Patents

Literature

34results about How to "Protect nutritional value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

Processing method for keeping Chinese yam fresh

InactiveCN104273215AEfficient removalGuaranteed aestheticsFruits/vegetable preservation by heatingFruits/vegetable preservation using acidsNutritive valuesFlavor

The invention discloses a processing method for keeping Chinese yam fresh. The processing method is suitable for iron stick yam (medicinal yam), especially for Dioscorea opposita ''foshou''. The processing method comprises the following processing steps: 1) cleaning and peeling; 2) removing mucus, sludge and impurities on the skin; 3) pickling; 4) desalinizing and slicing; 5) sterilizing and solidifying; 6) carrying out color protection; 7) packaging and vacuumizing; 8) sterilizing; and 9) packaging and warehousing. By the processing method, mucus on the skin of Chinese yam can effectively be removed, and mucus in Chinese yam can be protected from being lost. Beauty of a product can be guaranteed, and nutritive value of the product also can effectively be protected. By the processing method for manufacturing fresh-keeping Chinese yam, original nutritive value, mouthfeel and local flavor of Chinese yam can be maintained for a long time, storage life of the product is prolonged obviously, and it is convenient for storage, transport and usage.

Owner:陈连生

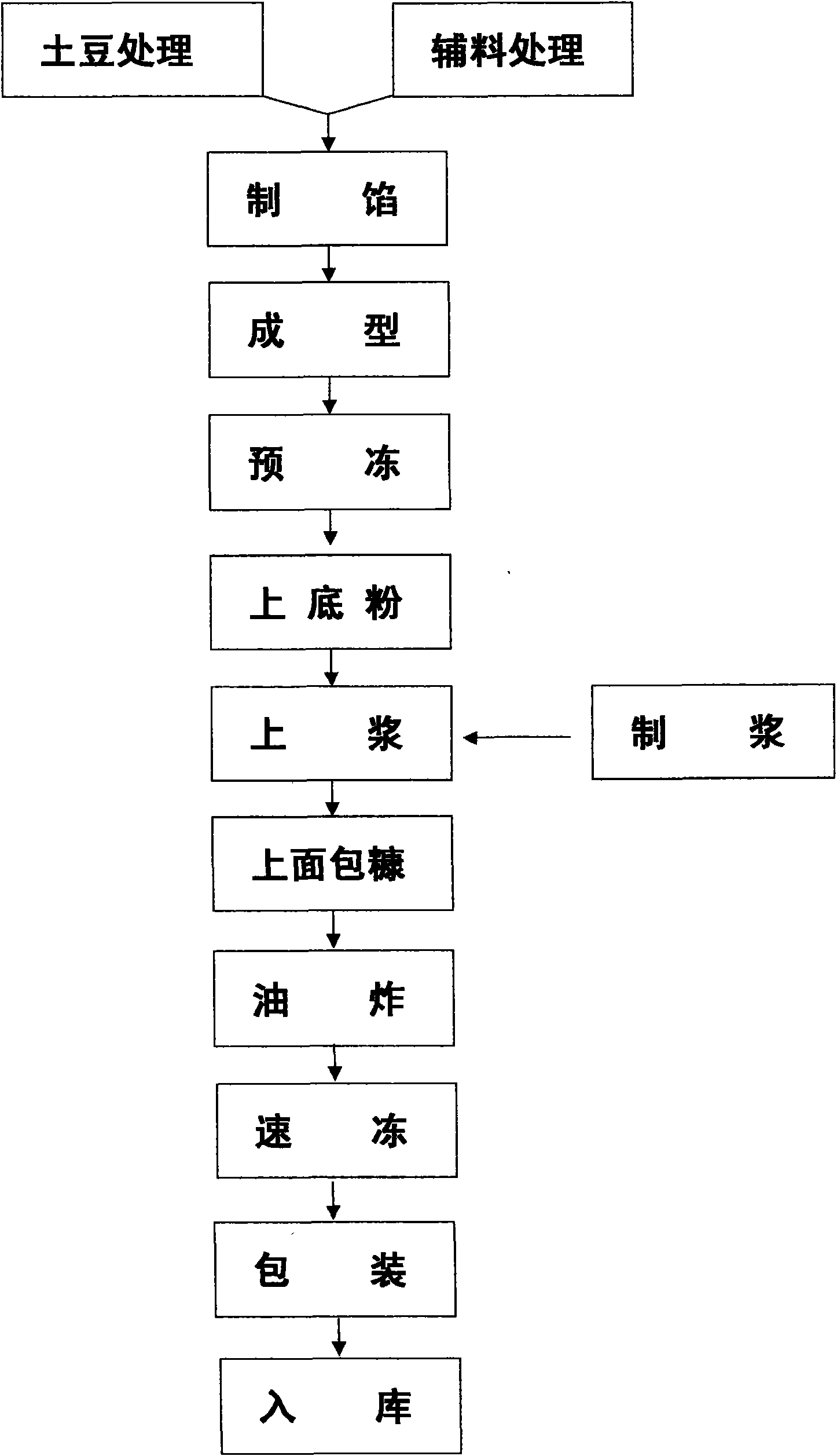

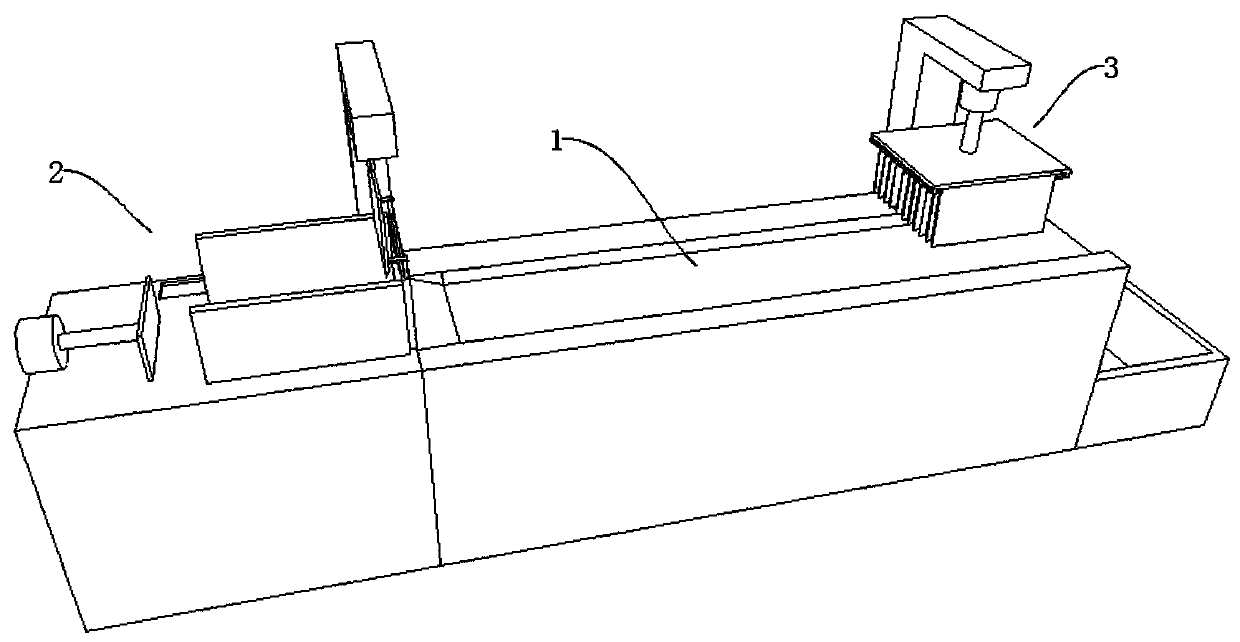

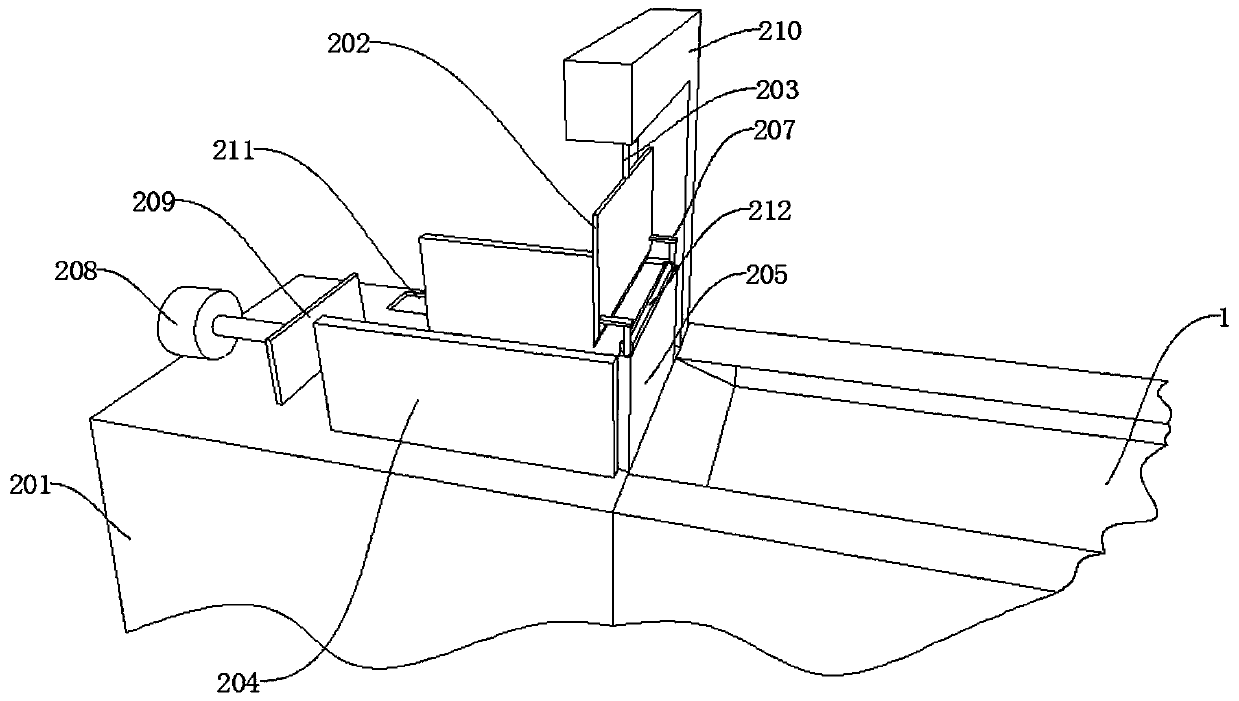

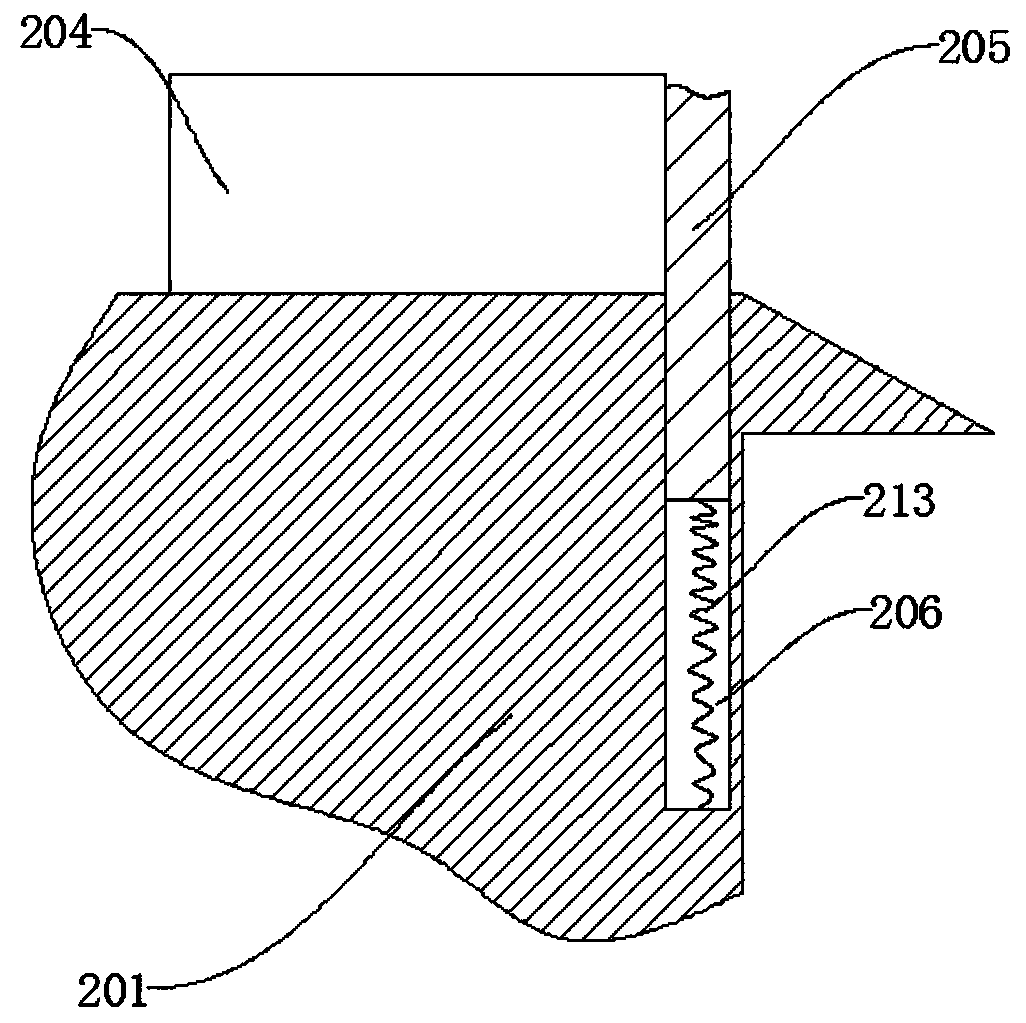

Preparation method of potato sticks

The invention discloses a deep-processed food, in particular a preparation method of potato sticks in industrialized production by taking potatoes as main material. Mungbean potato sticks contain thecomponents as follows: 47.5kg of mashed potatoes, 11.6kg of mungbean, 6.9kg of granulated sugar, 1.7kg of chicken oil, 0.7kg of low-gluten flour, 1.4kg of flour, 1.4kg of cornstarch, 0.2kg of modifiedstarch, 15.6kg of wet orange breadcrumbs and 12.9kg of water. The industrialized production method comprises the following steps of checking raw auxiliary materials, processing raw materials, preparing stuffing, forming, prefreezing, starching, braning, quickly freezing and packing. In the preparation method, potatoes are taken as the main raw material, formed by special forming equipment, extracted and refined and specially processed by a plurality of working procedures, and finally prepared into the potato sticks fit for the dietary taste of easterners; and the preparation method realizes the industrialized production, achieves unique shape and attractive section, effectively keeps the crisp mouthfeel of the potato sticks and sufficiently protects the nutritional value of the raw materials.

