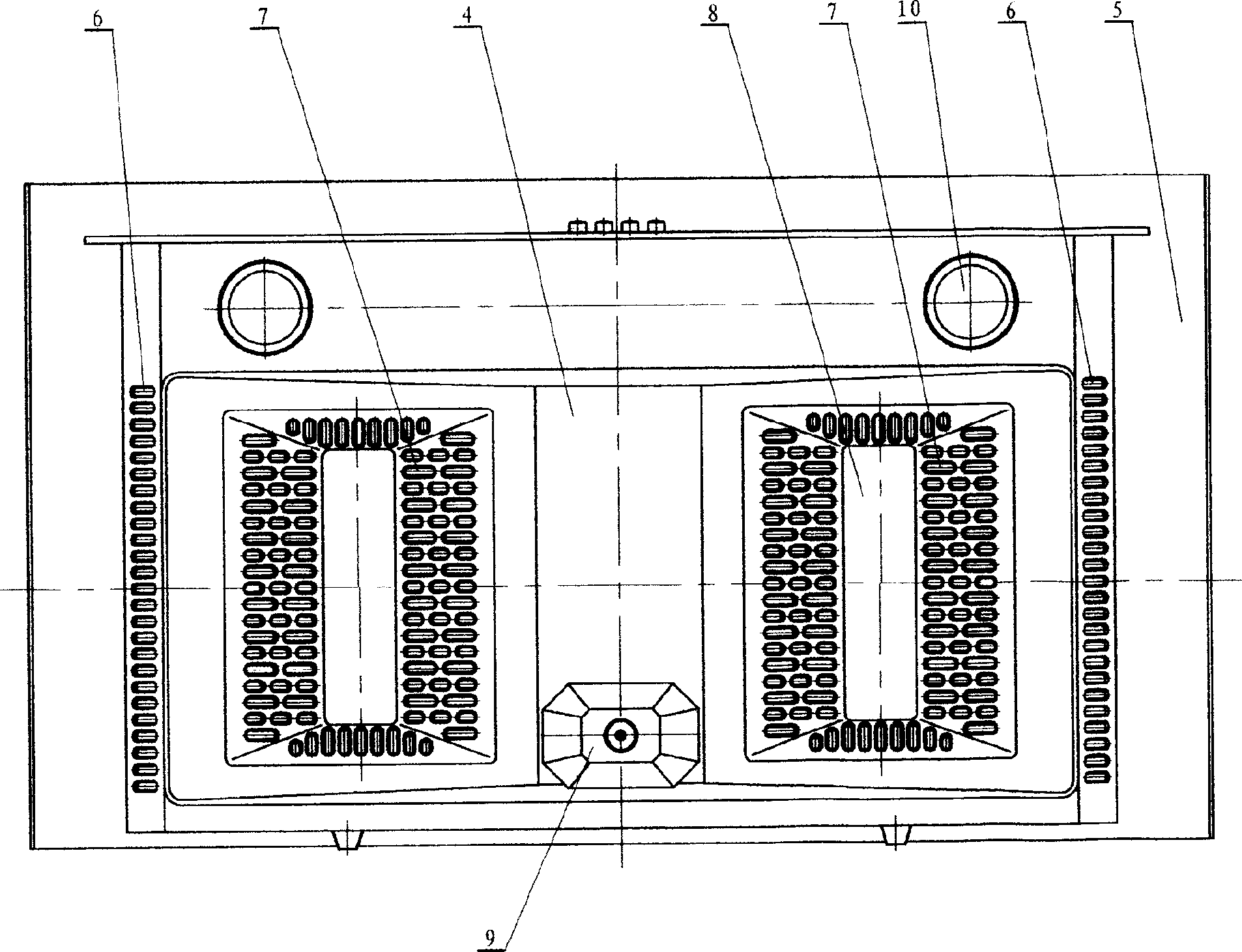

[0015] Example 1, see figure 1 and figure 2 . This is a smoke collecting hood 4 with two main air inlet cavity 8 in the shape of a prism, and a plurality of main air inlets 7 are evenly distributed on the four oblique sides of the quadrangular truss, and the shape of the main air inlet 7 is Long hole. The upper curved side plates 11 at both ends of the smoke collecting hood 4 are sandwiched with the downwardly extending part of the outer smoke collecting hood 5 to form left and right secondary air inlet concave cavities 12, which are opened on the upward curved side plates 11. There are a plurality of elongated secondary air inlets 6. The main air inlet 7 and the auxiliary air inlet 6 are processed at the same time when the smoke collecting hood 4 is being processed, and the air outlet is punched out of the steel plate by stamping to form a flanging hole, that is, the three sides of the hole are torn apart from the steel plate, and the other side is connected to the steel ...

