Efficient oil press for extracting oil from peanuts or soybeans

A technology for oil presses and soybeans, which is applied in the direction of presses, fat production, fat oil/fat production, etc. It can solve the problems of low automation, low oil extraction efficiency, and addition, so as to achieve convenient operation and use, improve oil extraction efficiency, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

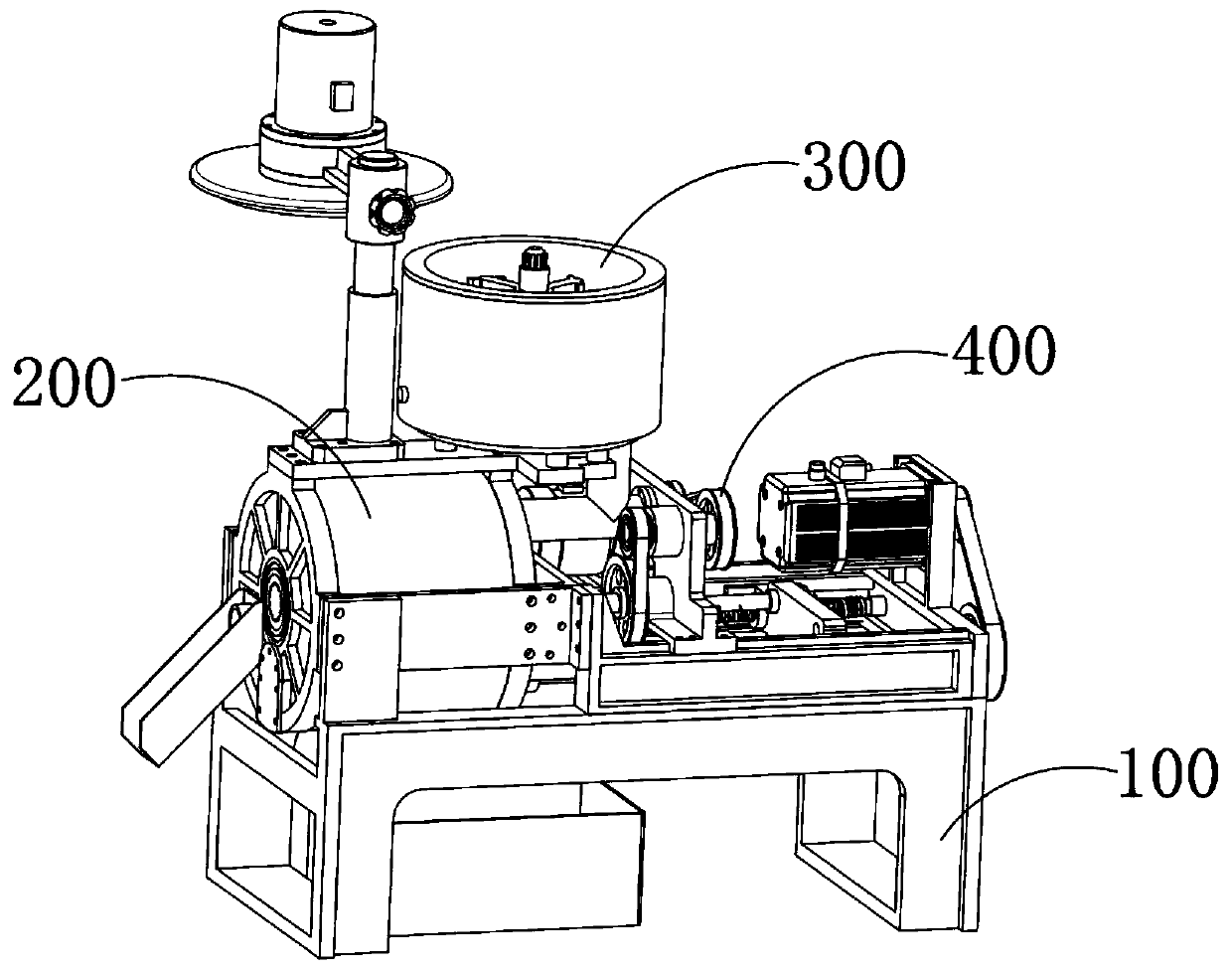

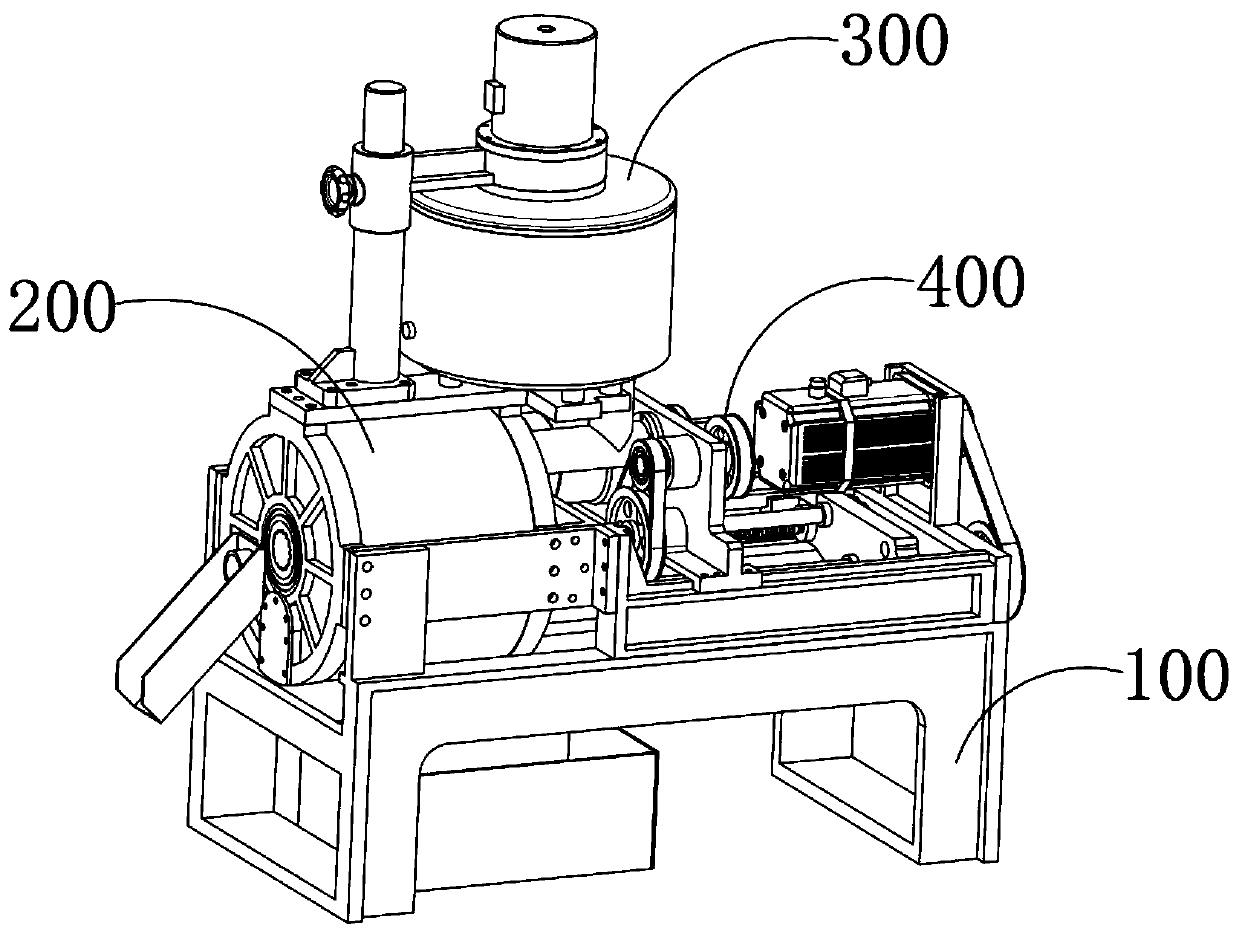

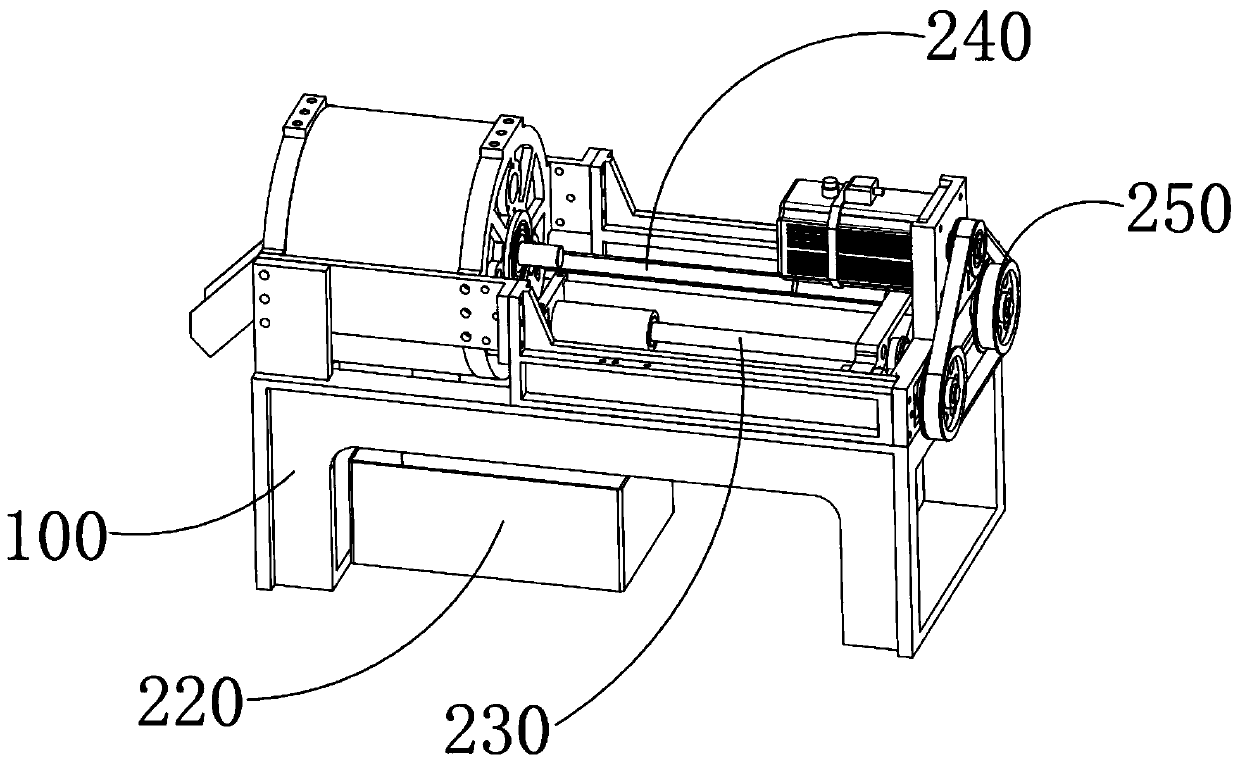

[0067] see Figure 1-27 , a high-efficiency oil press machine for extracting oil from peanuts or soybeans, which includes a solid installation frame 100 on the ground, an oil pressing device 200, a feeding device 300, and a power driving device 400, and the oil pressing device 200 and the power driving device 400 are fixedly arranged On the installation frame 100, the feeding device 300 is fixedly installed on the oil pressing device 200. The feeding device 300 is used to heat up the oil and fry the oil and transport and add the fried oil to the oil pressing device 200. , the oil extraction device 400 includes a plurality of oil extraction cylinders 210 that can be connected to the feeding device 300 in turn and accept the oil delivered by it, an oil receiving tank 220 for collecting the extracted vegetable oil, a pressing rod 230, and a slag discharge rod 240 And the feed drive mechanism 250, the feed drive mechanism 250 can drive the squeeze rod 230 to be inserted into a cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com