Owner:HENAN DAYONG INDUSTRIAL CO LTD

Raw beef cutting machine

PendingCN110574775AAvoid Manual LayingReduce manual labor intensityMetal working apparatusMeat shaping/cuttingRaw beefProduct processing

The invention relates to the technical field of meat product processing, and discloses a raw beef cutting machine. The raw beef cutting machine comprises a conveying mechanism, a slicing mechanism isarranged at the feeding end of the conveying mechanism, a strip-cutting mechanism is arranged between the slicing mechanism and the discharging end of the conveying mechanism, the slicing mechanism comprises a supporting table, a first cutter and a first driving device, and two longitudinal baffles and a transverse baffle are arranged on the top face of the supporting table, wherein the two longitudinal baffles are parallel to the motion direction of the conveying mechanism, and the transverse baffle is arranged on the sides, close to the conveying mechanism, of the longitudinal baffles; the first cutter is arranged on the upper part of a cavity and is parallel to the transverse baffle, and the first driving device drives the first cutter to move up and down along the inner wall of the cavity; and a groove provided with an upward opening and matched with the transverse baffle is formed in the top face of the supporting table, and the side, close to the transverse baffle, of the first cutter is connected with the transverse baffle through a connecting assembly. According to the raw beef cutting machine, slicing and strip cutting operation on raw beef can be achieved, the labor intensity of manpower is reduced, and strip beef is processed integrally and automatically.

Owner:XICHANG SIQIXIANG FOOD CO LTD

Preparation technology of canned yellow peaches

InactiveCN108850911AProtect nutritional valueImprove integrityFood ingredientsDiseaseNutritive values

The invention discloses a preparation technology of canned yellow peaches. The preparation technology comprises the following steps: (1) material selecting: selecting fresh and full yellow peaches ofwhich the maturity is 80 to 90 percent and which have no disease and insect pests and no mechanical damage; (2) cutting: cutting the yellow peaches into halves along joint seams; (3) pit removing: digging out pits of the yellow peaches after immersing by using a pit digger; (4) peel removing: uniformly paving the yellow peaches immersed in step (3) on a steel wire net of an alkali ironing machinein a single layer by enabling pit holes of the yellow peaches to face downwards, carrying out drip washing by using an alkali solution, taking down the yellow peaches, and flushing the alkali solutionby using clear water; (5) hot ironing: immersing the yellow peaches in a citric acid hot solution; (6) finishing: cutting off spots and residual peels from the yellow peaches by using a blade after hot ironing and cooling; (7) canning: putting the yellow peaches after finishing into packaging cans; (8) can sealing: sealing the packaging cans under thermal exhausting of an exhaust box; (9) sterilizing: sterilizing the packaging cans in boiling water. The preparation method disclosed by the invention has the advantages that the nutritive value is higher, the storage time of the canned yellow peaches is increased, and the like.

Owner:安徽金古堆绿色农业有限责任公司

Method for preparing soybean oil by aqueous enzymatic method and application thereof

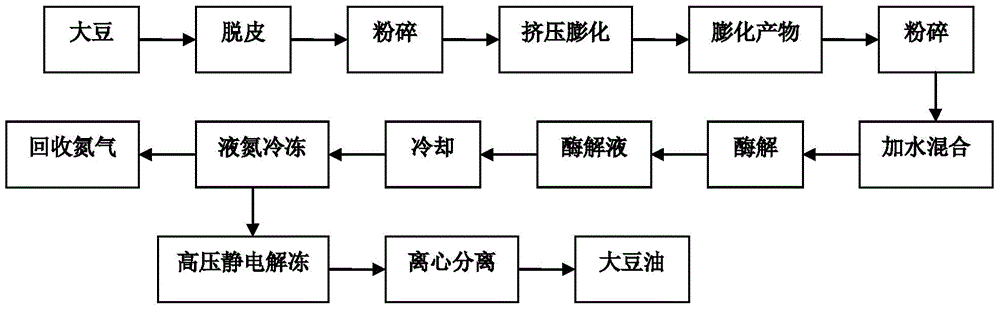

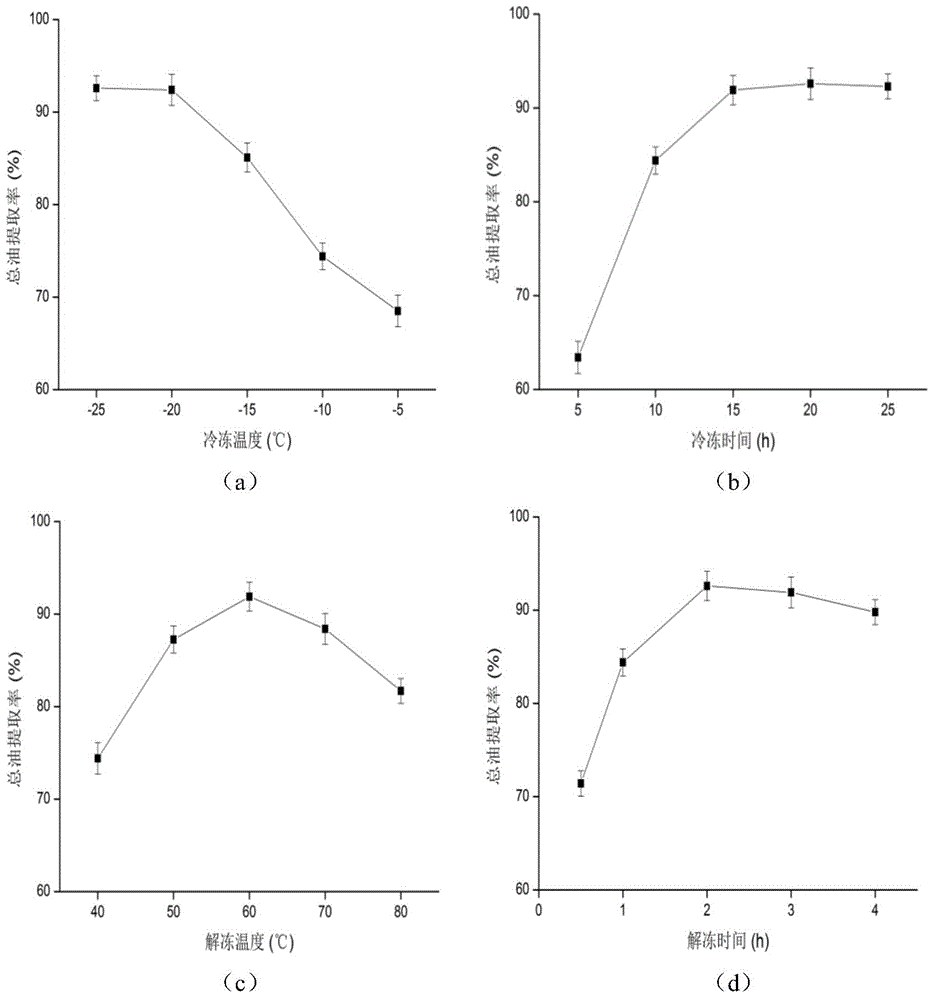

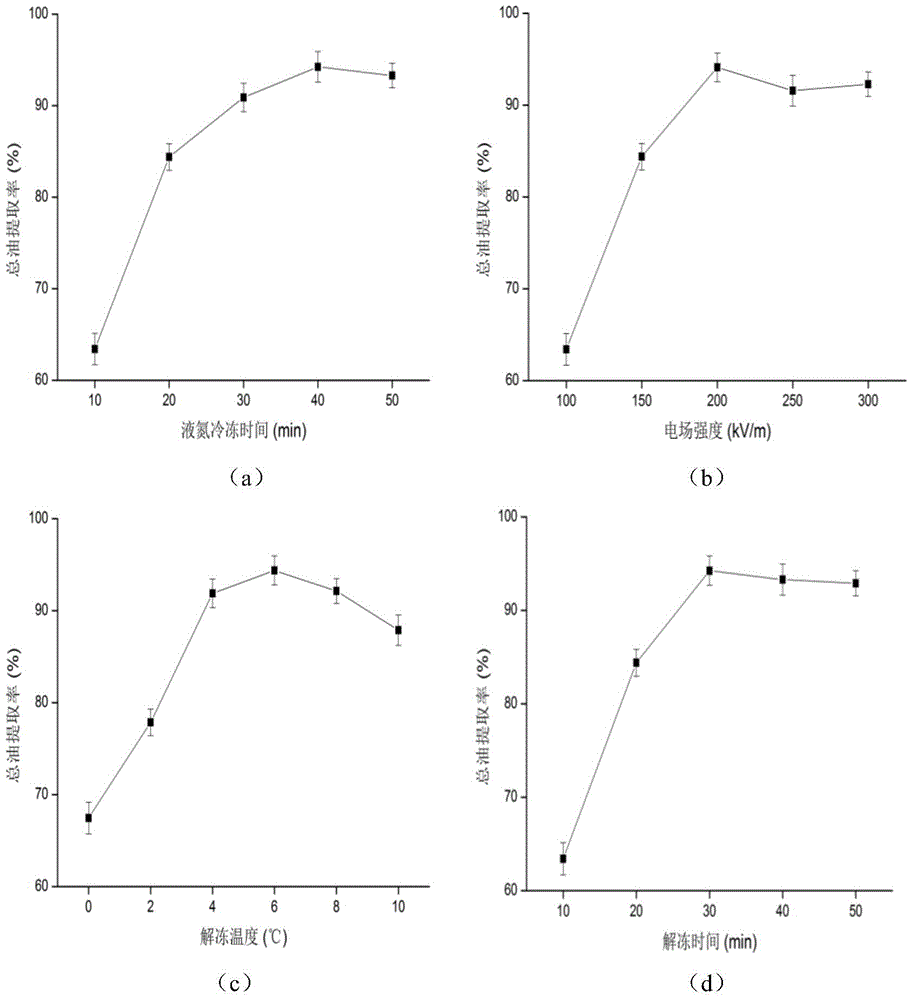

ActiveCN104450154ALow peroxide valueImprove antioxidant capacityFatty-oils/fats refiningFatty-oils/fats productionAlkaline proteaseHydrolysate

The invention discloses a method for preparing soybean oil by an aqueous enzymatic method and an application thereof, belonging to the technical field of plant oil extraction and processing. The method disclosed by the invention comprises the following steps: after cleaning and peeling soybeans, crushing the soybeans; then, extruding the crushed soybeans; after extrusion, crushing a puffed product; then, hydrolyzing the puffed product by using alkaline protease; freezing the hydrolysate by using a liquid nitrogen refrigeration method after hydrolysis; and finally unfreezing by virtue of a high voltage electrostatic method and carrying out centrifugal separation and unfreezing to obtain the soybean oil. The method disclosed by the invention has the characteristics of being short in oil extraction time and high in total oil extraction rate. Just in the freezing and unfreezing links, 93.1% of time in the method provided by the invention can be saved and the total oil extraction rate can reach 95.36%. Meanwhile, the extracted soybean oil has relatively low peroxide value, p-fennel value and TOTOX value, and the quality of the extracted oil is better.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

