Patents

Literature

59results about How to "Solve the stickiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

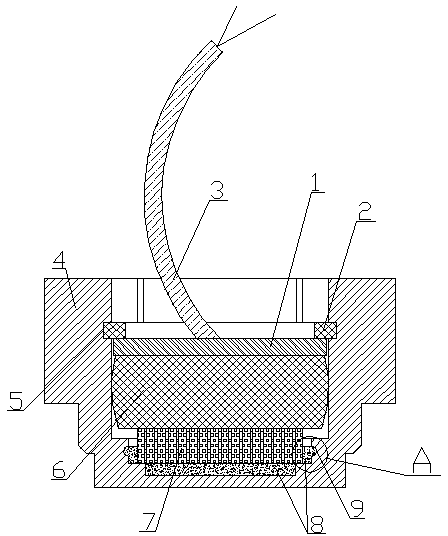

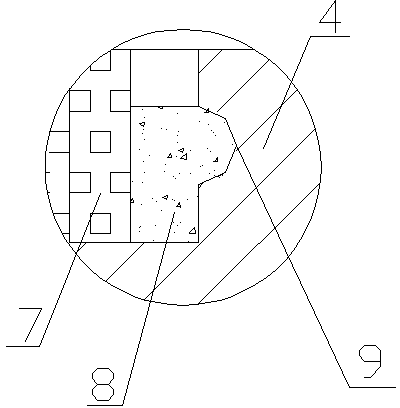

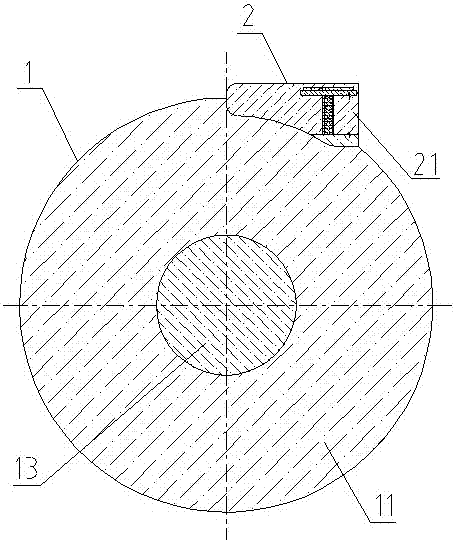

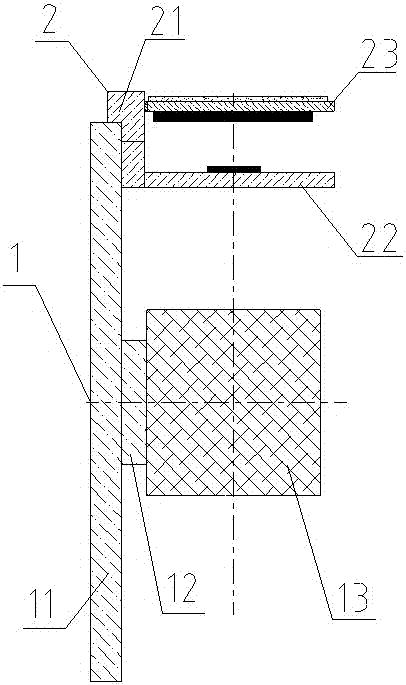

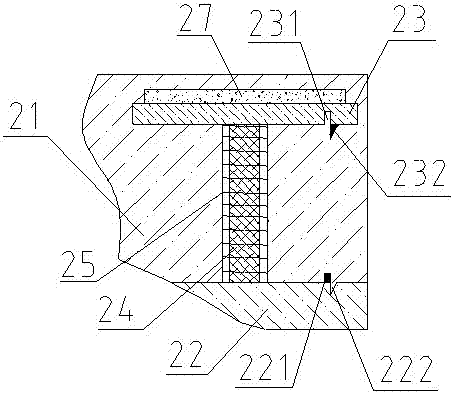

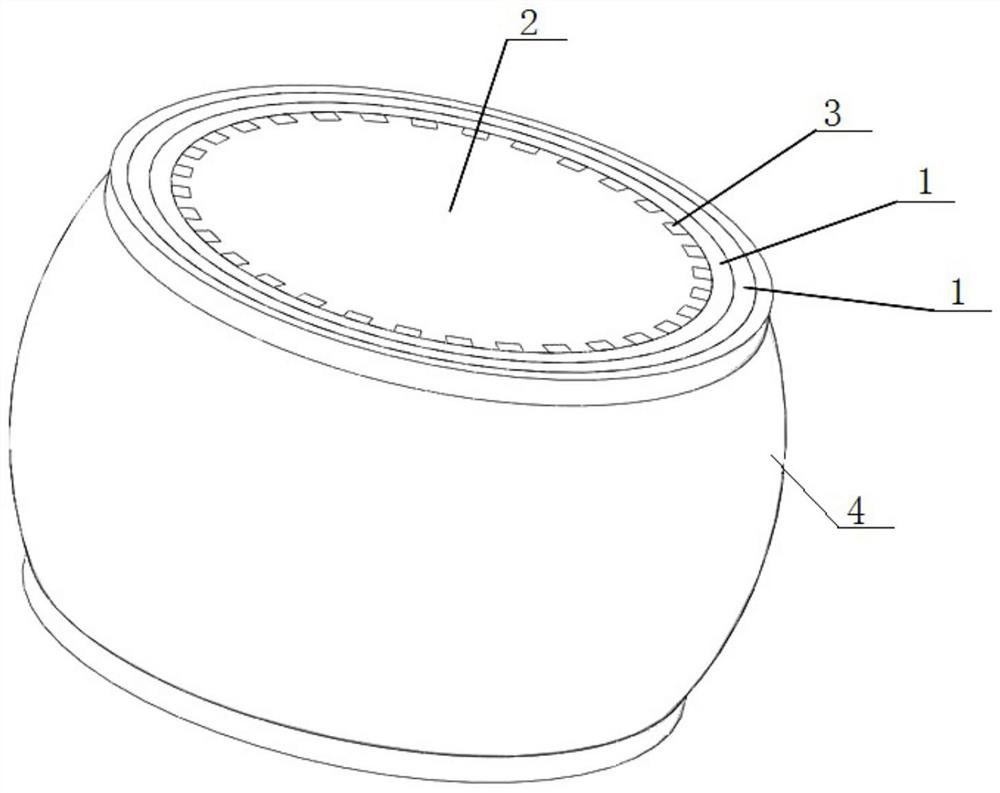

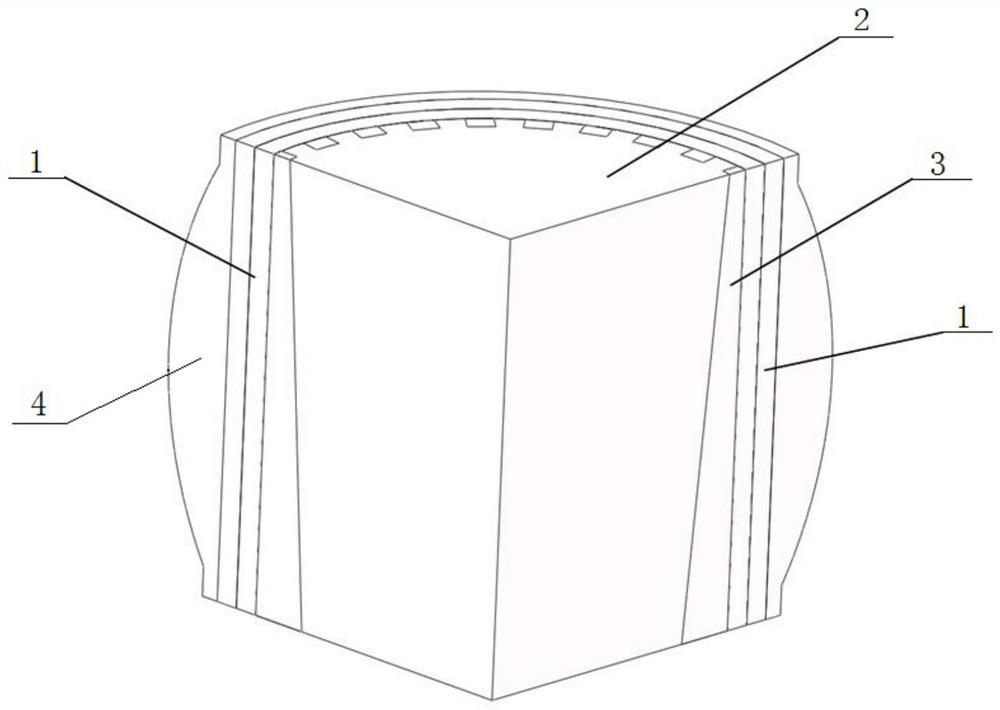

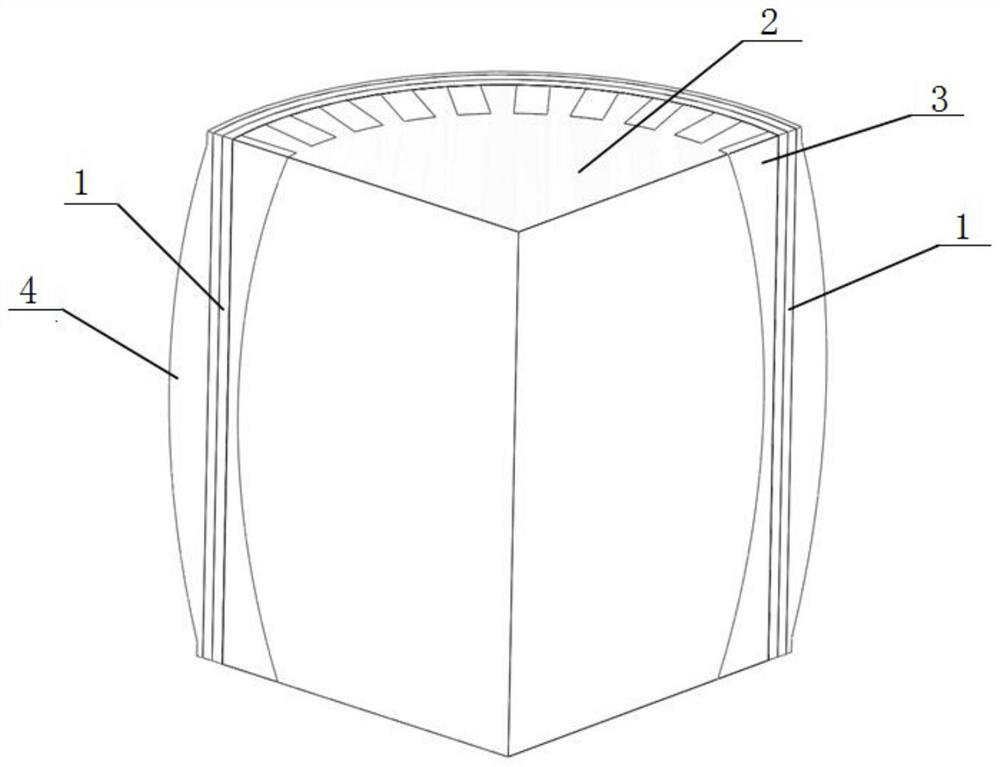

Transmitting-receiving underwater transducer

InactiveCN102708851AImprove sound absorptionFix stability issuesSound producing devicesElectricityTransducer

The invention relates to an ultrasonic transducer for flow detection, in particular to a transmitting-receiving underwater transducer which comprises a PPS (polyphenylene sulfite) housing, a piezoelectric chip, a backing layer and a matching adhesive glue, wherein a clamping spring, the backing layer and the piezoelectric chip are arranged in the space of the PPS housing from the inside out; the clamping spring is embedded into a clamping groove of the housing; the backing layer is made of sound absorbing rubber; and the piezoelectric chip and the housing are connected together through the matching adhesive glue mixed with a high-impedance material. Compared with the prior art, the piezoelectric chip and the backing layer are fixed and pressed tightly through the clamping spring so as to achieve a good sound absorbing effect of the backing layer and solve the problems that the output signal is unstable and the backing layer is not firm in bonding and easy to disengage due to the interference of the back reflection signal; and moreover, the piezoelectric chip and the PPS housing are connected together through the matching adhesive glue so as to realize the two-stage acoustic impedance matching of the chip and the liquid, and both the signal conversion ability and output signal stability are effectively improved.

