Shield segment additive and preparation method

A shield tunnel segment and admixture technology, which is applied in the field of building materials, can solve the problems of poor appearance, low early strength, and poor construction performance of shield tunnel segments, save manpower and material resources, reduce repairing procedures, and have a beautiful surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a kind of preparation method of shield segment admixture, comprising the following steps:

[0041] (1) Determine the distribution ratio of each component, add water to the container first, then add polycarboxylate high-performance water reducer, early strength agent, polyether synthetic defoamer, brightener and viscosity thixotropic agent in sequence, and mix and stir Uniform;

[0042] (2) Add air-entraining agent and stir evenly to get the finished product.

Embodiment 2

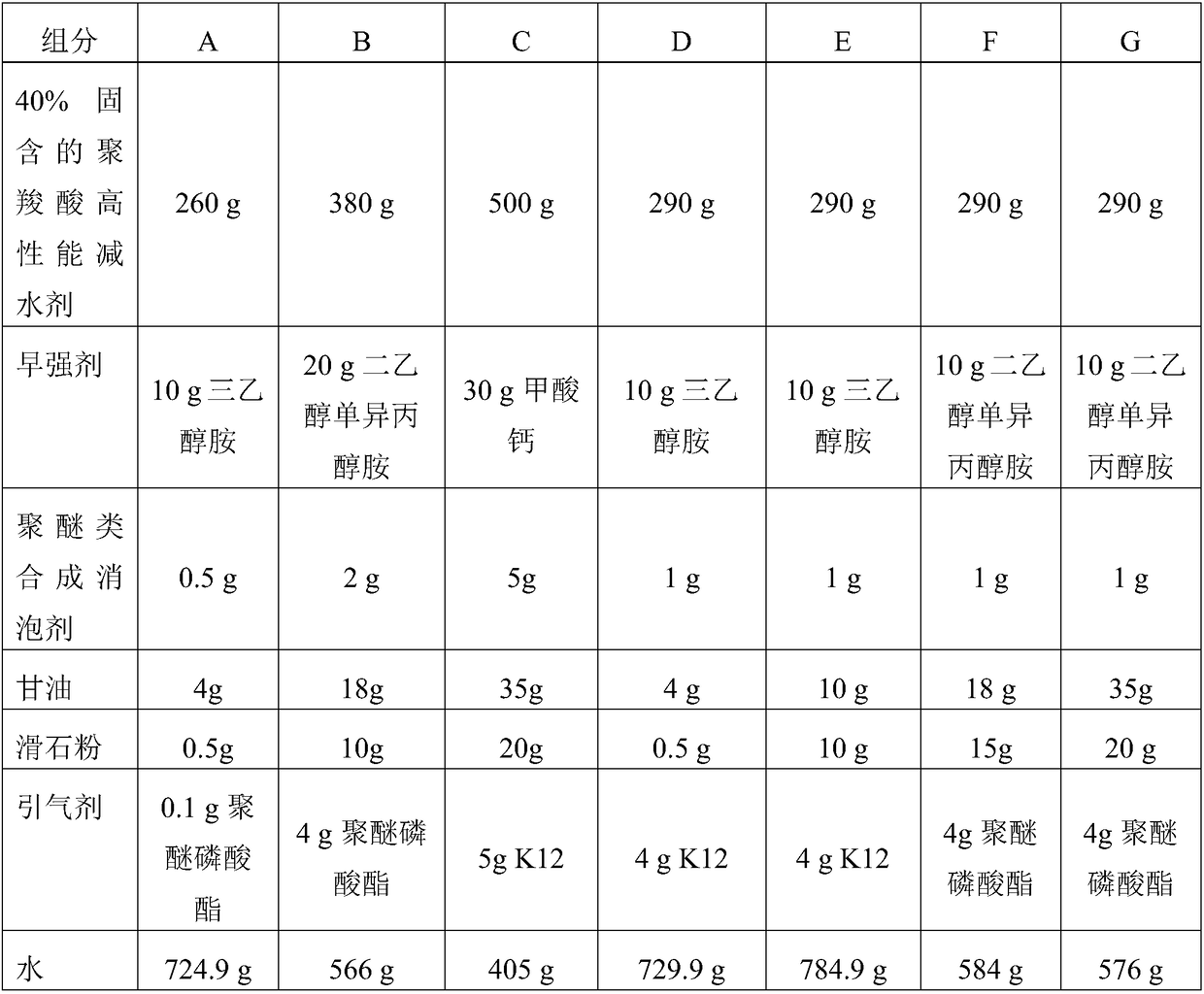

[0044] Using the preparation method provided in Example 1, seven shield segment admixtures A to G with different proportions were prepared in this example, and the specific formulations are shown in Table 1.