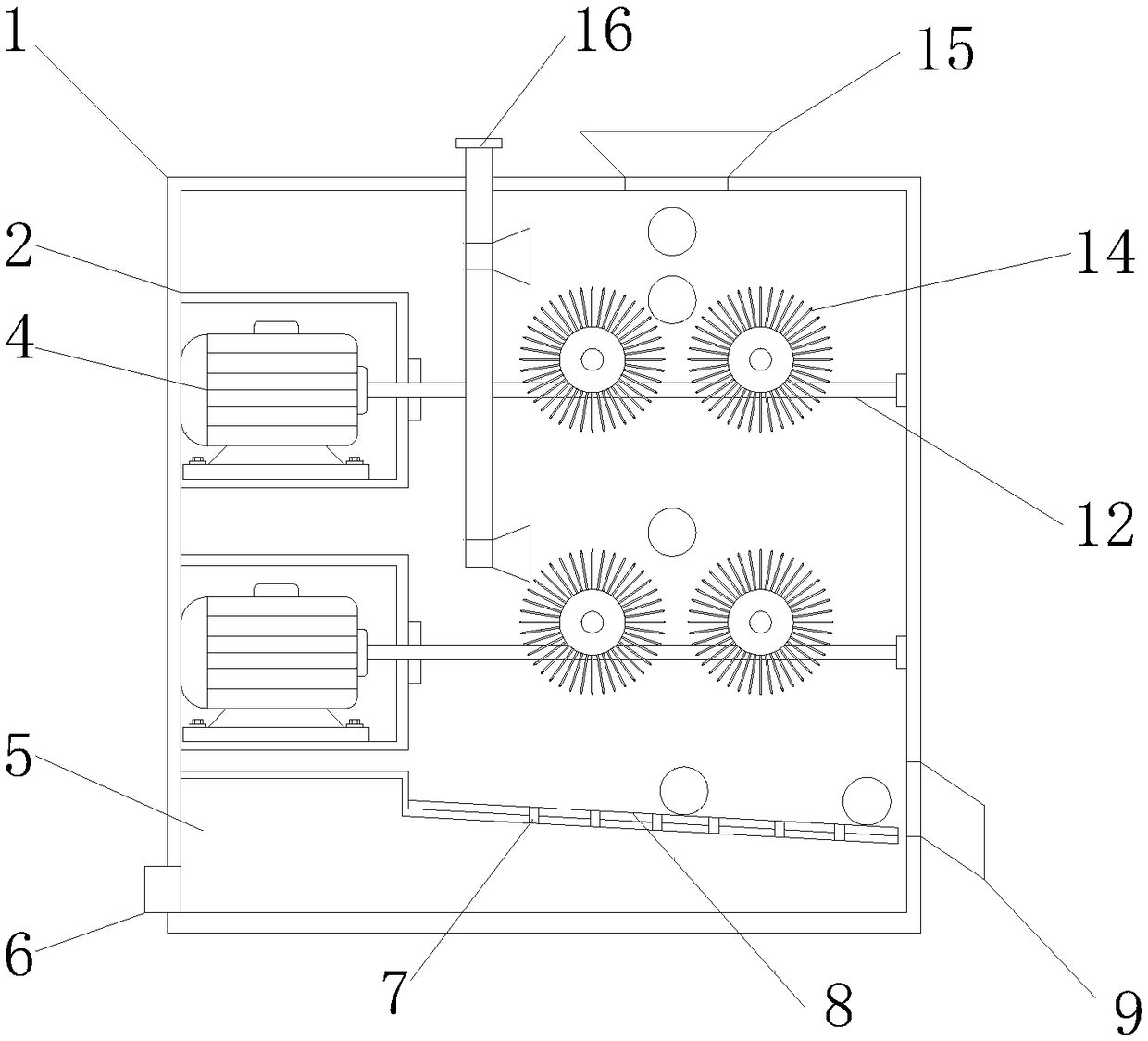

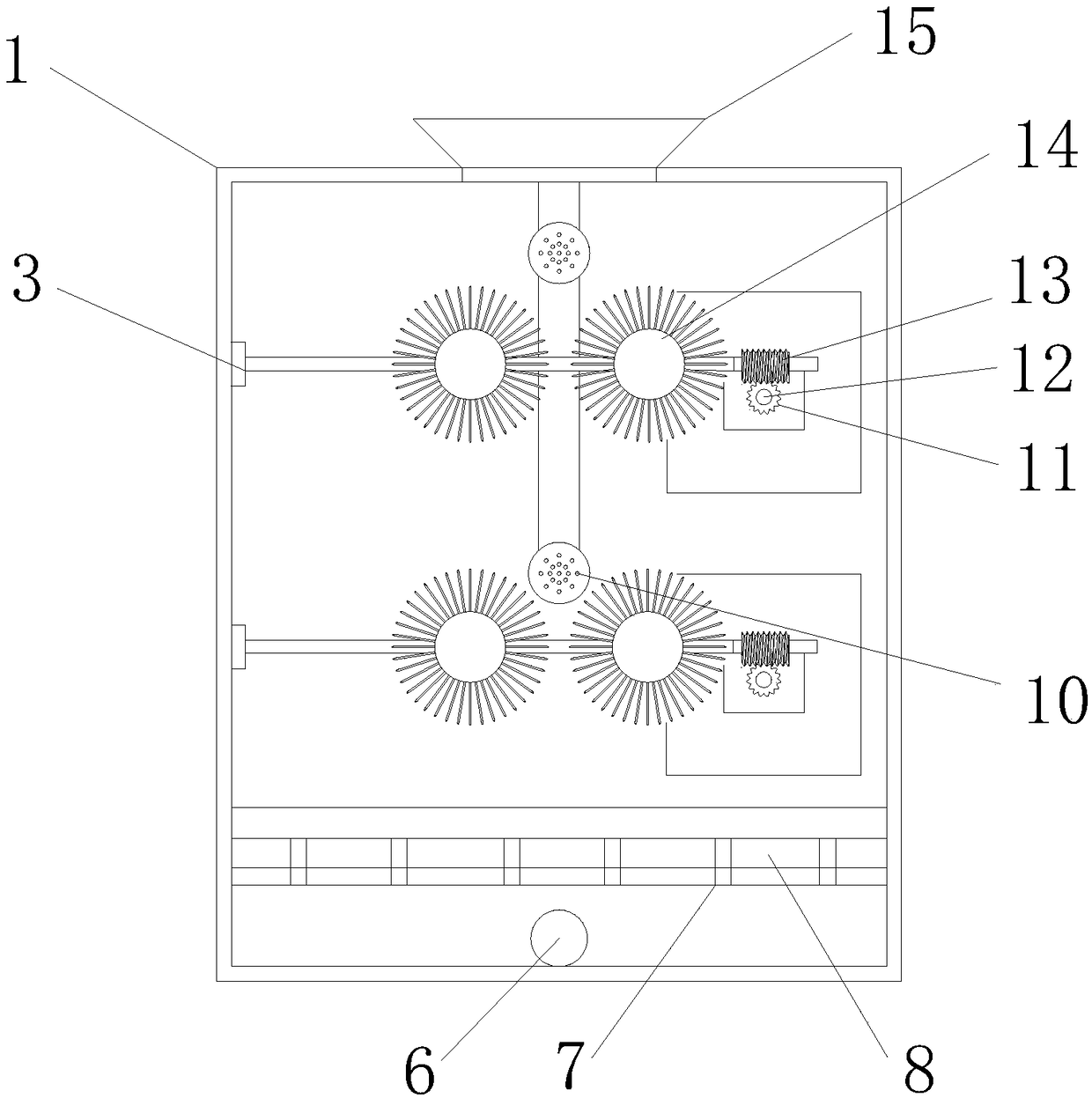

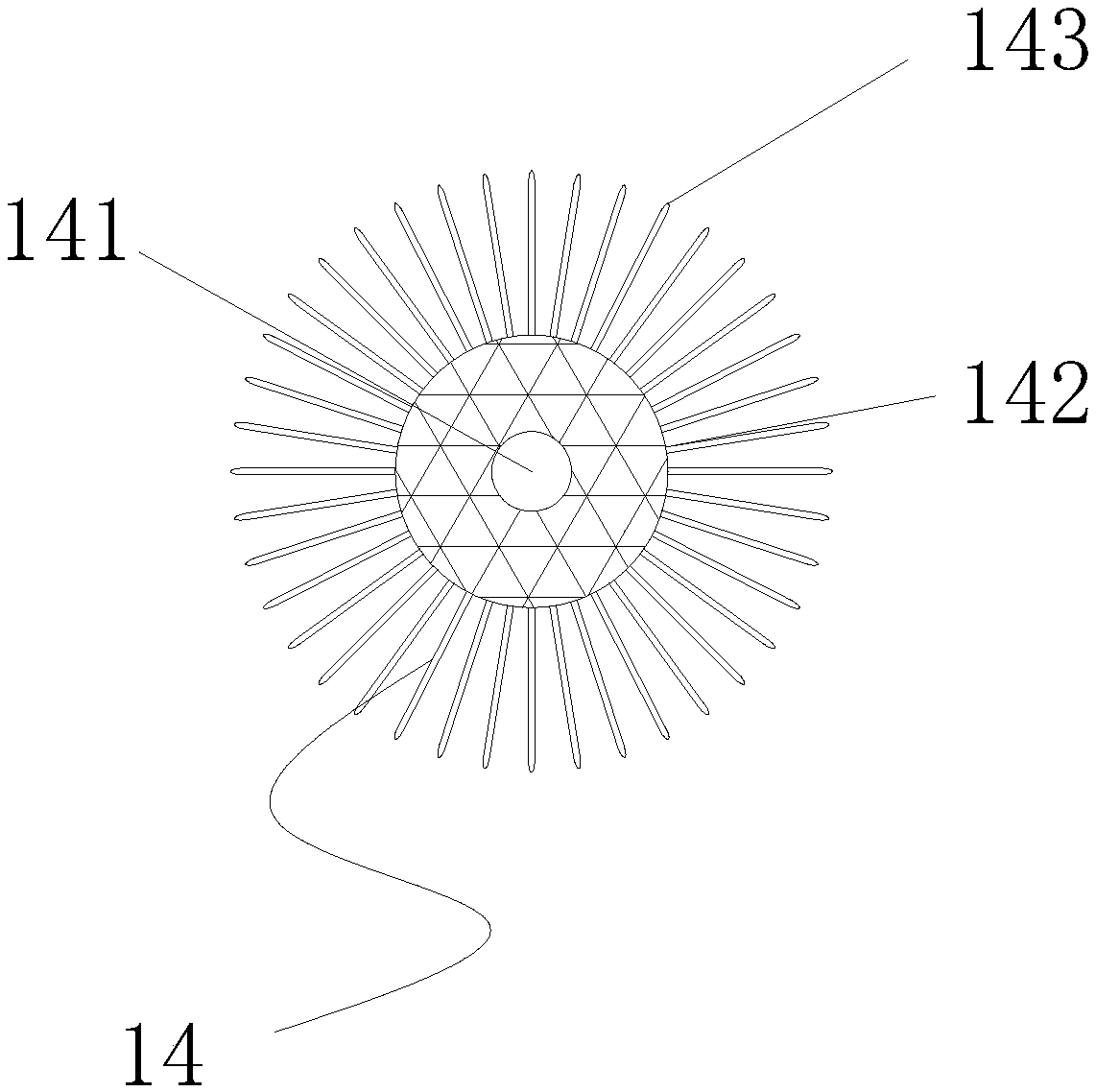

Blueberry surface layer washing device

The invention discloses a blueberry surface layer washing device. The blueberry surface layer washing device comprises a device box, machine boxes, shaft cushions, motors, a water box, a water outlet,draining holes, a silica gel cushion, a material outlet, nozzles, gears, driving shafts, worms, spheroidal soft brushes, a material inlet and a water inlet, wherein the two machine boxes are uniformly arranged on one side of the inner part of the device box; each driving shaft is arranged at one end of the corresponding motor; and every two gears are uniformly arranged at the middle part of the corresponding driving shaft. According to the blueberry surface layer washing device disclosed by the invention, through the nozzles, impurities on the surfaces of blueberries are thoroughly washed; then through the soft brushes made of plastic soft fibers, thorough washing is realized, and wax on the surfaces of the blueberries cannot be damaged, so that the blueberry surface layer washing deviceis high-efficiency and quick, and nutrient values of the blueberries can be protected to the greatest extent; through the bevel water box and the draining holes, a set of draining system is formed, sothat after washing is completed, sewage is automatically separated from the blueberries, and the impurities remained on the surfaces of the blueberries can also be greatly reduced; and the blueberrysurface layer washing device is automatic, high-efficiency, time-saving and labor-saving.

Owner:ANHUI HEZHONG AGRI SCI & TECH

Health-care coarse cereal mixed powder and processing technology

InactiveCN106036390AHighlight nutritionPossess qi and spleenFood ingredient functionsSalvia miltiorrhizaNutrient

The invention discloses health-care coarse cereal mixed powder and a processing technology. The health-care coarse cereal mixed powder comprises the following components in parts by weight: 15-20 parts of sorghum, 8-15 parts of unhusked rice, 7-12 parts of lentil, 5-8 parts of glutinous millet, 1-4 parts of safflowers, 2-3.5 parts of argy wormwood leaves, 0.5-1.5 parts of albizia bark, 1-1.8 parts of fresh ginger, 0.7-1.2 parts of caulis polygoni multiflori, 0.5-0.9 part of glossy ganoderma, 0.9-1.5 parts of radix salviae miltiorrhizae, 1.2-1.6 parts of American ginseng, 0.5-1.1 parts of dried orange peel, and 0.9-1.4 parts of costus roots. The invention provides the health-care coarse cereal mixed powder and the processing technology. The health-care coarse cereal mixed powder has the efficacies of nourishing the stomach, stimulating the appetite, alleviating deficiency, clearing stomach heat and treating stomachache, is reasonable in collocation, convenient to make, good in mouth feel when being eaten and high in nutrient value, also has the efficacies of protecting heart and cerebral vessels and promoting blood circulation, has a good health-care effect, and solves the problems that conventional coarse cereal powder is low in nutrient value and poor in health-care effect.

Owner:ANHUI YANZHIFANG FOOD

Health care wild tea

InactiveCN105875932AEmerald green colorAroma is mellowPre-extraction tea treatmentBitter gourdAllergy

The invention discloses health care wild tea, which is prepared from the following raw materials: wild tea leaves, honeysuckle flower, wild chrysanthemum flower, bitter gourd, mint, raw liquorice roots, radix sophorae flavescentis, rhizoma ligustici wallichii, radix angelicae, safflower, aloe, radix rehmanniae, herba houttuyniae, motherwort herb, colla corii asini, peach blossoms, fruit of Chinese wolfberry and honey. The health care wild tea provided by the invention has the advantages that the color and the luster are emerald green; the fragrance is mellow; the liquor color is green and bright; the mouthfeel is fresh; the efficacies of producing a refreshing effect to the mind, reaching health care and detoxication, clearing summer-heat, purging intense heat, nourishing blood, nourishing the liver, moistening the spleen, tonifying the kidney, clearing away the heart-fire, improving eyesight, tonifying qi and Yang, resisting allergy and cancer, regulating lipid, losing weight and enhancing the human immunity are achieved; the health care wild tea is suitable for being drunk for user groups in each stage.

Owner:周学付

Double strain co-immobilized fermented papaya wine and preparation method thereof

InactiveCN106085712AIncrease profitReduce the risk of slow salesAlcoholic beverage preparationMicroorganism based processesUltrafiltrationChemistry

The invention discloses a double strain co-immobilized fermented papaya wine and a preparation method thereof. The preparation method comprises the steps of papaya selection, cleaning, peel and seed removing, breaking, pulping, enzymolysis, centrifugation, ingredient regulating, pasteurization, cooling, immobilized saccharomyces cerevisiae and aroma producing yeast fermentation (primary fermentation), clarification, filtration, secondary fermentation, ageing, blending, filtration, ultrafiltration membrane purification, filling and finished product obtaining. According to the double strain co-immobilized fermented papaya wine and the preparation method thereof, the problems that in the papaya mature season, the amount of papayas is large, the papayas are not prone to storage, for traditional fermentation wine, operation is tedious, and strains are prone to inactivation can be effectively solved; the papayas can be used for continuously producing fruit wine on a large scale, the production cycle is shortened, the production capacity is improved, the strains can be reused, and the production cost is reduced; the obtained papaya wine has the advantages that the papaya wine is clear and transparent, the color and luster are stable and orange yellow, the fragrance of papayas is prominent, the papaya wine is rich in fragrance, soft in taste and beneficial for digestion and absorption of foods by human bodies, and the effects of invigorating spleen to promote digestion and prolonging life are achieved.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Purple potato fine powder production method capable of increasing content of anthocyanin

ActiveCN103766815AProtects the Purple ShadeProtect nutritional valueFood ingredient functionsFood preparationNutritive valuesPotato starch

The invention relates to a purple potato fine powder production method capable of increasing content of anthocyanin. The method comprises the following steps: thoroughly removing potatoes with diseases, cleaning purple potatoes and drying for later use; grinding, finely grinding, filtering potato paste, carrying out dehydration separation on starch milk, extracting the anthocyanin in potato residue and starch milk, cleaning and purifying the starch milk, mixing the starch milk with a purified anthocyanin extract, and evenly mixing the purified anthocyanin extract with the cleaned and purified starch milk. The purple potato fine powder production method has the positive effects that the purple potatoes are taken as main raw materials for producing purple potato fine powder; the anthocyanin in the purple potatoes is firstly separated and purified, the purple potato starch is then purified, and the purple potato starch is mixed with the anthocyanin; the content of the anthocyanin of the dry purple potato starch fine powder is within the range of 0.08-0.15mg / g, so that the unique purple color and the nutritive value of the purple potatoes are protected.

Owner:YANGXIAN KANGYUAN ECOLOGICAL AGRI

A kind of processing method of Hericium erinaceus vegetarian meat jerky

ActiveCN105053980BMeet consumer demandHigh economic profitVitamin food ingredientsFood ingredient functionsNutritive valuesCholesterol

The present invention relates to an edible fungus processing field, namely a dried hericium erinaceus vegetable meat processing method. The technology processes are as follows: selecting hericium erinaceus, soaking to swell, washing, slicing into strips, debittering, washing, centrifuging to dehydration, blending materials and pickling, hot wind and microwave combined drying, brushing by using condensed milk, hot-air oven-drying, cooling, vacuum packaging and thereby obtaining the dried hericium erinaceus vegetable meat. The dried hericium erinaceus vegetable meat is prepared by blending materials and pickling, and ultrahigh pressure sterilizing, can not only protect the original nutritional value and consumption health-care efficacy, but also enable the products to have refreshing flavor, and is suitable for the introduction of enterprises, and the various accessory materials used during the processing are inexpensive and readily available, and the products have relative high economic profits. The prepared dried hericium erinaceus vegetable meat products have appearance like dried meat, has a mouthfeel of dried meat, and is low in fat and sugar, and free of cholesterol, and thus consumers will not be worried about excessive intake of fat, sugar and cholesterol, and the dried hericium erinaceus vegetable meat is in line with modern consumer demands. Meanwhile, the product is vacuum-packed and ultrahigh-pressure sterilized, and thus can be preserved at room temperature for 12 months.