Owner:唐山济邦节能科技有限公司

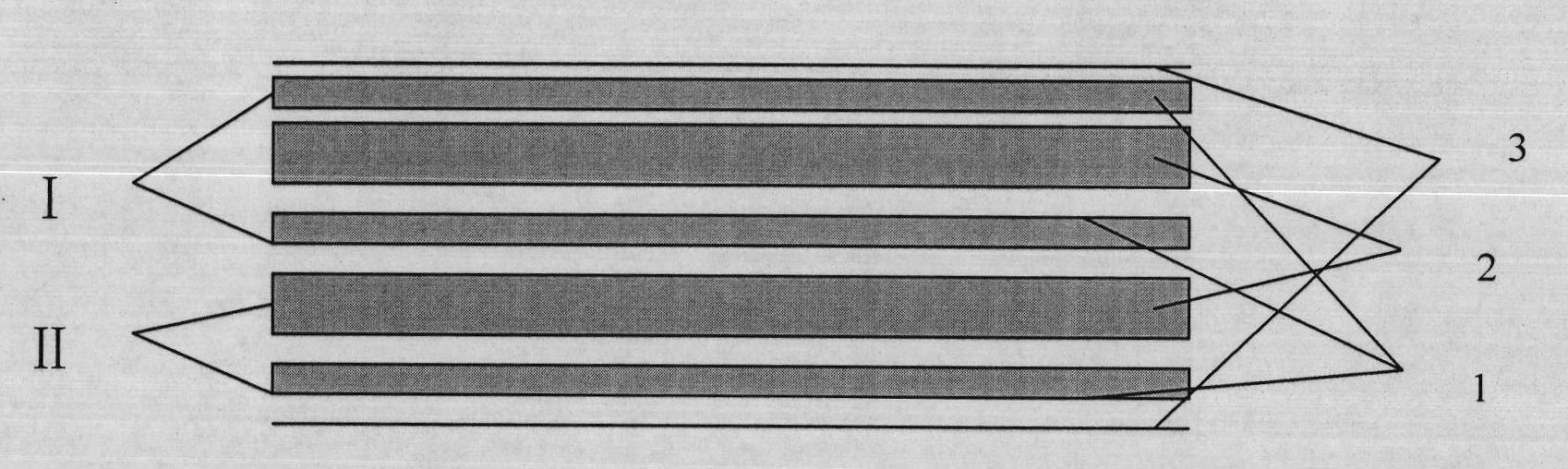

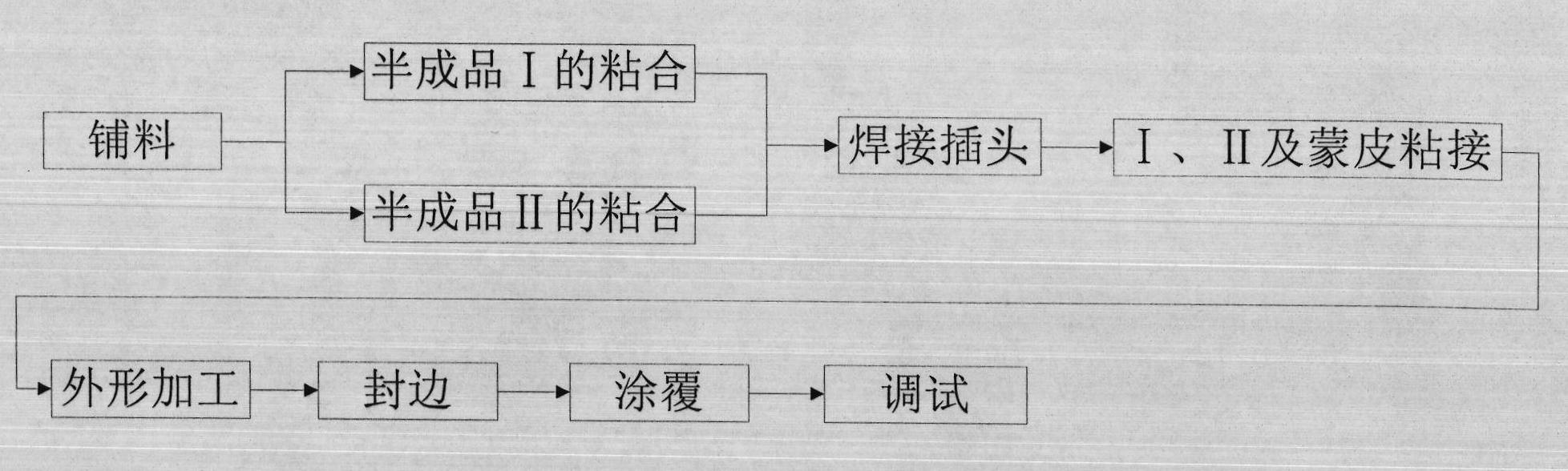

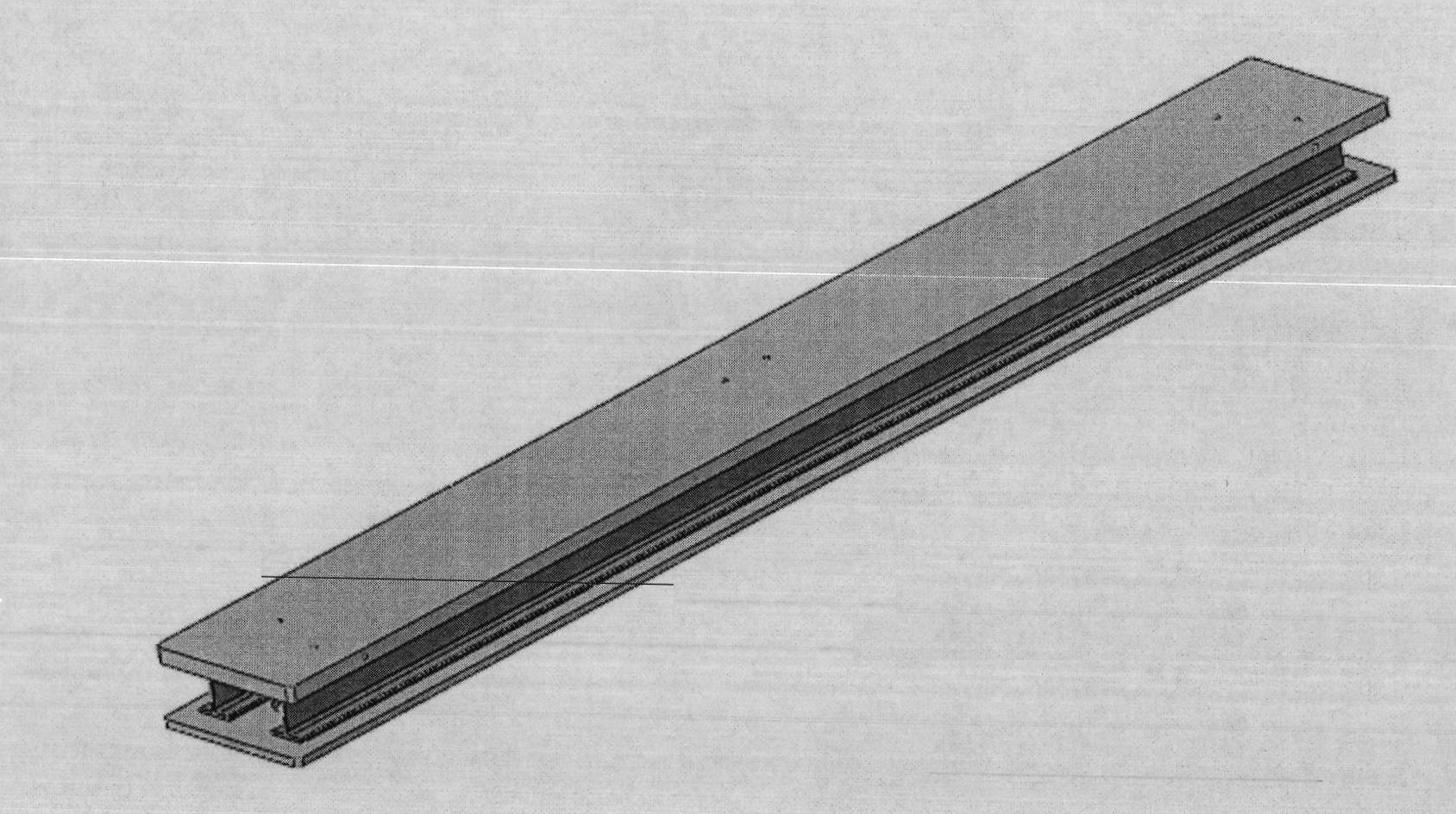

Composite material stripline antenna processing method

InactiveCN102157786ASolve the stickinessSolve processabilityRadiating elements structural formsL&D processTime parameter

The invention relates to a composite material stripline antenna processing method. The method comprises the following processes of: selecting an antenna material; designing a special mould; determining process parameters; and manufacturing an antenna according to a processing flow. The method comprises the following specific processes of: (1) selecting the antenna material, namely selecting polyether polyimide foam as a core material, selecting an acrylic adhesive film as an adhesive film, and selecting intermediate temperate cured flame retardant epoxy aramid fabric prepreg as a skin; (2) designing the mould, namely designing a main mould used for performing layering, vacuum bag package and curing of antenna