Embodiment 2

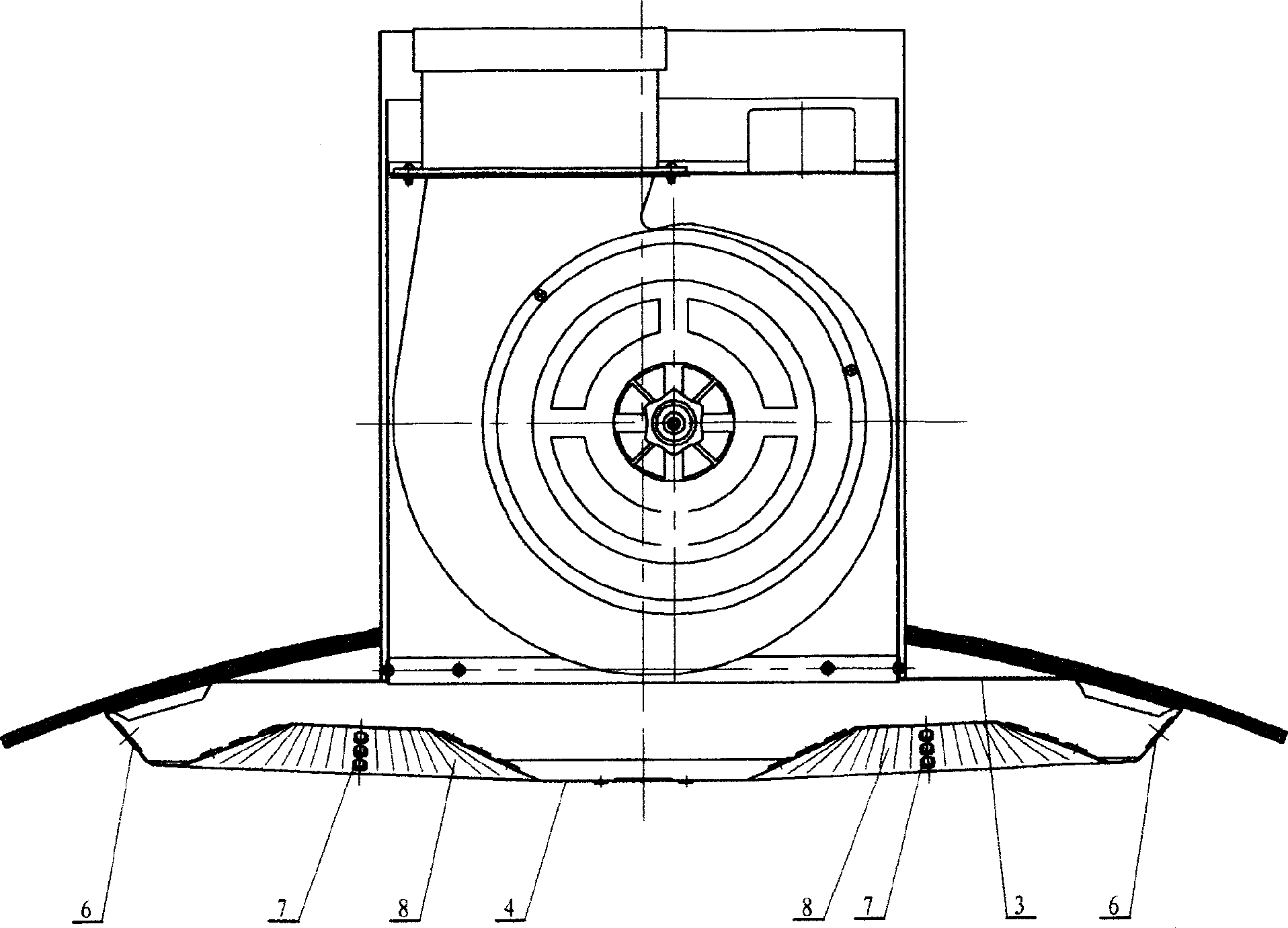

[0016] Example 2, see image 3 and Figure 4 . This is the shape of the two main air inlet cavities 8 of the fume collecting hood 4 in the shape of a truncated cone (or a sphere). The shape of the tuyere is a long strip hole. The upper curved side plates 11 at both ends of the smoke collecting hood 4 are sandwiched with the downwardly extending part of the outer smoke collecting hood 5 to form left and right secondary air inlet concave cavities 12, which are opened on the upward curved side plates 11. There are long side air inlets. The main air inlet 7 and the auxiliary air inlet 6 are processed simultaneously when processing the smoke collecting hood 4, and the tuyere is processed into a flanged hole.

Embodiment 3

[0017] Example 3, see Figure 5 and Image 6 . The main air inlet cavity 8 on the fume collecting hood 4 is a circular frustum, and the main air inlet 7 is formed on the side wall of the circular table and the upper bottom of the circular table. The tuyere shape of a plurality of main air inlets 7 on the side wall is a long hole, and the main air inlets 7 on the upper bottom are round holes. In this example, when the tuyere is being processed, all the steel plates at the tuyere are punched open to form holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com