Patents

Literature

72results about How to "Shorten steaming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-volume coal ash ceramsite foam concrete and preparation method thereof

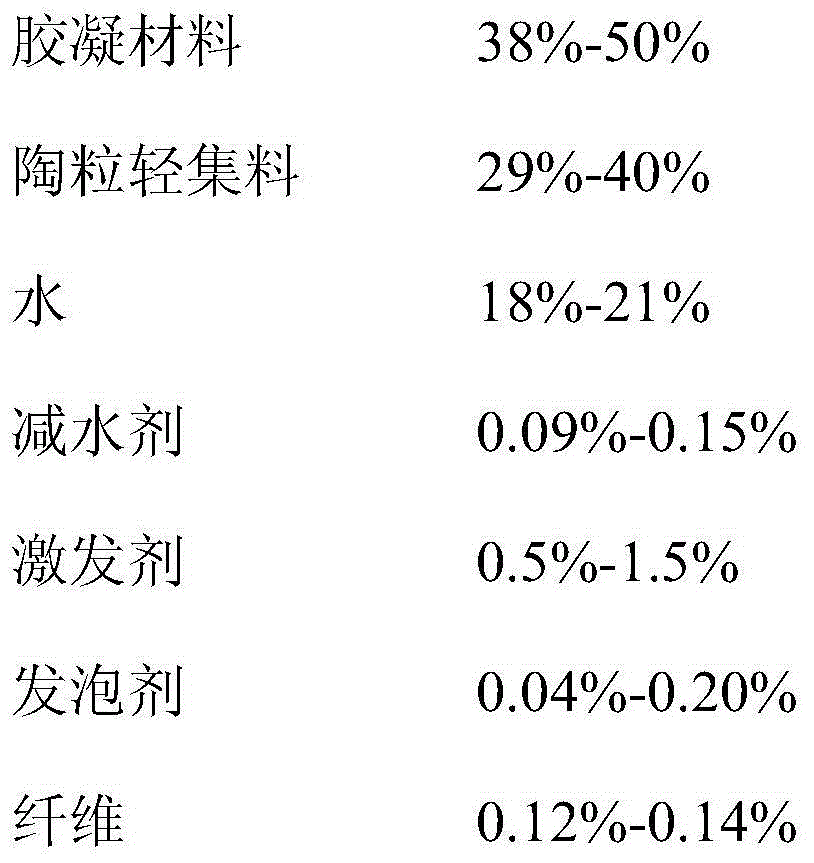

The invention provides a preparation method of high-volume coal ash ceramsite foam concrete. The preparation method of the ceramsite foam concrete comprises the following steps: putting 38%-50% of a binding material, 29%-40% of ceramsite lightweight aggregates, 0.5%-1.5% of an excitant and 0.12%-0.14% of a fiber into a stirrer, and stirring evenly; simultaneously adding 0.04%-0.20% of a foaming agent and foam which is formed by a part of water in a foaming machine and has the particle sizes of 50-1,000mu m, the residual water and 0.09%-0.15% of a water reducer into the stirrer, and stirring with powder evenly to form slurry; adding the foam into the slurry, stirring evenly, and then pouring into a mold to mold; and demolding to prepare the ceramsite foam concrete of which the density is 300-800kg / m<3>. According to the formula provided by the invention, low-cost coal ashes are taken as a main raw material, and the material cost is reduced; meanwhile, the volume-weight of the concrete is reduced by adding the ceramsite lightweight aggregates with different particle sizes; and the mechanical strength and the stability of the concrete are effectively improved.

Owner:中冶武汉冶金建筑研究院有限公司

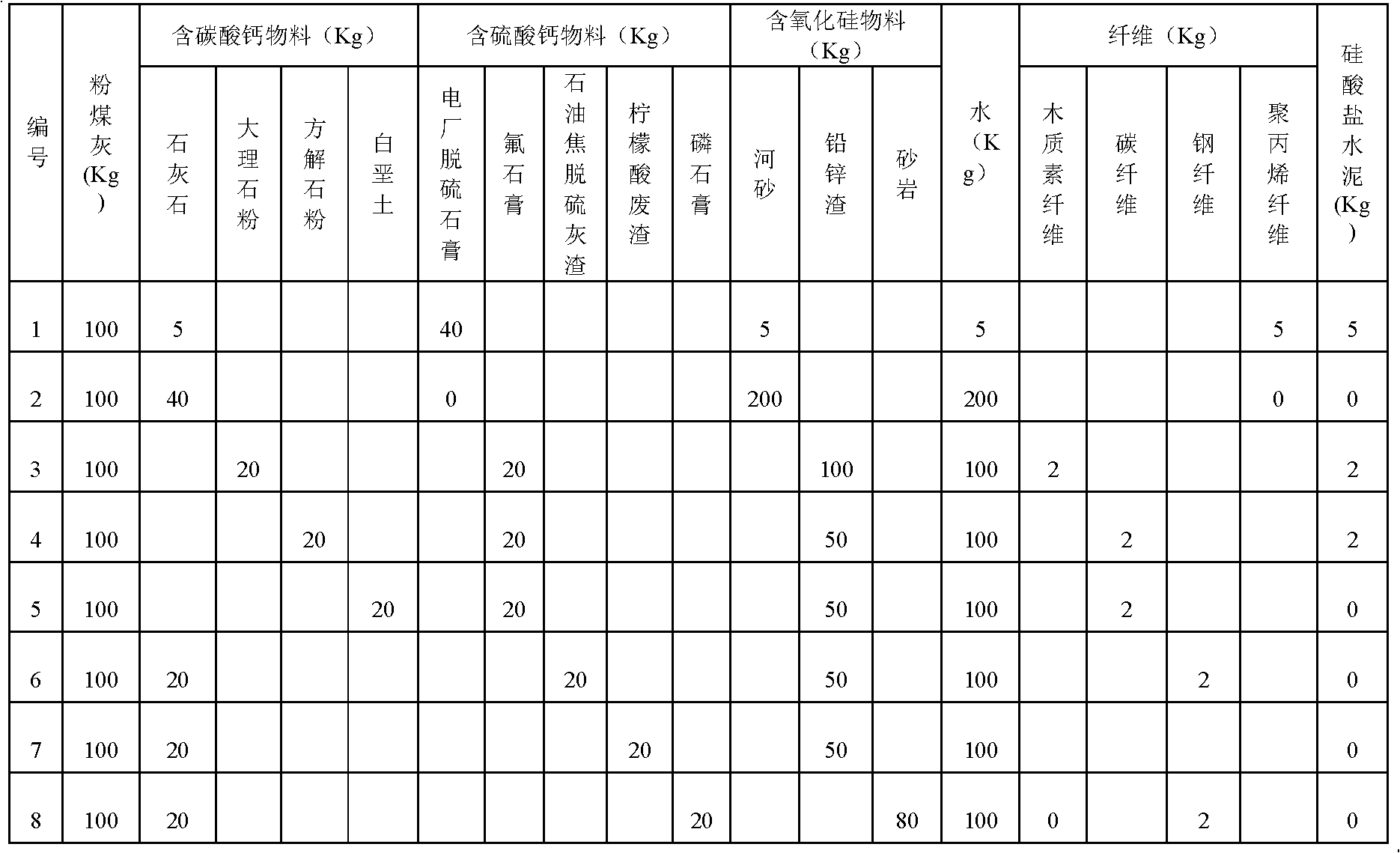

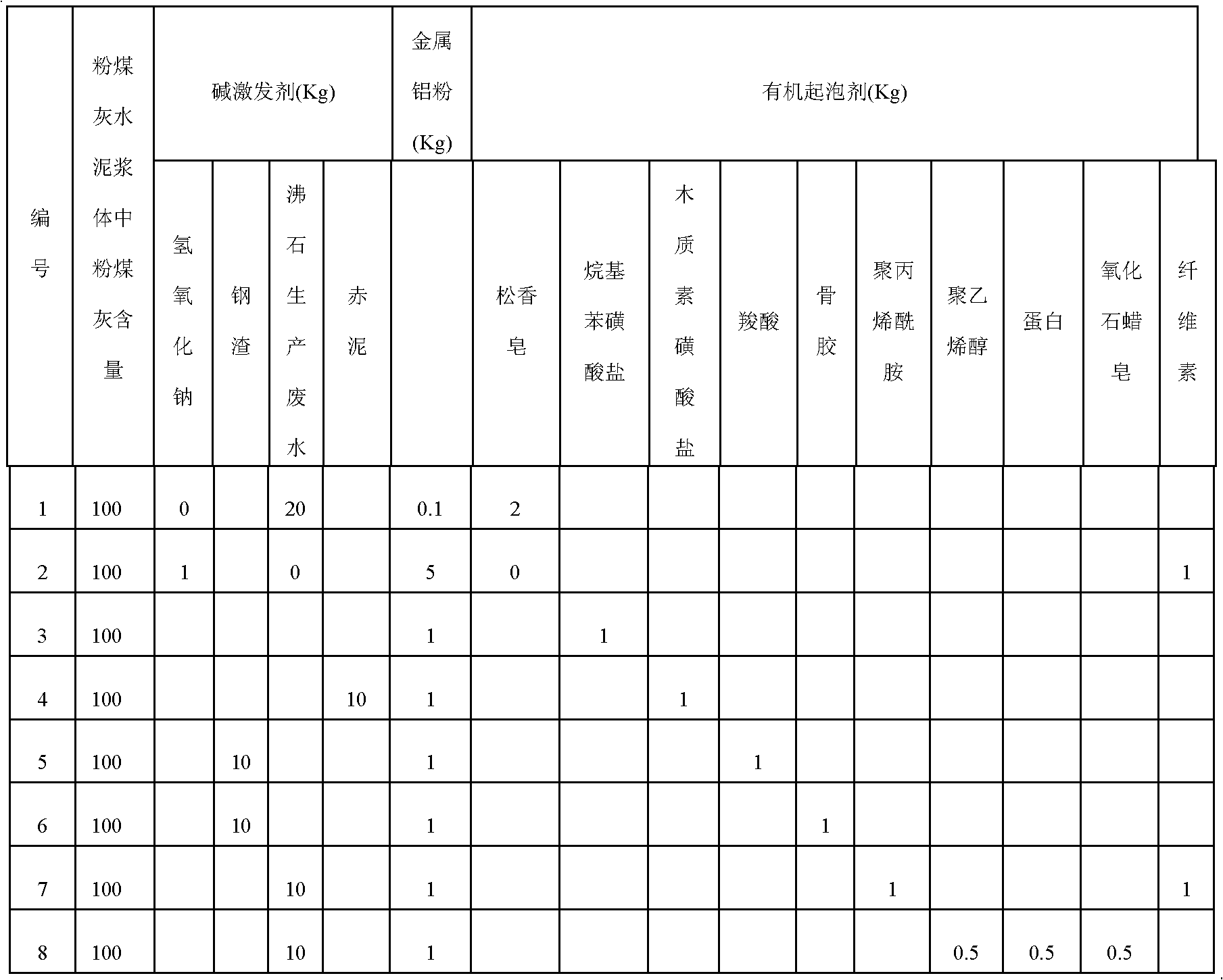

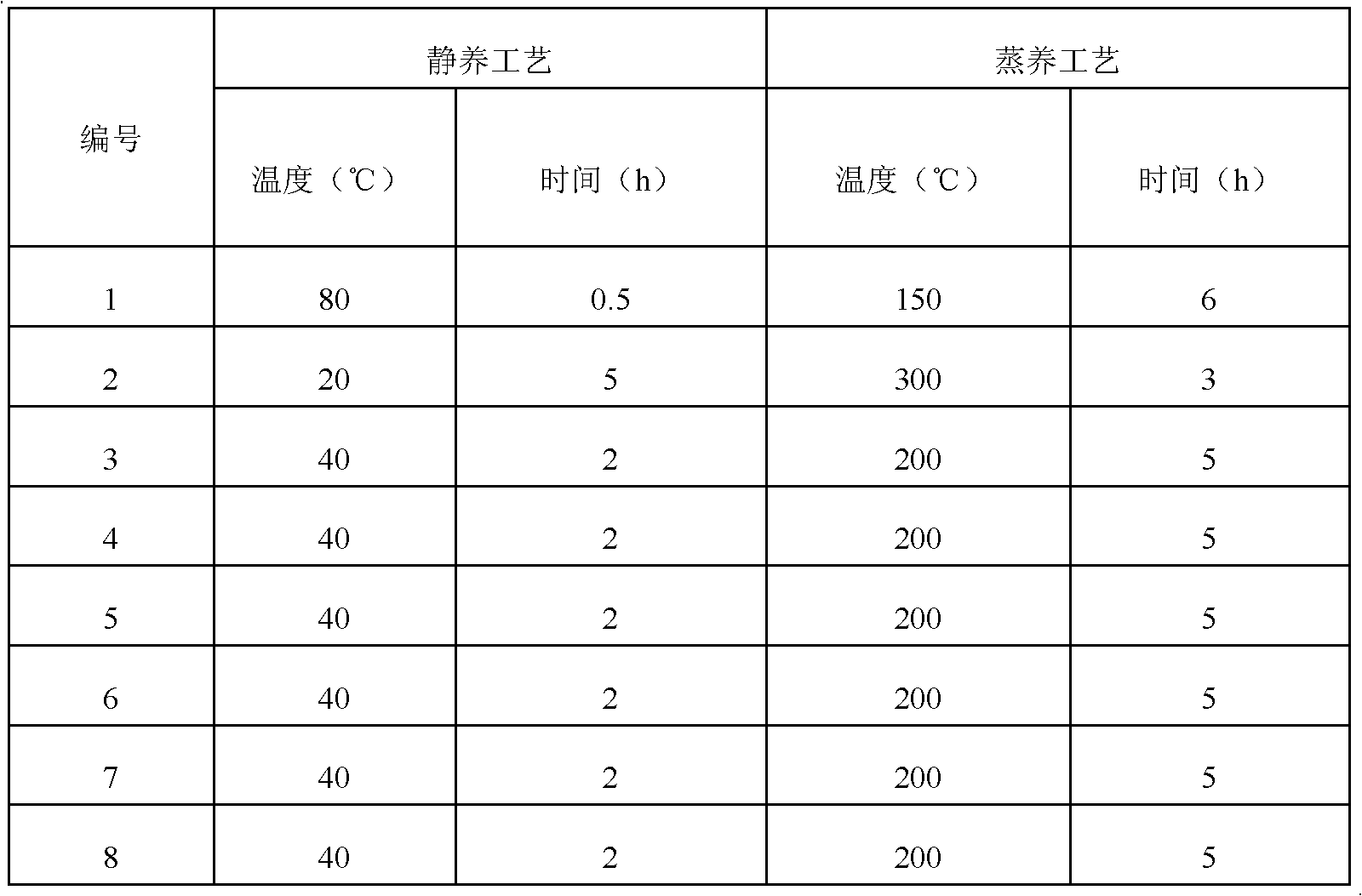

Preparation method for pulverized coal-ash-based porous artificial stone

InactiveCN102584322AImprove productivityShorten steaming timeSolid waste managementCeramicwareFiberWater vapor

