Method for preparing rapeseed oil in inertia pressurization mode

A technology of rapeseed oil and inertia, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of high oil residue content and waste of oil resources, etc., achieve high degree of automation, avoid waste of resources, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

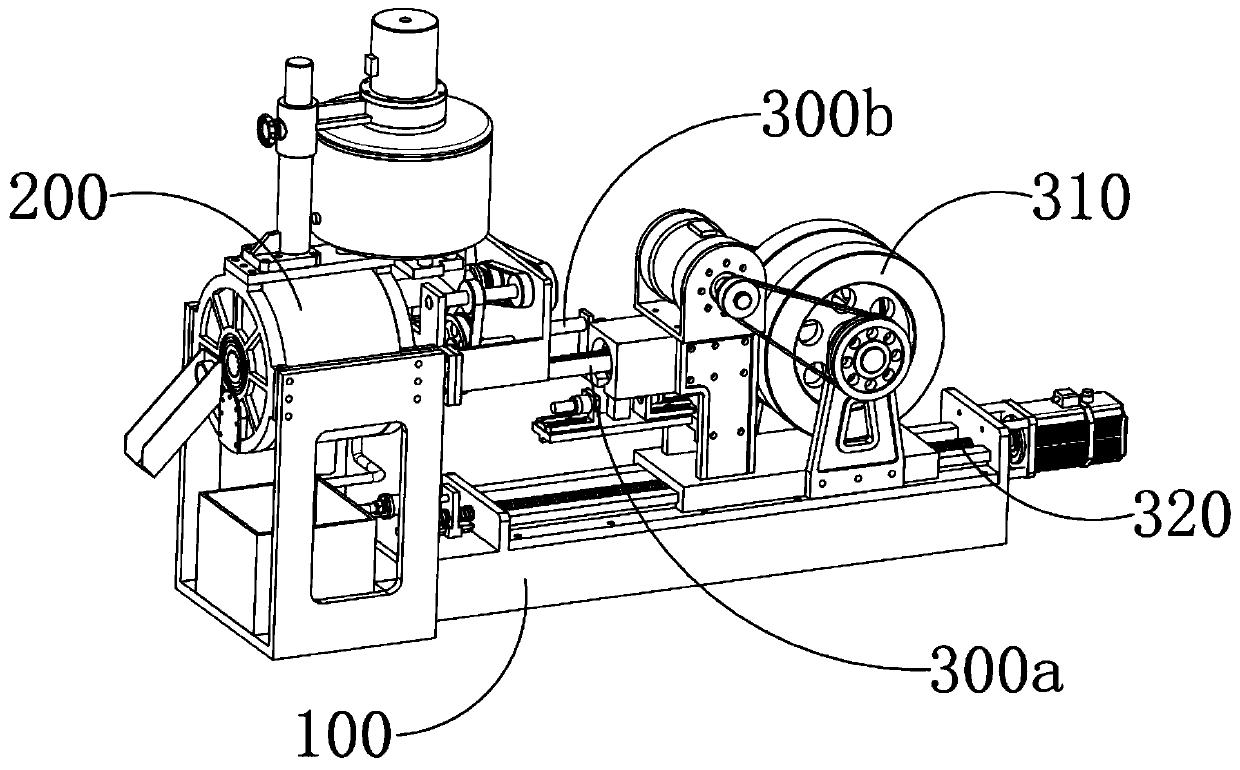

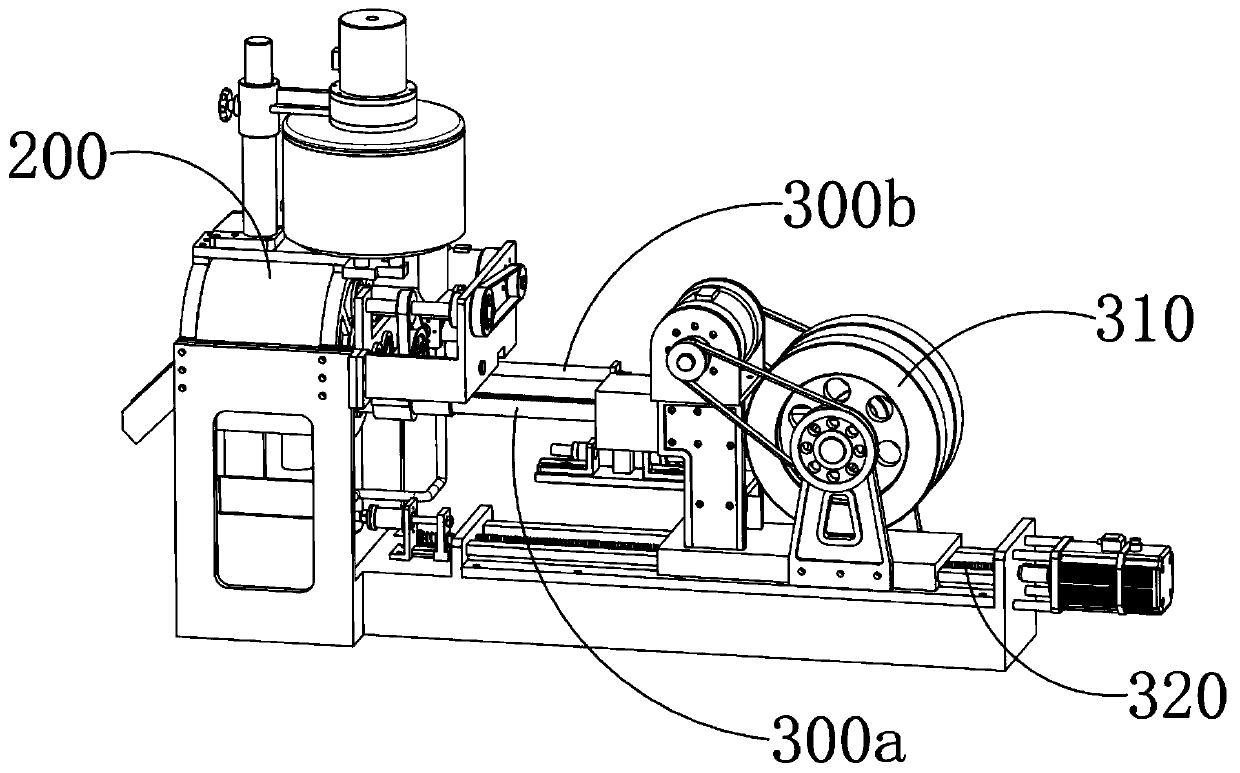

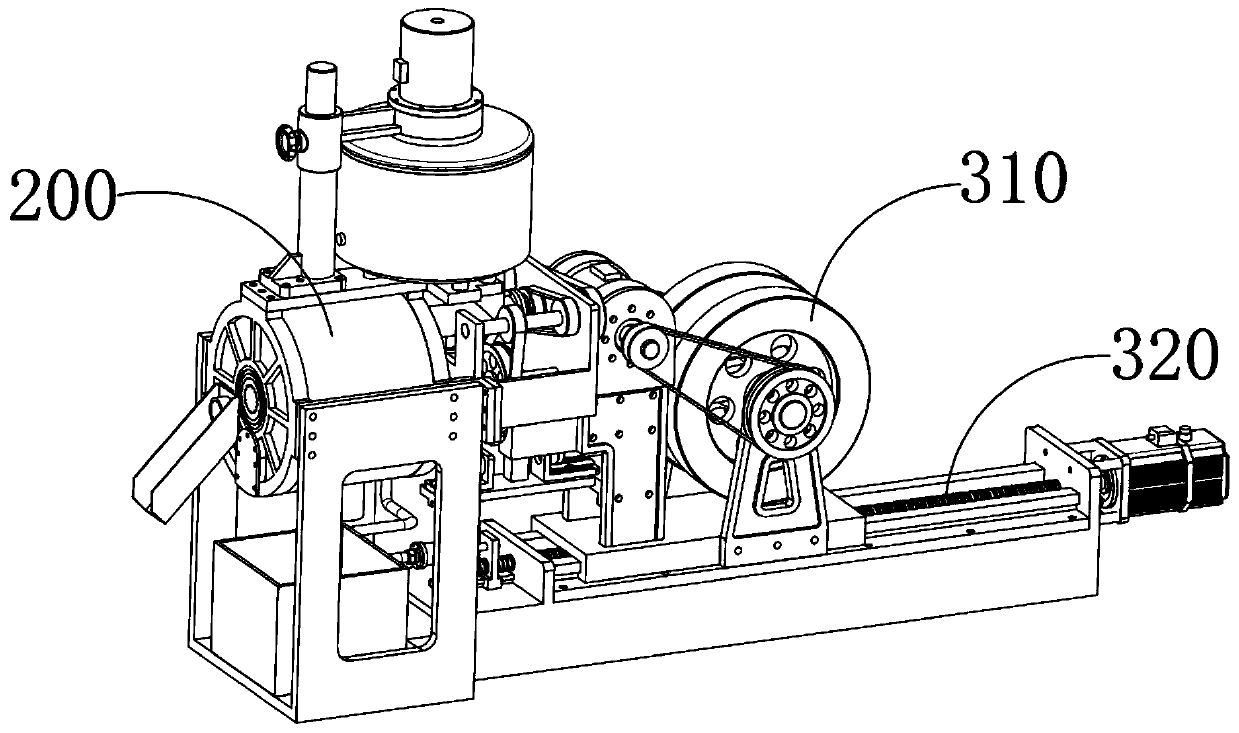

[0052] Adopt the method for producing rapeseed oil of inertia pressurized formula, its step is:

[0053] (1) Cutting stage;

[0054] S1: The user places an appropriate amount of oil in the unloading mechanism 210, and the unloading mechanism 210 receives the power of the power drive device 400 and sequentially transports the hot oil into the squeeze cage 206 in the oil extraction barrel 200;

[0055] The user adds oil into the feeding mechanism 210, and the feeding mechanism 210 heats the oil, and then, the feeding mechanism 210 receives the power of the power drive device 400 and sequentially transports the heated oil to the squeezer in the oil extraction barrel 200. Inside the cage 206;

[0056] (2) The stage of oil extraction;

[0057] S2: Start the flywheel booster mechanism 310 and the feed drive mechanism 320, the feed drive mechanism 320 will drive the flywheel booster mechanism 310 to move close to the front fixed plate 201, and the flywheel booster mechanism 310 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com