Method for preparing soybean oil by aqueous enzymatic method and application thereof

A technology of soybean oil and water enzymatic method, which is applied in the direction of fat oil/fat production, fat generation, fat oil/fat refining, etc., can solve the problem of unused extraction and processing of thawed emulsion oil, achieve the protection of nutritional value and shorten the oil extraction time , High oil extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

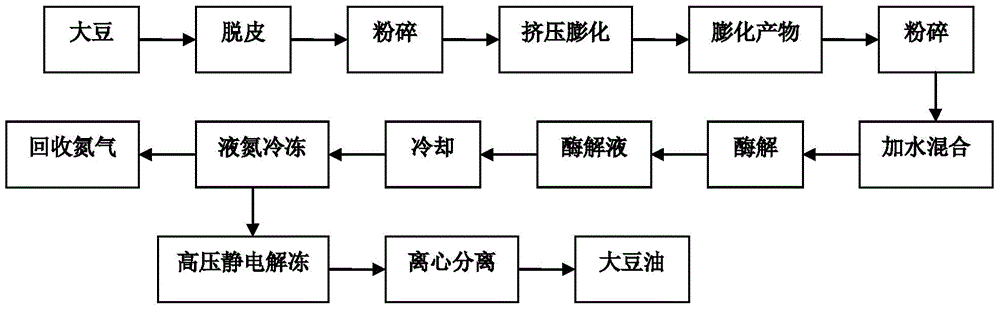

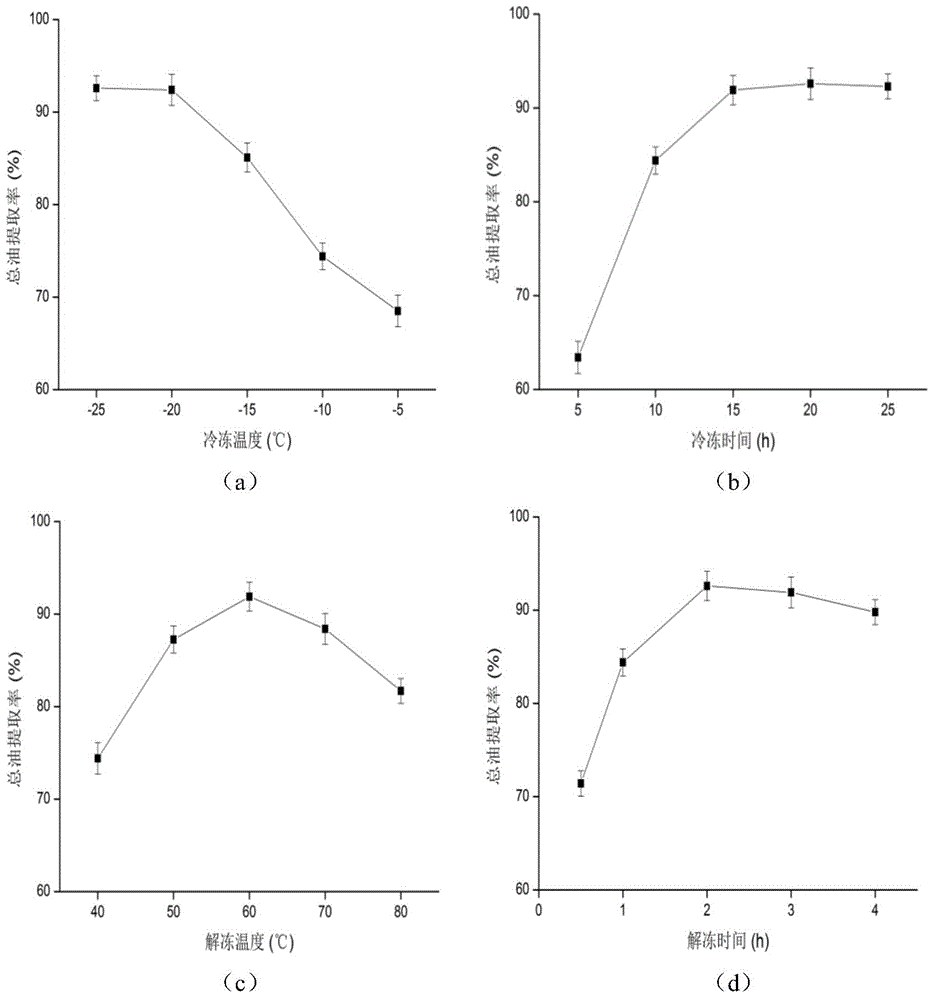

[0038]The present embodiment provides a kind of soybean oil extraction method with traditional freezing and thawing treatment, concrete operation is as follows:

[0039] After crushing the peeled soybeans, extruding and puffing is performed at a sleeve temperature of 95°C, a die hole diameter of 18mm, a screw speed of 100r / min, and a material moisture content of 14% to obtain puffed products, which are crushed and mixed with Mix with water to obtain a mixed solution, and add 3% Alcalase alkaline to the mixed solution under the conditions that the liquid-to-material ratio is 6:1 (mL:g, the same below), the enzymolysis temperature is 55°C, and the enzymolysis pH is 9. Protease hydrolyzed for 3 hours to obtain the enzymatic solution, freezing at -20°C for 15 hours, thawing the frozen enzymolyzed solution at 60°C for 2 hours, and thawing the enzymatically Centrifuge to obtain soybean oil.