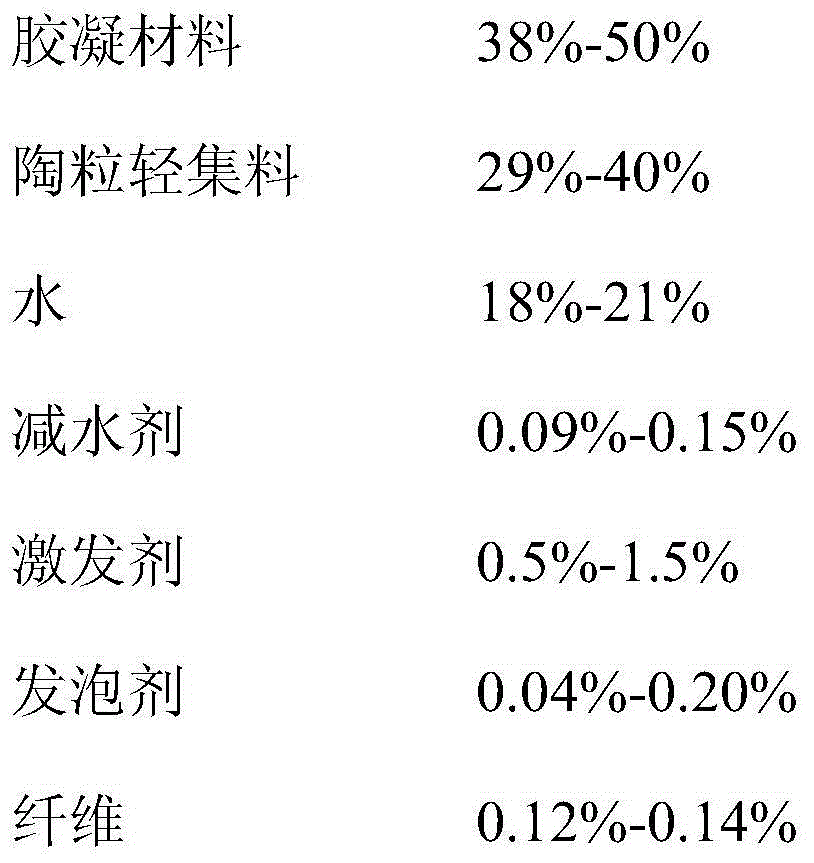

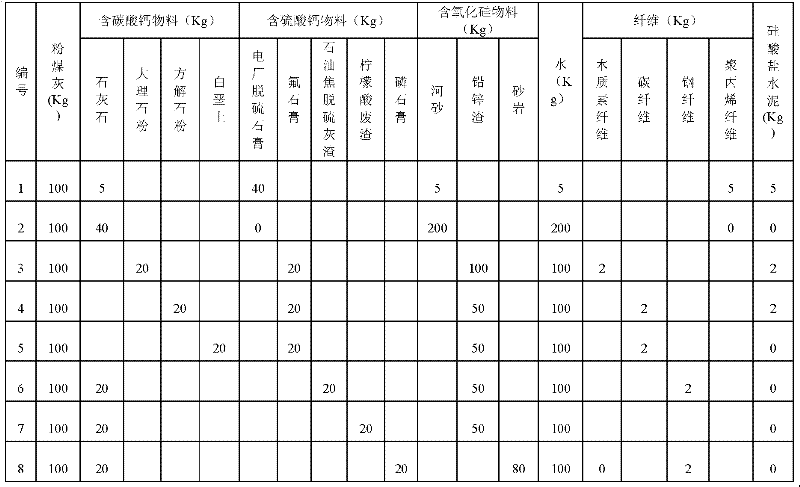

The invention discloses a preparation method for a pulverized-coal-ash-based porous artificial stone. The preparation method is characterized in that the method comprises the steps of: adding materials containing calcium carbonate, calcium sulfate and silicon oxide, water, fibers and Portland cement into pulverized coal ash, evenly agitating, adding alkali-activator, metal aluminum powder and organic foaming agent, and evenly mixing; and statically curing, cutting into cement blocks or cement blank plates, and curing the cement blocks or cement blank plates in a vapor environment to obtain the pulverized-coal-ash-based porous artificial stone. The artificial stone mainly contains tobermorite and xonotlite, can replace the existing autoclaved aerated concrete and can be used as a load-bearing building block, a filler wall, a partition wall, a roof board or a wall board.

Owner:SHAANXI UNIV OF TECH

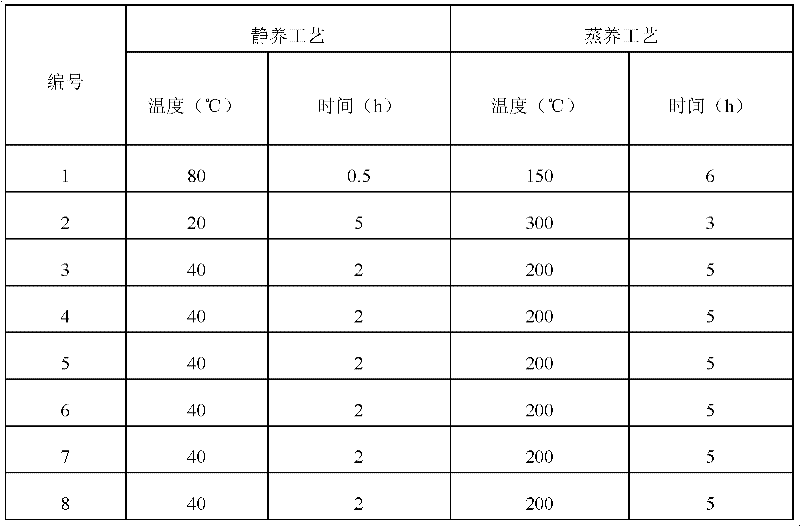

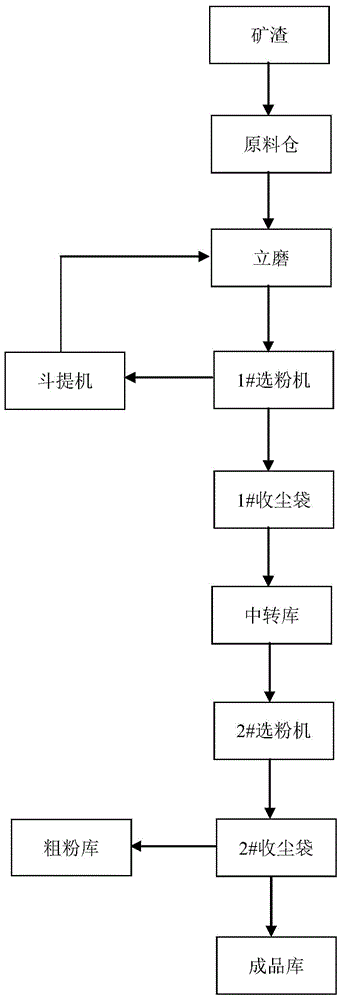

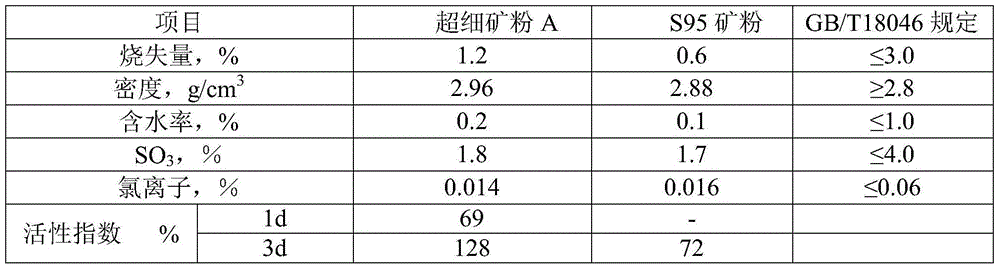

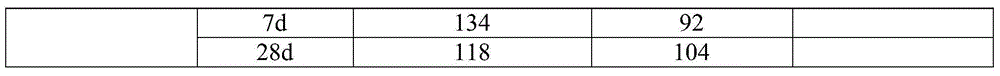

Ultrafine slag powder, and preparation method and application thereof

InactiveCN104478269AImprove finenessHigh activitySolid waste managementSlagUltimate tensile strength

The invention belongs to the field of comprehensive utilization of solid waste resource, and especially relates to an ultrafine slag powder, and a preparation method and application thereof. Vertical-milling grinding and two stages of sorting technologies are combined, a slag pre-grinded material subjected to vertical milling is subjected to a first stage of grading processing, so that a mineral powder with the specific surface area according with a requirement is sorted out, and unqualified slag crude powder falls into a vertical mill for grinding. The slag powder according with the requirement is subjected to a second stage of grading processing, so that a slag powder with the particle size of 20 mu m or less is sorted out, overly grinding phenomenon is avoided, and energy consumption and cost are reduced. The prepared slag powder has relatively high activity, can be applied to concrete as a mineral doping material, is capable of reducing the cost of concrete and concrete products, increasing the strength of concrete and improving the endurance of concrete, and also is applicable to production of pipe sheets and pipe piles. After the concrete is doped with the ultrafine slag powder, the doping amount of a cementing material can be properly reduced, and thus the purpose of saving energy and reducing cost and improving effect are realized.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

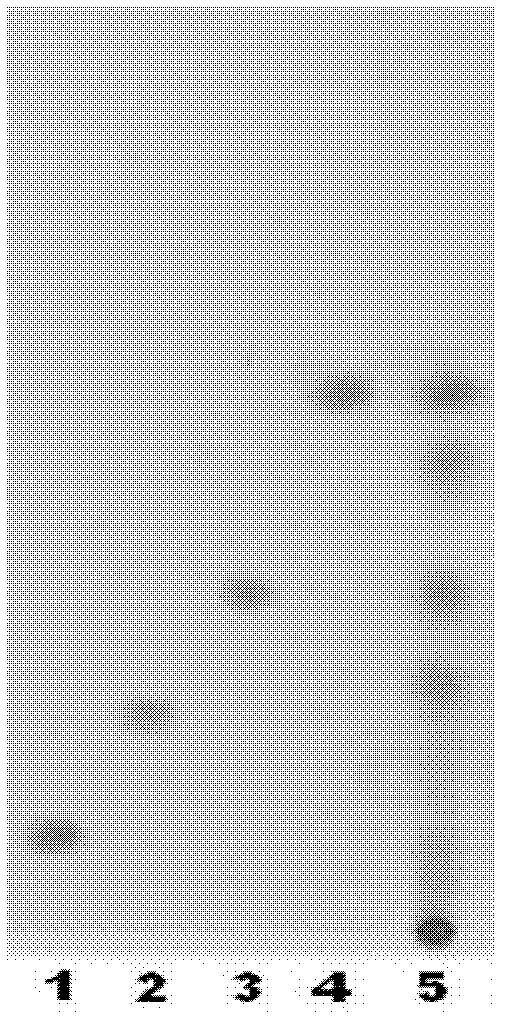

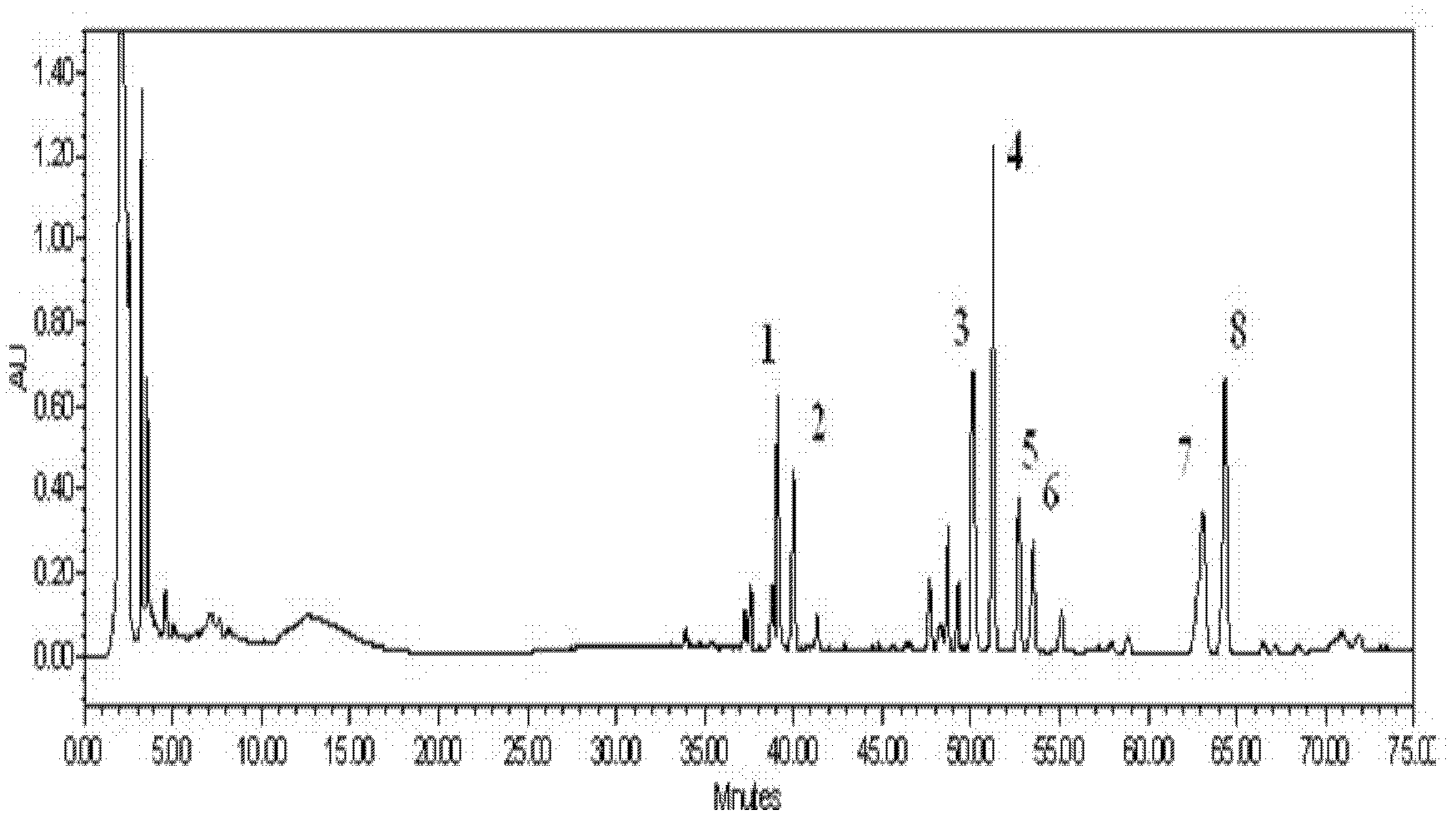

Preparation method of cooked panax notoginseng extract and total ripe panax notoginseng saponins

InactiveCN102416028AConducive to structural transformationFast conductionPlant ingredientsPANAX NOTOGINSENG ROOTChemical composition

The invention provides a preparation method of cooked panax notoginseng extract and total ripe panax notoginseng saponins, which is different from the prior art. The preparation method is characterized in that the raw panax notoginseng extract is steamed to obtain the cooked panax notoginseng extract; since the extract is in the state of aqueous solution, the structure conversion of saponin is beneficial, the heat conduction is faster, the heating is more uniform in steaming, the conversion of the saponin constituents is consistent, simultaneously the steaming time is shortened, and the energy consumption is reduced. In addition, the concentrated panax notoginseng extract is used for steaming, so that the volume of the steamed raw material is greatly reduced, the simplification of steaming equipment is beneficial, the production cost is reduced, simultaneously the operation is convenient, the preparation process is simple and easy, the production cycle is short, and the on-scale preparation and the industrial production are easy. According to the cooked panax notoginseng extract and the total ripe panax notoginseng saponins produced by the method, the chemical compositions are completely consistent to those of products prepared by the existing steaming method, the quality of the products is easy to control, and the standardization of the production is easy to realize.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

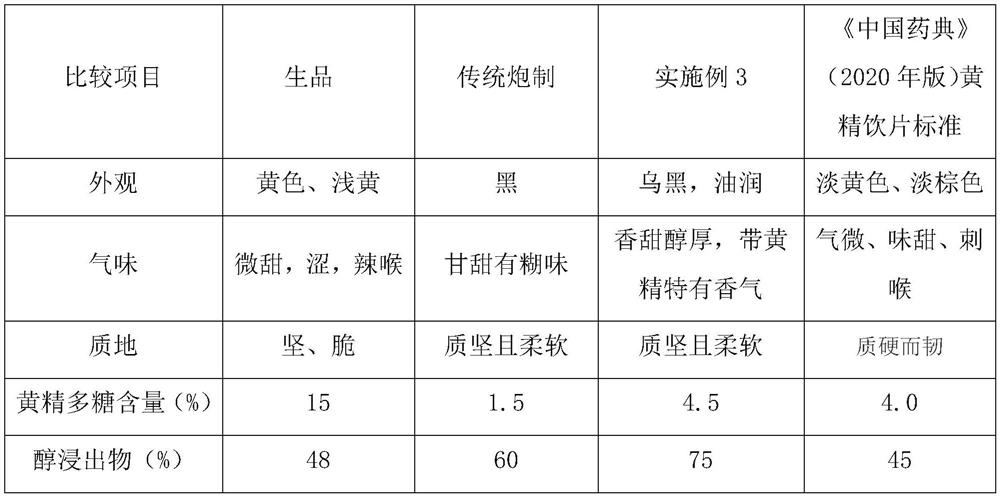

Method for preparing wine processed polygonatum kingianum decoction piece

InactiveCN104147351AShorten steaming timeLess loss of active ingredientsPlant ingredientsVapor pressureAdditive ingredient

The invention discloses a method for preparing a wine processed polygonatum kingianum decoction piece, and belongs to the technical field of traditional Chinese medicament processing. The method comprises the following steps: (1) selecting clean polygonatum kingianum, moistening the polygonatum kingianum by vapor, taking out the polygonatum kingianum, and slicing into thick slices for later use; (2) adding yellow rice wine into the thick slices in the step (1), uniformly stirring, steaming for 4-6 hours by vapor, collecting the steamed liquor, and uniformly stirring the steamed liquor with the polygonatum kingianum, steaming for 4-6 hours, collecting the steamed liquor and uniformly stirring with the polygonatum kingianum, and drying. The method follows the traditional preparation process, the polygonatum kingianum is moistened by vapor and sliced, and is uniformly mixed with the yellow rice wine for secondary vapor steaming, so that the steaming time can be effectively shortened, effective ingredient loss can be reduced, and the drug effect can be enhanced. The final product is uniform in quality and high in yield; and the preparation method is simple and low in cost and is suitable for large-scale industrial production, wherein polygonatum kingianum moistening by vapor is performed at a temperature of 110-120 DEG C and vapor pressure of 0.13-0.17MPa, the subsequent steaming time can be shortened, and loss of phlegm containing polygahatous polysaccharides can be reduced.