Owner:TONGHUA NORMAL UNIV

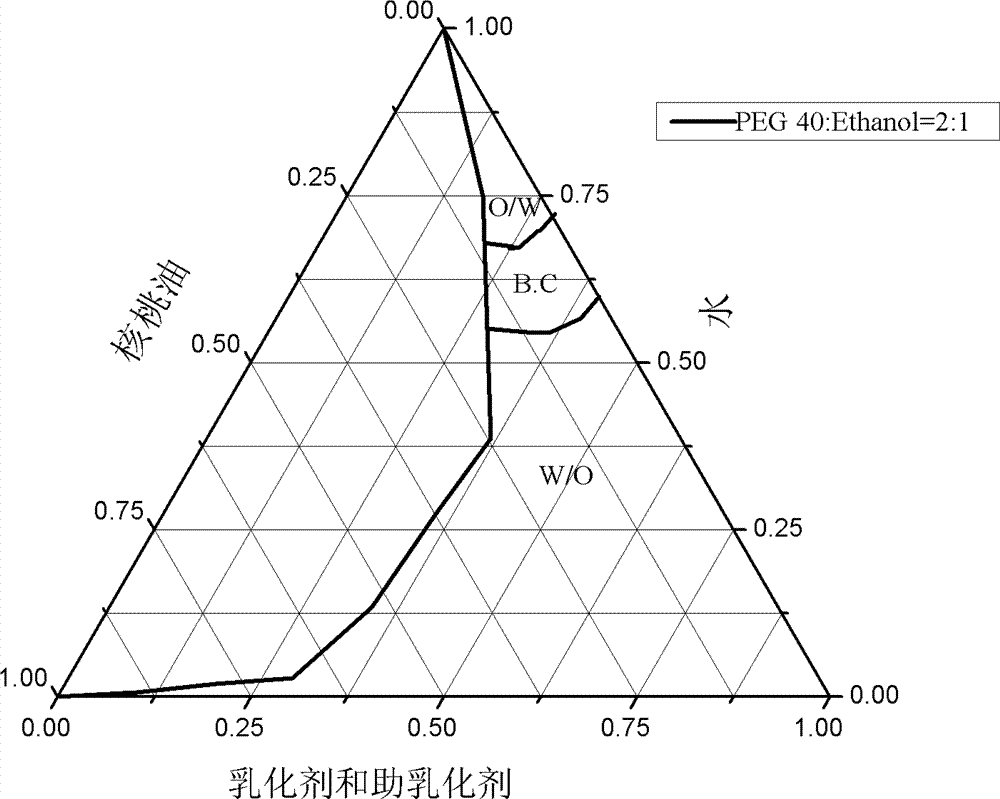

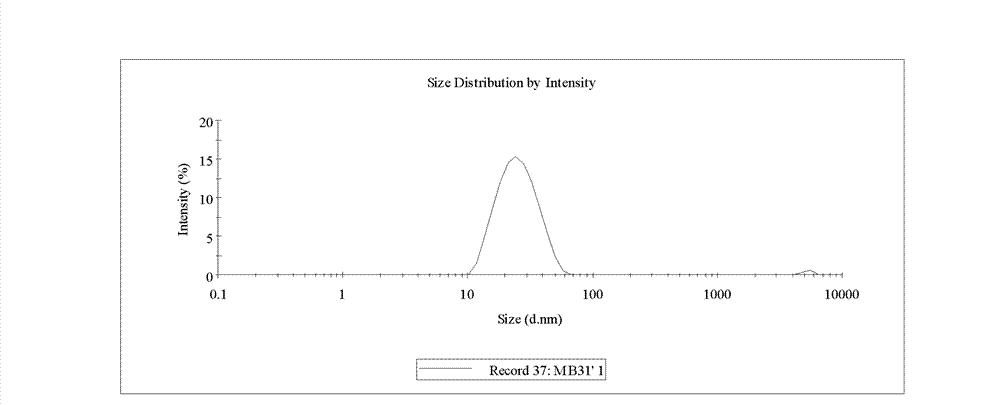

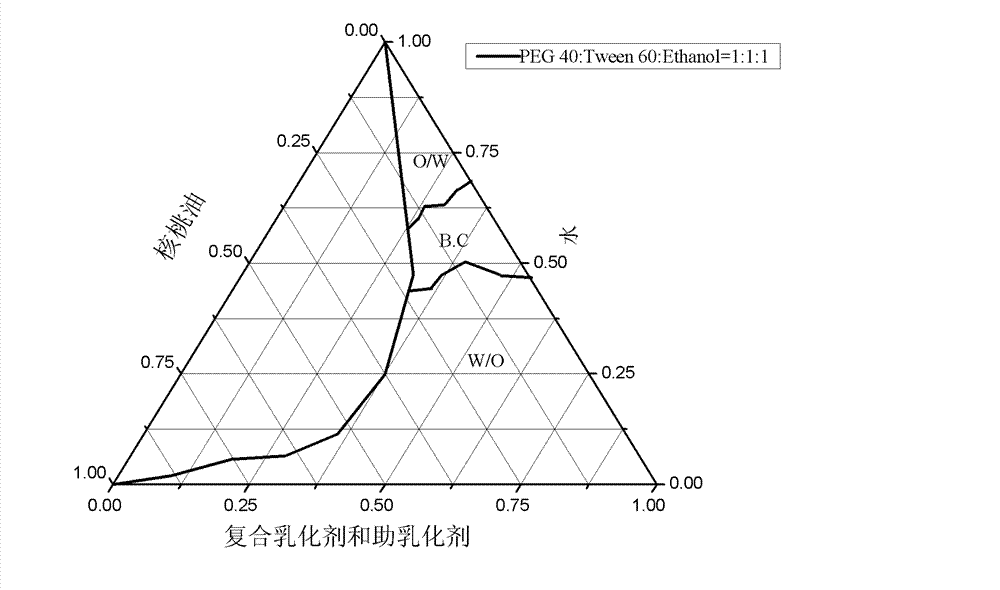

Method for preparing microemulsion of walnut oil

ActiveCN102178240BProtection is not fullProtect fatty acid compositionFood preparationNutritive valuesMicroemulsion

The invention relates to a method for preparing microemulsion of walnut oil, which uses a primary emulsifier and a secondary emulsifier, and comprises a step of emulsifying and a step of mixing with water for preparing oil / water (O / W) type microemulsion of walnut oil. The prepared microemulsion of walnut oil can solubilize the walnut oil, remove the fishy smell of the walnut oil, reduce the oxidation of unsaturated fatty acid in walnut oil, and retain the nutritional value of the walnut oil; therefore, the prepared microemulsion of walnut oil can improve the quality of products and the biological utilization rate of nutrients, and enlarges the range of applications of the products in the fields of functional drinks, liquid health-care products, functional food ingredients and the like.

Owner:鹰潭中投科技有限公司

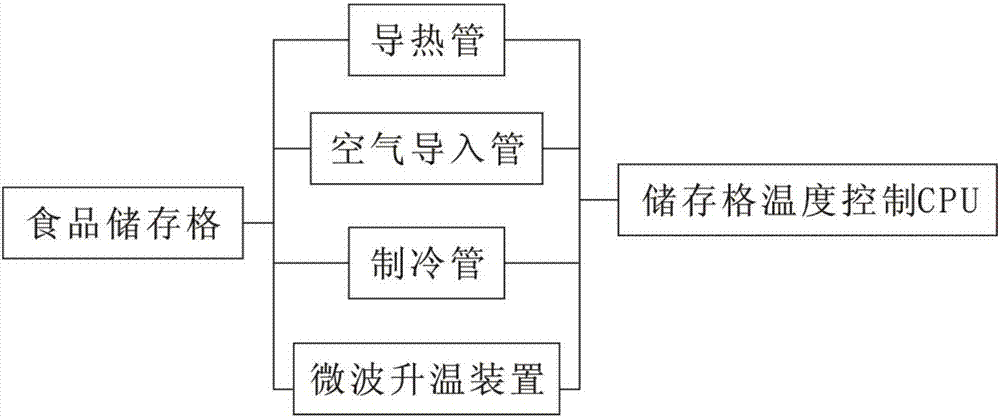

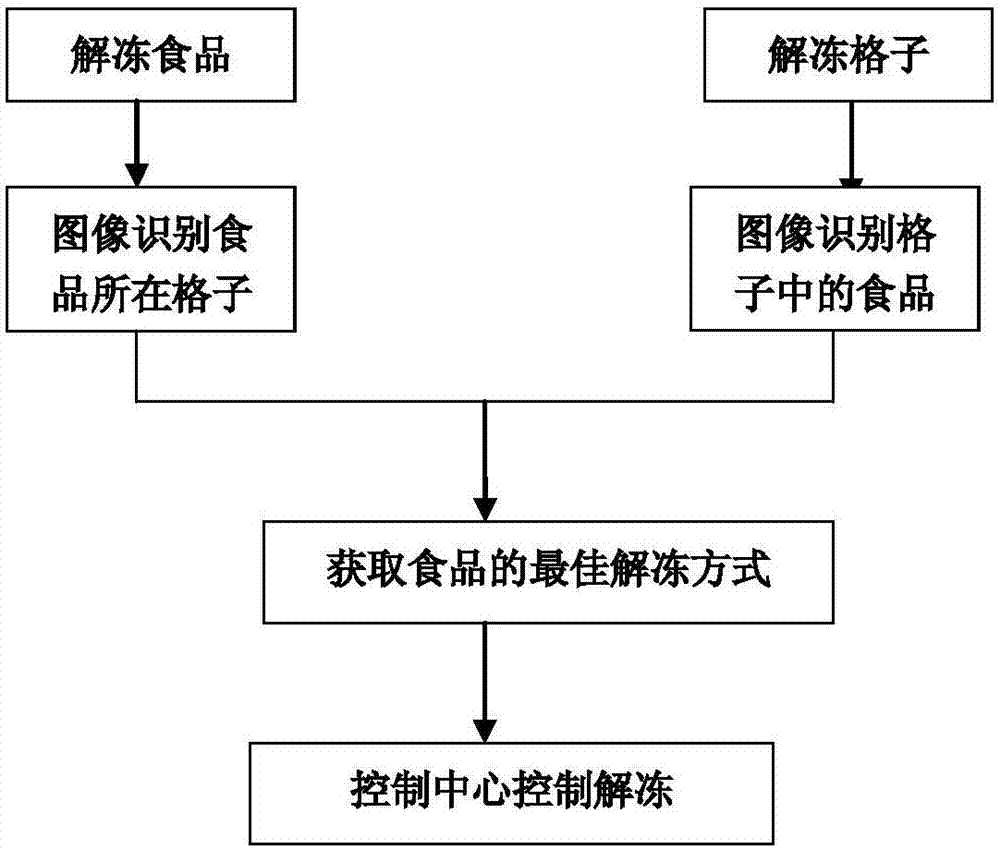

Food automatic defrosting system and method applied to refrigerator

InactiveCN107461988AImprove experienceProtect nutritional valueLighting and heating apparatusDomestic refrigeratorsTemperature controlMicrowave

The invention discloses a food automatic defrosting system and method applied to a refrigerator. The refrigerator internally comprises a plurality of food storing cases and a storing case temperature control CPU for controlling the food storing cases in a one-to-one correspondence mode. The food storing cases communicate with air guide-in pipes and air guide-out pipes, the exteriors of the food storing cases are provided with heat guiding pipes and refrigerating pipes and further provided with microwave heating devices correspondingly, and the heat guiding pipes, the refrigerating pipes and the microwave heating devices are in electric communication connection with the storing case temperature control CPU. According to the food automatic defrosting system and method applied to the refrigerator, the defrosting mode of one single or combined form of air defrosting, heating temperature-rising defrosting and microwave heating defrosting can be achieved, defrosting control can be achieved remotely through an intelligent terminal by a user under any condition, and food does not need to be taken out for defrosting through defrosting operation of the food automatic defrosting system and method, so that the experience of the user is greatly improved, the nutrition value is protected, and the physical and mental health of people are facilitated.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

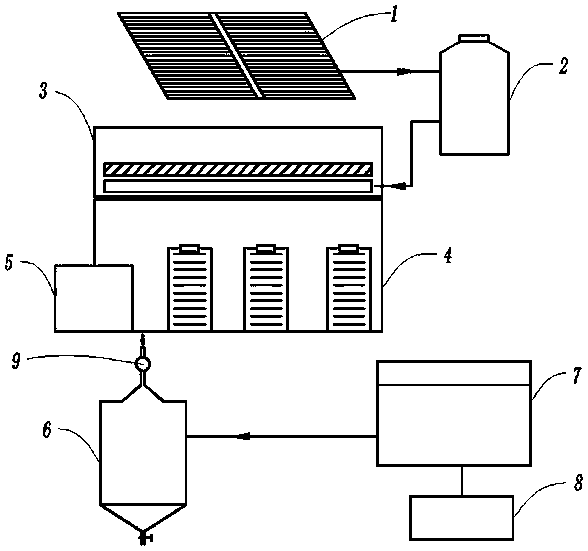

Rose drying and bud water synchronous recycling method

InactiveCN109237879ASpeed up evaporationCongeal fastSolar heating energyDrying gas arrangementsVolatilesResource utilization

The invention relates to the technical field of agricultural product processing, in particular to a rose drying and bud water synchronous recycling method. According to the method, the cooperation ofan solar greenhouse effect (indirect sunlight) and an air energy heat pump dryer is utilized to perform low-temperature heating and drying, and a high-frequency micro-vibration device is added to accelerate the evaporation of water and volatile nutrients in a rose, and the nutrient volatiles are recovered through a pressurized cooling recovery device, thereby improving the liquid collection rate of bud water of the rose and increasing the resource utilization rate.

Owner:乡宁县美聚香凝农产品开发有限公司

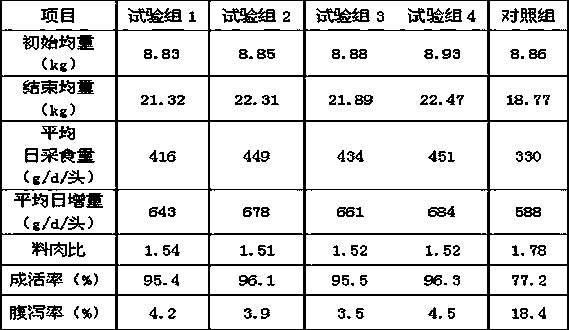

Preparation method of biological feed for piglets and application thereof

PendingCN108813188ACrunchy and fragileImprove digestion utilizationWorking-up animal fodderMixed materialsDigestion

The invention discloses a preparation method of a biological feed for piglets and application thereof. The preparation method comprises the following steps of (1) selecting feed primer, and crushing;(2) freezing the prepared material in step (1); (3) puffing the treated material in step (2), so as to obtain the puffed material; (4) selecting red date powder, and mixing with the puffed material instep (3), so as to obtain a mixed material A; (5) cooling the mixed material A in step (4), and drying; (6) crushing the treated material in step (5), so as to obtain a powdery carrier material B; (7) mixing a fresh wet fermenting feed, a mildew-proof agent and the powdery carrier material B, so as to obtain a mixed material C; (8) granulating the mixed material C in a cold way; (9) cooling the prepared feed in step (8), and packaging. The preparation method of the biological feed has the advantages that the activity of beneficial components in the fresh fermenting feed is ensured; the attraction property and palatability of the prepared feed are good, the mouth feel is crisp, the digestion is easy, and the health state and growth property of the piglet are improved.

