Smoke gathering plate for range hood and range hood

A range hood and smoke plate technology, which is applied in the direction of removing oil fumes, applications, and household stoves, can solve the problems of high hanging point, waste of resources, and inability to adjust the area of the smoke inlet, so as to increase the area, increase the air volume, and improve the suction. The effect of oil fume efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

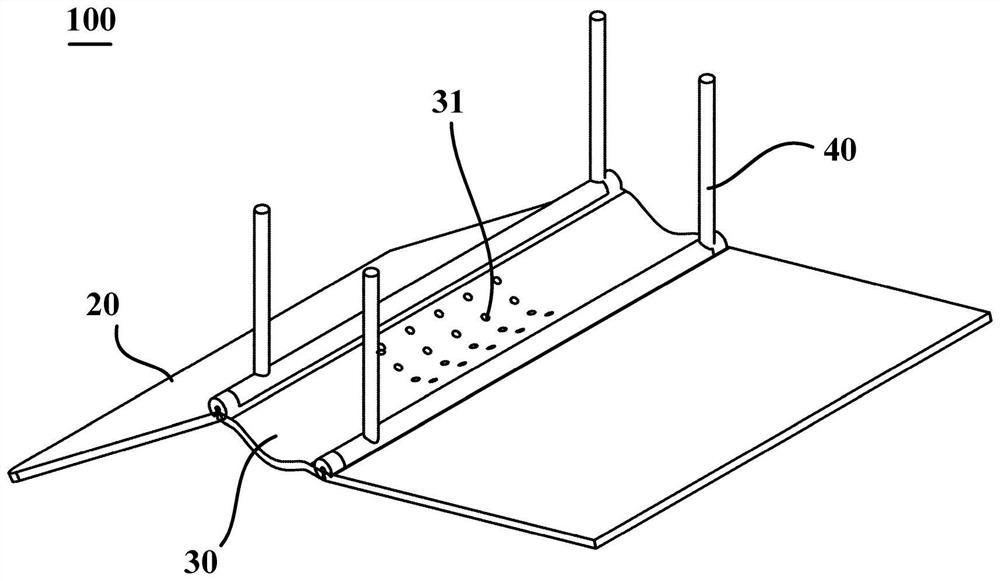

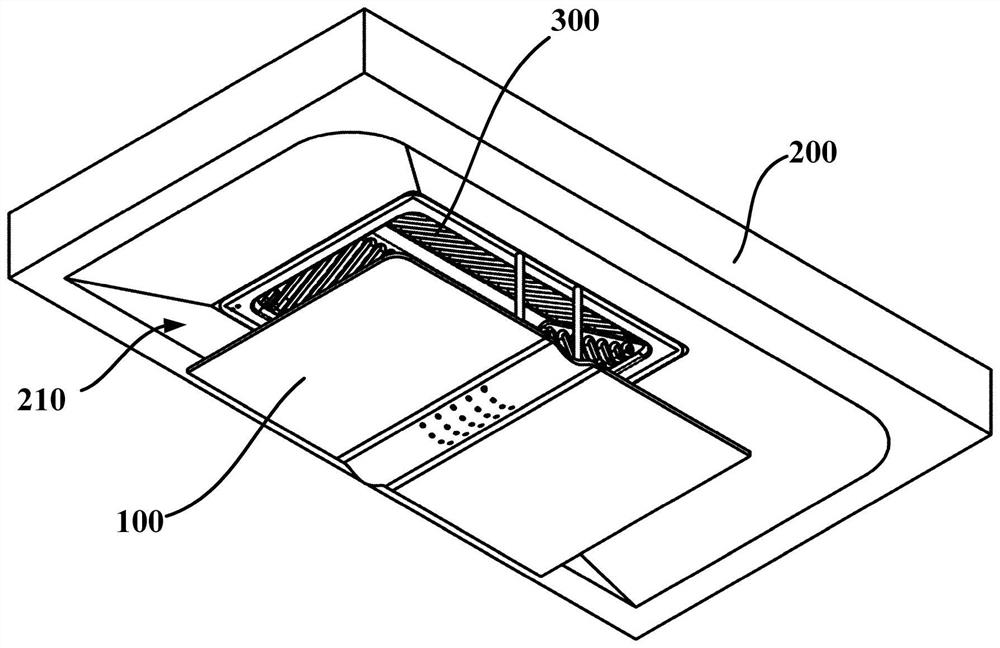

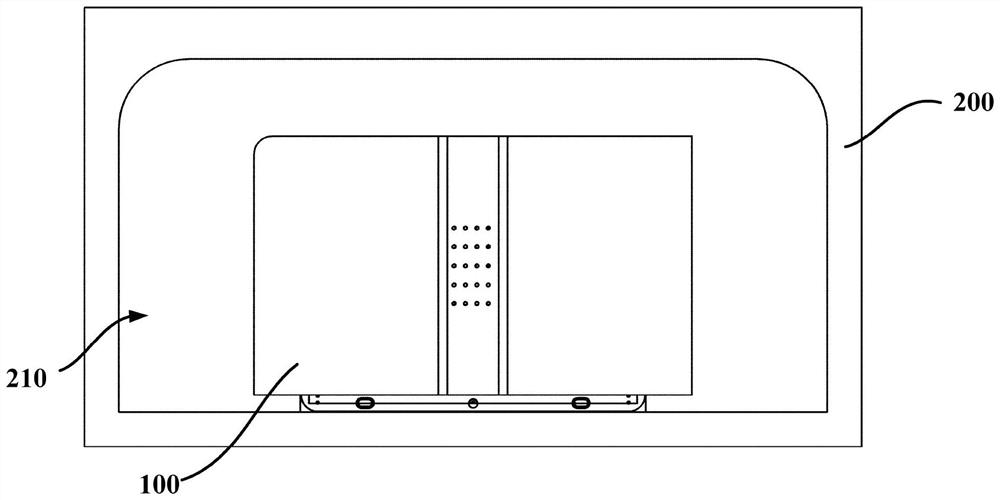

[0029] figure 1 It is a schematic structural diagram of a smoke collecting plate for a range hood according to an embodiment of the present invention. Such as figure 1 shown, and refer to Figure 2 to Figure 10 , the embodiment of the present invention provides a smoke collecting plate 100 for a range hood, and the smoke collecting plate 100 includes two side baffles 20 . Two side baffles 20 are arranged in sequence along the transverse direction, and each side baffle 20 is located on the lower side of the smoke inlet 211 of the range hood. Each side baffle 20 has a first side and a second side arranged in sequence along the transverse direction, and the second side is adjacent to the middle of the smoke inlet 211 . Each side baffle 20 is rotatably arranged so that the first side of the side baffle 20 is rotated upward to a preset position for blocking air flow from the first side of the side baffle 20 into the smoke inlet. 211. For example, if Figure 5 and Figure 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com