Owner:ZHENGZHOU RUILONG PHARMA

Sulfuric acid fly ash brick and its production process

InactiveCN102295438AShorten the timeRelieve pressureCeramic shaping apparatusBrickAdditive ingredient

The invention belongs to the technical field of building wall materials, and in particular relates to a sulfuric acid fly ash brick and a production process thereof. Sulfuric acid fly ash brick, prepared from the following components by weight: 22-26 parts of fly ash, 8-14 parts of calcium carbide mud, 60-66 parts of stone powder weathered sand, mixed in every 100 parts of the above ingredients Add 2-5 parts of industrial sulfuric acid solution with a concentration of 3%-6%. The invention is simple in operation, practical and reliable, energy-saving and emission-reducing, benefit-enhancing, and popular; this patent can solve the shortcomings of the original fly ash autoclaved bricks, which have a large coal consumption and low output, and can greatly reduce the coal used in production. Steam can reduce pollution, reduce emissions and increase production. For the unburned bricks that are naturally maintained, the amount of cement can be reduced and energy can be saved.

Owner:陈英辉

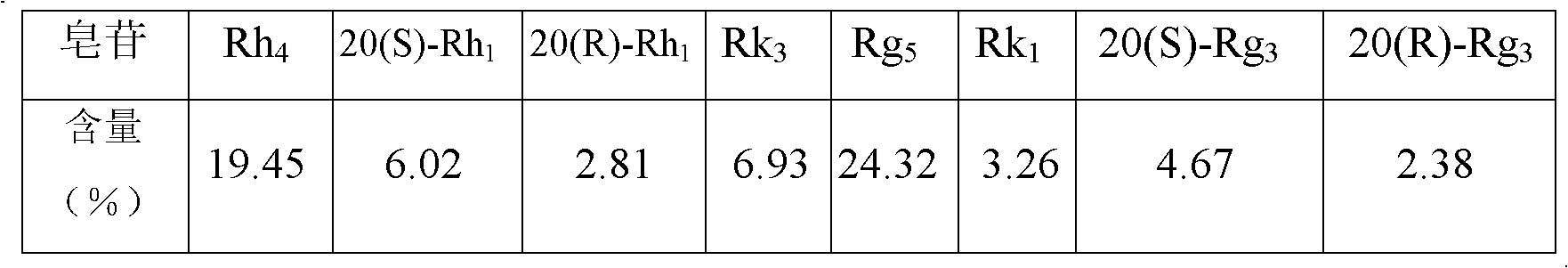

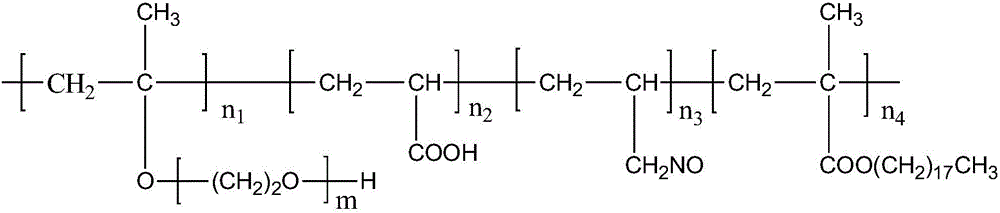

Concrete early strength agent and preparation method thereof

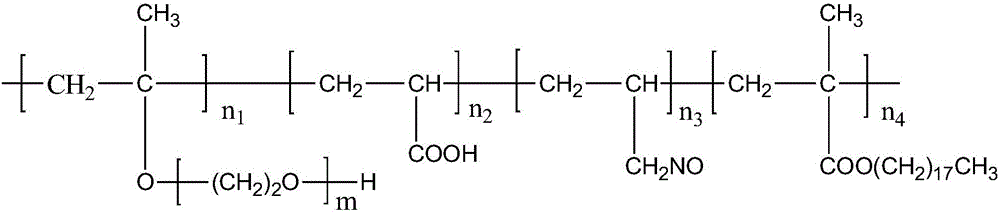

ActiveCN106243289AHigh water reduction rateGood early strengthCompressive strengthUltimate tensile strength

The invention relates to a concrete early strength agent and a preparation method thereof and aims to provide a concrete early strength agent which has water-reducing and early strength functions and can rapidly raise early strength of concrete after being doped and a preparation method thereof. The concrete early strength agent is obtained by free radical polymerization of VPEG, any one ingredient selected from a group consisting of methacrylic acid, acrylic acid and maleic anhydride, acrylamide or maleimide, and octadecyl methacrylate. The prepared concrete early strength agent has high water-reducing rate and excellent early strength performance. When solid volume discount is 0.2%, the water-reducing rate can reach 30% and above, 1d compressive strength rate of concrete reaches 240% and above, and 3d compressive strength rate reaches 220% and above. During production of a prefabricated part in winter, steam curing time can be shortened. During production in summer, the steam-curing process can be avoided. Thus, energy consumption is greatly reduced, and production cost of the prefabricated part is lowered.

Owner:CHONGQING SANSHENG IND CO LTD

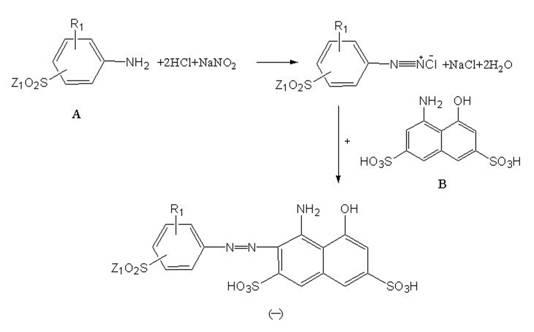

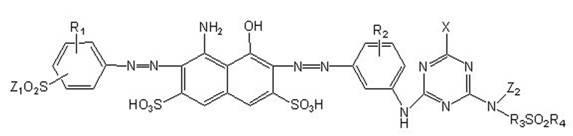

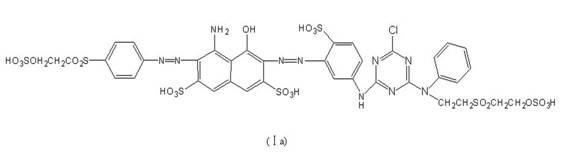

Reactive dark blue bisazo dye and preparation method thereof

ActiveCN102504582AImprove responseStrong color fixing abilityReactive dyesDyeing processFiberPhenyl group

The invention relates to a reactive dark blue bisazo dye having a structural formula shown in the formula (1), wherein R1 and R2 are selected from -H, CH3 (CH2)n-, CH3(CH2)n-O-, -COOH or -SO3H and n is between 0 and 3; R3 is can be -CH2CH2- or -CH2CH2CH2-; R4 can be -CH2CH3 or -CH2CH2-W and W is an acid radical or halogen element; X is a halogen element; Z1 is -CH2-CH2-U and U is an acid radical or halogen element; and Z2 can be phenyl, tolyl, naphthyl or naphthyl sulfonyl. The dye provided by the invention has high reactivity, excellent color fixation and excellent deep dyeing property and good stability of combination with fiber fabric, and the fabric dyed with the reactive dark blue bisazo dye has excellent light fastness, humidity resistance and acid-base-resistance fastness; in addition, the invention relates to a preparation method of the dye and the application of the dye in fabrics such as cotton.

Owner:吴江桃源染料有限公司

Vinegar processed pseudo-ginseng and processing technology and application thereof

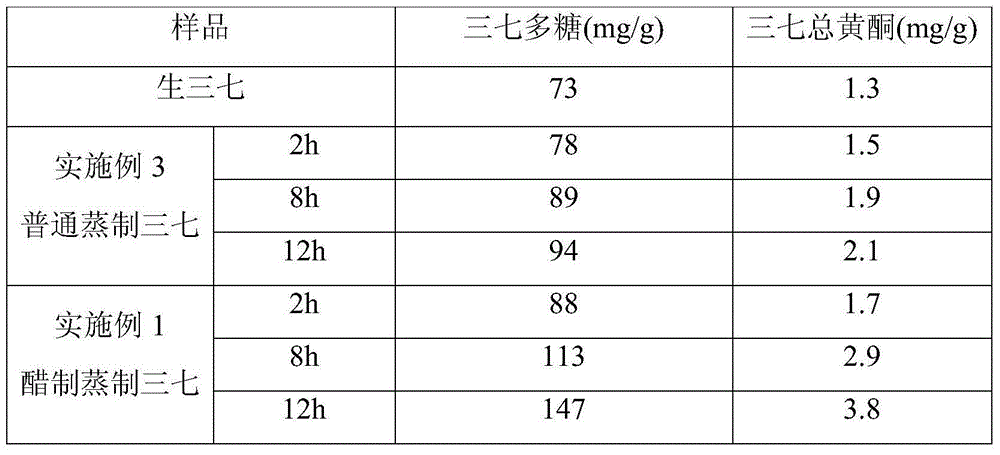

ActiveCN104800257AIncrease contentSimple methodDigestive systemPlant ingredientsComputer sciencePolysaccharide

The present invention relates to a novel processing method of pseudo-ginseng and belongs to the field of medicine. The invention discloses a vinegar processed pseudo-ginseng and a processing technology and application thereof. The processing technology comprises the following steps: A, using pseudo-ginseng as a raw material, adding vinegarin the amount 0.15-3 times of the pseudo-ginseng and soaking; B, steaming the soaked pseudo-ginseng with steam; and C, drying. The method can substantially increase the contents of pseudo-ginseng polysaccharide and pseudo-ginseng general flavone.

Owner:CHENGDU XUERUIAN HEALTH MANAGEMENT CO LTD

Steam cycling and energy-saving device

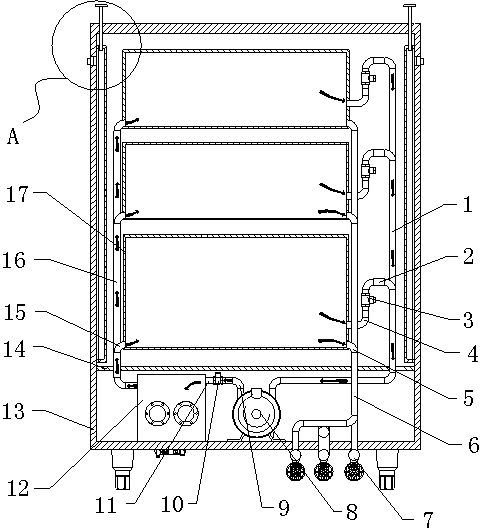

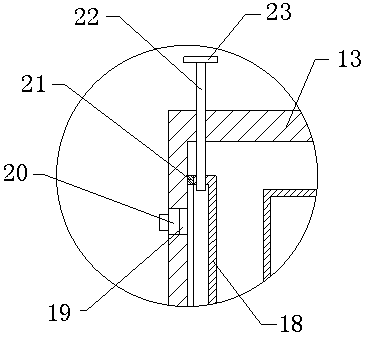

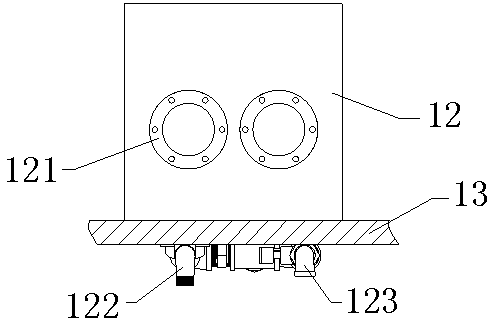

InactiveCN109124314AReduce wasteImprove efficiencySteam generation heating methodsSteam cooking vesselsWater storageSteam line

The invention discloses a steam cycling and energy-saving device including a device body, a circulation mechanism and a heat insulation mechanism. The main body of that device includes an outlet pipe,a drainage pipe, a drain gate valve, a steam cabinet, partitions and steam chambers, the circulation mechanism includes a steam outlet conduit, a steam outlet pipe I, a one-way check valve, a steam outlet pipe II, an exhaust fan, a steam line one, a one-way check valve II, a steam transmission pipe II, a steam generator, a steam inlet pipe and a steam outlet pipe, the heat insulation mechanism isinstalled on the left end surface of the steam cabinet. The heat insulation mechanism comprises a water storage cover, a water adding hole, a plug, a sealing gasket, a hollow pipe and a flange. Compared with the prior art, the heat insulation mechanism has the following beneficial effects: waste of energy is reduced, efficiency of a steam cabinet is improved, use safety of the steam cabinet is increased, service life of the steam cabinet is prolonged, and the purpose of heat insulation and scald prevention is achieved.