processing; designing an auxiliary mould used for smoothing a layer to ensure the requirement on the flatness of surface of the antenna; and designing a cutting mould to serve as a standard template used for cutting to ensure the consistency of the sizes when cutting the antenna material; and (3) determining the process parameters, namely acquiring a sandwich bonding curve and a skin bonding curve through experiments for determining curing temperature and time parameters of each process to ensure the process consistency of the antenna. The processed antenna has low antenna weight and low cost, meets electrical performance requirement and mechanical performance requirement, and passes various environmental tests of products.

Owner:中国兵器工业第二〇六研究所

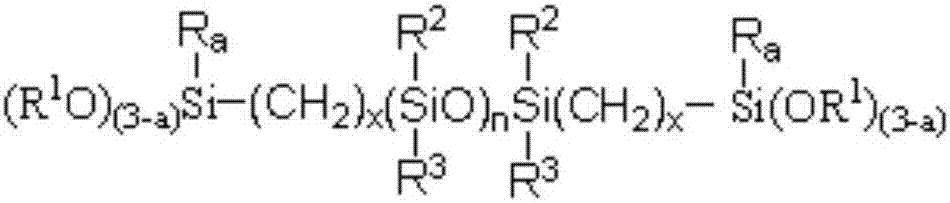

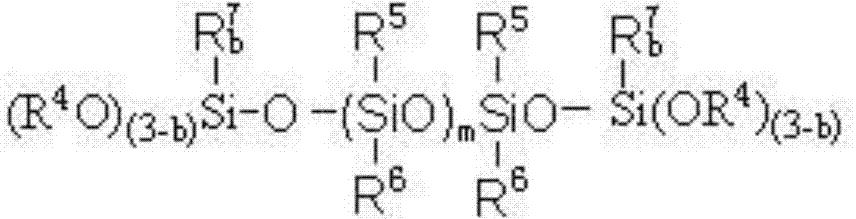

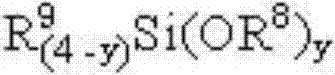

Dealcoholization type storage-resistant RTV electronic coating glue and preparation method thereof

ActiveCN107513367ASolve storage stabilityGood adhesionNon-macromolecular adhesive additivesAdhesion forceSolvent free

The invention discloses dealcoholization type storage-resistant RTV electronic coating glue and a preparation method thereof. The electronic coating glue is prepared by mixing an alkoxy-terminated polysiloxane base polymer, an inorganic reinforcing filler, a polyalkoxy silane crosslinking agent, a silane coupling agent and a catalyst in a certain mass ratio, wherein the alkoxy-terminated polysiloxane base polymer is prepared by mixing a base polymer (I) with a base polymer (II). According to the dealcoholization type storage-resistant RTV electronic coating glue, the problem that dealcoholization type RTV electronic coating glue is poor in storage stability is solved; the preparation method is simple and feasible, and the glue is solvent-free and environment-friendly and has excellent flowability; and after being cured, the glue has very good electrical insulating property, tensile strength and transparency, has strong adhesion force to a PCB and can meet 'three-prevention' requirements of the PCB.

