Conveniently dismounted charging system of asphalt reaction kettle

A technology of convenient disassembly and feeding system, applied in the field of feeding system, can solve the problems of improper mixing of raw materials, difficult maintenance of pipelines, affecting production efficiency, etc., and achieves the effects of convenient disassembly and maintenance, convenient feeding, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

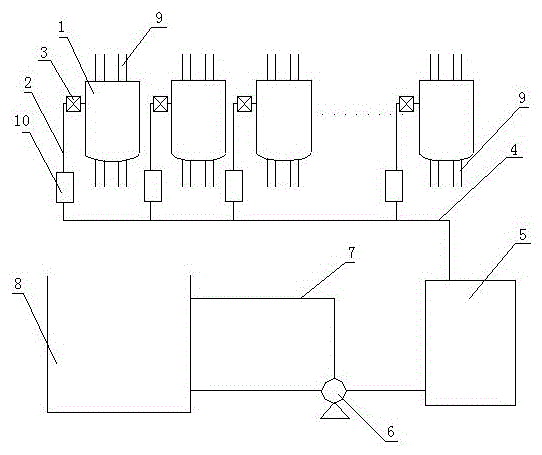

[0011] see figure 1 , the present invention relates to a feeding system for an asphalt reactor that is easy to assemble and disassemble, comprising a plurality of reactors 1, each of which is connected with a vacuum branch pipe 2, wherein each vacuum branch pipe 2 is provided with There are check valves 3 and rubber hoses 10, and the end of each vacuum branch pipe 2 is connected to the vacuum main pipe 4. The end of the vacuum main pipe 4 is connected to the buffer tank 5, and the buffer tank 5 is connected to the buffer tank 5 through the pipeline. The vacuum pump 6 is connected, and the vacuum pump 6 is connected to the pool 8 through the water circulation pipeline 7, and a water circulation system is formed between the vacuum pump 6 and the pool 8, and the air drawn in the vacuum pump 6 is discharged to the pool 8 through the water circulation pipeline 7, and finally To the outside world, the top and bottom of the reactor 1 are provided with a plurality of liquid feeding pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com