Owner:中山市多创电器设备有限公司

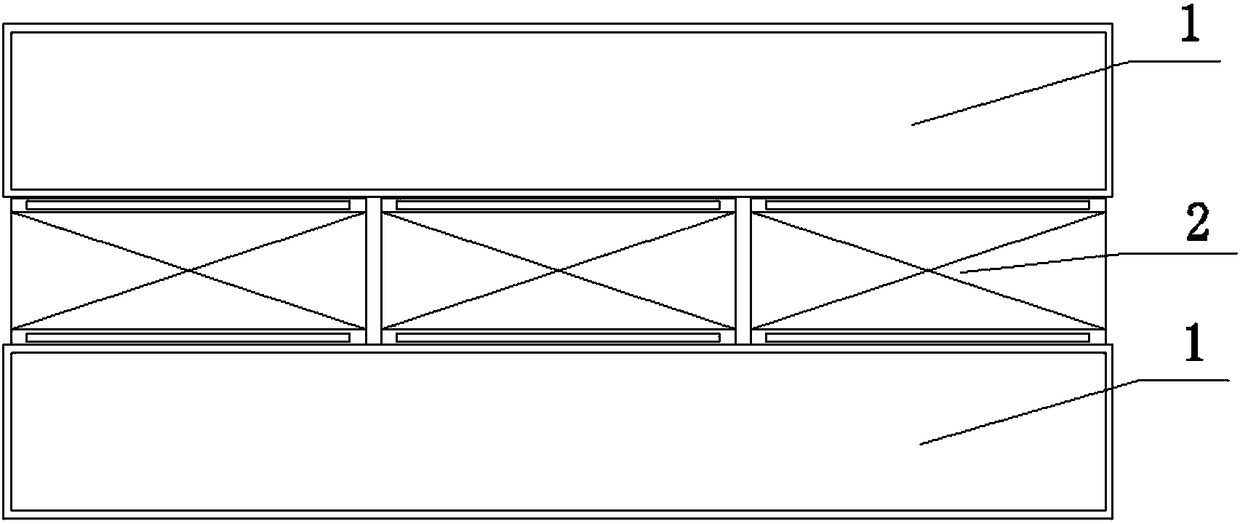

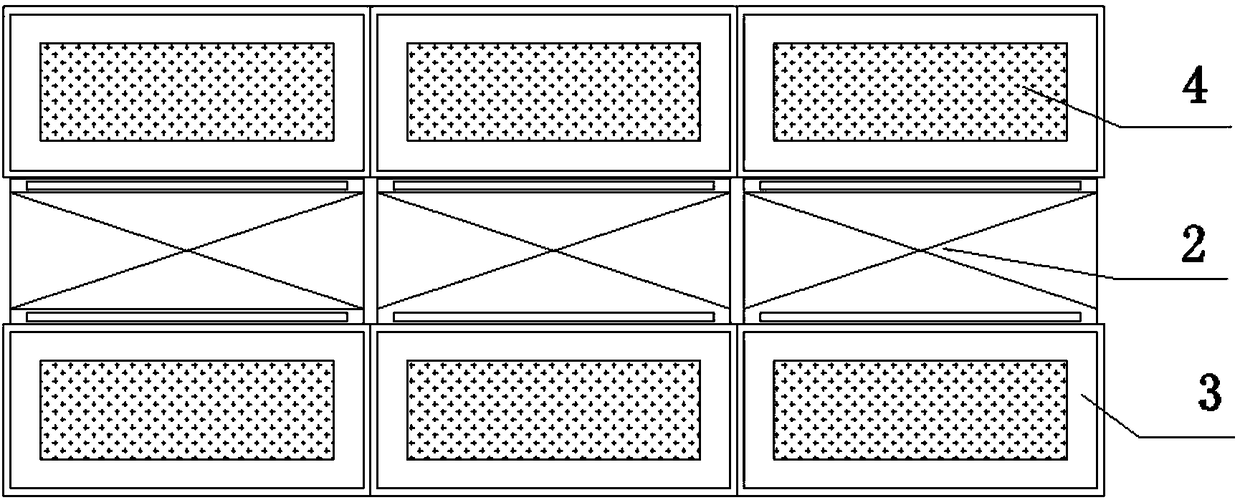

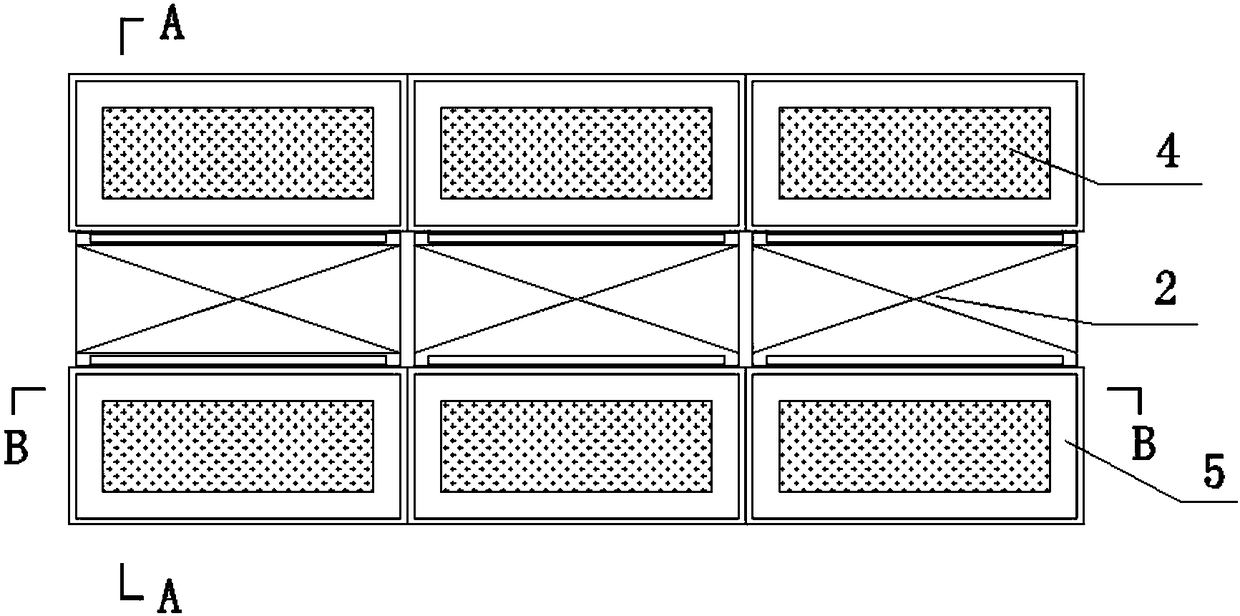

High-rise intelligent three-dimensional production system for prefabricated components

PendingCN108789806ATake advantage ofSmall footprintCeramic shaping plantsHigh riseEnergy conservation

The invention discloses a high-rise intelligent three-dimensional production system for prefabricated components, and belongs to the field of prefabricated component production. The system comprises abottommost-layer raw material stacking area, multiple middle-layer component production areas, multiple upper-layer component curing areas, a transportation area and a carrying vehicle; the componentproduction areas and the component curing areas are arranged on two side surfaces of the transportation area, and are both provided with mold table support legs; component mold tables are placed on the mold table support legs; the transportation area consists of multiple vertical transportation elevators; and the vertical transportation elevators and the carrying vehicle cooperate to work. The intelligent production system adopts three-dimensional independent space structure, reduces the labor cost, improves the production efficiency, shortens the concrete strength curing time, and accelerates the construction progress; the curing of the prefabricated components is not influenced by the external environment, the temperature and the humidity, so that the production quality and the construction period of the prefabricated components are guaranteed; the curing insulation effect is good; the energy is saved; the steaming time is shortened; and the utilization rate of the component mold tables is improved.

Owner:BEIJING ZHIHUI YUNJIAN TECH CO LTD

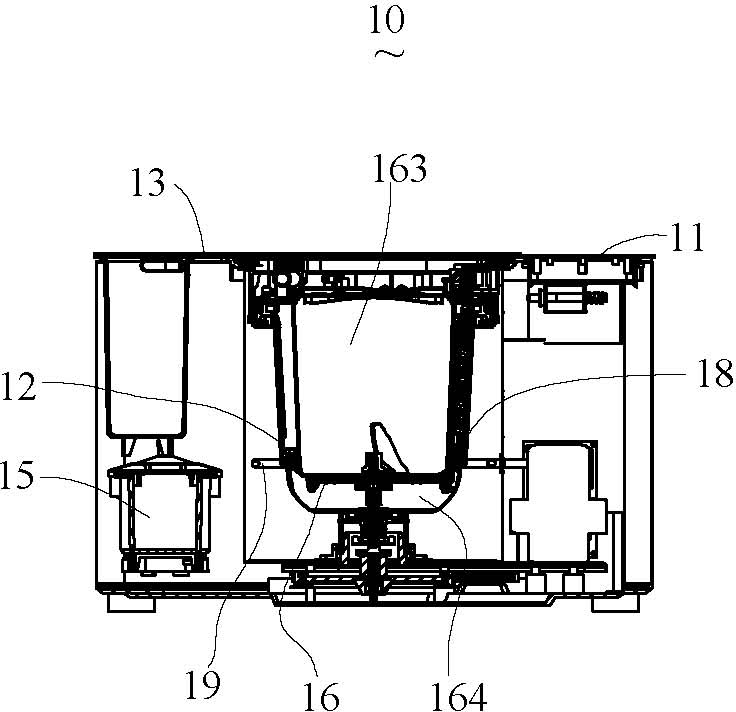

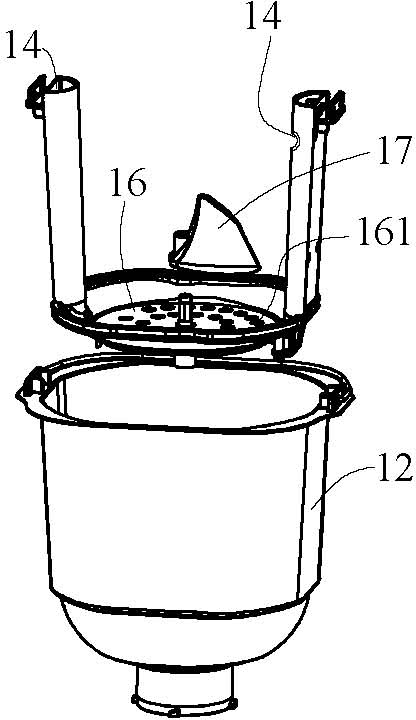

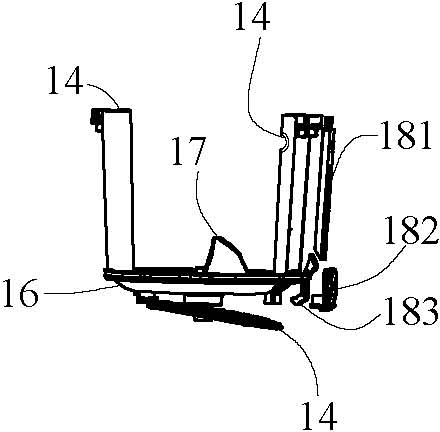

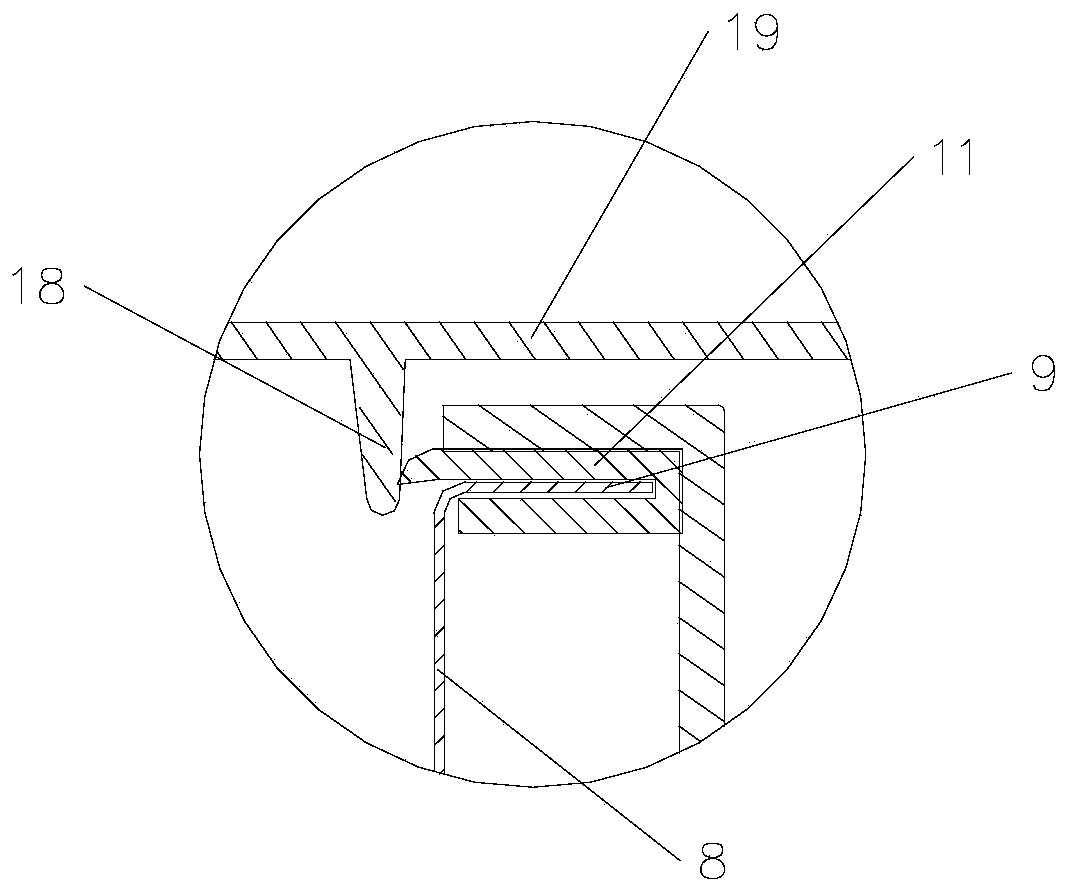

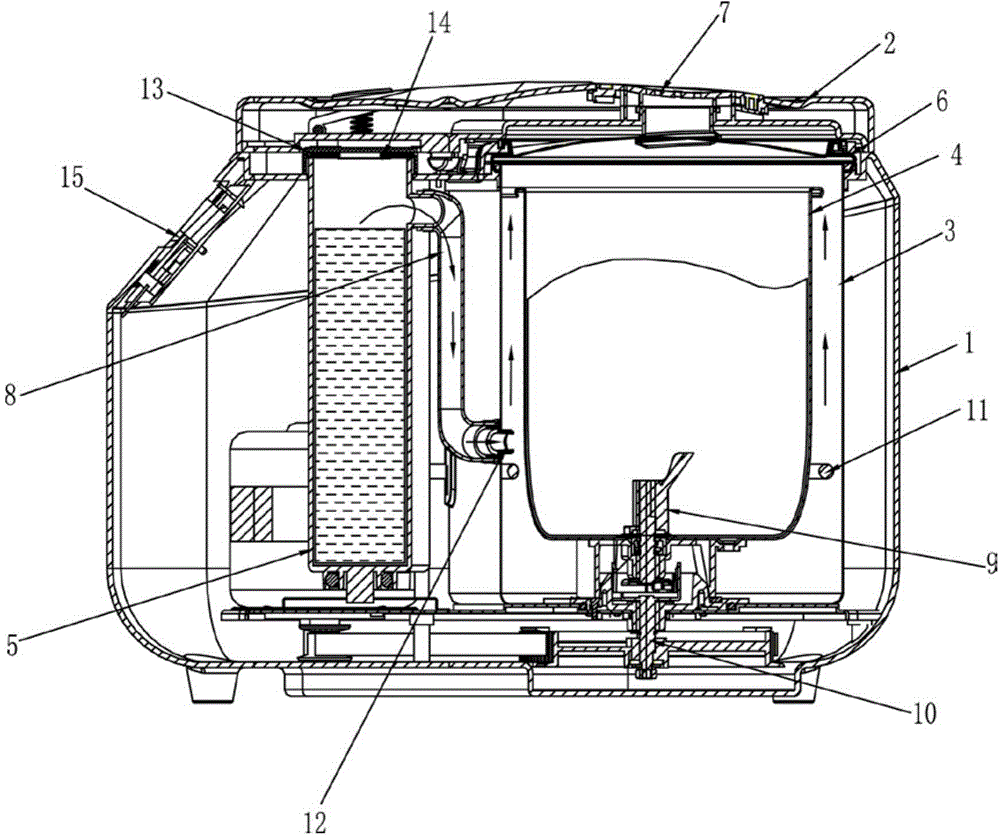

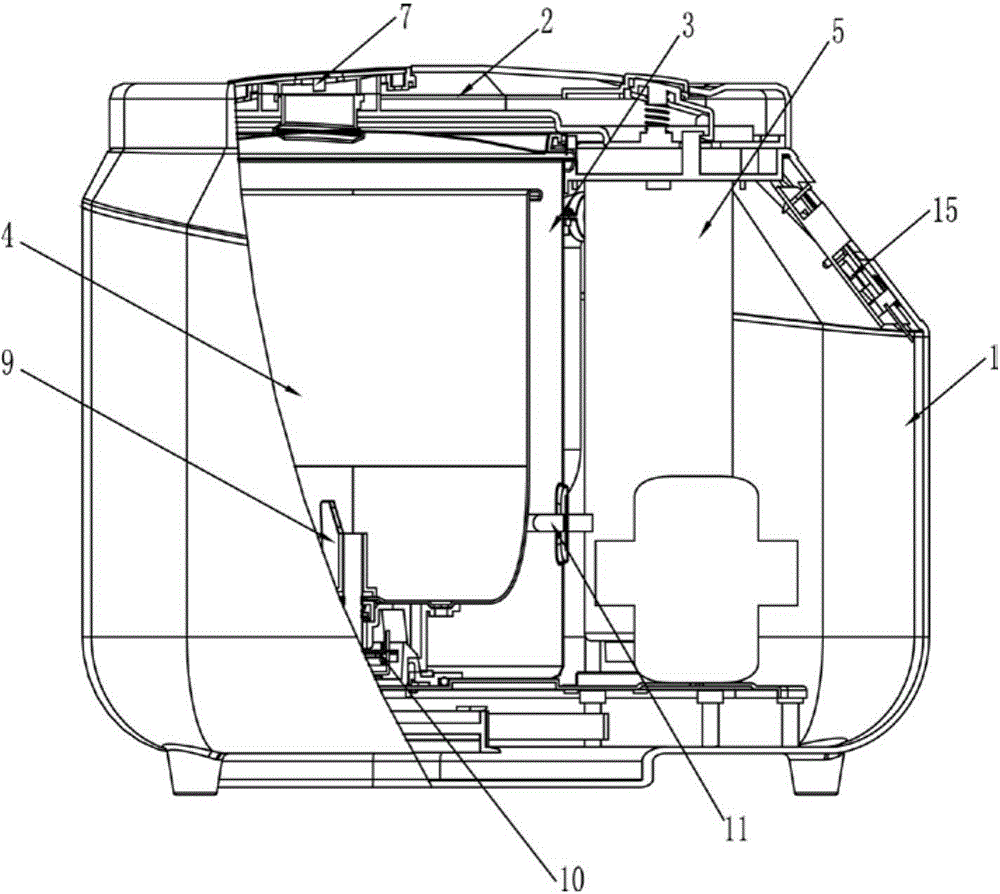

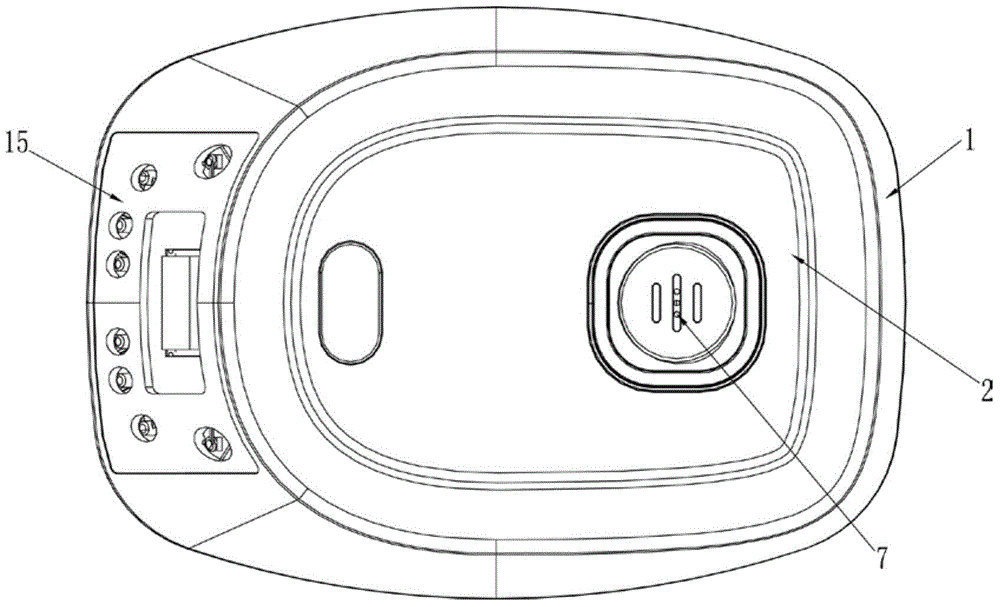

Method for making steamed bread by utilizing multifunctional wheaten food cooking machine

The invention relates to a method for making steamed bread by utilizing a multifunctional wheaten food cooking machine, comprising the following steps of: a, adding water into an inner barrel, driving a stirring knife, mixing and stirring materials to be uniform, so as to obtain a steamed bread base; b, stopping stirring, and fermenting the steamed bread base; and c, opening a steam rack cover, communicating holes of a steam rack with a lower steam chamber, and steaming the steamed bread by the way that steam produced by a steam generating device enters into an upper steam chamber and the lower steam chamber. Thus, appropriate flour water ratio can be effectively guaranteed and manual complex labour can be avoided, and dough water absorption consistency is ensured; meanwhile, heat of the steam can permeate into the the steamed bread base from the upper surface and the lower surface of the steamed bread base, steamed bread steaming speed is improved, steaming time is shortened, and danger of unsteamed bread can be avoided.