[0045] Table 1 Specific raw material components of admixtures A to G

[0046]

Embodiment 3

[0048] In the test, the concrete mix ratio was designed according to the subway segment strength grade C50, and the amount of each material in the concrete mix ratio is shown in Table 2.

[0049] Table 2 The amount of each material in concrete

[0050] Material

pebbles

water

Admixture

Mass (kg / m 3 )

390

60

708

1105

145

4.5

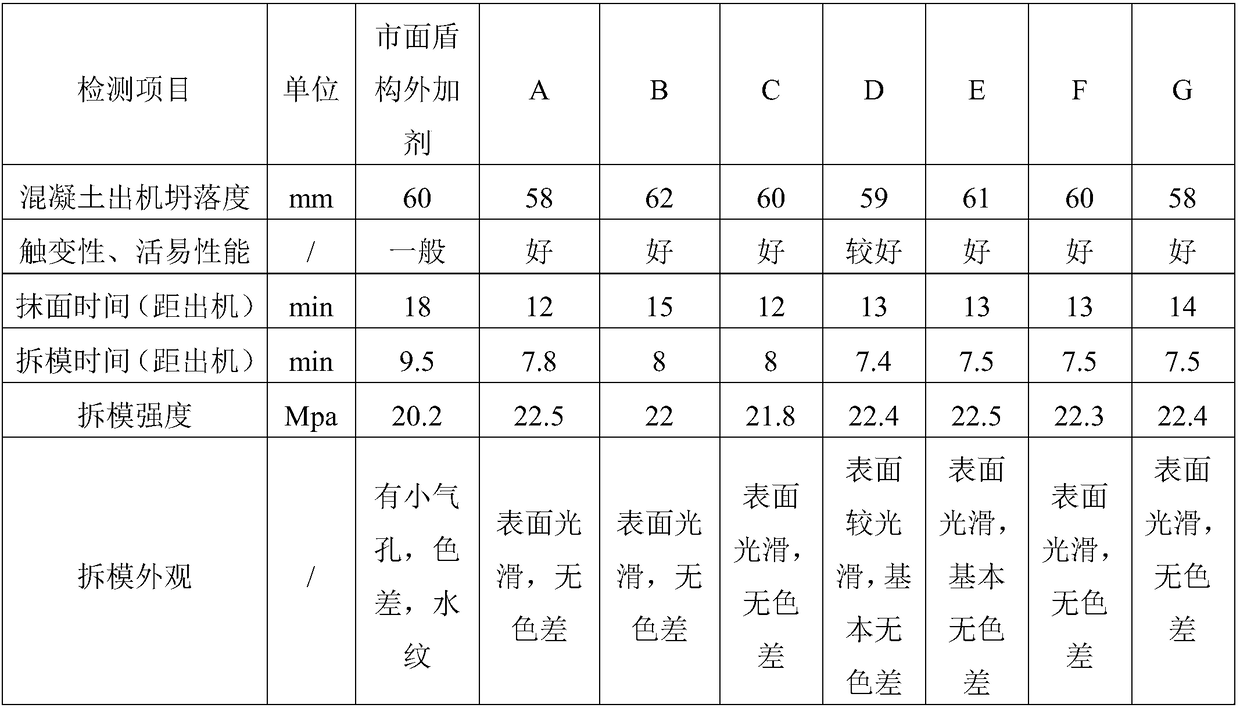

[0051] Apply admixtures A to G to the above concrete. The amount of admixture for the shield segment shall be 1.0% of the total amount of glue (cement + fly ash), and the concrete shall be prepared according to the methods in GB / 50152-92 and other standards. Performance measurement, measurement results are listed in Table 3.

[0052] Table 3 Performance test results of corresponding concrete with admixtures A~G added

[0053]

[0054] From the above tests, it can be seen that the shield segment admixture provided by the present invention can make the detection i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com