Owner:刘建华

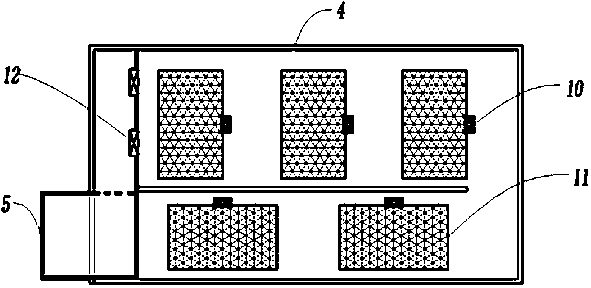

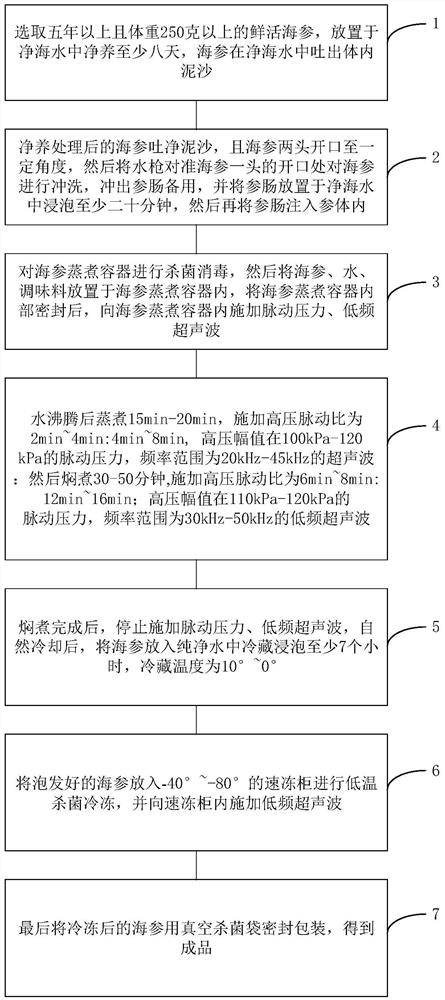

Production method of instant solid sea cucumbers

InactiveCN111838577AReduce processing timeFull of nutritionFood freezingFood ultrasonic treatmentNutritionEnvironmental engineering

The invention provides a production method of instant solid sea cucumbers. The production method comprises the following steps: selecting fresh sea cucumbers which are more than five years old and have the weight of more than 250g, putting the sea cucumbers into clean seawater for clean culture for at least eight days, and spitting silt in bodies of the sea cucumbers in the clean seawater; aligning a water gun with an opening at one end of the sea cucumber to flush the sea cucumber, flushing out sea cucumber intestines for later use, sterilizing and disinfecting, putting the sea cucumber, water and seasonings into a sea cucumber cooking container, sealing the inside of the sea cucumber cooking container, and applying pulsating pressure and low-frequency ultrasonic waves into the sea cucumber cooking container; after natural cooling, putting the sea cucumbers into purified water to be refrigerated and soaked, putting the soaked sea cucumbers into a quick-freezing cabinet to be subjectedto low-temperature sterilization and freezing, applying low-frequency ultrasonic waves into the quick-freezing cabinet, finally sealing and packaging and obtaining finished products. The sea cucumbers are in a pulse high-pressure, sealed and ultrasonic environment in the processing process so that the processing time of the sea cucumbers is shortened, the processing efficiency is improved, and the processed sea cucumbers are rich in nutrition, good in taste and easy to store.

Owner:薛新耀

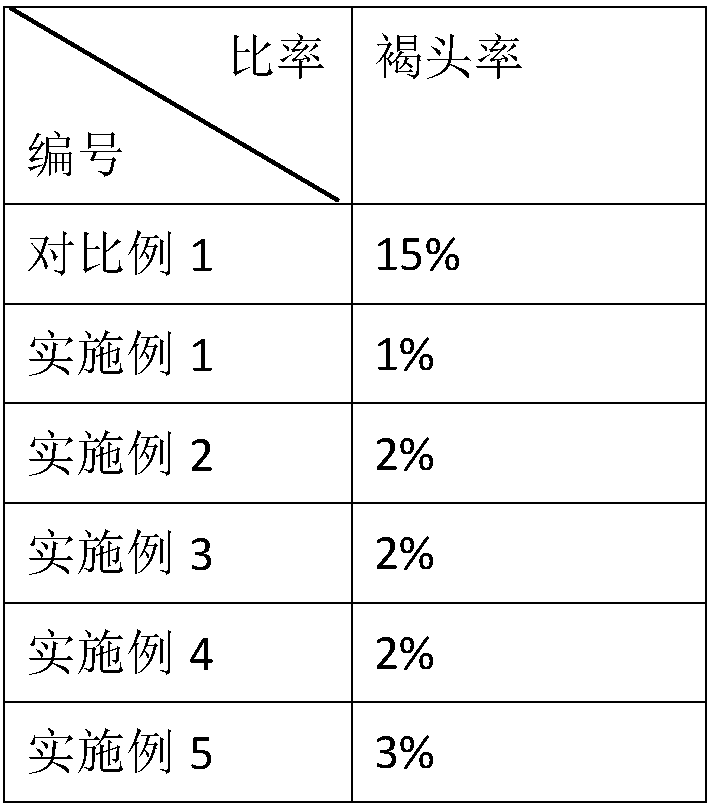

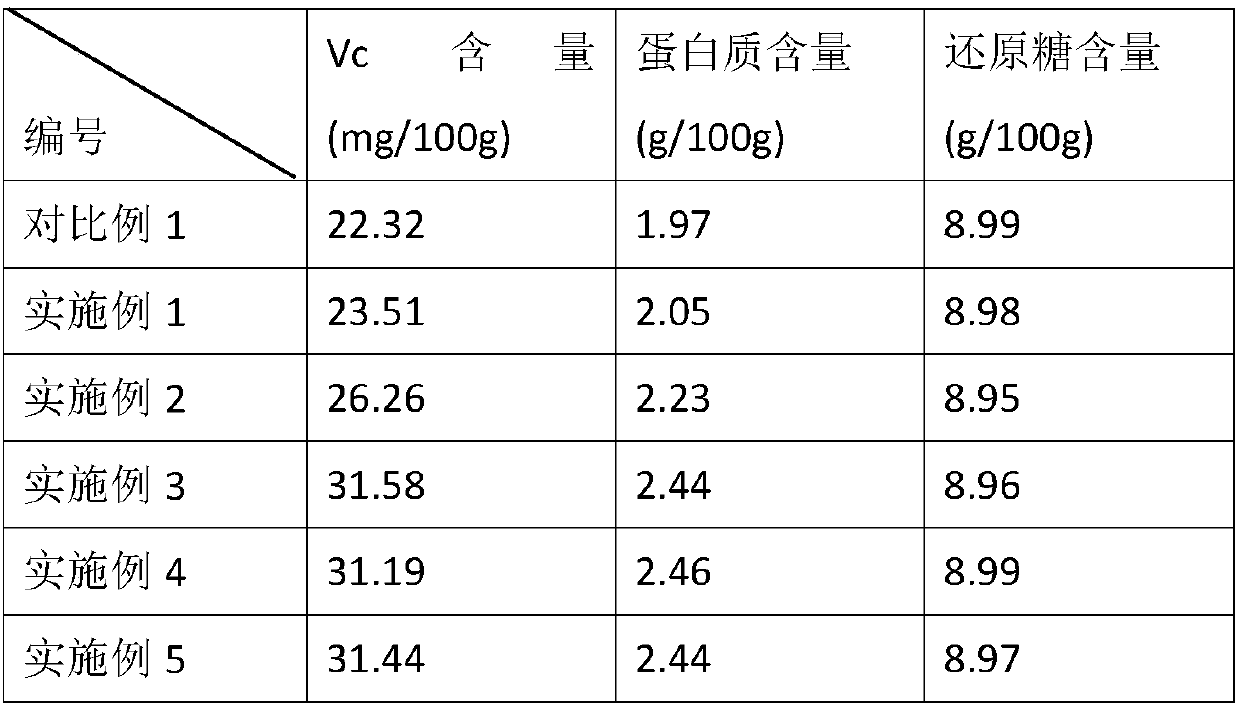

Production technology of sulfur-free day lilies

InactiveCN107927522AShorten steaming timeReduce the temperatureFood dryingFood ingredient functionsFlavorSignalling molecules

Natural hormones of plants are active substances which can be used for preservation treatment of plants. XXFG is an oligosaccharide plant natural hormone and can play a role in regulating physiological reactions in plants as a signal molecule. The invention provides a production technology of sulfur-free day lilies. It is found that the steaming time of day lilies in the production process can beshortened effectively, the steaming temperature of the day lilies can be reduced and the brown head rate of the day lilies can be decreased by soaking the day lilies in a certain concentration of XXFGsolution in the day lily production process, so that the storage life of the day lilies is prolonged. With the adoption of the technological treatment, the color, flavor, sensory quality and storagelife of dried day lilies can be significantly improved, the sanitation, safety and nutrient value of the dried day lilies can be improved, and meanwhile, energy consumption for drying of day lilies can be reduced to be only 40% of that for traditional hot blast drying and 70% of that for heat pump drying.

Owner:四川省宕府王食品有限责任公司

Preparation method of red beet yoghurt powder

PendingCN113180113AReduces bitterness and earthy tasteRich taste requirementsMilk preparationLactobacillusChemistryLeavening agent

The invention discloses a preparation method of red beet yoghurt powder, and relates to the technical field of yoghurt processing, and the preparation method comprises the following steps: treating special varieties of red beet, freeze-drying, breaking walls and crushing to obtain red beet powder, and mixing the red beet powder with whole milk, coconut milk and the like; taking lactobacillus bulgaricus and streptococcus thermophilus which produce fragrance and viscosity as leavening agents for fermentation, and then performing spray drying to obtain the red beet yoghurt powder which can protect pigment and nutritional value of the red beet and has good flavor.

Owner:SHENYANG UNIV

Processing method of pleurotus ostreatus ready-to-eat dish

InactiveCN106036807AProtect nutritional valueReduce complexityFood ingredient as mouthfeel improving agentReady to eatFood flavor

The invention relates to a processing method of a pleurotus ostreatus ready-to-eat dish. The processing method comprises the following operation steps of (1) selecting materials; (2) performing cleaning; (3) performing splitting; (4) performing embrittlement; (5) performing blanching; (6) performing rinsing and coling; (7) performing stir-frying and dehydrating; (8) mixing materials; (9) performing packaging and sterilization; (10) performing cooling; and (11) performing inspection. Through the adoption of the processing method disclosed by the invention, the original nutrient value and edible health-care efficacies of products can be protected, and refreshing flavor is given to the products. Besides, the processing method is low in complexity and suitable for being used for enterprises, various auxiliary materials used in the processing course are low in price and easy to obtain, and the economic profit of the products is high.

Owner:TONGHUA NORMAL UNIV

A kind of processing method of fresh-keeping Chinese yam

InactiveCN104273215BEfficient removalGuaranteed aestheticsFruits/vegetable preservation by heatingFruits/vegetable preservation using acidsFlavorSludge

The invention discloses a processing method of fresh-keeping yam. This processing method is suitable for noodle yam (medicinal yam), especially for bergamot yam. The processing steps included are: 1) cleaning and peeling; 2) removing skin mucus, sludge, and impurities; 3) pickling; 4) desalination, Slicing; 5) Sterilization and curing; 6) Color protection; 7) Packing and evacuation; 8) Sterilization; 9) Packing and storage. This processing method can effectively remove the mucus in the epidermis of the herbal medicine, and keep the mucus in the yam from losing, which not only ensures the beauty of the product, but also effectively protects the nutritional value of the product; the fresh-keeping yam made by this processing method can grow The original nutritional value, taste and flavor of yam are maintained for a long time; the shelf life of the product is obviously extended, and it is convenient for storage, transportation and use.

Owner:陈连生

A kind of production method of purple sweet potato fine powder that improves anthocyanin content

The invention relates to a purple potato fine powder production method capable of increasing content of anthocyanin. The method comprises the following steps: thoroughly removing potatoes with diseases, cleaning purple potatoes and drying for later use; grinding, finely grinding, filtering potato paste, carrying out dehydration separation on starch milk, extracting the anthocyanin in potato residue and starch milk, cleaning and purifying the starch milk, mixing the starch milk with a purified anthocyanin extract, and evenly mixing the purified anthocyanin extract with the cleaned and purified starch milk. The purple potato fine powder production method has the positive effects that the purple potatoes are taken as main raw materials for producing purple potato fine powder; the anthocyanin in the purple potatoes is firstly separated and purified, the purple potato starch is then purified, and the purple potato starch is mixed with the anthocyanin; the content of the anthocyanin of the dry purple potato starch fine powder is within the range of 0.08-0.15mg / g, so that the unique purple color and the nutritive value of the purple potatoes are protected.