Owner:JOYOUNG CO LTD

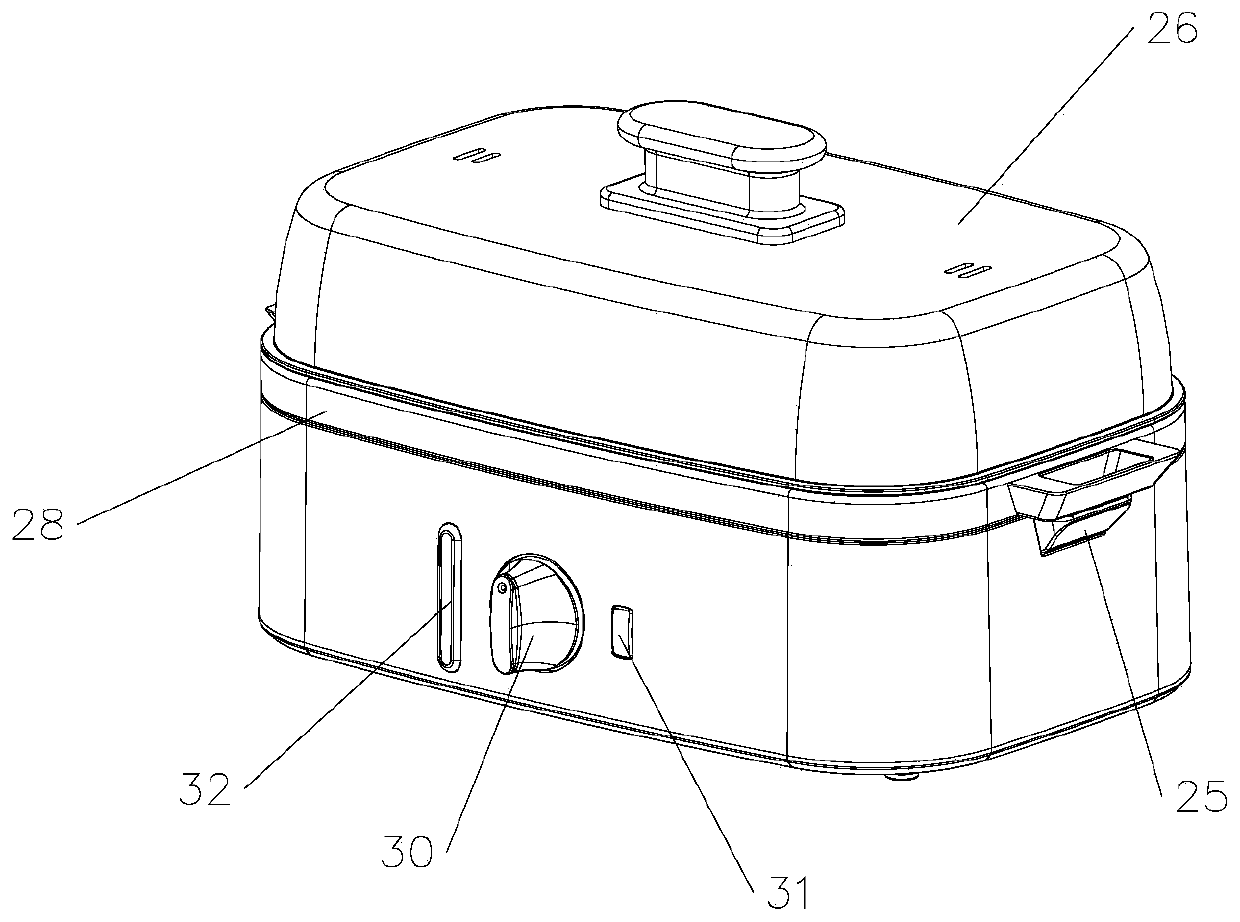

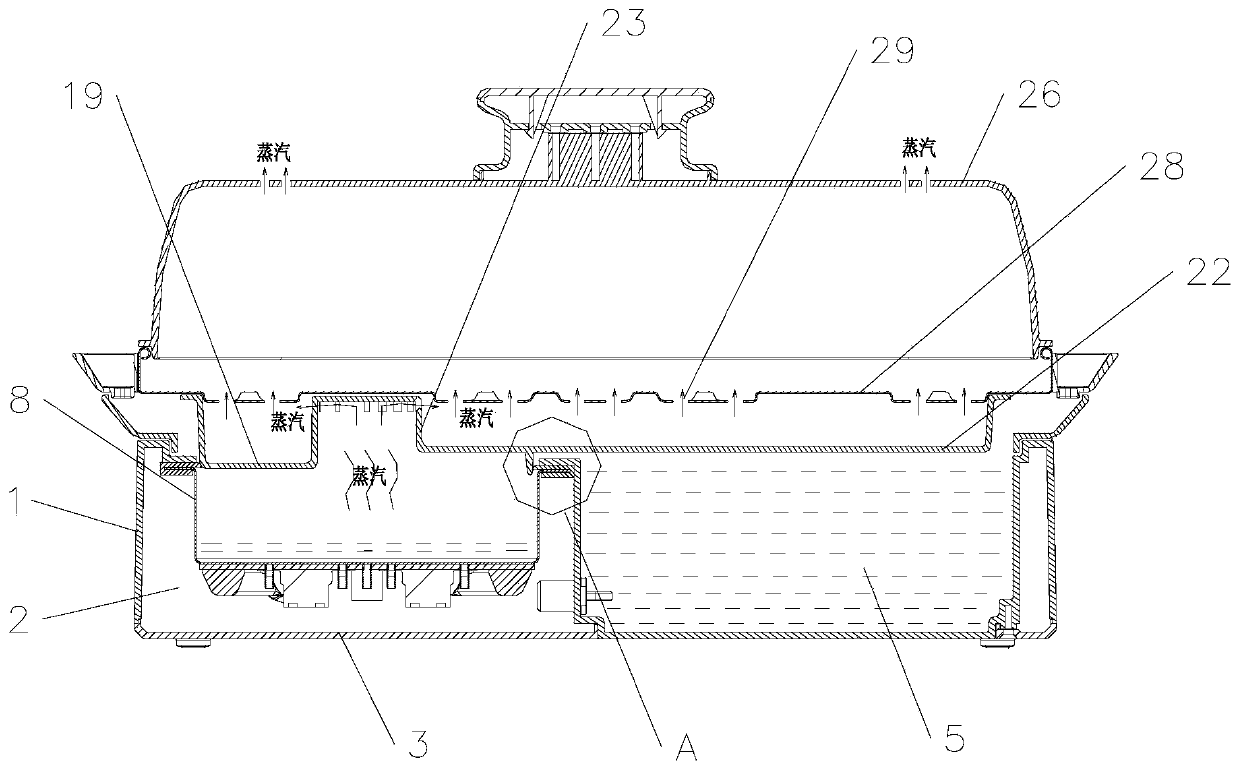

Top-speed steamer

InactiveCN111407145APrevention of dry burningAvoid power outagesSteam generation heating methodsSteam cooking vesselsEngineeringMechanical engineering

The embodiment of the invention provides a top-speed steamer. The steamer comprises a main machine and a steamer assembly capable of being arranged on the main machine, and is characterized in that the main machine comprises a machine body, the top of the machine body sinks inwards to form an independent water tank with an open top and an independent steam generation cavity of a steam generator, and the water tank is communicated with the steam generation cavity through a water supply waterway; the steamer assembly comprises a juice accumulation disc, a steam guide part in sealed butt joint with the top opening of the steam generation cavity is arranged on the back face of the juice accumulation disc, and a steam outlet is formed in the top of the steam guide part. According to the top-speed steamer disclosed by the embodiment of the invention, the open water tank and the open steam generation cavity are directly formed in the steamer body, so that the water tank and the steam generator can be conveniently cleaned; the steam generator is independently arranged instead of directly heating at the bottom of the water tank, so that water can be quickly evaporated to generate steam, steaming and stewing time is shortened, energy is saved, and efficiency is improved.

Owner:GUANGDONG BARSETTO ELECTRIC IND CO LTD

Steam-powered steamed bread machine and steamed bread making method

InactiveCN104083076AUniform temperatureEliminate the effects ofSteam cooking vesselsLiquid waterSteam power

The invention relates to the technical field of food processing, and discloses a steam-powered steamed bread machine which comprises a machine body and an upper cover covering the machine body, an outer cylinder, a steamed bread cylinder and a steam generator are arranged inside the machine body, the steamed bread cylinder is arranged inside the outer cylinder, the upper cover is sealed with the top of the outer cylinder, a gap is formed between the inner side wall of the outer cylinder and the outer side wall of the steamed bread cylinder, and the steam generator is arranged on the periphery of the outer cylinder and is connected with the lower portion of the outer cylinder through a steam connecting pipe. The invention further discloses a steamed bread making method based on the steam-powered steamed bread machine. According to the steam-powered steamed bread machine and the steamed bread making method, the steam generator for generating steam and the steamed bread cylinder for containing steamed breads are arranged in different containers, so that the liquid water and the gaseous steam can be separated effectively, the steam enters the steamed bread cylinder through the lower portion of the gap between the outer cylinder and the steamed bread cylinder, the inner area and the outer area of the steamed bread cylinder are filled with the steam, the steam temperature difference in the steamed bread steaming space can be eliminated effectively, and the surface color and luster of the steamed bread are improved; meanwhile, too much condensate water generated in the steamed bread steaming space can be avoided.

