Method for making steamed bread by utilizing multifunctional wheaten food cooking machine

A multi-functional, noodle-based technology, applied in food preparation, food science, application, etc., can solve the problems of increased user labor, high stickiness of steamed buns, unfavorable cleaning of users, etc., to avoid complicated labor, increase speed, and shorten steaming the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

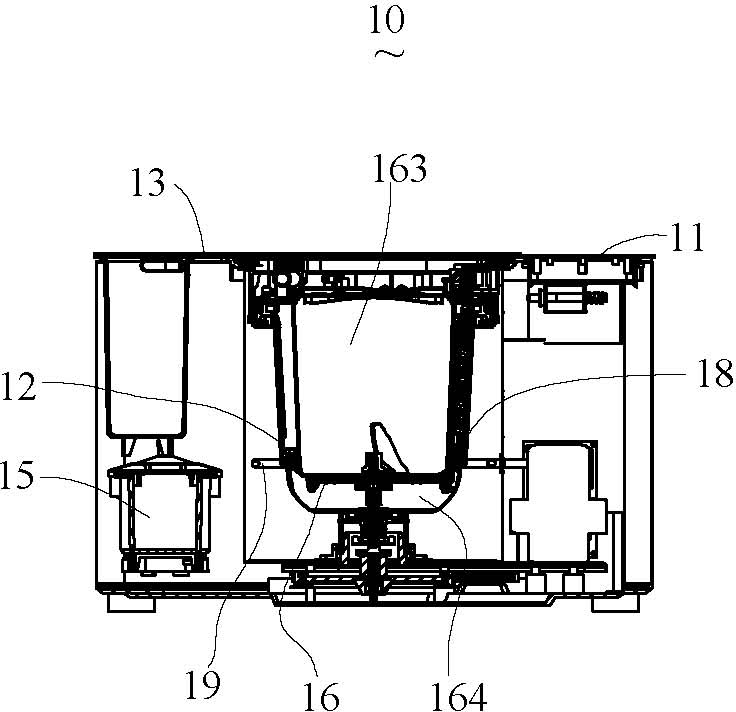

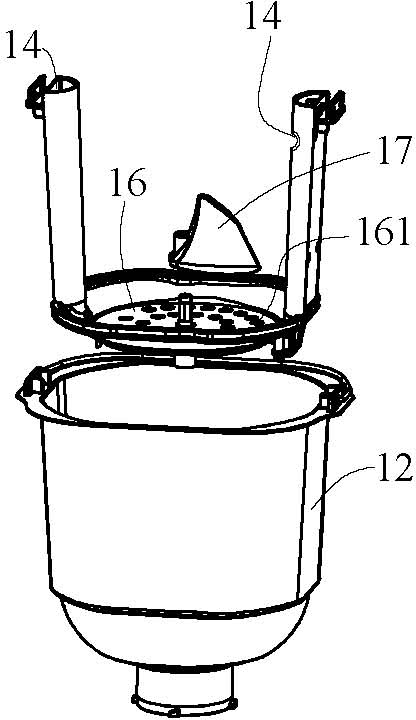

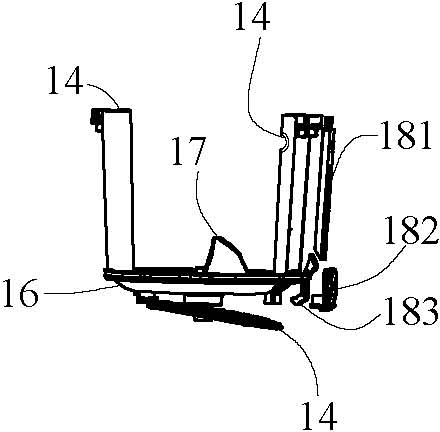

[0035] Please also refer to figure 1 , figure 2 and image 3 As shown, the pasta processing machine 10 of the present invention comprises a control device 11, an inner barrel 12, a cover body 13, a steam generating device 15, a steaming rack 16 with a steaming hole 161 at the bottom, a stirring knife 17, and a cover body 13 and steam The steam passage 14 communicated with the generating device 15 and the baking heating pipe 19 surrounding the inner tub 12 . The steam rack 16 is placed in the inner barrel 12 and divides the inner barrel 12 into upper and lower steam chambers ( 163 , 164 ). A steam rack cover 162 is provided between the steam rack 16 and the lower steam chamber 164 . Stirring knife 17 is installed on the axle that runs through steam frame 16. The steam channel 14 communicates with the steam generating device 15 and the upper steam chamber 163 and the lower steam chamber 164 . The pasta processor 10 also includes an opening and closing device 18 for opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com