Owner:YANGXIAN KANGYUAN ECOLOGICAL AGRI

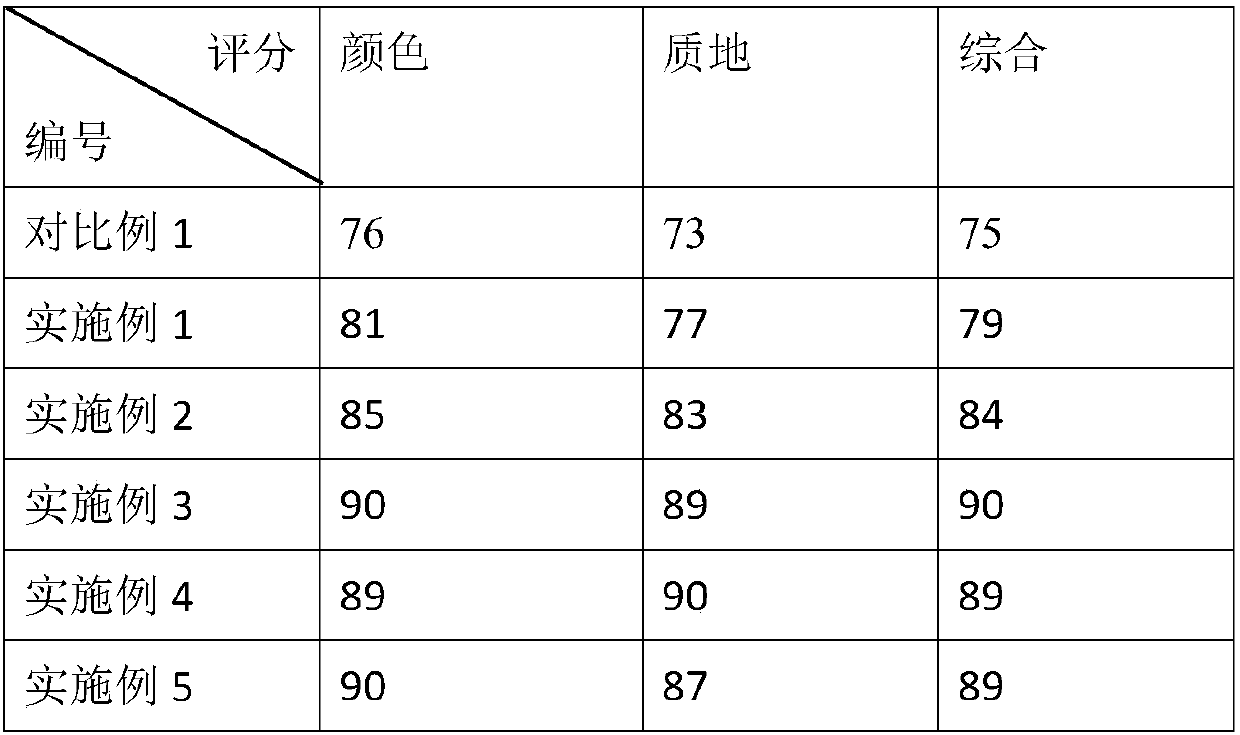

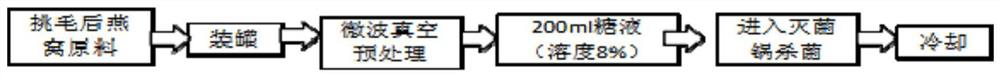

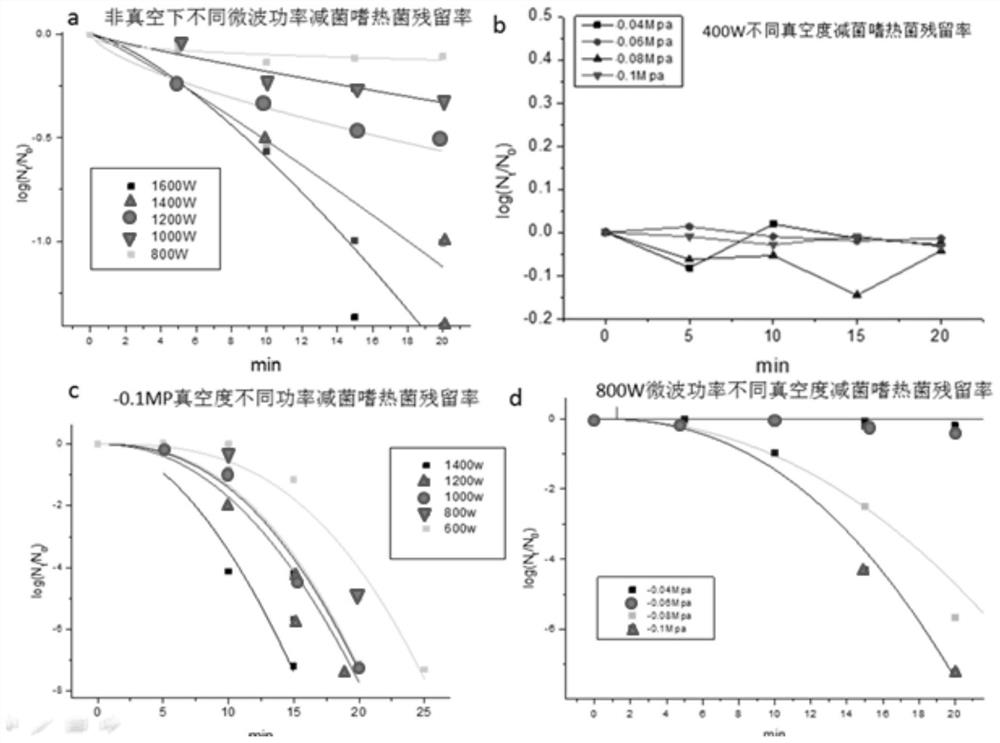

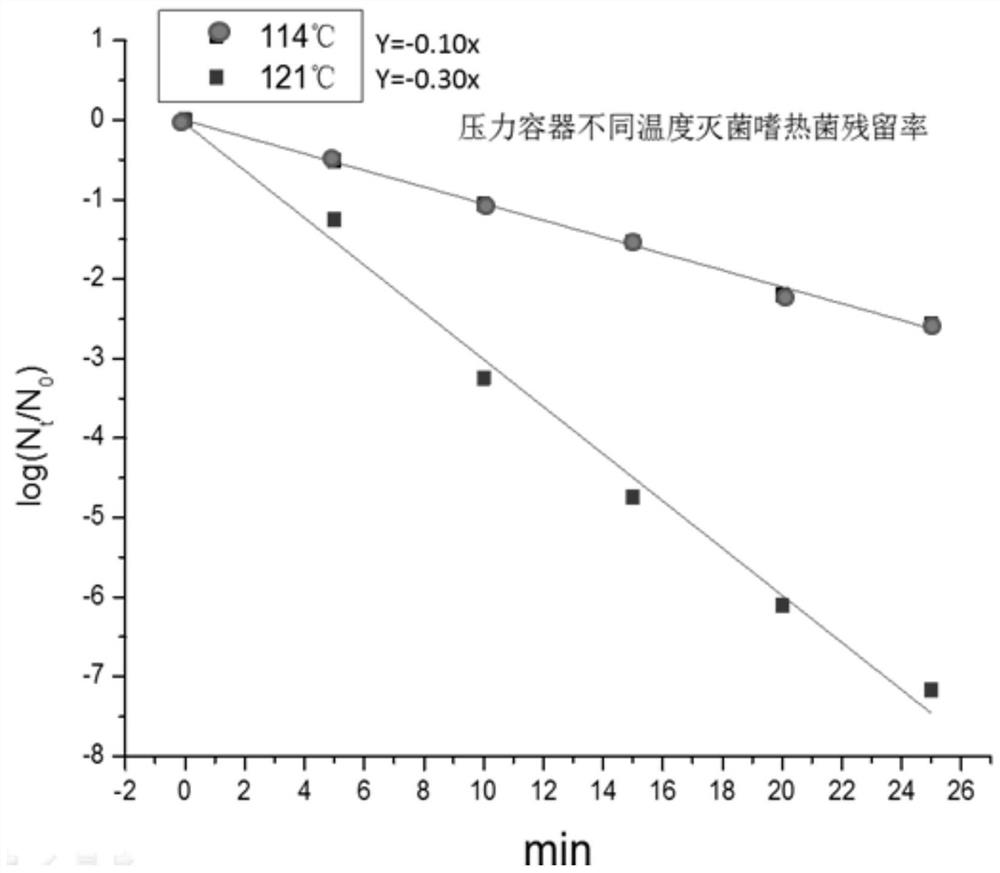

Process for processing canned cubilose through cooperation between microwaves and vacuum pretreatment

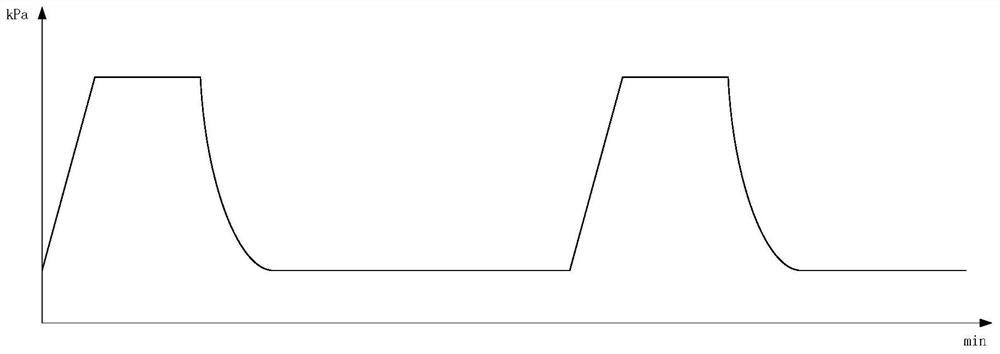

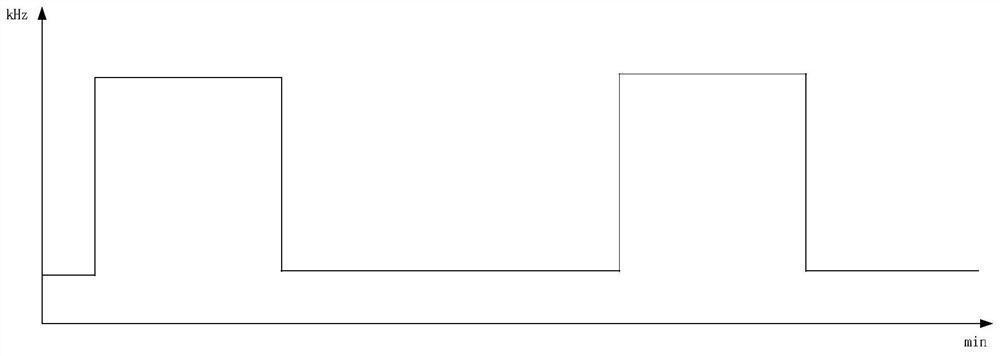

PendingCN113519829AProtective propertiesProtect nutritional valueFood thermal treatmentFood preservationAfter treatmentProcess engineering

The invention discloses a process for processing canned cubilose through cooperation between microwaves and vacuum pretreatment. The process comprises the following steps: putting a raw cubilose material into a can bottle, putting the can bottle in a microwave vacuum sterilization chamber, setting a vacuum degree to be -0.08 to -0.1 MPa, microwave intensity to be about 20 W / g and a temperature to be 105-115 DEG C, performing microwave vacuum sterilization treatment on the raw cubilose material for 12-15 minutes, conducting filling of sugar liquid after treatment, and performing sterilizing for 5-10 minutes through saturated steam with a temperature of 121 DEG C. Thus, the shelf life of the canned cubilose is kept at 6-12 months. According to the process, the effect which cannot be achieved by sterilization under a single microwave or single vacuum condition is achieved through cooperation between microwaves and vacuum sterilization pretreatment; the damage of microwave vacuum pretreatment and traditional thermal sterilization to the quality of the canned cubilose is far less than the damage of traditional thermal cansterilization to food materials; and the process greatly protects product quality and is suitable for further popularization and application.

Owner:FUJIAN AGRI & FORESTRY UNIV

Cuttlefish vegetable crisp and processing technology thereof

InactiveCN104522749AHigh nutritional valueProtect nutritional valueFood preparationDiuresisProtein content

The invention discloses cuttlefish vegetable crisp and a processing technology thereof, relating to the technical field of aquatic product processing. The cuttlefish vegetable crisp is processed from the following raw materials in parts by weight: 2 parts of cuttlefish, 1 part of onion and 1 part of tomatoes. The technology comprises the following steps: pretreating the cuttlefish, treating the onion, treating the tomatoes, seasoning, shaping, frying and packaging. The cuttlefish vegetable crisp disclosed by the invention is high in nutritive value, the nutritive values of various raw materials in the cuttlefish vegetable crisp are greatly protected, the protein content is high, the human essential amino acids are rich and are balanced, and the cuttlefish vegetable crisp has the effects of scavenging in-vivo oxygen free radicals, enhancing the metabolism capability, defying age, preventing osteoporosis, stopping bleeding, reducing blood pressure, inducing diuresis, improving digestion, helping produce saliva and slake thirst, clearing away heat and toxic materials and cooling blood and calming the liver and is convenient to eat and has crispy taste and attractive appearance.

Owner:宁德市登月水产食品有限公司

Garlic bolt sauce and preparation method thereof

The invention discloses a garlic bolt sauce, which comprises, by weight, 70-90 parts of garlic bolt, 3-6 parts of garlic, 1-9 parts of edible salt, 2-20 parts of hot pepper, 2-12 parts of ginger, 0.3-1.5 parts of sucrose, 0.8-1.6 parts of monosodium glutamate, 2-4 parts of potassium sorbate, 2-8 parts of soy sauce, and 0.8-2.8 parts of starch. A preparation method of the garlic bolt sauce comprises: pre-treating the raw materials; treating the garlic bolt and the garlic for 25-40 min at a temperature of 68-75 DEGC while combining with high voltage pulse electric field treatment, wherein the electric field intensity is set to 25-40 Kv / cm, and the number of the pulses is set to 10-60; immersing, and carrying out beating breaking; decocting for 50-80 min at a temperature of 60-70 DEGC while applying pressure of 0.2-0.35 MPa; and finally carrying out cooling, sterilizing packaging and other processes to prepare the garlic bolt sauce product. According to the present invention, with the preparation method, the nutrient loss in garlic bolt and garlic are low, the prepared garlic bolt sauce does not have sour odor, and further has characteristics of high nutritional value and good flavor,and the method is suitable for industrial production.