Owner:周武轩

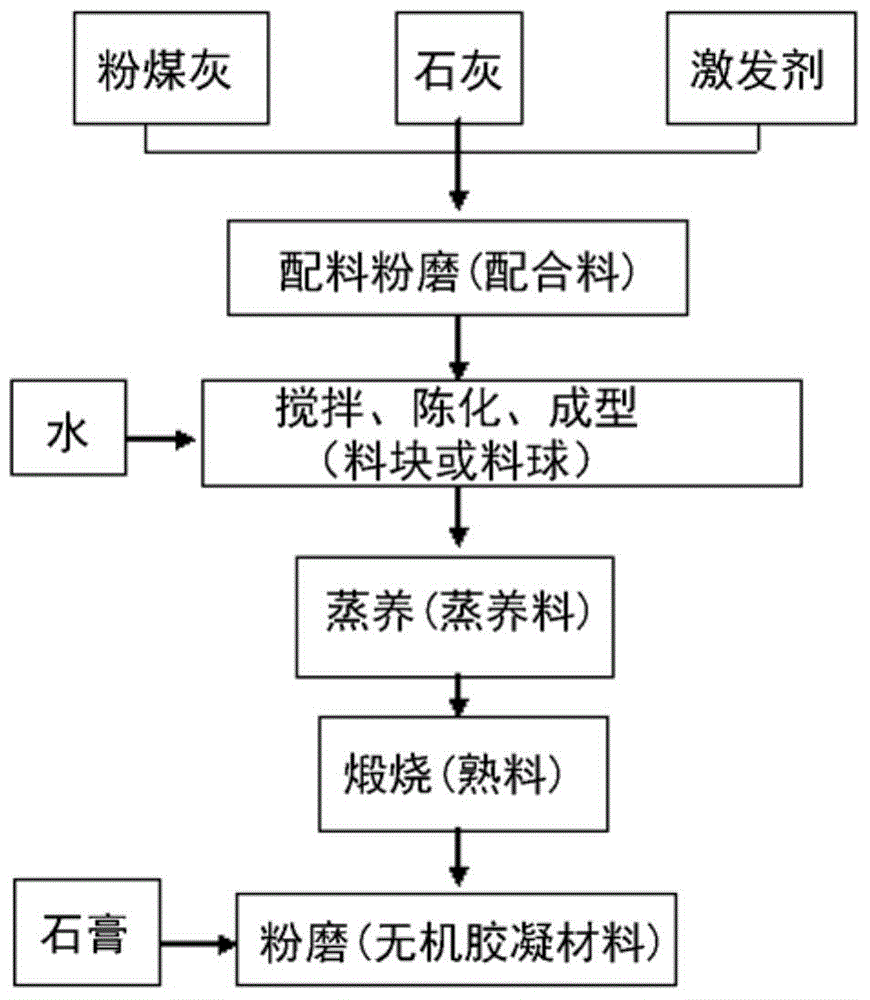

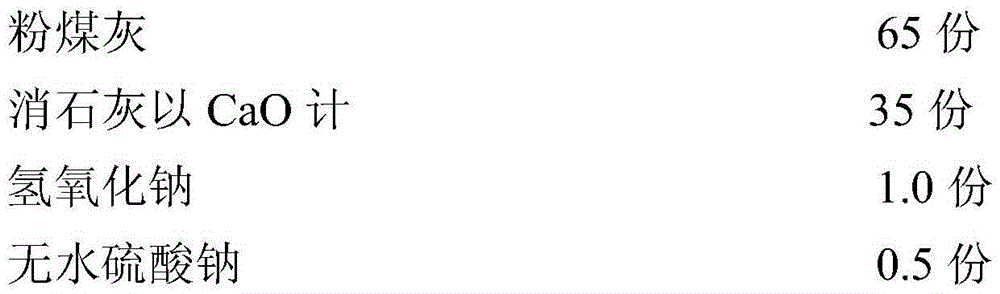

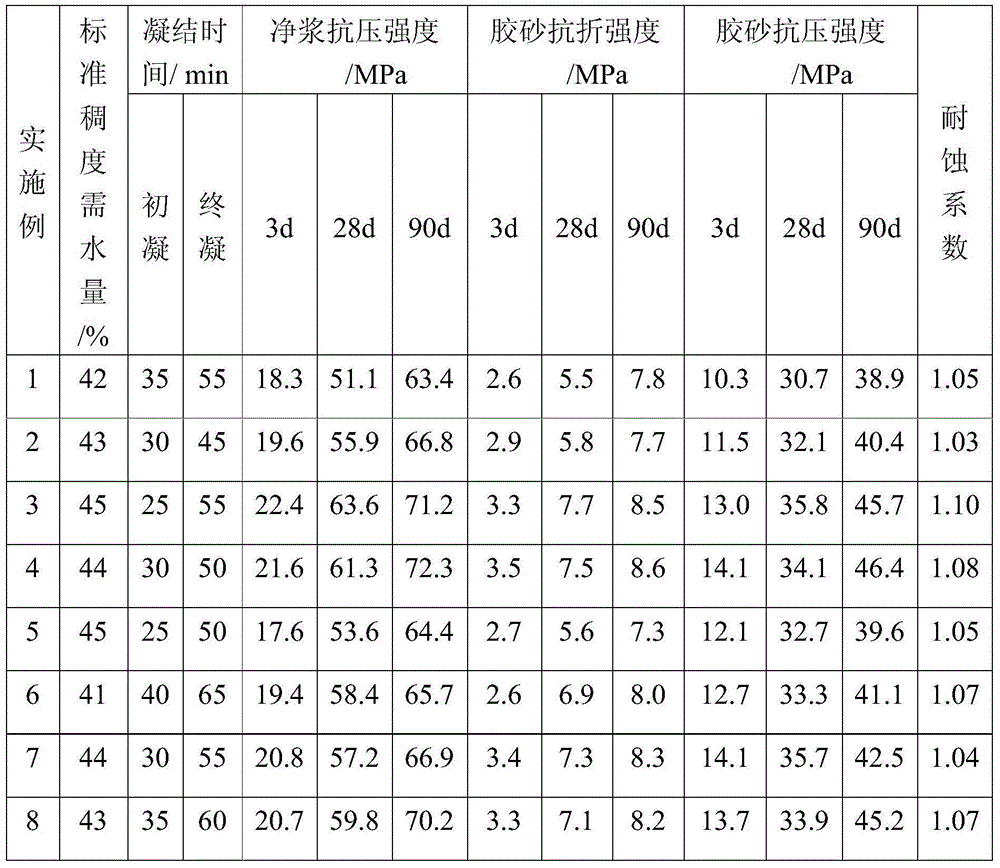

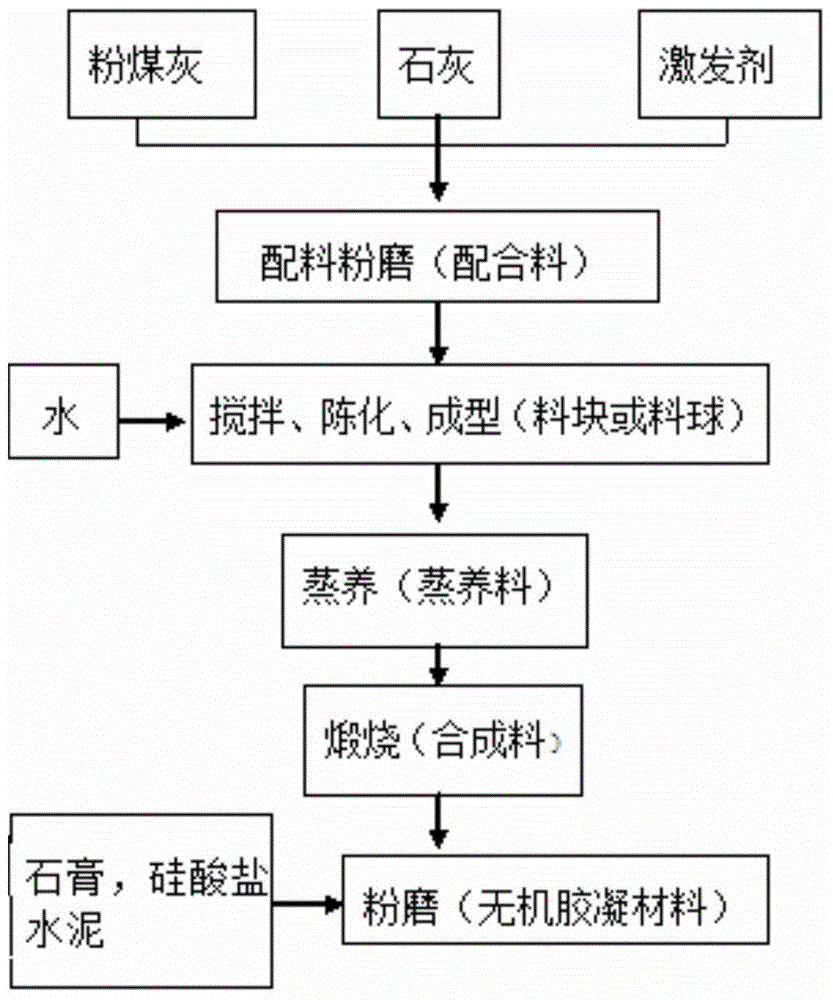

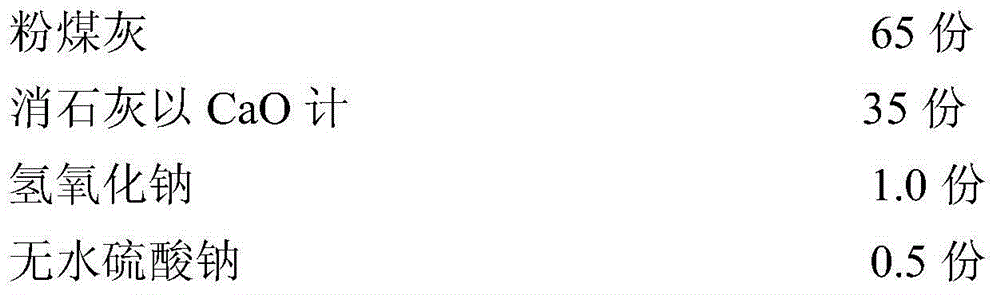

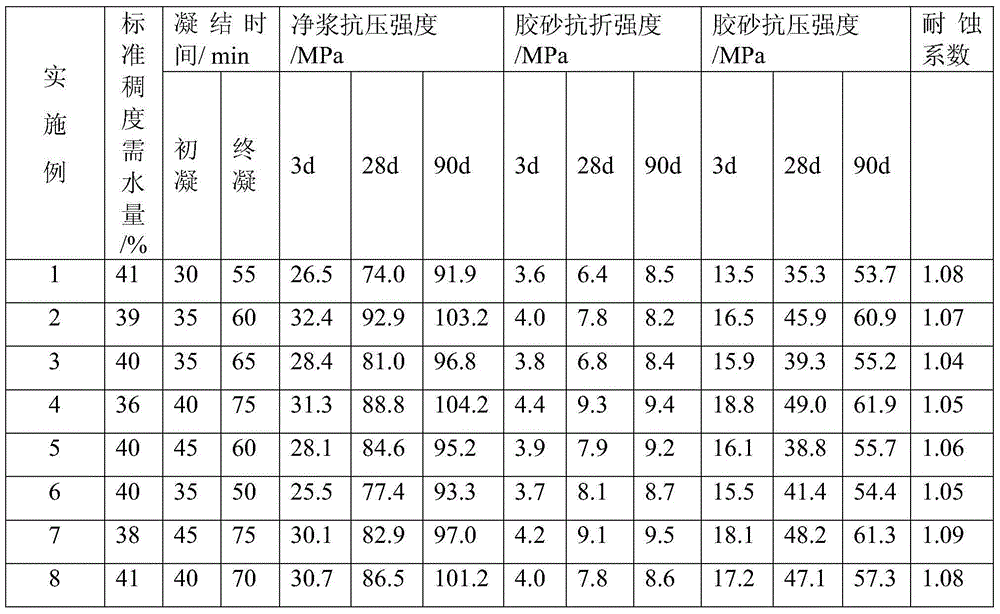

Inorganic cementing material and preparation method thereof

InactiveCN105985038AIncrease profitReduce occupancyCement productionSulfateUltimate tensile strength

The invention provides an inorganic cementing material and a preparation method thereof. The cementing material is obtained by jointly grinding grog obtained by steam curing and calcinating material blocks or material balls prepared from coal ash, lime, an exciting agent and water and gypsum. The preparation method includes the steps that by mass, 65-80 parts of coal ash, 20-35 parts of effective CaO of lime and 0.5-2.0 parts of the exciting agent are jointly ground into a batch mixture with the degree of fineness being 45 microns and the residue on sieve being smaller than 10%, 15-50 parts of water is added, the mixture is mixed to be uniform, then aging is conducted for 2-3 hours, the material blocks or the material balls are subjected to steam curing for 8-16 hours at the temperature of 90-98 DEG C after being formed, then calcinated for 15-120 minutes at the temperature of 750-1,000 DEG C and then air cooled or cooled in air, and the grog is obtained; 90-95 parts of the grog and 5-10 parts of gypsum are jointly ground till the specific area is 350-500 m<2> / kg, and the inorganic cementing material is prepared. Low-quality coal ash which is high in carbon content can be used as the main material of the inorganic cementing material, calcinating temperature and heat consumption are low, and a product has the advantages of being high in setting speed and hardening speed, high in long-term strength and good in water resistance and sulfate resistance.

Owner:HUAZHI ENERGY CONSERVATION HK

Modified melamine high-efficiency water reducing agent with low cost

The invention belongs to the field of building materials and chemical synthetic techniques, in particular to a modified melamine high-efficiency water reducing agent with low cost and a preparation method thereof. Urea, melamine, formaldehyde, sodium hydrosulfite and sodium pyrosulfite are used as raw materials, sodium hydroxide and sulfuric acid are used as pH regulators, and at the condition that the temperature is 50-95 DEG C, hydroxymethylation, sulfonation, condensation reaction, alkaline reforming and the like are carried out for 4-8 hours to generate the faint yellow and transparent melamine high-efficiency water reducing agent. The product has low product cost and high water reducing yield, and has remarkable application effect in steamed concrete.

Owner:安徽海螺材料科技股份有限公司

Processing method of day lily flowers

InactiveCN105341134ANatural colorNatural aromaMeat/fish preservation by dryingCooking & bakingMicrowave

The invention relates to a processing method of day lily flowers. The processing method comprises the following steps of picking and spreading for cooling: picking fresh day lily flowers, and spreading for cooling the picked day lily flowers; steam fixation: performing steam fixation on the cooled day lily flowers; primary baking: sending the day lily flowers after the fixation to a hot air dryer for primary baking, so that the water ratio of the obtained day lily flowers is reduced to 45%-48%; and secondary baking, sending the day lily flowers after primary baking to a microwave drier for secondary baking, so that the water ratio of the obtained day lily flowers is reduced to 13%-16%.Through the processing method of the day lily flowers, the day lily flowers can maintain a good shape, the color of the day lily flowers can also be improved, the quality of the day lily flowers can be greatly improved, and the effect of preventing the day lily flowers from being damaged by worms is achieved. In addition, according to the processing method, additives, such as essence, are not added, so that the safe and healthy consumption trend for the day lily flowers can be met.

Owner:HUIZHOU YULUMING AGRI DEV CO LTD

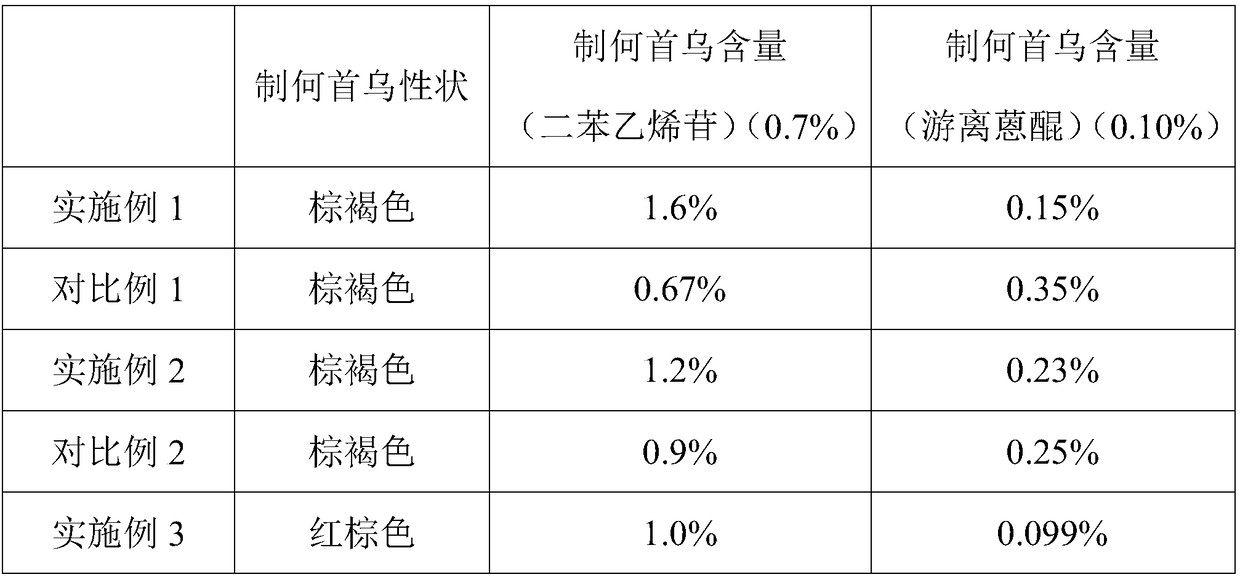

A processing method for radix Polygoni Multiflori decoction pieces from medicinal materials and a product

InactiveCN109172648ASimple production processGuaranteed stabilityNervous disorderMetabolism disorderMedicinal herbsBULK ACTIVE INGREDIENT

The invention discloses a processing method for radix Polygoni Multiflori decoction pieces from medicinal materials and a product . The processing method comprises the following steps: a washing step,a moistening step, a step of preparing black soybean juice, a step of steaming medicine and a step of baking medicine, namely, the radix Polygoni Multiflori decoction pieces are obtained. On the onehand, under the guidance of pharmacopoeia, the processing technology of Radix Polygoni Multiflori Preparata is optimized, and the best effect of wetting and swelling is obtained by the method of decompressing and moistening drugs, so as to ensure the content of active ingredients to meet the legal standard; on the other hand, the processing technology of radix Polygoni Multiflori is optimized. Product appearance and internal quality are improved, and the stability and reproducibility of varieties and processes are guaranteed.