Owner:CHENGDU GUIBAO NEW MATERIAL

Novel photovoltaic assembly structure

InactiveCN103354249AImprove electrical insulation strengthSolve the cooling problemPhotovoltaic energy generationSemiconductor devicesPolyethylene glycolMetal sheet

The invention discloses a photovoltaic assembly structure of a photovoltaic building part. The structure successively comprises a glass layer, a solar cell and a backboard from top to bottom. A backboard material is a metal sheet, glass or composite sheet material. An insulation film layer is arranged between the solar cell and the backboard. The solar cell and the insulation film layer are connected through an EVA rubber sheet. The insulation film layer and the backboard are connected through the EVA rubber sheet or an adhesion agent. The insulation film layer is a polyimide, polyethylene glycol terephthalate and polypropylene film or an organic silicon film. By using the photovoltaic assembly structure of the photovoltaic building part of the invention, an insulating property is good, a heat dissipation effect is good and production manufacturing cost is low; structure intensity of the photovoltaic assembly is increased; simultaneously, problems that bonding of the related materials is difficult, the EVA is easy to age and weather-proof performance is poor are solved; the photovoltaic assembly structure and other materials can be combined and form the photovoltaic building part and other products.

Owner:合肥微纳电工有限公司

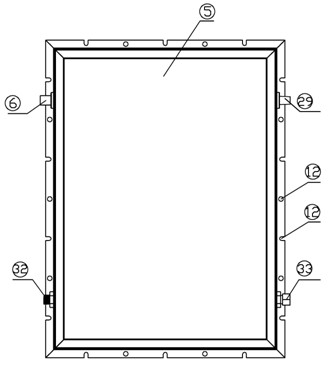

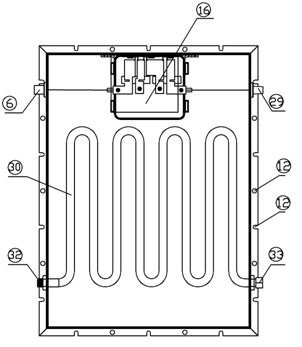

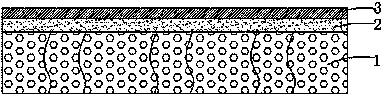

Photovoltaic honeycomb component module with heat collecting pipe

ActiveCN102593218ALow costSolve the cooling problemSolar heating energySolar heat devicesAluminum honeycombEngineering

The invention relates to a photovoltaic honeycomb component module with a heat collecting pipe, comprising a photovoltaic component formed by a photovoltaic plate, a connector and a connecting box, wherein a solar heat collecting pipe, a honeycomb core layer and a back plate are arranged at the lower layer of the photovoltaic plate in sequence and are adhered through a hot melt adhesive membrane to form a main body structure of the component module; an aluminum alloy frame is arranged at the periphery of the main body structure of the component module; the connector includes a positive electrode connector and a negative electrode connector; two ports of the solar heat collecting pipe are provided with an inlet joint and an entrance joint which are respectively arranged at the two sides ofthe component module; and the connecting box is arranged inside the honeycomb core layer. The photovoltaic honeycomb component module integrates the advantages of photovoltaic batteries and the heat collecting technology, has all the performance characteristics of aluminum honeycomb plates, better solves the problems of the peeling of the photovoltaic component and materials and heat dissipation of the diode in the connecting box and the like, and has the advantages of standard modular structure design, strong integrity, convenience in install and relatively lower cost.