Owner:张国朋

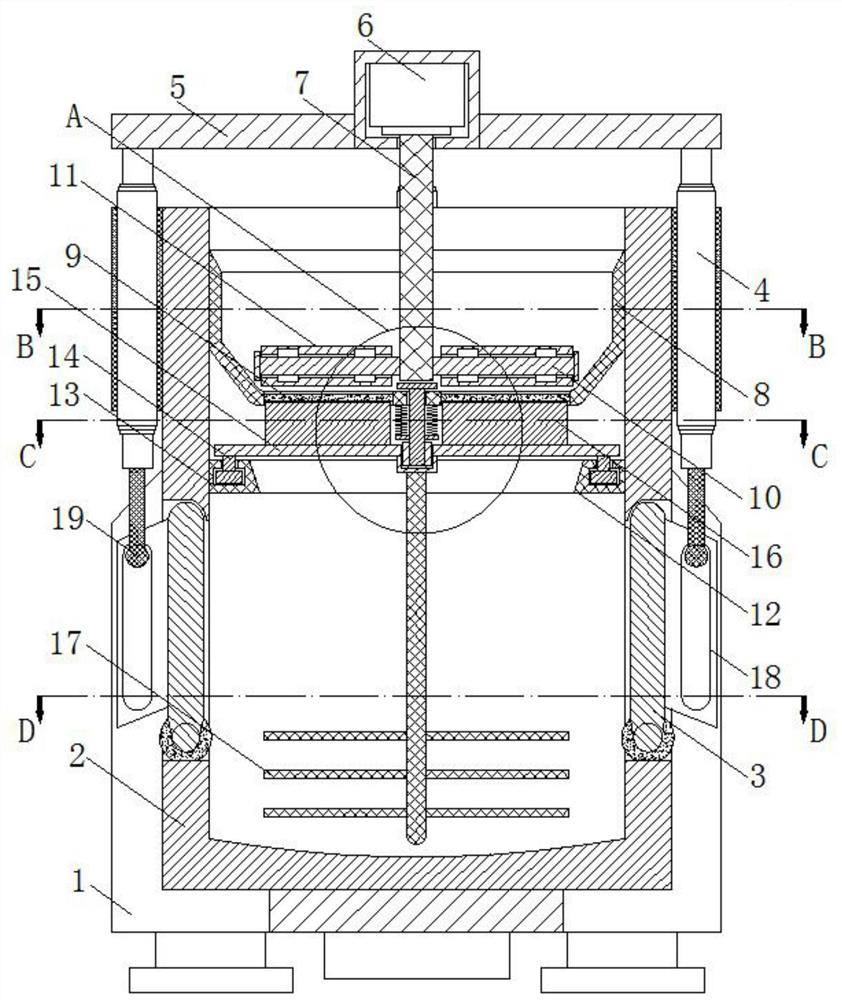

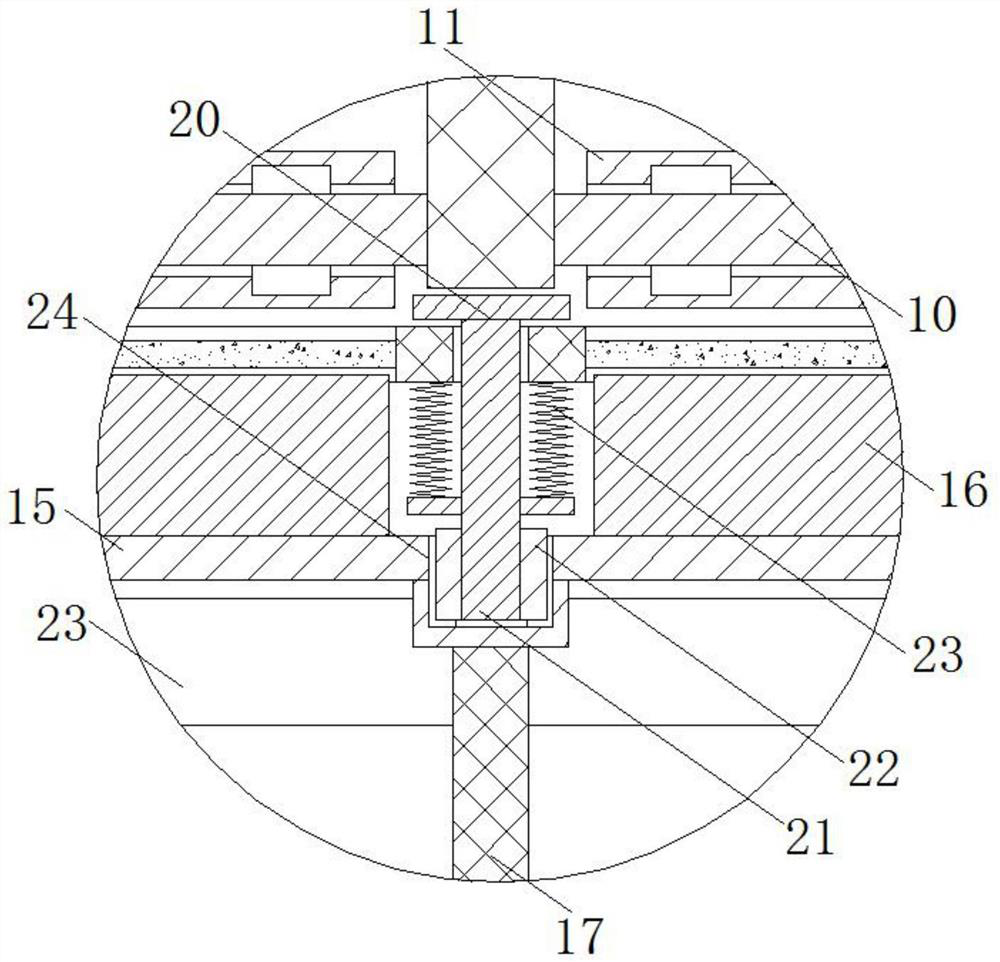

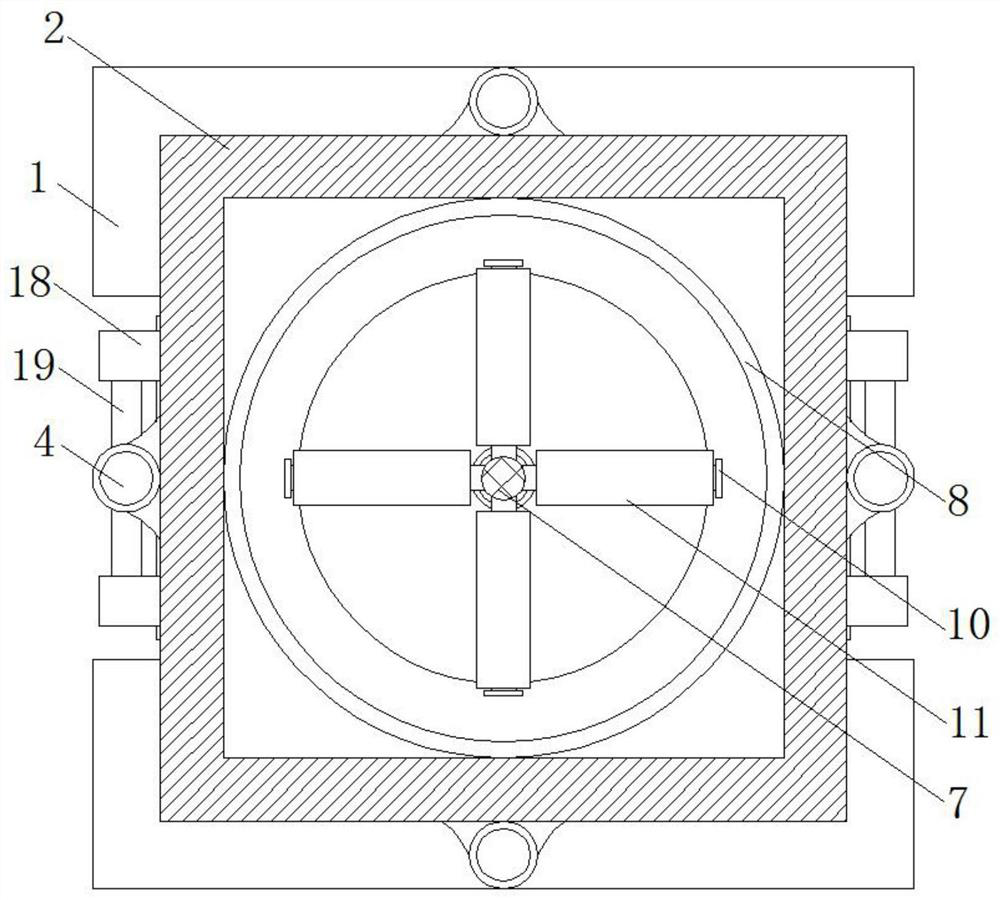

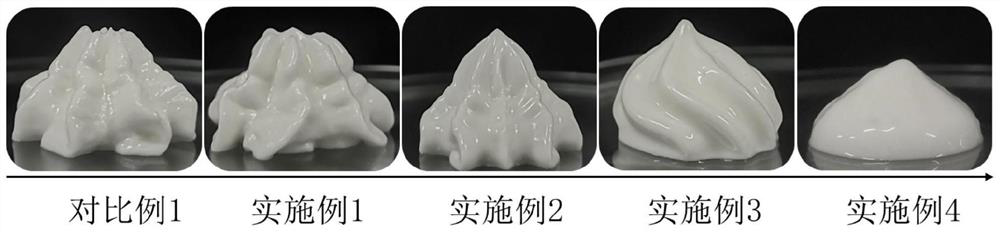

Mung bean cake rich in nutrition

The invention discloses a mung bean cake rich in nutrition, relates to the field of mung bean cakes, and provides the following scheme for solving the problems that nutritional ingredients of existingmung bean cakes are prone to being damaged, peeling is not comprehensive, the taste is affected, and the production efficiency is low in the production and manufacturing process of the existing mungbean cakes. A scheme is proposed as follows: a heating base is included, wherein a square cylinder is arranged in the heating base; cover plates are rotationally connected to the left side face and the right side face of the square cylinder; a bidirectional hydraulic rod is fixedly installed on each side face of the square cylinder; a supporting plate is fixedly connected to the upper ends of thebidirectional hydraulic rods; a motor is fixedly installed on the upper end face of the supporting plate, and a rotating rod is fixedly connected to the output end of the lower side of the motor.; a conical cylinder is fixedly mounted on the inner wall of the upper side of the square cylinder; a filter screen is arranged on the lower bottom face of the conical cylinder; and a plurality of supporting rods are fixedly connected to the side face of the lower end of the rotating rod. The characteristics that the peeling is convenient, the nutritional value is effectively protected, meanwhile, themixing processing is convenient, and the production efficiency is improved are achieved.

Owner:黄山市胡兴堂文化发展有限公司

Method for improving emulsifying property of vegetable protein by using soapbark extract

PendingCN114343190AProtect nutritional valueA wide range of additivesCosmetic preparationsToilet preparationsPlant basedQuillaja saponaria bark

The invention provides a method for improving the emulsifying property of vegetable protein by using a soapberry bark extract, which comprises the following steps: S1, mixing and hydrating vegetable protein and a natural soapberry bark extract by using water or a buffer solution and alcohol according to a proper proportion to obtain a mixed solution of the vegetable protein and the soapberry bark extract; and S2, drying the mixed solution of the vegetable protein and the soapberry bark extract to obtain the compound of the vegetable protein and the soapberry bark extract. The protein emulsifying property can be remarkably improved only by adding a small amount of natural soapberry bark extract without complex protein modification, the process operation is simple and convenient, no reagent exists, pure plant base is achieved, and industrial continuous production is easy to achieve.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

