Construction process for large-area structure repair systems

A construction technique and a large-area technology, applied in the direction of building structure, construction, covering/lining, etc., can solve problems such as sag or collapse, and the repair system cannot meet the needs, etc., to achieve good anti-slip and sag, excellent wet bonding Effect of strength and thixotropy, excellent wet bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

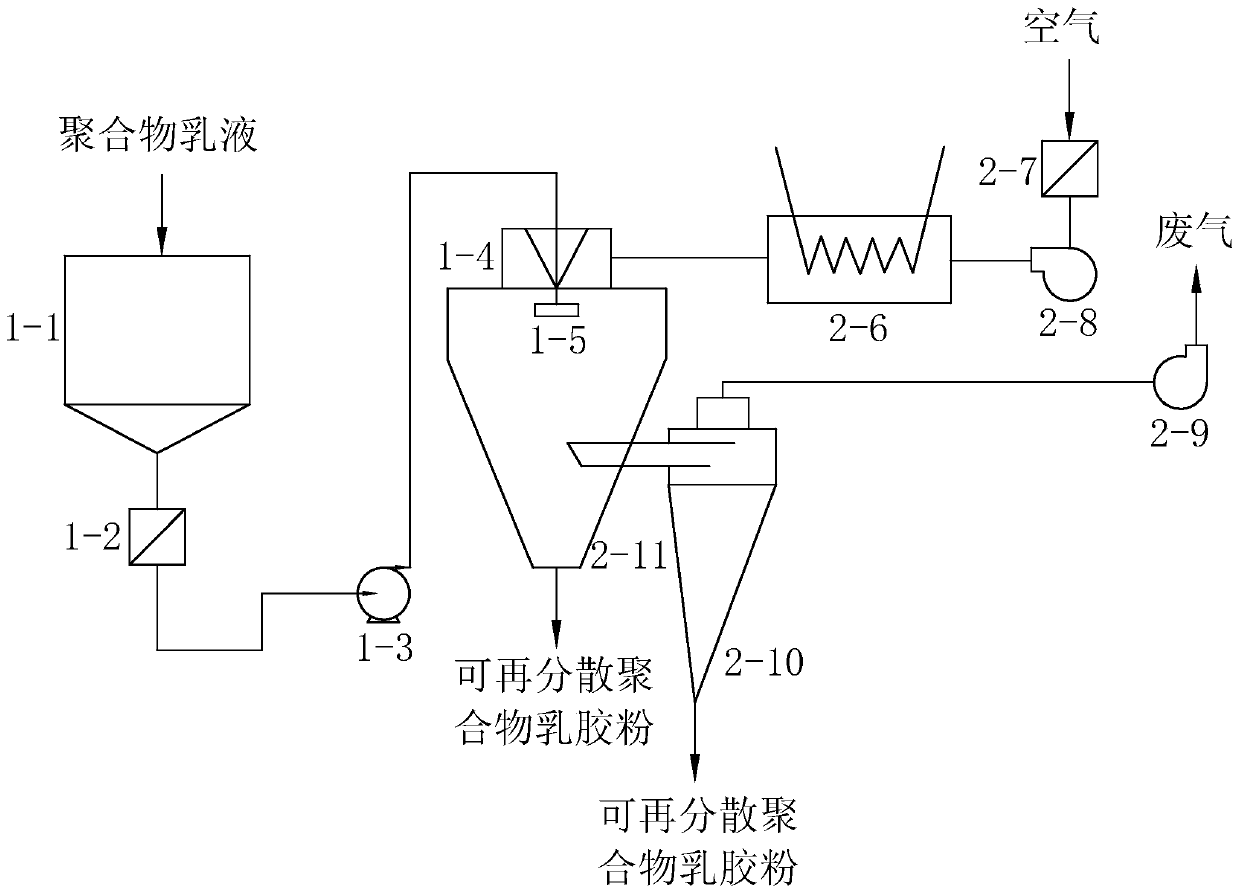

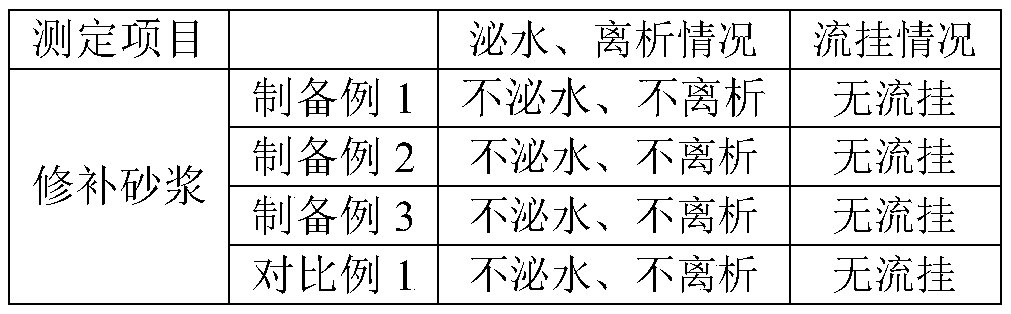

preparation example 1

[0034] Dissolve 6.5Kg of mercaptopolyvinyl alcohol in 135Kg of water at 90°C, add 9Kg of methyl methacrylate and 1.5Kg of sodium bicarbonate to the aqueous solution of mercaptopolyvinyl alcohol at 80°C and mix well, then add the weight percentage Concentration of 1% ammonium persulfate aqueous solution 17.5Kg, heat preservation reaction for 1 hour; keep the reaction temperature of 80 ℃ and start to drop 52Kg of methyl methacrylate, 58Kg of triisopropoxysilyl propyl methacrylate, 4,4 , the mixed monomer of 4-trifluoro-2-butenol 18Kg, phosphoenol pyruvic acid 12Kg and the weight percentage concentration are 1% ammonium persulfate aqueous solution 55Kg, the time of the dropwise addition of control mixed monomer is 5 hours, controls The dripping time of the ammonium persulfate aqueous solution with a concentration of 1% by weight is 6 hours; after the addition of the mixed monomers, the insulation reaction is continued for 1 hour to obtain a polymer emulsion;

[0035] A mixture of...

preparation example 2

