Multi-cylinder rotary oil pressing component for pressing rapeseeds to prepare rapeseed oil

A technology of rapeseed and rapeseed oil, applied in the field of multi-cylinder rotary oil pressing components, can solve the problems of repeated operations, low degree of automation, and low oil extraction efficiency, and achieve high degree of automation, convenient operation and use, and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

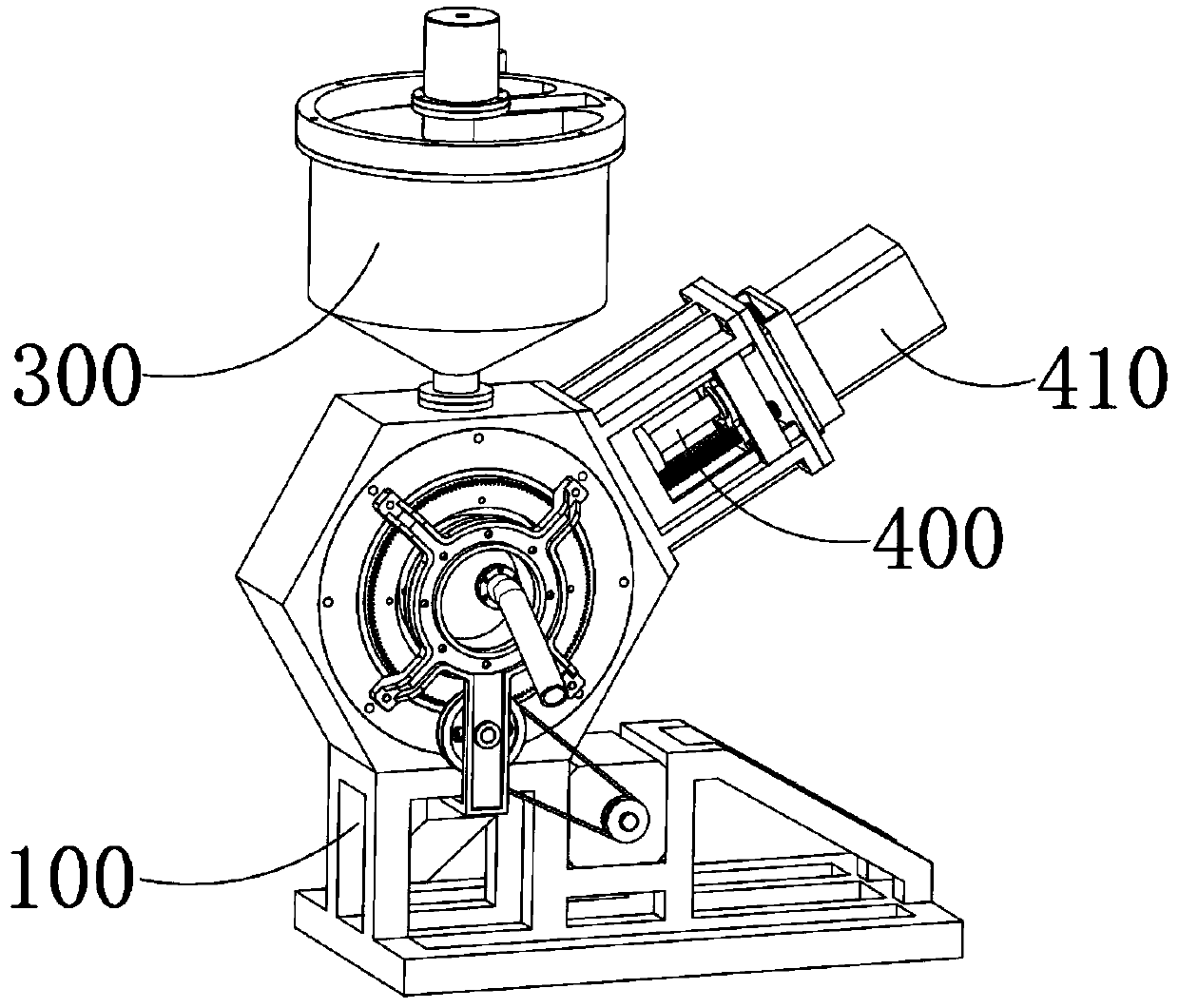

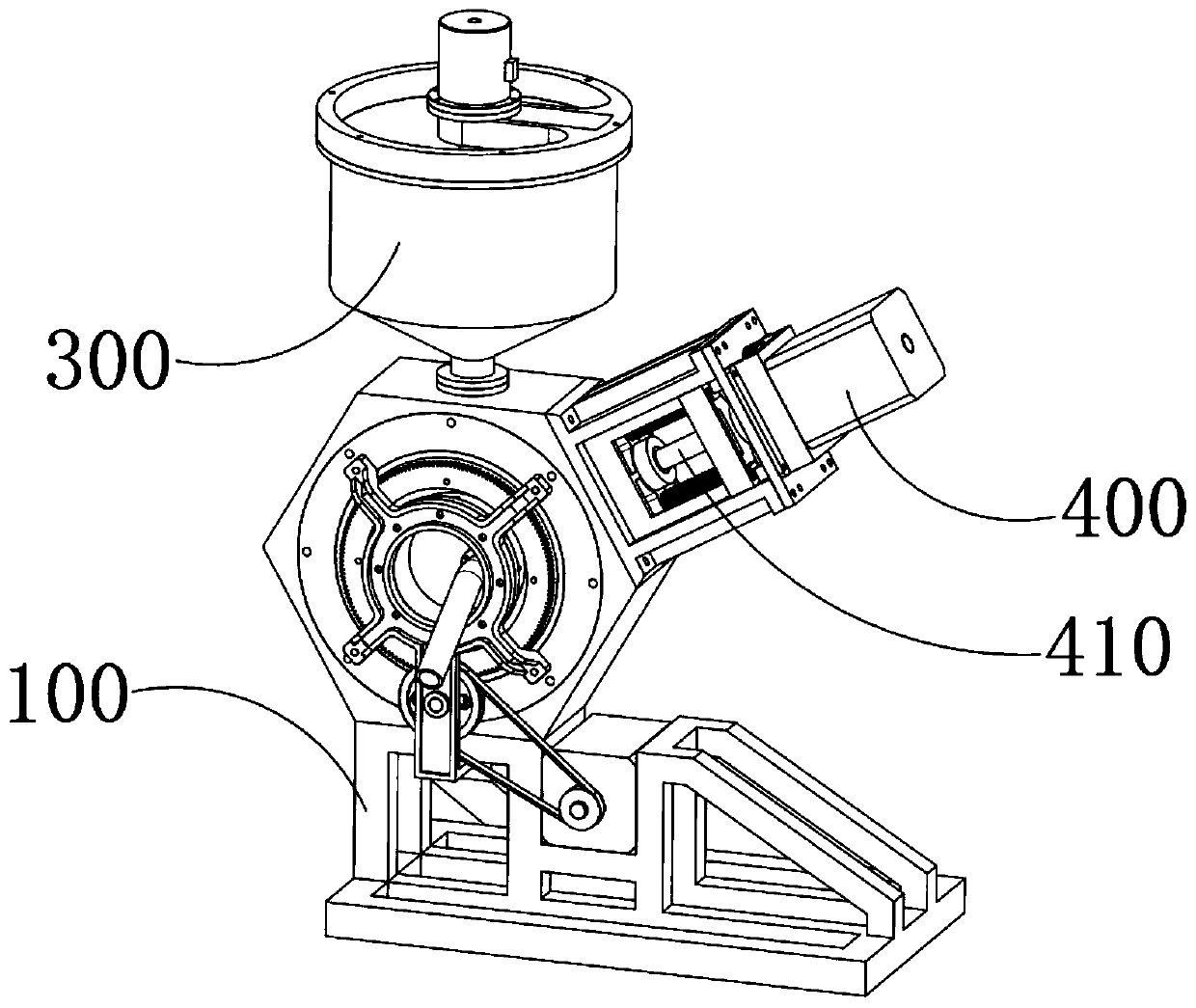

