Household oil press

An oil press, household technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increasing the volume and weight of the oil press, reducing the volume and weight of the oil press, and being unfavorable for household use, so as to improve the efficiency of oil pressing. , reduce the volume and weight, improve the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

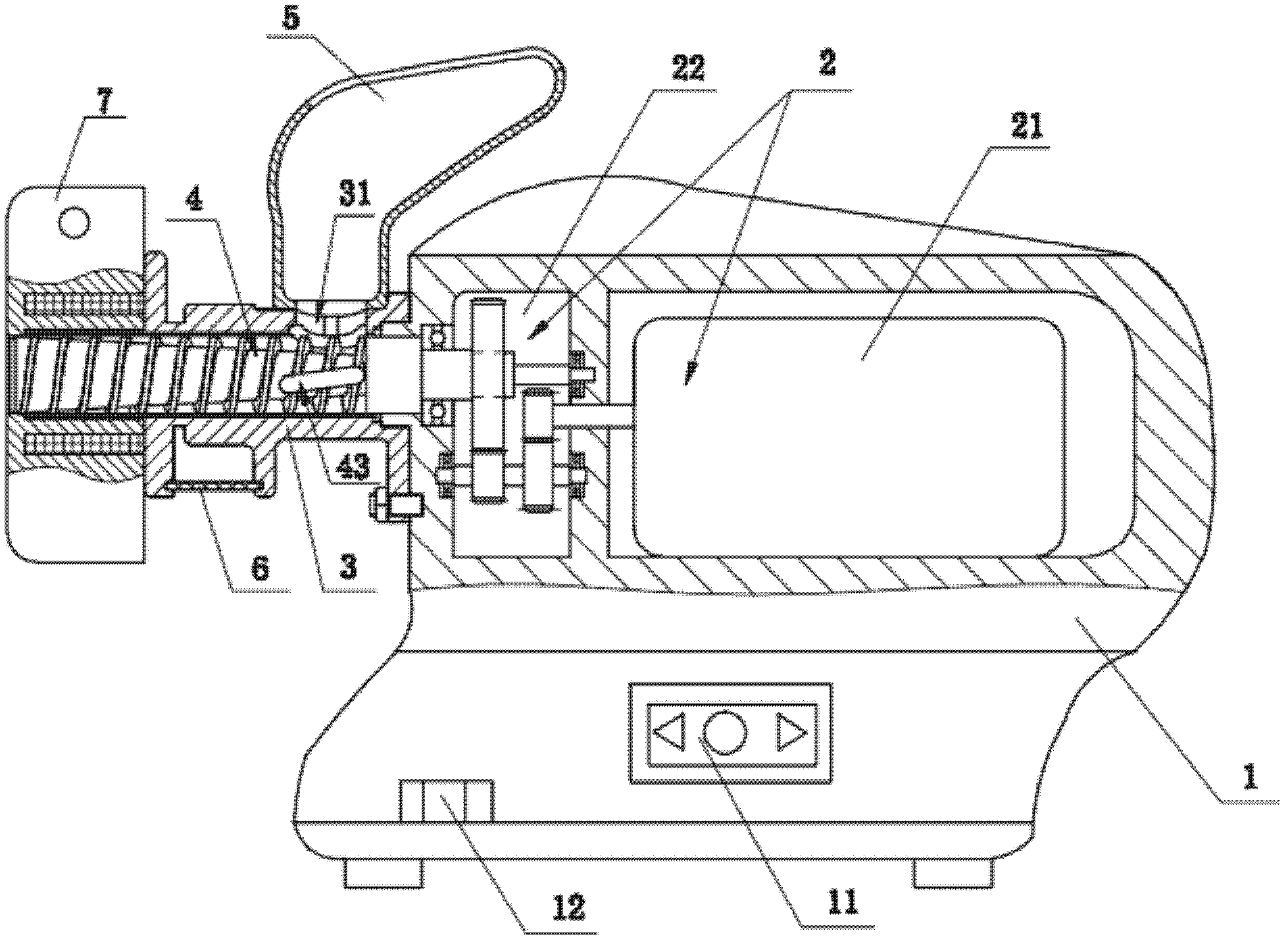

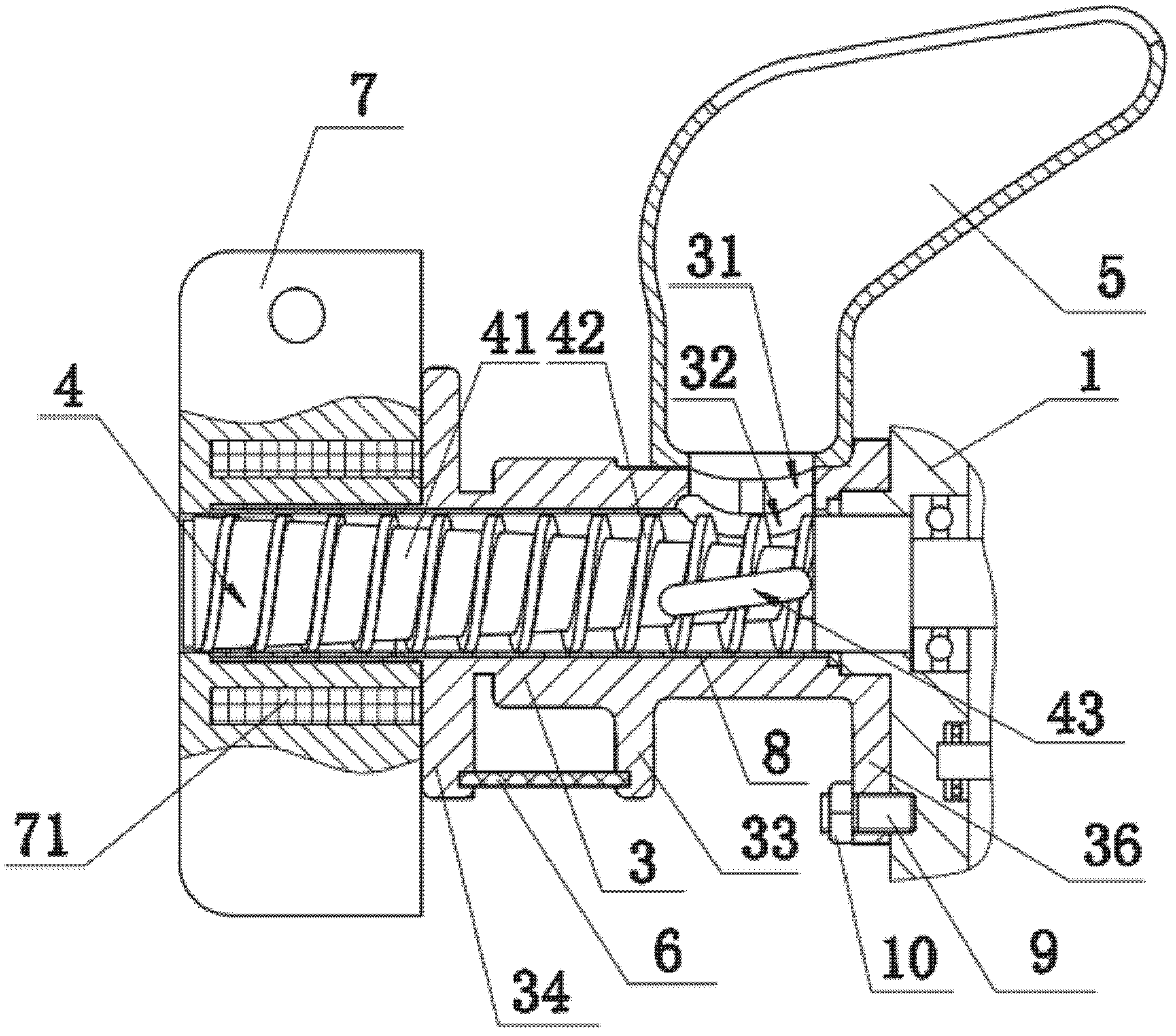

[0028] See figure 1 and figure 2 The household oil press of the present embodiment consists of a machine base 1, a power unit 2 located in the machine base 1, an oil extraction screw 4 connected to the power unit 2, an oil extraction cylinder 3 set outside the oil extraction screw 4, and an oil extraction cylinder 3 located on the The hopper 5 on the oil press cylinder 3, the constant temperature heater 7 and the filter screen 6 constitute, wherein,

[0029] see figure 1 , the power unit 2 is composed of a motor 21 and a reduction mechanism 22, wherein the reduction mechanism 22 is a two-stage cylindrical gear reduction mechanism;