[0037] Dissolve 5Kg of mercaptopolyvinyl alcohol in 140Kg of water at 92°C, add 10Kg of methyl methacrylate and 1Kg of sodium bicarbonate to the aqueous solution of mercaptopolyvinyl alcohol at 78°C and mix evenly, then add the weight percent concentration of 1% ammonium persulfate aqueous solution 20Kg, heat preservation reaction for 1 hour; keep the reaction temperature of 78 °C and start to drop 50Kg of methyl methacrylate, 60Kg of triisopropoxysilyl propyl methacrylate, 4,4,4- The mixed monomer of trifluoro-2-butenol 15Kg, phosphoenol pyruvic acid 15Kg and weight percent concentration are 1% ammonium persulfate aqueous solution 50Kg, and the dropwise addition time of control mixed monomer is 5 hours, controls weight percent concentration The dripping time of the 1% ammonium persulfate aqueous solution is 6 hours; after the addition of the mixed monomers, the insulation reaction is continued for 1 hour to obtain a polymer emulsion;

[0038] The mixture comprising the polyme...

preparation example 3

[0040] Dissolve 8Kg of mercaptopolyvinyl alcohol in 130Kg of water at 93°C, add 8Kg of methyl methacrylate and 2Kg of sodium bicarbonate to the aqueous solution of mercaptopolyvinyl alcohol at 82°C and mix evenly, then add the weight percentage concentration of 1% ammonium persulfate aqueous solution 15Kg, heat preservation reaction for 1 hour; keep the reaction temperature of 82 °C and start to drop 55Kg of methyl methacrylate, 55Kg of triisopropoxysilyl propyl methacrylate, 4,4,4- The mixed monomer of trifluoro-2-butenol 20Kg, phosphoenol pyruvic acid 10Kg and the weight percent concentration are 60Kg of ammonium persulfate aqueous solution of 1%, and the dropwise addition time of control mixed monomer is 5 hours, controls weight percent concentration The dripping time of the 1% ammonium persulfate aqueous solution is 6 hours; after the addition of the mixed monomers, the insulation reaction is continued for 1 hour to obtain a polymer emulsion;

[0041] The mixed material of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com