Full-automatic oil press for soybean oil preparation

A fully automatic, soybean oil technology, used in presses, manufacturing tools, oil/fat production, etc., can solve the problems of low degree of automation of the whole machine and low oil extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

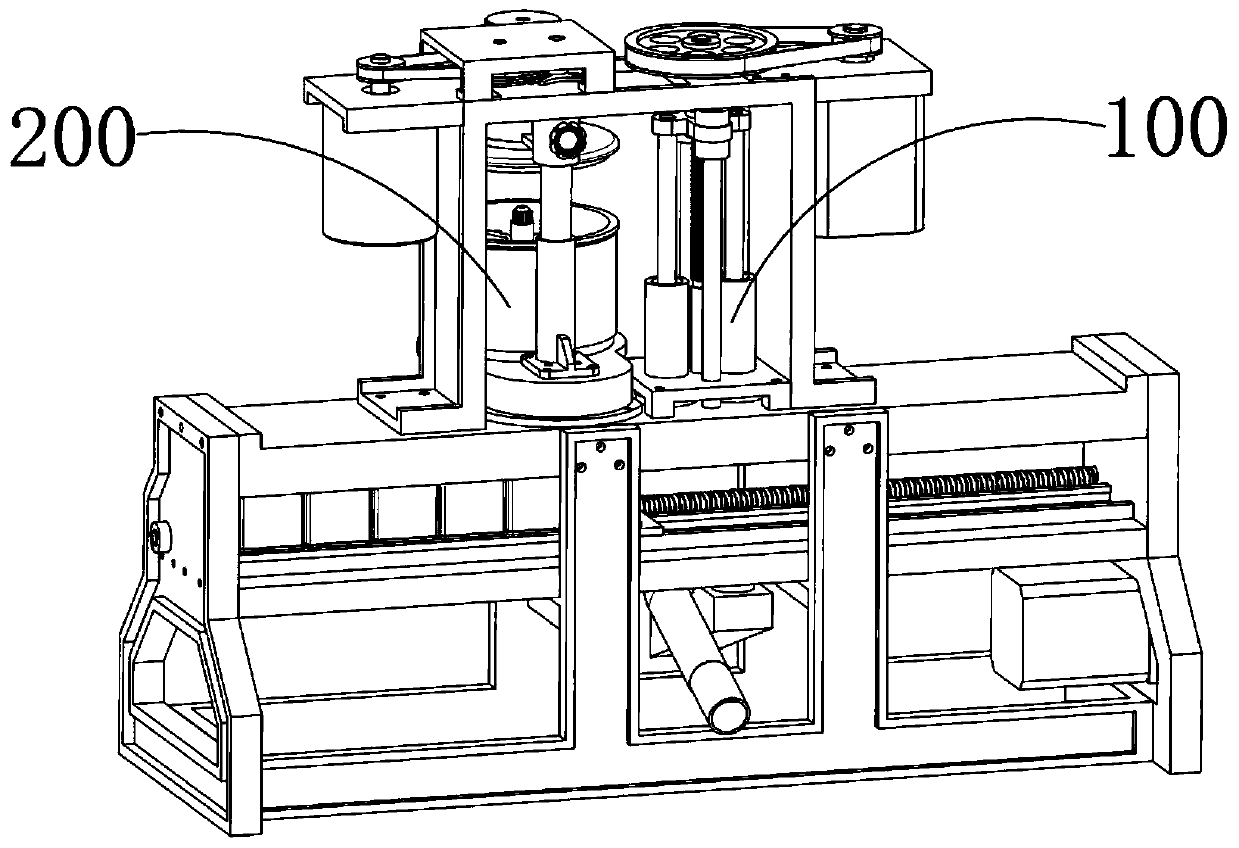

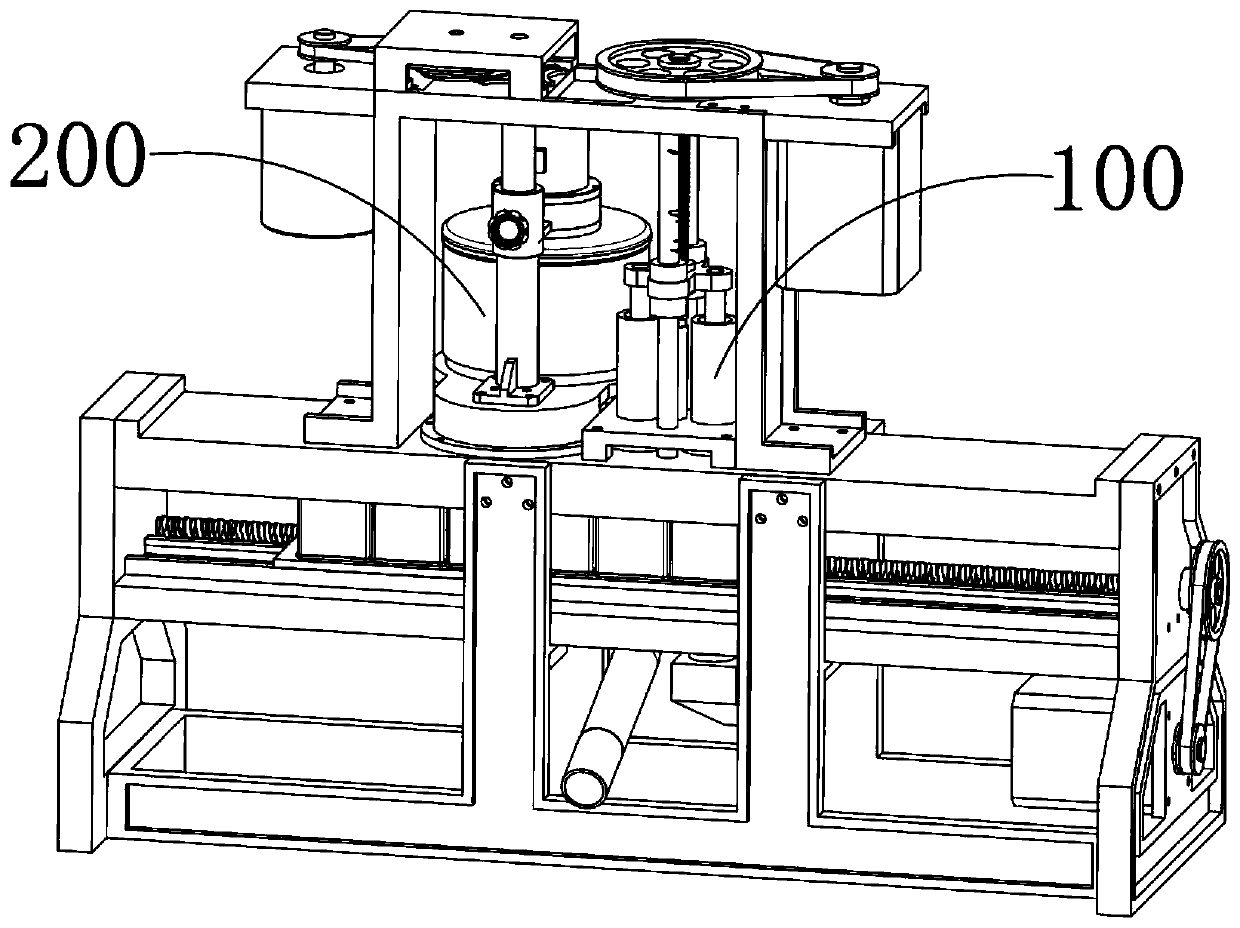

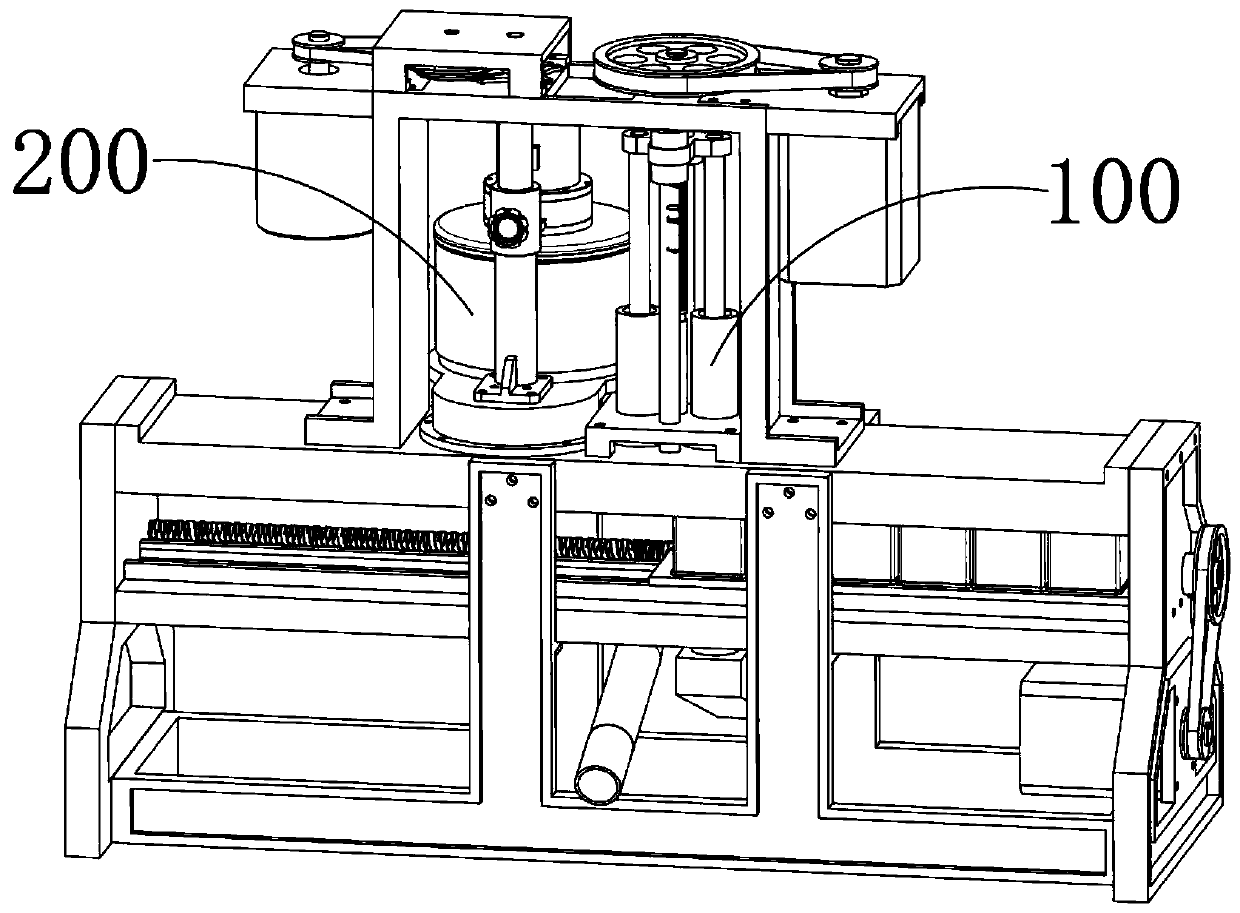

[0069] see Figure 1-31 , a fully automatic oil press for soybean oil production, which includes an oil press device 100 and a material adding device 200, wherein the oil press device 100 includes a mounting base 110, a cylinder discharge mechanism 120 including a plurality of oil press cylinders 124 and a resisting The push mechanism 140, the push mechanism 140 includes two working ends, one of which can be inserted into the oil extraction cylinder 124 from top to bottom to squeeze the oil inside to extract edible oil, and this working end is the pressing working end , the other working end can be inserted into the oil extraction cylinder 124 from top to bottom, and the oil residue inside can be ejected downward and discharged, and this working end is the slag discharge working end. Arrangement and the straight line direction is the feed travel direction of the oil extraction cylinder 124, along the feed travel direction of the oil extraction cylinder 124, the slag discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com