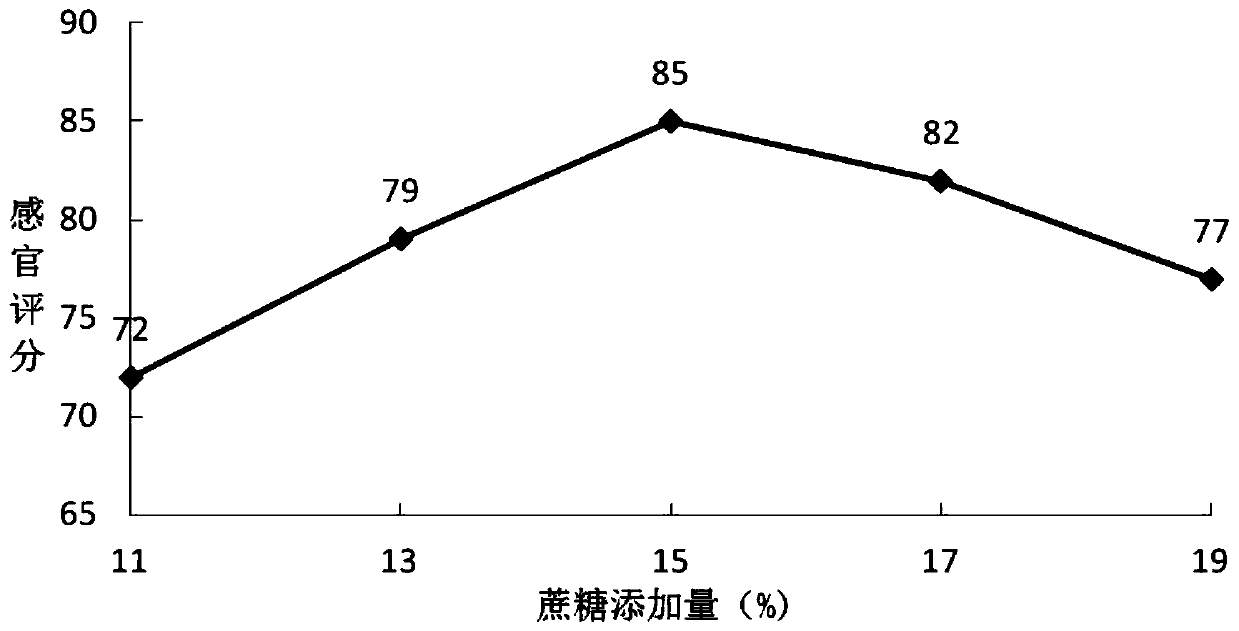

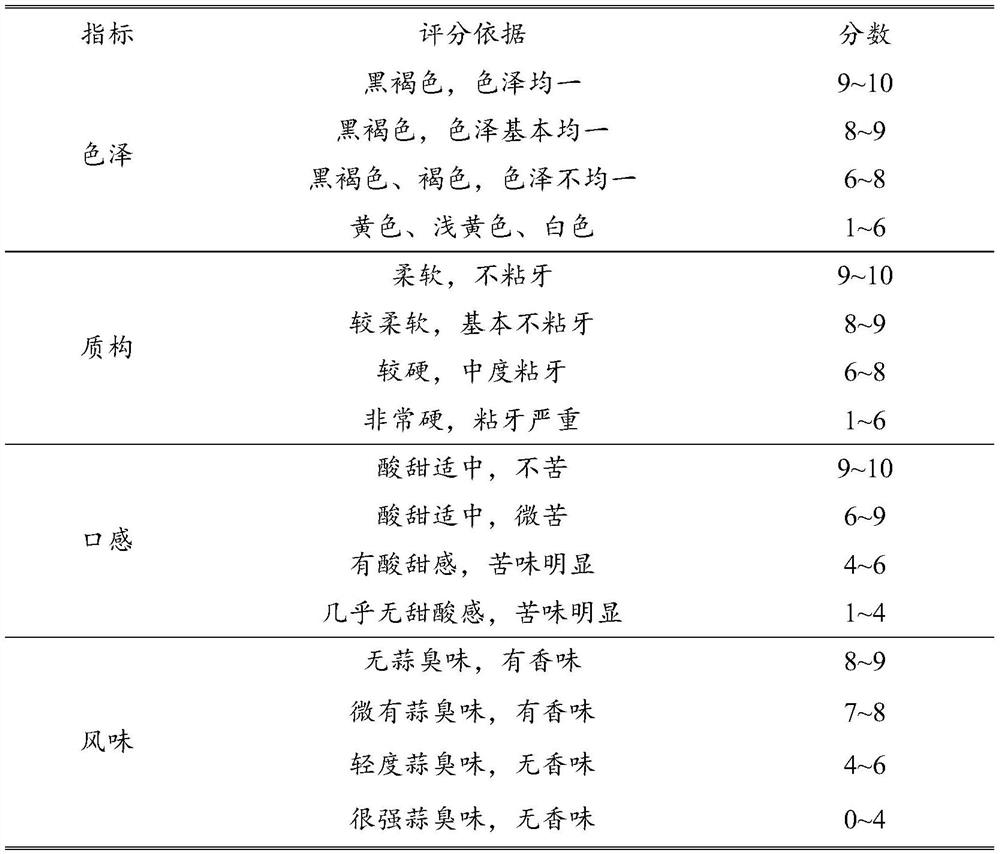

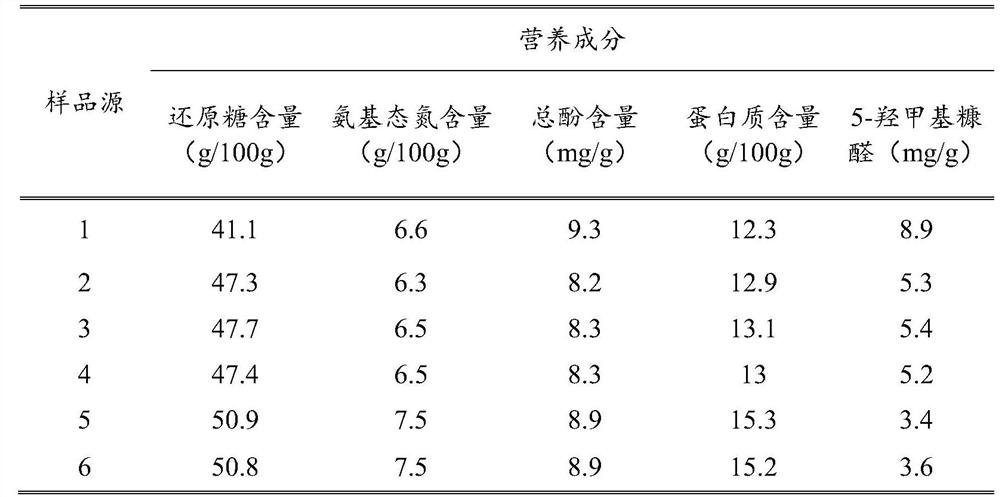

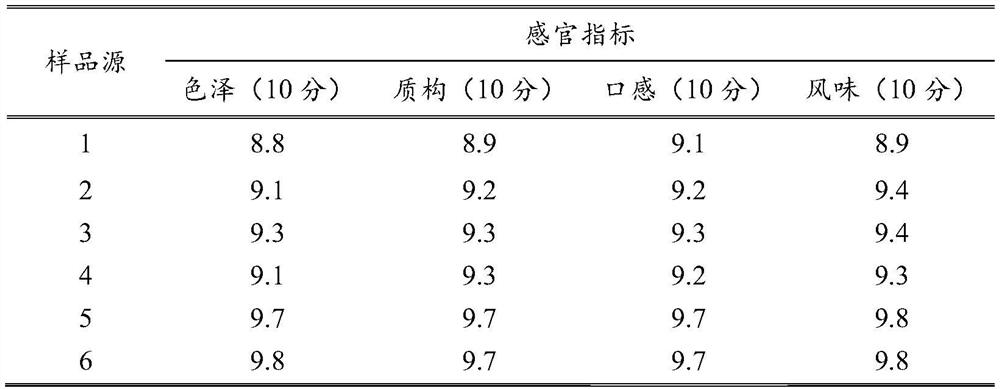

Fermented coriander jelly and production method thereof

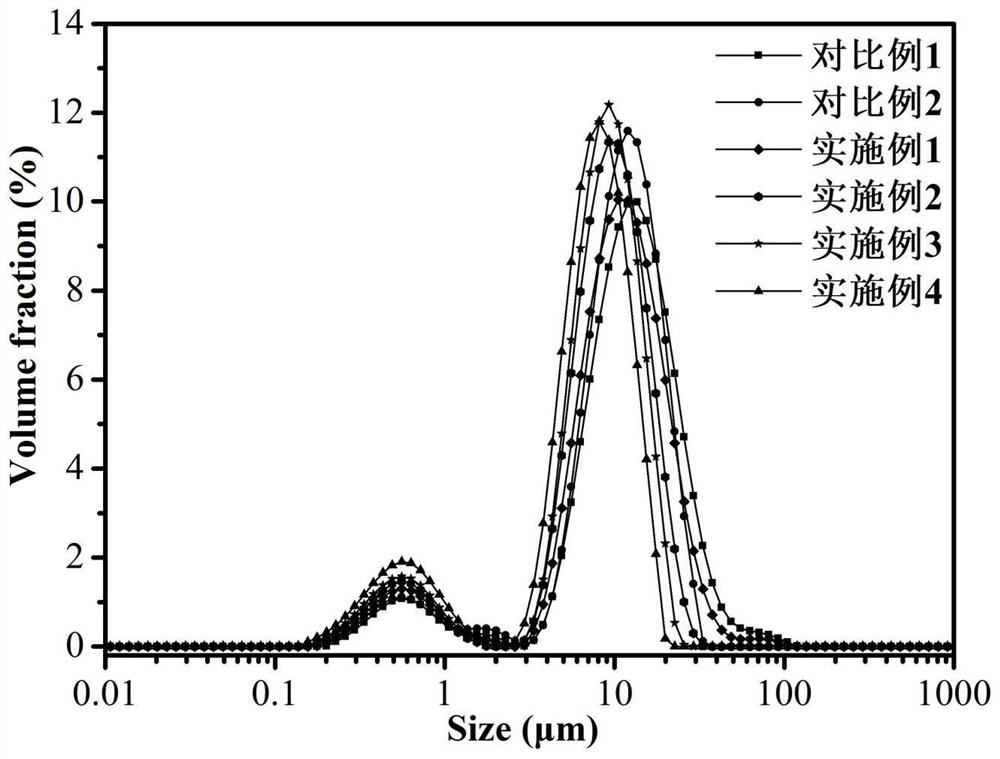

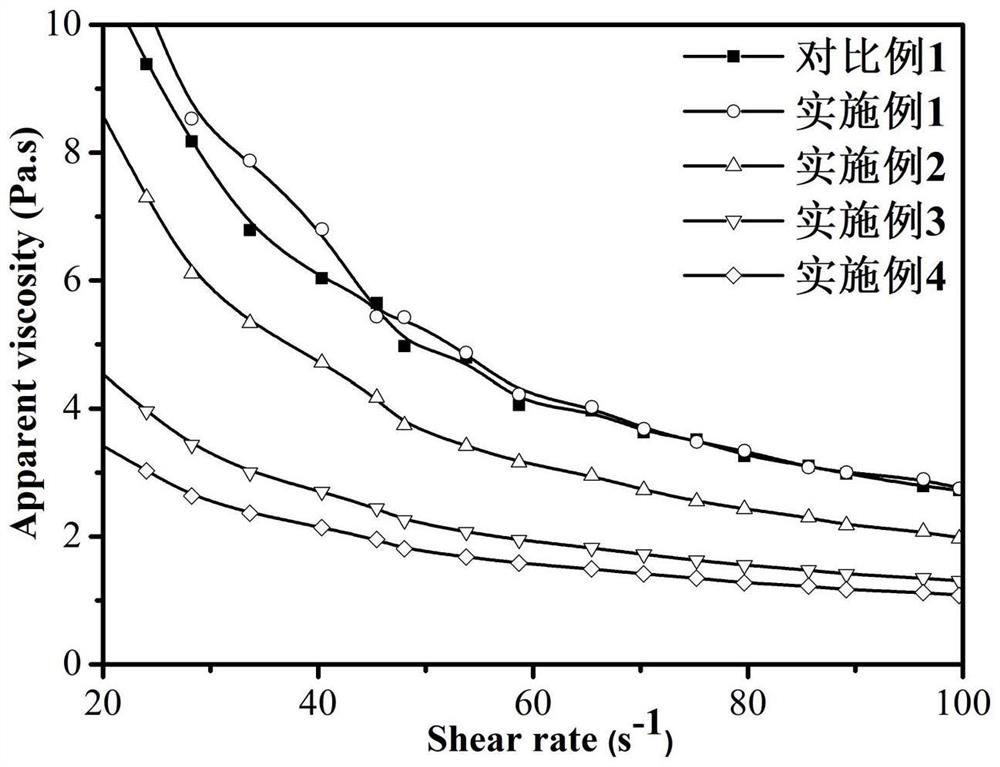

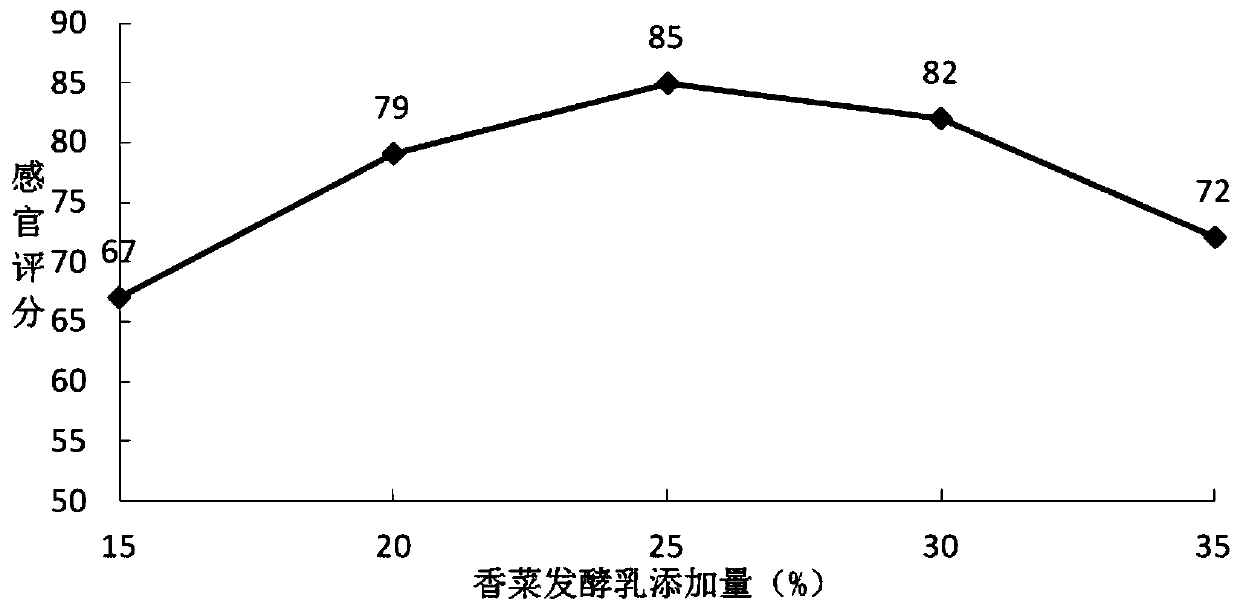

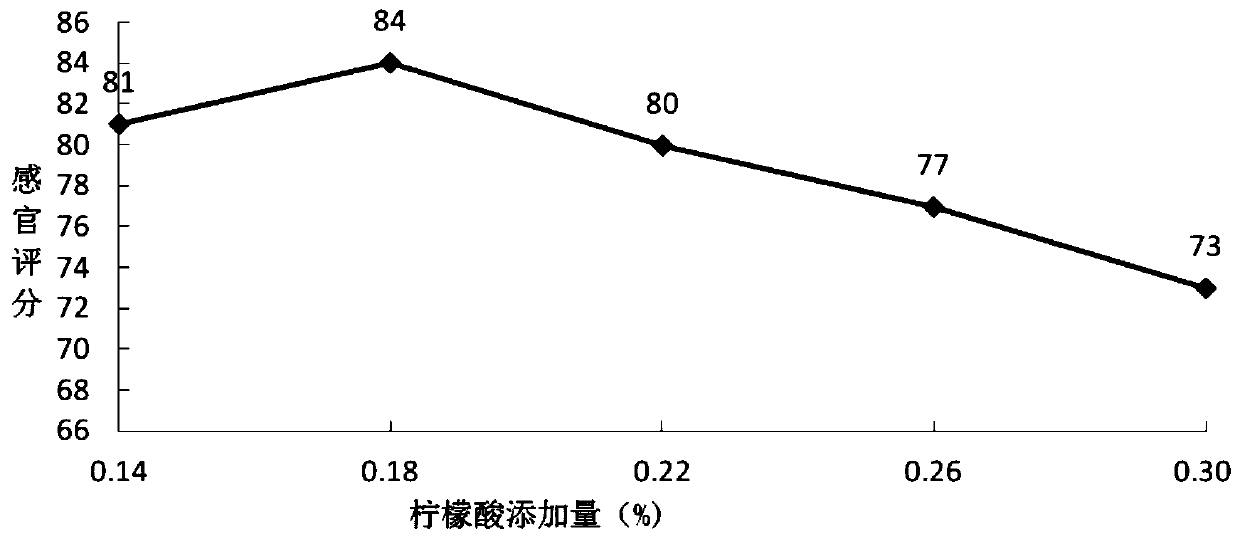

ActiveCN111202230ADelicate and elasticPrevent uneven colorFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentBiotechnologyBrowning

The invention discloses fermented coriander jelly and a production method thereof. The fermented coriander jelly contains 15%-40% of coriander fermented milk, 0.8%-1.6% of compound gum, 11%-19% of sucrose and 0.14%-0.3% of citric acid. Through a large number of experiments, the formula components are selected, the content of each component is optimized, the unstable phenomena of sedimentation, layering, flocculation and the like are overcome, the problem of loss, due to oxidation and browning, of nutrition and emerald green color is solved, and the obtained fermented coriander jelly is not only smooth and flawless in appearance, delicate, chewy and elastic in taste, moderate in acidity and sweetness and rich in milk fragrance, but also has a significant antioxidant effect, a significant health care function of scavenging free radicals and extremely high nutritive value, and is suitable for being eaten by various people. Meanwhile, by means of the provided production technology of the fermented coriander jelly, the nutritive value of a product is protected furthest, operation is simple, and the production cost is low, so that the provided production technology of the fermented coriander jelly is suitable for industrial production.

Owner:LINGNAN NORMAL UNIV

A kind of preparation method of black garlic soy sauce

ActiveCN109511943BKeep the flavorHigh natural anti-corrosion abilityFood freezingFood ingredient as taste affecting agentBiotechnologySoya sauce

The invention discloses a preparation method of black garlic soy sauce, which specifically comprises the following steps: A. screening raw materials of garlic, soybeans and corn; B. pre-treating garlic with low-temperature and variable-temperature freezing, and pre-treating soybeans and corn with a high-voltage pulse electric field; C. fermenting and maturing Preparation of black garlic, cooked soybeans and cooked corn; D. Pressing, E. After mixing, microwave irradiation and ultrasonic treatment of the mixture; F. Inoculation and koji making to obtain koji; G. Fermentation, and four stages of preparation to mature Sauce unstrained spirits; G. pouring oil to obtain raw soy sauce; H. sterilizing and precipitating; I. packaging to obtain finished products. The invention prepares black garlic soy sauce through low-temperature freezing, high-voltage pulse electric field, pressing, microwave, ultrasonic, biological fermentation, etc., the production cycle is greatly shortened, cost is saved, and the production process is strictly optimized and controlled, the conversion rate of raw materials is greater than 99%, and the manufacturing process is realized. High natural antiseptic ability, while ensuring the flavor of black garlic soy sauce.

Owner:江苏黎明食品集团有限公司

Rice preventing nutritional ingredients from loss and preparation method thereof

InactiveCN103070340AAvoid churnProtect nutritional valueFood preparationNutritive valuesAdditive ingredient

The invention relates to the field of food industrial production, in particular to rice preventing nutritional ingredients from loss and a preparation method thereof. The rice comprises the following raw materials in part by weight: 1 to 1.2 parts of water, 0.8 to 1.2 parts of rice and 0.05 to 0.15 parts of cooking oil. According to the invention, all the food materials are organically combined, and supplement one another; and the preparation method comprises three steps: near fire cooking, far fire steaming and residual heat stewing, can prevent nutritional ingredients from loss to the utmost extent, protects the nutritive value, improves mouthfeel, and causes rice to be loosened, without sticking and breaking.

Owner:TIANJIN YUETAN STUDENT NOURISHING MEAL DISTRIBUTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com