Small oil squeezing device

An oil extraction device, small technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high noise, affecting the living environment, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

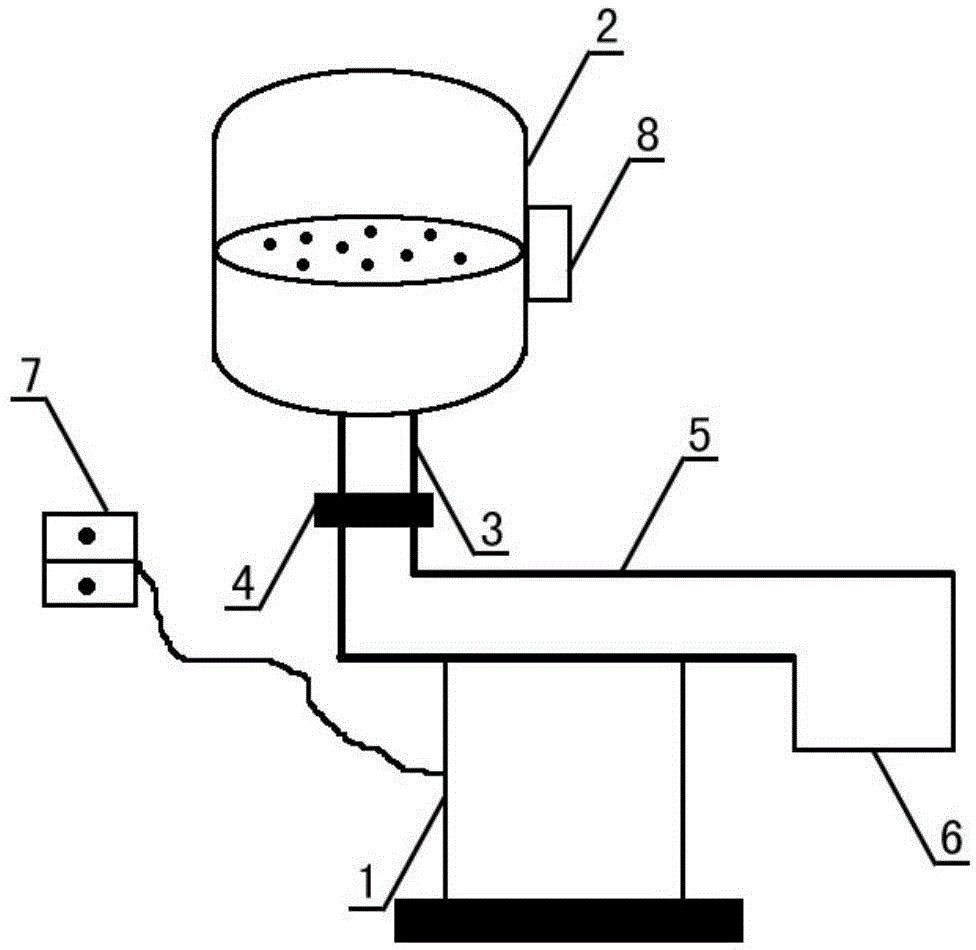

[0013] Embodiment: as shown in the accompanying drawing. A small oil pressing device, comprising a frame (1), on which a feeding barrel (2) is arranged, a dense screen is arranged in the middle of the feeding barrel (2), and a Squeezing device (3), the motor (4) is installed in the middle of the squeezing device (3), the oil outlet pipeline (5) is arranged on the squeezing device (3), and the oil collection basket (6) is arranged at the end of the oil outlet pipeline, so that the rapeseed is evenly distributed during use. Pour into the feed barrel (2), filter the excess impurities with the screen, the motor (4) is running and the temperature of the pressing device (3) is preheated to rotate the internal pressure, and the oil is discharged through the oil outlet pipe (5) and transferred to the oil collection basket ( 6).

[0014] The utility model relates to a small oil pressing device, the oil outlet pipeline (5) has a built-in oil filter to filter vegetable oil residue.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com