Embodiment 2

[0041] The present embodiment provides an example of soybean oil prepared by the method of the present invention, and the specific operation process is as follows:

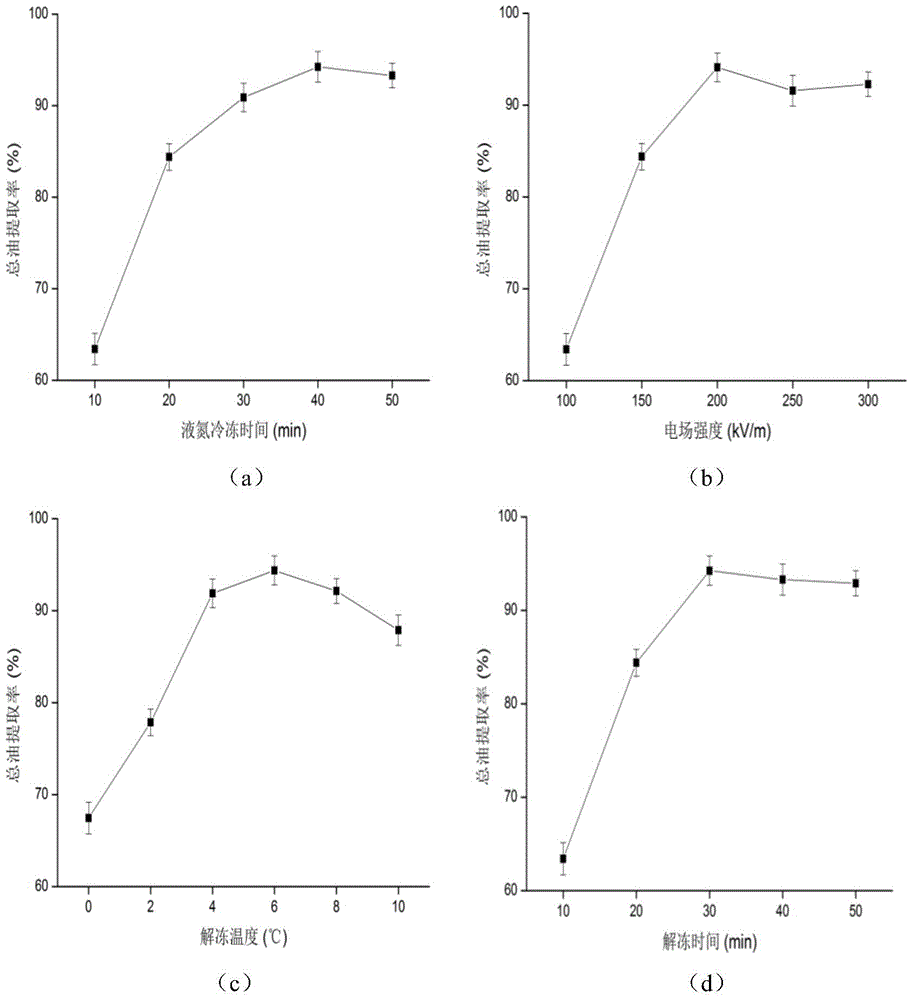

[0042] After crushing the peeled soybeans, extruding and puffing is carried out at a sleeve temperature of 95°C, a die hole diameter of 18mm, a screw speed of 110r / min, and a material moisture content of 15% to obtain puffed products, which are crushed and mixed with Mix water to obtain a mixed solution. At a liquid-material ratio of 6.5:1, an enzymolysis temperature of 55°C, and an enzymolysis pH of 9.5, add 2.5% Alcalase alkaline protease to the mixture for 3.5 hours to obtain enzymolysis solution, after cooling the enzymolysis solution to room temperature, carry out liquid nitrogen freezing treatment at a freezing temperature of -196°C for 40 minutes and recover nitrogen gas, and then freeze the enzymolysis solution at an electric field strength of 200kV / m and a thawing temperature of 6°C The solution was subje...

Embodiment 3

[0044] The present embodiment provides another example of soybean oil prepared by the method of the present invention, and the specific operation process is as follows:

[0045] After crushing the peeled soybeans, extruding and puffing is carried out at a sleeve temperature of 100°C, a die hole diameter of 20mm, a screw speed of 120r / min, and a material moisture content of 16% to obtain puffed products, which are crushed and mixed with Mix water to obtain a mixed solution. When the liquid-to-material ratio is 7:1, the enzymolysis temperature is 50°C, and the enzymolysis pH is 9, add 3% Alcalase alkaline protease to the mixed solution for enzymolysis for 3 hours to obtain an enzymolysis solution , after cooling the enzymolysis solution to room temperature, freeze the enzymolysis solution with liquid nitrogen for 30 minutes at a freezing temperature of -196°C and recover nitrogen gas. Perform high-voltage electrostatic thawing treatment for 40 minutes, and centrifuge the thawed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com