Owner:KANGMEI PHARMA

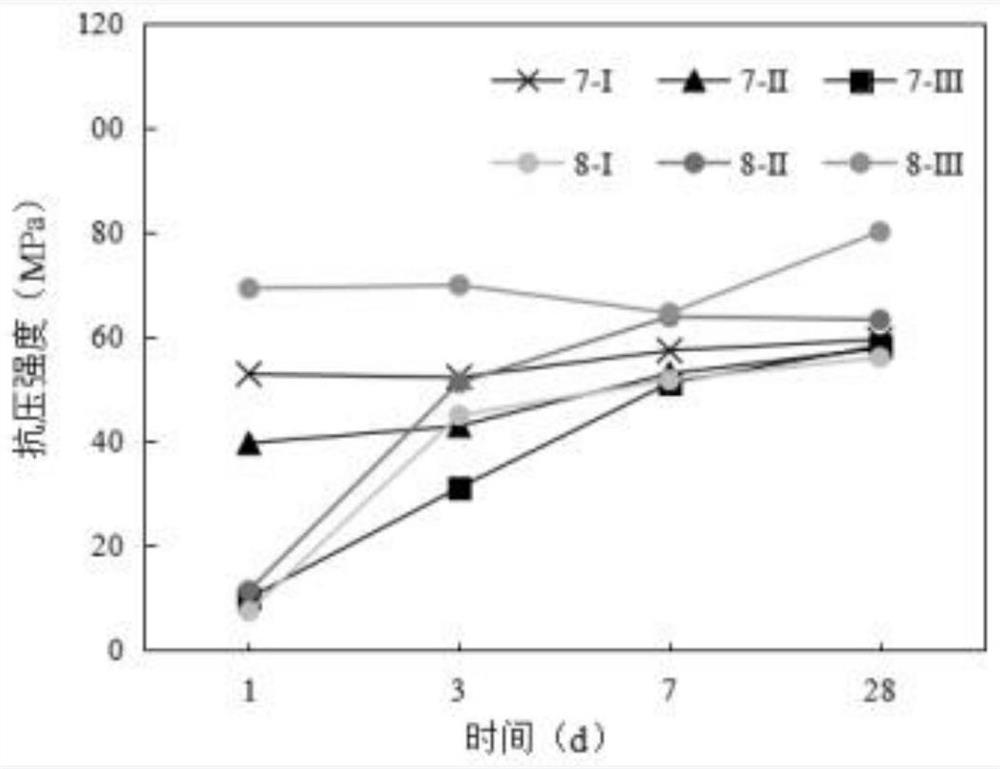

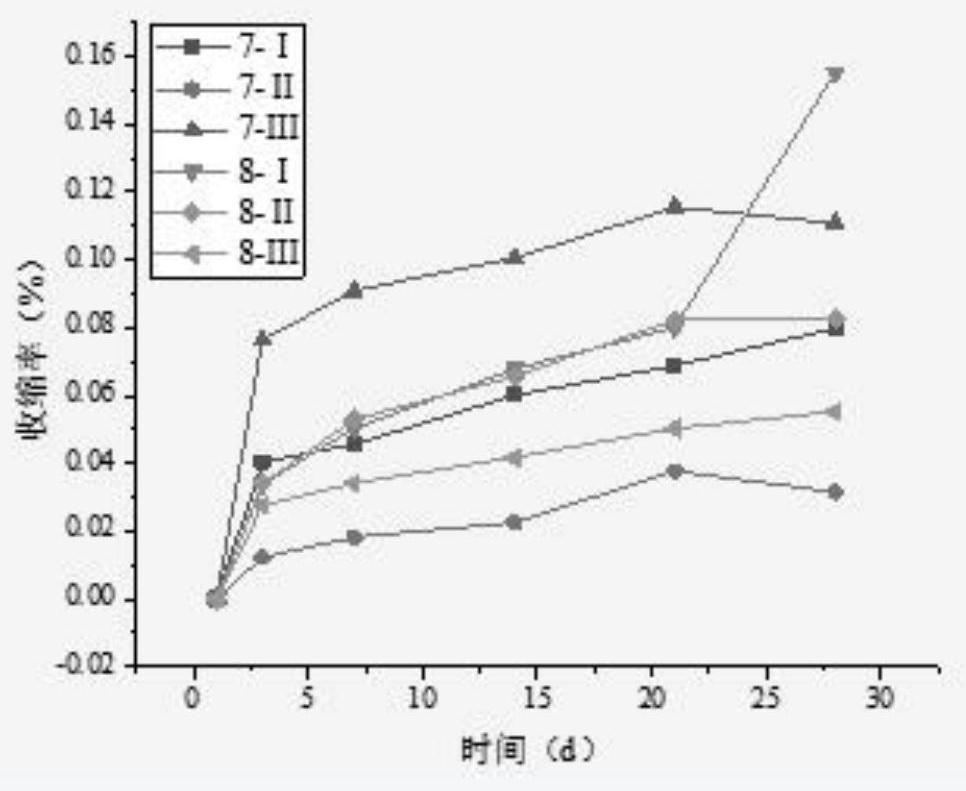

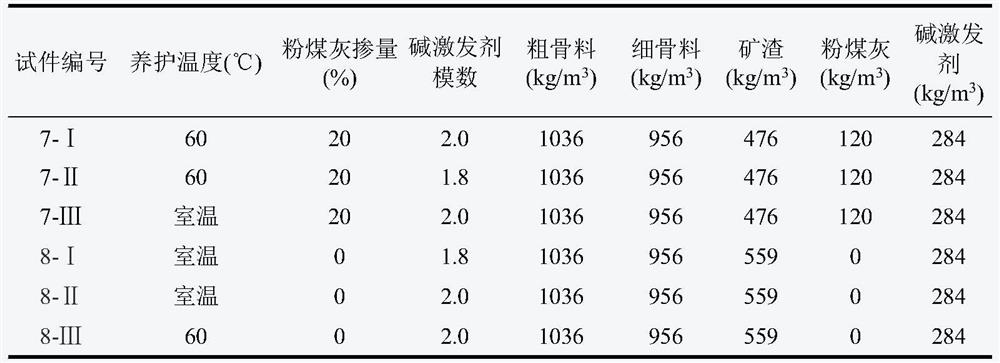

Steam-cured alkali-activated slag concrete and preparation method thereof

PendingCN113402242AQuality improvementSolve Shrinkage CrackingSolid waste managementExtreme weatherSlag

The invention belongs to the technical field of building materials, and relates to steam-cured alkali-activated slag concrete and a preparation method thereof. When the steam-cured alkali-activated slag concrete is applied to engineering in alpine regions, the steam curing time is shortened by 1-2 hours, so that the characteristics of high strength, good freezing resistance and high chloride ion erosion resistance can be utilized, the quality of components is improved, and the steam-cured alkali-activated slag concrete is adapted to extreme weather conditions; besides, the problems of long forming and curing time and long construction period can be solved, the component steam curing and mold removal time is shortened, the mold turnover rate is greatly increased, the construction period is shortened, and the adverse effect caused by construction in winter is relieved; meanwhile, 20-30% of fly ash is doped to replace slag, and the problem of shrinkage cracking of the alkali-activated concrete is effectively solved by adopting a steam curing system; in addition, cement is not used for preparing the concrete, so that energy consumption and carbon emission are greatly reduced, and energy conservation and environmental protection are achieved; and river sand is replaced with machine-made sand, so that the usage amount of natural resources is reduced, the production cost is saved, and the steam-cured alkali-activated slag concrete has important significance on healthy and sustainable development of the building industry.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Preparation process of vinegar fructus schisandra chinensis

InactiveCN104523957AImprove absorption rateShorten the soaking timePlant ingredientsMedicinal herbsOfficinal

The invention discloses a preparation process of vinegar fructus schisandra chinensis, and belongs to the technical field of preparation of traditional Chinese medicines. The preparation process particularly comprises the following operation processes of: cleaning; moistening, steaming, drying and the like. According to the preparation process, the steaming process is as follows: a negative pressure condition is adopted, steaming time and steaming temperature have definite parameters in the process, and the parameters are more scientific compared with a subjective judgment terminal; the moistening process is as follows: a medical multi-dimensional mixer is adopted to dynamically moisten till rice vinegar is completely absorbed; and finally the drying process is carried out in a gradient mode. The vinegar fructus schisandra chinensis produced through the preparation process disclosed by the invention is stable and uniform in quality. The preparation process disclosed by the invention ensures the preparation mechanism of enhancing vinegar quality and weakening acerbity by sufficiently contacting an auxiliary material and a medical material, is effectively shortened in production period and reduced in production energy consumption and labor cost, can realize the continuous production, and is more suitable for industrialized large-scale production.

Owner:BEIJING KANGRENTANG PHARMA

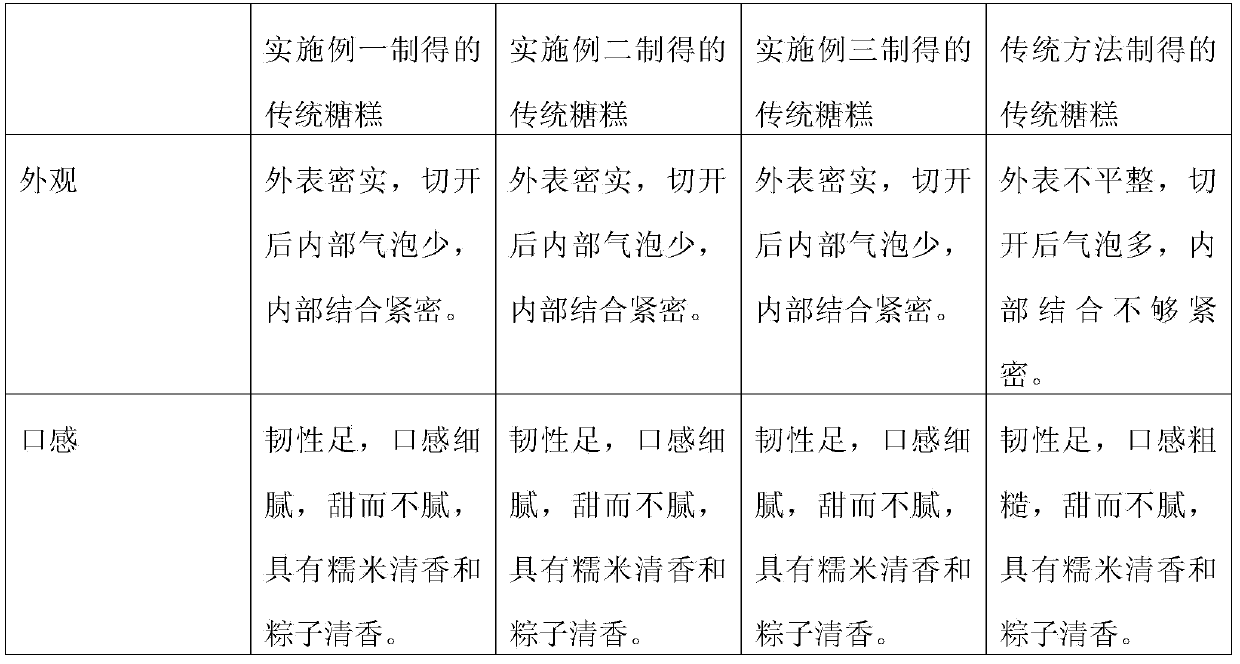

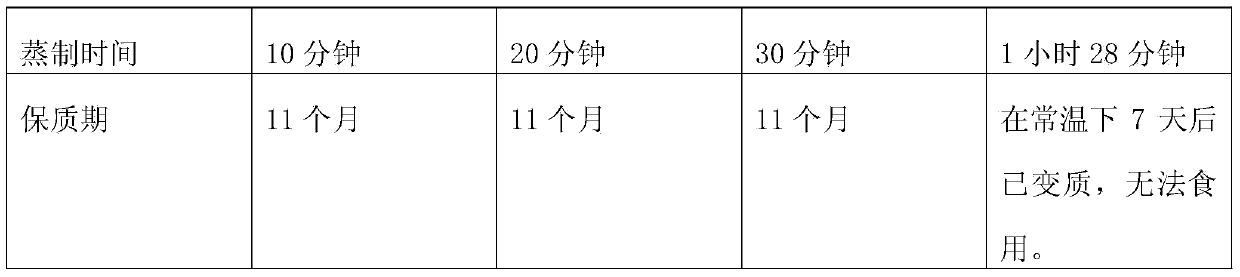

Method for industrially producing traditional sugar cake

The invention relates to a method for industrially producing traditional sugar cake. The traditional sugar cake with traditional flavor is obtained according to the steps of selection of raw materials, low-speed mixing, steaming in a wooden steamer, cooling, cutting, vacuum packaging and temperature-controlled sterilizing. The method has the beneficial effects of reducing air bubbles in the traditional sugar cake through low-speed mixing during production so as to guarantee uniform quality and smooth taste of the sugar cake, keeping the flavor of the traditional sugar cake by virtue of steaming with the wooden steamer, prolonging the shelf life of the traditional sugar cake and achieving a ripening effect to shorten the steaming time of the traditional sugar cake by virtue of the temperature-controlled sterilizing, thereby implementing the industrial production of the traditional sugar cake, and guaranteeing stable quality of the produced sugar cake and special flavor of the traditional sugar cake. The production efficiency of the method is improved by more than ten times compared with that of traditional production methods, the shelf life of the traditional sugar cake produced by the method reaches more than ten months and the method has a good application effect and is easy to popularize.

Owner:ZHEJIANG CAOMIAO FOOD

Preparation method for pulverized coal-ash-based porous artificial stone

InactiveCN102584322BImprove productivityShorten steaming timeSolid waste managementCeramicwareFiberWater vapor

Owner:SHAANXI UNIV OF TECH

Yam sweet dumpling and preparation method thereof

The invention discloses a yam sweet dumpling and a preparation method thereof. The yam sweet dumpling is prepared from raw materials in parts by weight as follows: a yam sweet dumpling wrapper: 100-150 parts of glutinous rice flour, 2-5 parts of quick-frozen oil and 90-110 parts of water; yam sweet dumpling stuffing: yams or a mixture of the yams and one of Chinese wolfberries and red dates. The preparation method comprises steps as follows: Step 1, a preparation process of the yam sweet dumpling wrapper; Step 2, a preparation process of the yam sweet dumpling stuffing. According to the yam sweet dumpling and the preparation method thereof, processes distinct from traditional sweet dumpling processes are adopted, so that the steaming time is shortened, and few microelements of the yams are lost. The problem of high viscosity of the steamed yams is solved, the stuffing does not leak during cooking of the sweet dumpling prepared by a machine, and the stuffing is more sweet and delicious under the condition that the taste and the flavor of the yams are not changed.

Owner:焦作市欣冻食品有限公司

Preparation method of preboiled rice

InactiveCN109730251AHigh nutritional valueHigh meal rateSeed preservation by heatingUltra high pressureHigh pressure

The invention relates to a preparation method of preboiled rice, and belongs to the technical field of food processing technologies. The preparation method comprises the following steps of cleaning and grading, segmented soaking, ultra-high-pressure treatment, steaming and gelatinization, drying and rice husking and milling; wherein segmented soaking comprises the steps that firstly, rice after cleaning and grading is soaked for 0.5-1 h at 80-90 DEG C and then soaked for 1-2 h at 50-70 DEG C until the moisture content of the rice reaches 32-35%. The preparation method of the preboiled rice hasthe advantages that adopted temperature varying soaking can greatly shorten the soaking time of the preboiled rice; the combination of the ultra-high-pressure treatment can make the distribution of the moisture in the rice more uniform, thereby improving the gelatinization degree of the preboiled rice, and shortening the steaming time, so that the gelatinization of the preboiled rice is more uniform, the white heart grains of the preboiled rice is eliminated, the rice color also becomes light, the appearance of the preboiled rice is more uniform, and the acceptability of customers can be greatly improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

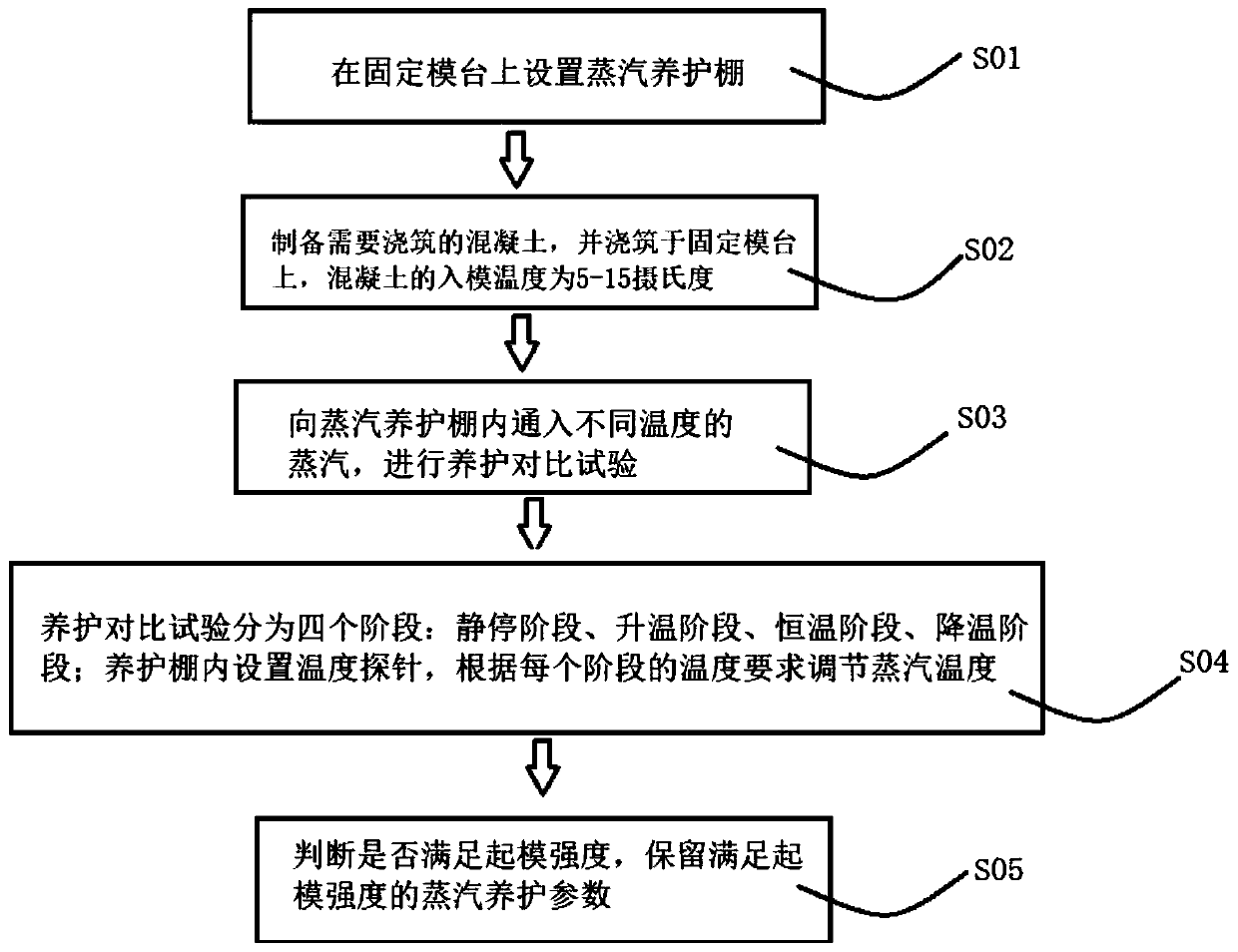

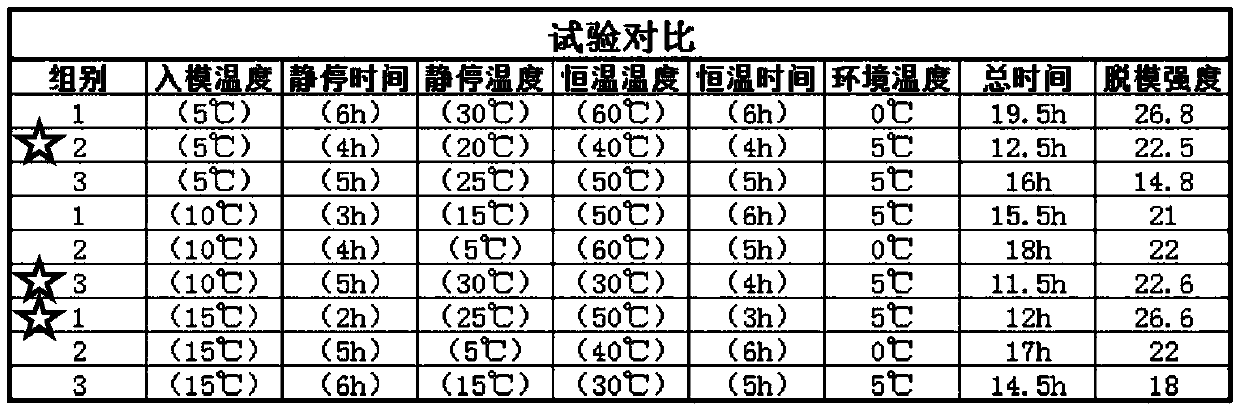

Test method and device for acquiring steam curing parameters of prefabricated part at low temperature and steam curing method

InactiveCN110962224AOptimal Steaming ParametersGood quality finished productCeramic shaping apparatusThermodynamicsProcess engineering

The invention belongs to the technical field of building prefabricated part improvement, and discloses a test method and device for acquiring the steam curing parameters of a prefabricated part at a low temperature and a steam curing method. The test method comprises the following steps: arranging a steam curing shed on a fixed mold platform; preparing concrete to be poured, and pouring the concrete onto the fixed mold platform, wherein the pouring temperature of the concrete is 5 to 15 degrees centigrade; introducing steam with different temperatures into the steam curing shed, and performinga curing comparison test which is divided into four stages including a standing stage, a heating stage, a constant-temperature stage and a cooling stage; arranging a temperature probe in the curing shed, and adjusting the temperature of the steam according to the temperature requirement in each stage; and determining whether the stripping strength is satisfied or not, and keeping the steam curingparameters satisfiying the stripping strength. The method specifies better steam curing parameters for different pouring temperatures (5, 10 and 15 degrees centigrade) of concrete at a low temperature, shortens the steam curing time, improves the mold turnover rate and reduces the steam curing cost.

