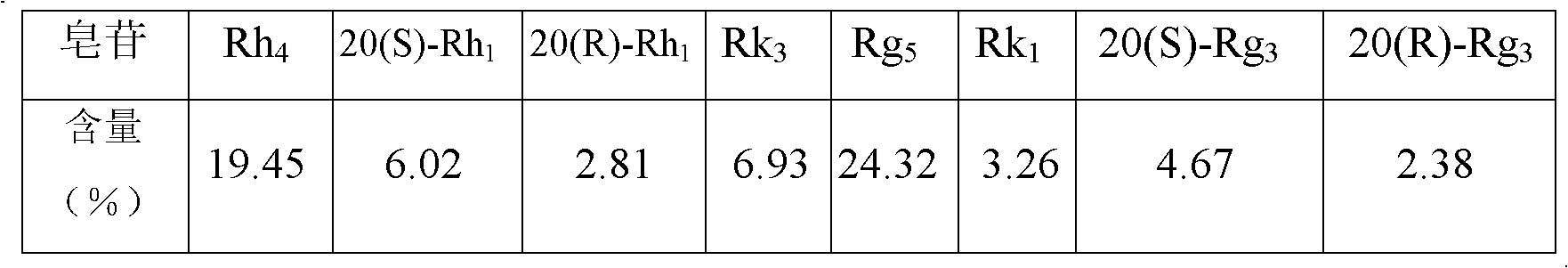

Preparation method of cooked panax notoginseng extract and total ripe panax notoginseng saponins

A technology for cooking Panax notoginseng and extracts, which can be applied to medical preparations, pharmaceutical formulations, plant raw materials and other directions containing active ingredients, and can solve the problem of inconsistent conversion degree of saponin components, uneven distribution of moisture and heat, and increase the time required for steaming. and other problems, to achieve the effect of easy operation and large-scale production, easy product quality, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] One, the preparation method of cooked Panax notoginseng extract and cooked Panax notoginseng total saponins extract of the present invention:

[0018] 1. The preparation method of cooked Panax notoginseng extract:

[0019] The plant raw material used to prepare the cooked Panax notoginseng extract is the fresh or dried whole root or various underground parts of Panax notoginseng (Burk.) F.H.Chen of Araliaceae, including rhizomes (commonly known as scissors) , reed head), main root (commonly known as head), branch root (commonly known as tendon, large tendon) and fibrous roots and the above-mentioned different parts mixed in various proportions.

[0020] The concrete steps that the present invention prepares cooked Panax notoginseng extract are as follows:

[0021] Raw Panax notoginseng crude extract preparation: dry or fresh underground part of Panax notoginseng is mechanically crushed to a certain particle size. Using ethanol or methanol or different concentrations o...

Embodiment 2

[0044] Preparation of cooked Panax notoginseng extract:

[0045] Take 5 kg of dry root of Panax notoginseng and crush it, extract 3 times with 70% ethanol under reflux at 80°C, concentrate and distill off the alcohol to obtain about 2 L of crude extract.

[0046] The crude extract of notoginseng was placed in a 5L glass triangular flask and steamed in an autoclave at 120°C for 8 hours.

[0047] After the liquid is cooled, the concentrated liquid is placed in a freeze dryer and freeze-dried to obtain 720 g of cooked Panax notoginseng extract with complete conversion of saponins.

Embodiment 3

[0049] Preparation of cooked Panax notoginseng extract:

[0050] Take 5 kg of dried notoginseng, crush it, extract by cold immersion in 70% methanol three times, concentrate and evaporate to remove alcohol, and obtain about 1.3 kg of brown-black notoginseng extract.

[0051] The notoginseng extract was placed in a white enamel dish and steamed in an autoclave at 100°C for 6 hours.

[0052] After the liquid was cooled, the concentrated liquid was placed in a freeze dryer and freeze-dried to obtain 764 g of the Panax notoginseng extract with complete conversion of cooked saponins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com