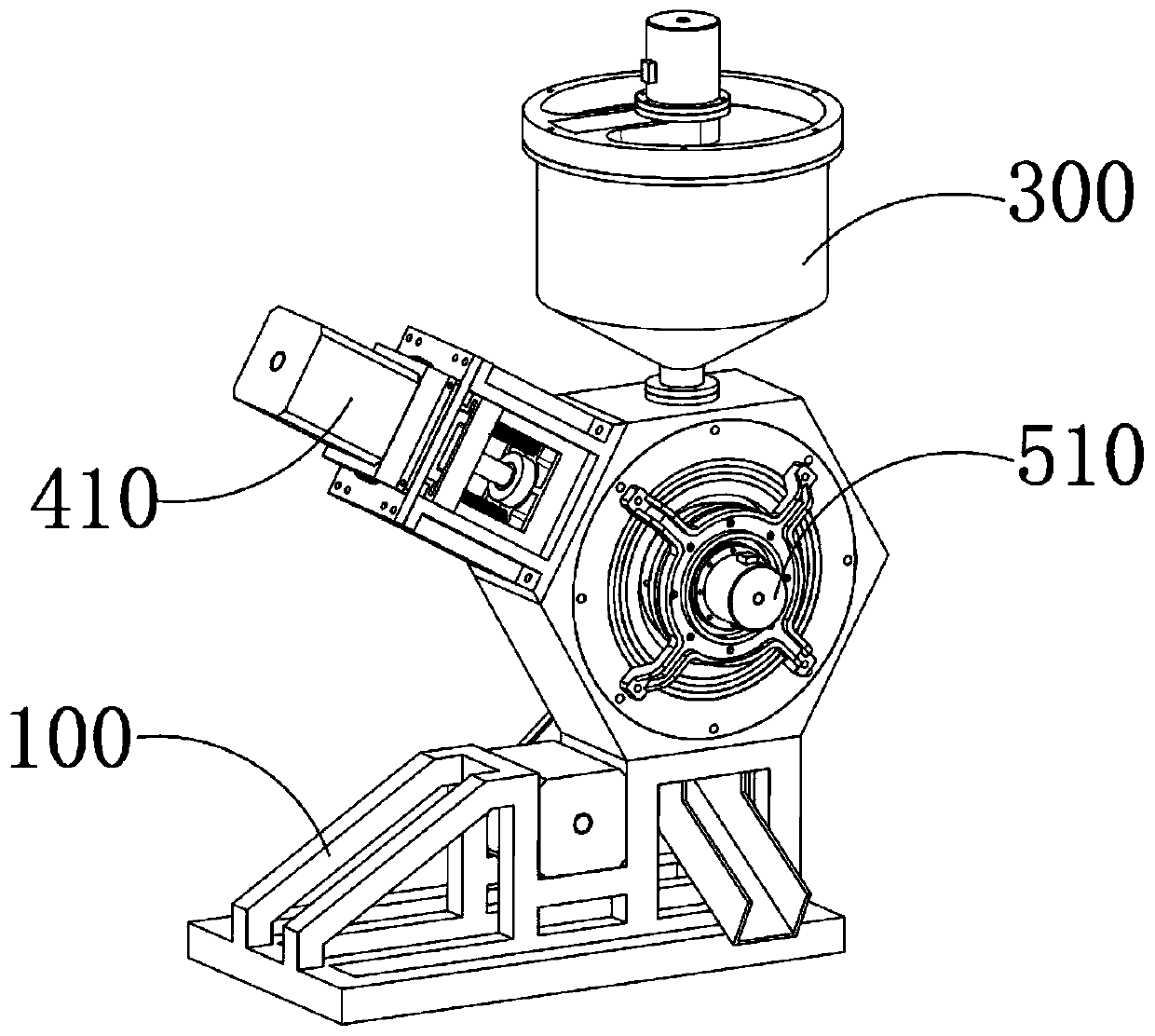

[0051] see Figure 1-30 , a vertical rotary circulation physical oil press, which includes a mounting base 100, a plurality of oil extraction barrels 200, a feeding mechanism 300, a pressing rod 400 and its pressing driving mechanism 410, a slag discharging block 500 and its slagging driving mechanism 510, a plurality of oil extraction cylinders 200 are movably arranged on the installation base 100 and arranged in an array around the circumferential direction. The oil extraction cylinders 200 are a cylinder structure with openings at both ends and a squeezing bore is formed inside. The feeding mechanism 300 is used for The steamed / fried oil is supplied to the oil press barrel 200 in turn, and the press rod 400 can be driven by the pressing drive mechanism 410 and inserted into the oil press barrel 200 containing the oil plants in sequence to squeeze the oil inside to extract the oil, drain The slag block 500 can be driven by the slag discharge drive mechanism 510 and inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com