Owner:ZHONGTIAN CONSTR GROUP +1

Inorganic cementing material and preparation method thereof

The invention provides an inorganic cementing material and a preparation method thereof. The cementing material is obtained by jointly grinding a composite material obtained by steam curing and calcinating material blocks or material balls prepared from coal ash, lime, an exciting agent and water, Portland cement and gypsum. The preparation method includes the steps that by mass, 65-80 parts of coal ash, 20-35 parts of effective CaO of lime and 0.5-2.0 parts of exciting agent are jointly ground into a batch mixture with the degree of fineness being 45 microns and the residue on sieve being smaller than 10%, 15-50 parts of water is added, the mixture is mixed to be uniform, then aging is conducted for 2-3 hours, the material blocks or the material balls are subjected to steam curing for 8-16 hours at the temperature of 90-98 DEG C after being formed, and a steam cured material is obtained; the steam cured material is calcinated for 15-90 minutes at the temperature of 750-1,000 DEG C and then air cooled or cooled in air, and the composite material is obtained; 60-70 parts of the composite material, 20-30 parts of Portland cement and 5-10 parts of gypsum are jointly ground till the specific area is 350-450 m<2> / kg, and the fast-setting high-strength inorganic cementing material is prepared.

Owner:HUAZHI ENERGY CONSERVATION HK

Chili sauce and manufacture method thereof

InactiveCN108523091AUnique flavorNot easy to get angryFood preservationFood ingredient as flavour affecting agentNutritive valuesVegetable oil

The present invention discloses a chili sauce and a manufacture method thereof, and belongs to the technical field of food. The chili sauce is prepared from the following raw materials in parts by weight: 300 parts of crushed chilies, 75-90 parts of soybean paste, 100-120 parts of vegetable oil, 20-24 parts of edible salt, 15-18 parts of edible vinegar, 12-14 parts of white sugar and 1.5-1.8 partsof baijiu. The raw materials are mixed evenly; and the mixture is steamed for 20-30 minutes to obtain a finished product. The chili sauce prepared by the method is fragrant, spicy and fresh in mouthfeel, rich in various vitamins and minerals in the chilies and soybean paste, high in nutritional value and not easy to cause internal heat.

Owner:李超

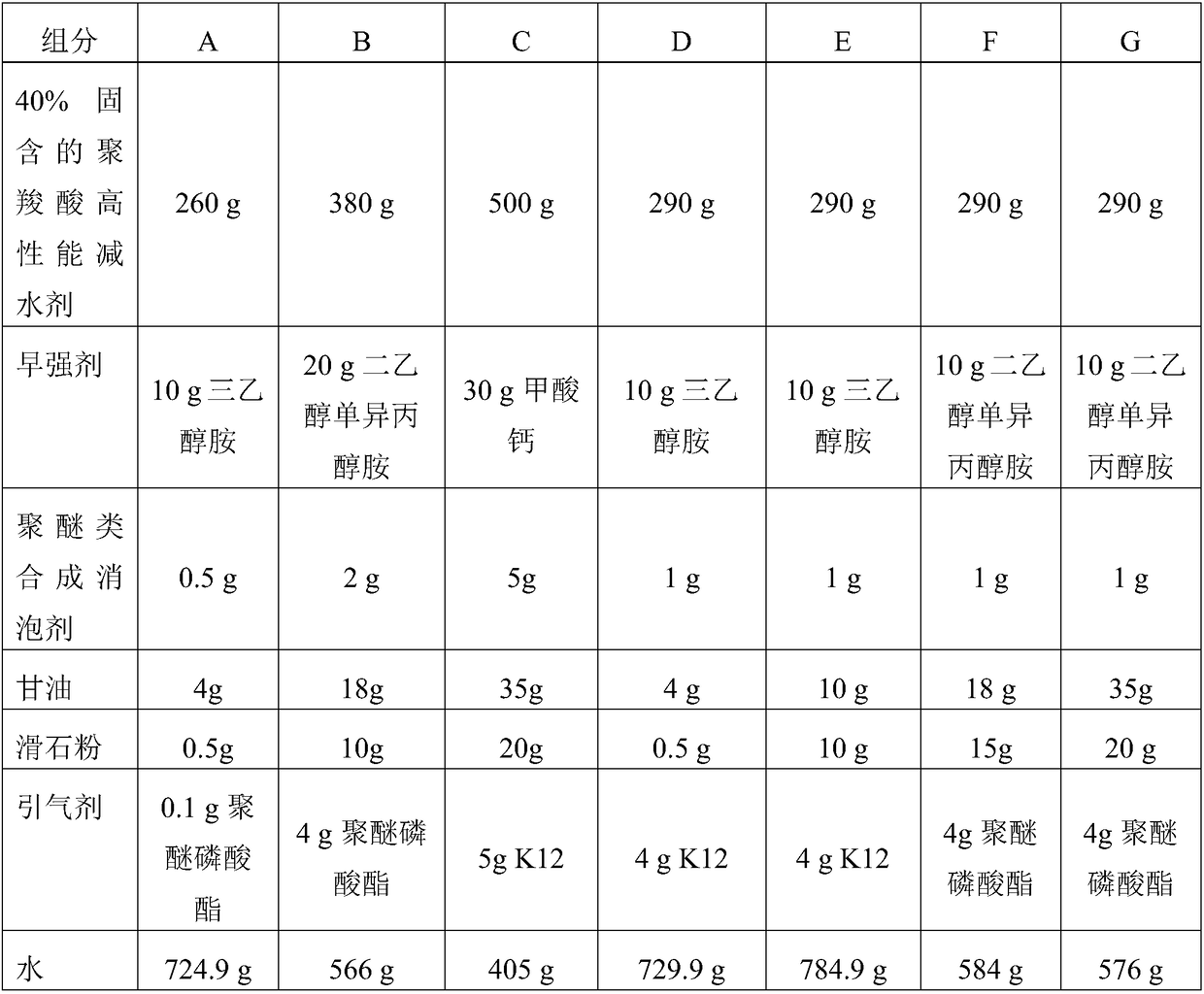

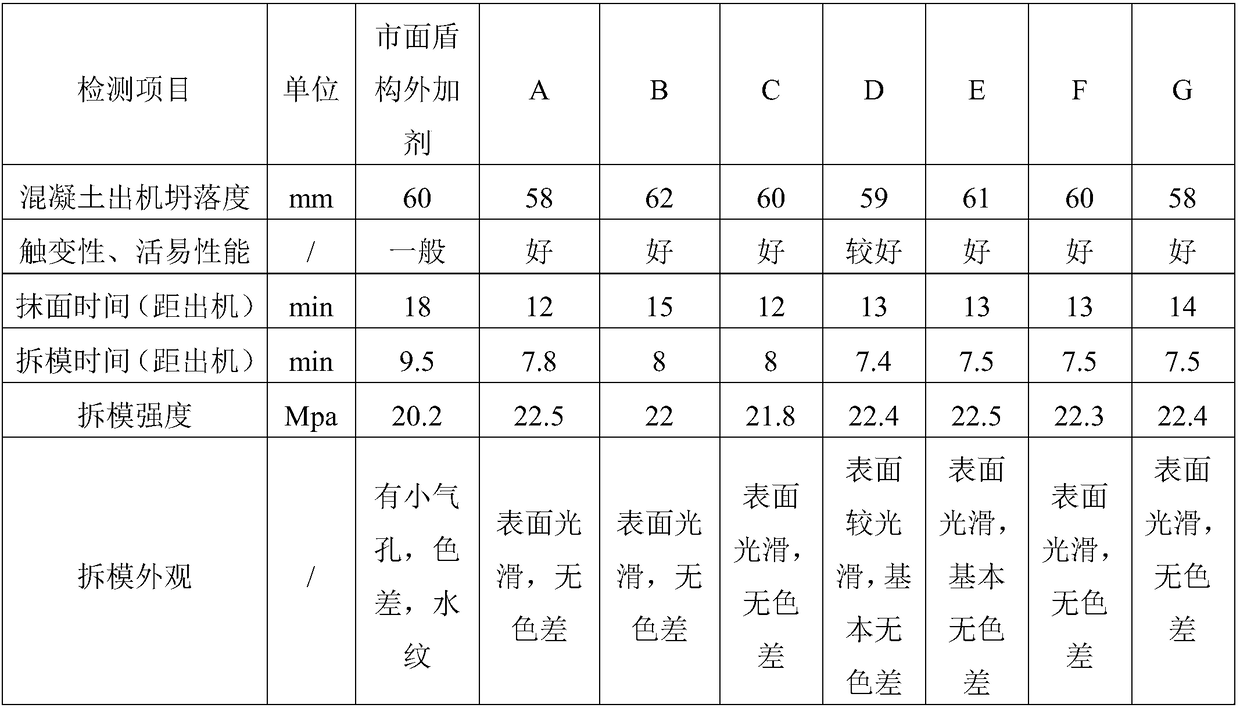

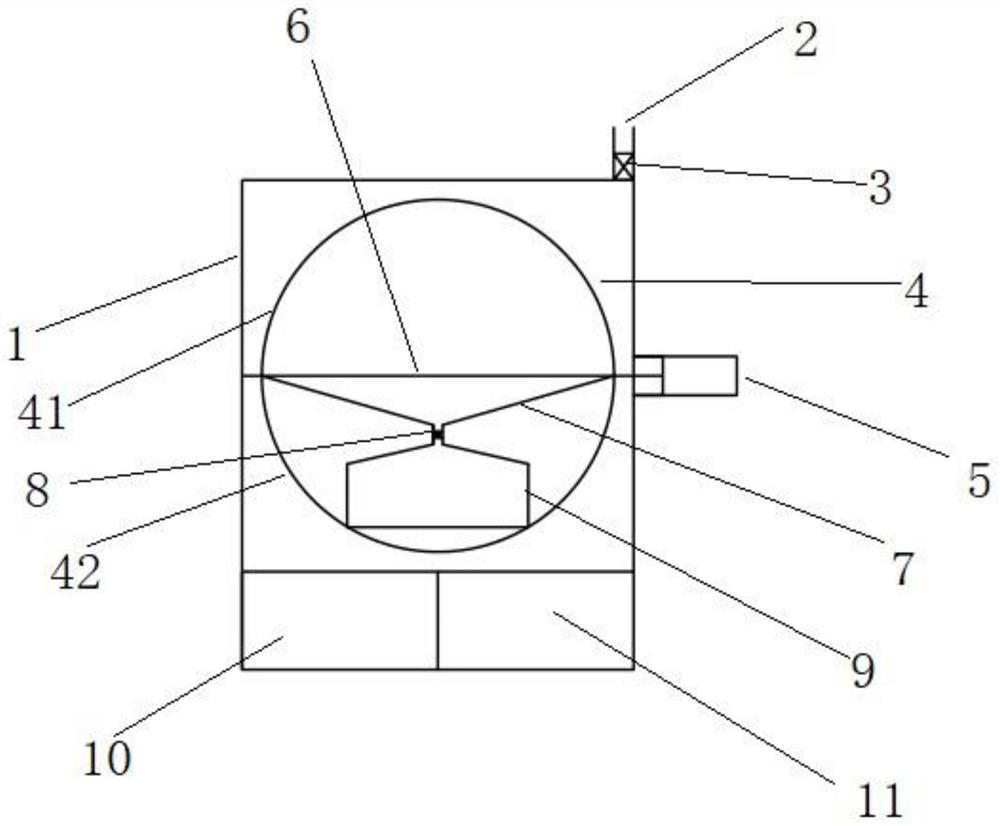

Shield segment additive and preparation method

The invention provides a shield segment additive. The shield segment additive is prepared from the following components in percentage by mass: 25.75 to 50.25 percent of polycarboxylic acid high-performance water-reducing agent, 1 to 3 percent of early strength agent, 0.01 to 0.5 percent of air entraining agent, 0.05 to 0.8 percent of polyether synthetic defoaming agent, 0.4 to 3.5 percent of brightening agent, 0.05 to 2 percent of viscosity thixotropic agent and the balance of water. The invention also provides a preparation method of the shield segment additive. By adoption of the shield segment additive provided by the invention, the thixotropy and peaceability requirements of concrete can be guaranteed while low slump degree of the concrete is controlled under the early strength settingtime requirement, the construction time of workers is saved, the strength of the concrete within 8 hours exceeds the form stripping requirement, the steam curing time of the concrete is shortened, amold turnover rate of a segmental factory is increased, and the production efficiency is improved; in addition, a surface is attractive after form stripping, a repairing process is reduced, and manpower and material resources are further saved.

Owner:HUNAN ZHONGYAN BUILDING MATERIAL TECH CO LTD

Non-autoclaved admixture for PHC tubular pile and method for preparing PHC tubular pile

The invention provides a non-autoclaved admixture for a PHC tubular pile and a method for preparing the PHC tubular pile, and belongs to the technical field of building materials. The non-autoclaved admixture for the PHC tubular pile is prepared from the following components in percentage by weight: 58-74% of superfine slag powder, 20-30% of II-grade coal ash, 5-10% of desulfurized gypsum and 1.0-2.0% of excitant, wherein the total is 100%. The non-autoclaved admixture for the PHC tubular pile is prepared by the following steps: uniformly mixing the components in percentage by mass; adding thepre-stressed concrete into a cementing material and stirred with aggregate, an additive and water to prepare a pre-stressed concrete mixture, preparing the pre-stressed high-strength concrete pipe pile with stable later strength and excellent durability, and finally, performing short-time maintenance of a normal-pressure steam maintenance process. An autoclaving process in the production processof the pipe pile can be omitted, the workability of concrete is improved, the steam curing time is shortened, and the production cost is effectively reduced.

Owner:河北科晖环境资源有限公司

Method and device for processing rhizoma polygonati through nine-steam-nine-bask

PendingCN113144094AShorten steaming timeHigh in polysaccharidesPlant ingredientsProcess engineeringPolysaccharide

The invention discloses a method for processing rhizoma polygonati through nine-steam-nine-bask, which comprises the following steps: 1) placing fresh rhizoma polygonati in a pressure cooker for high-pressure steaming for 6-8 hours, taking out the rhizoma polygonati, drying, and obtaining soup for later use; (2) after the rhizoma polygonati is dried, uniformly mixing the soup with the rhizoma polygonati to enable the rhizoma polygonati to fully absorb the soup, preserving for 10-20 hours, continuously turning over during preservation, and steaming for 4-5 hours under high pressure; and (3) repeating the step (2) for 7 times, uniformly mixing the soup with the rhizoma polygonati, drying and storing. The method has the characteristics that the steaming processing time of the polygonatum kingianum can be shortened, the polysaccharide content of the polygonatum kingianum is increased, the taste is improved, and mildewing of the polygonatum kingianum is avoided.

Owner:云南摩都农业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com