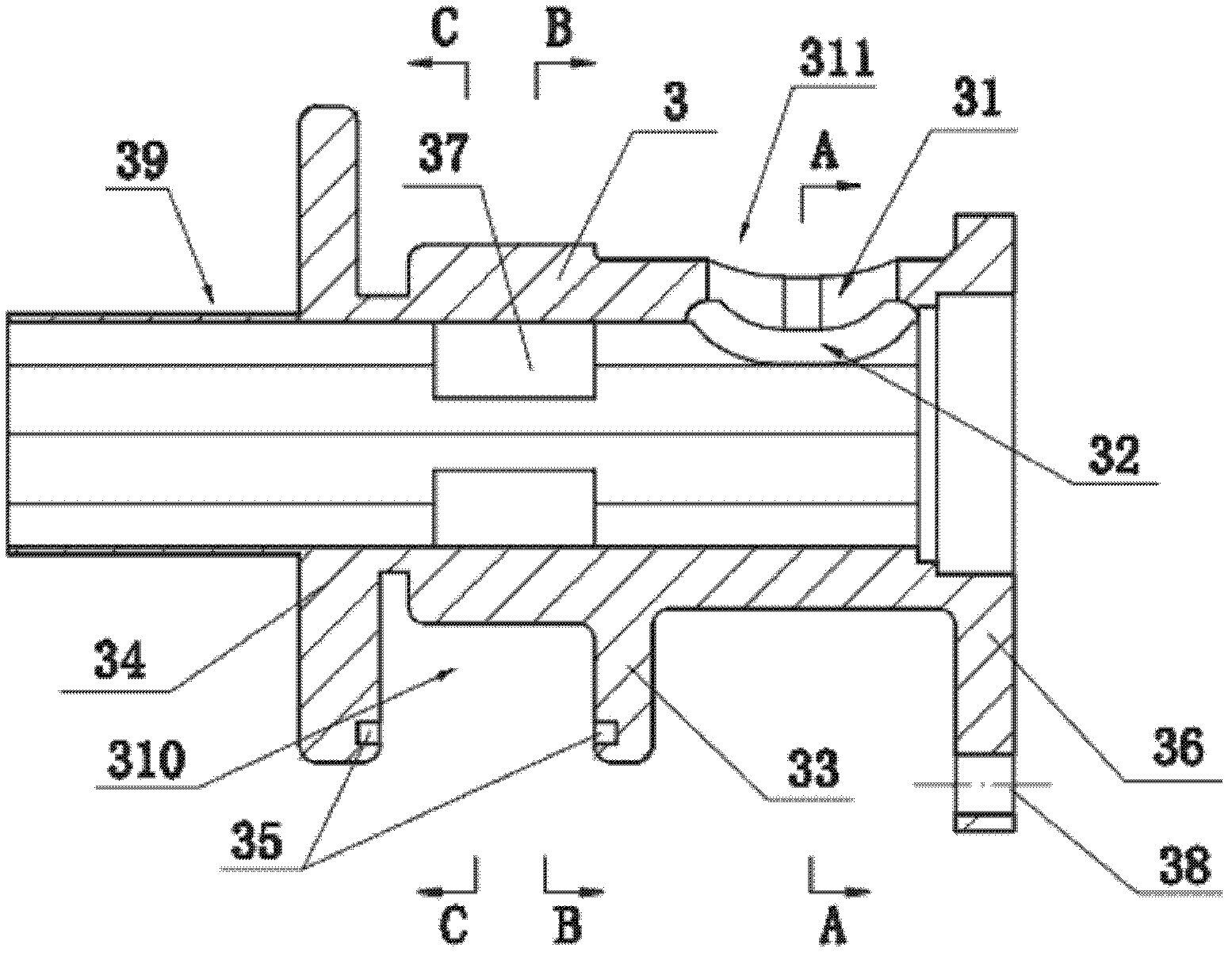

[0030] see Figure 2 to Figure 7, the oil press cylinder 3 is composed of the feeding part 311 at both ends, the heating part 39 and the oil outlet part 310 in the middle. Wherein, the feeding part 311 is provided with a feeding port 31, and the bottom of the feeding port 31 is provided with an expansion part 32 on the side where the rotation ...

Embodiment 2

[0036] see Figure 16 and Figure 17 The difference between this implementation and Example 1 is that there is only one auxiliary feed slit 43 provided on the oil extraction screw 4 in this embodiment, and the auxiliary feed slit 43 is cut into the end of the rod body 41 by the top of the screw thread 42 The surface is formed so that the longitudinal centerline of the auxiliary feeding slit 43 is parallel to the axis line of the oil extraction screw 4 . In the section of the screw thread 42 cut off by the auxiliary feed slit 43 in each auxiliary feed slit 43, the section towards the direction of rotation of the oil extraction screw 4 is set in a knife-edge shape, during the rotation of the oil extraction screw 4 Among them, the blade part plays a role in crushing the raw materials for oil extraction.

[0037] The auxiliary feed slit 43 in this example is shallower than the auxiliary feed slit 43 in embodiment 1, and the feed speed can be slightly slower, but due to the exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com