Owner:合肥微纳电工有限公司

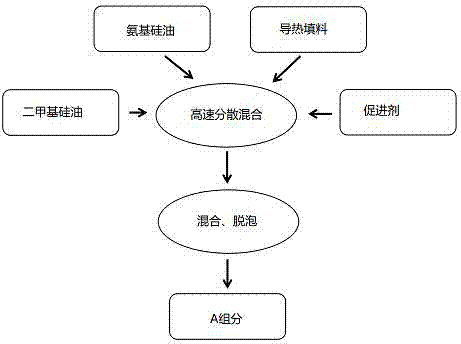

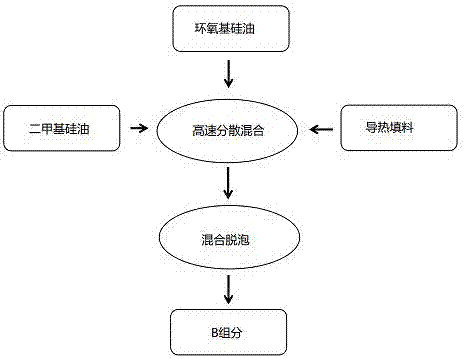

Two-component pouring sealant and preparation method thereof

InactiveCN107325782ASolve the stickinessSolve the shortcomings of not being resistant to earthquakes and high and low temperaturesNon-macromolecular adhesive additivesBoron nitrideSealant

The present invention relates to a two-component pouring sealant and a preparation method thereof, wherein the raw materials comprise, by weight, a component A and a component B, wherein the component A comprises, by weight, 100 parts of amino silicone oil, 10-50 parts of dimethyl silicone oil, 10-50 parts of silicon micro-powder, 10-200 parts of alumina, 5-10 parts of boron nitride, and 0.2-6 parts of an accelerator, and the component B comprises, by weight, 100 parts of epoxy silicone oil, 10-50 parts of dimethyl silicone oil, 10-50 parts of silicon micro-powder, 10-200 parts of alumina, and 5-10 parts of boron nitride. The preparation method comprises: (1) preparing the component A: carrying out high-speed dispersed mixing on amino silicone oil, silicon micro-powder, alumina and boron nitride, adding dimethyl silicone oil and an accelerator added to the obtained mixture, continuously mixing, and carrying out deaeration to obtain the component A; and (2) preparaing the component B: carrying out high-speed dispersed mixing on amino silicone oil, silicon micro-powder, alumina and boron nitride, adding dimethyl silicone oil to the obtained mixture, continuously mixing, and carrying out deaeration to obtain the component B.

Owner:GOLOHO TECH CHANGZHOU CO LTD

Mixed coating lithium battery diaphragm and preparation method thereof

PendingCN111129393AImprove thermal safetyImprove wettabilitySecondary cellsCell component detailsAdhesiveLithium-ion battery

The invention provides a lithium ion battery composite diaphragm and a preparation method thereof, relating to the technical field of batteries. The lithium ion battery composite diaphragm comprises abase film and an aramid fiber coating and the water-based PVDF composite coating which coat one side of the base film; the water-based PVDF composite coating is prepared from, by weight, 1-10% of a base material and the balance of deionized water, and the base material is prepared from PVDF, a dispersing agent, a thickening agent, an adhesive, nano aramid fiber powder, DMAC or DMF, a cosolvent, an emulsifying agent and a pore forming agent. Compared with the prior art, the aramid fiber coating diaphragm disclosed by the invention has better heat resistance, stability, electrical insulating property and flame retardant property on the whole; the PVDF coating is obtained by coating and drying water-based PVDF slurry, the traditional process that acetone and other oily substances serve as solvents of an existing PVDF-coated lithium ion battery diaphragm is abandoned, and the safety performance, the rate capability and the cycle performance of a lithium ion battery prepared from the diaphragm are obviously improved.

Owner:高芳

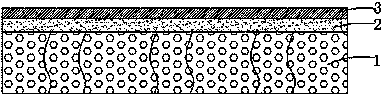

Method for co-bonding embedded copper strip and composite prepreg

The invention discloses a method for co-bonding an embedded copper strip and a composite prepreg. The embedded copper strip and a glass fiber-reinforced resin matrix composite material are co-bonded through a vacuum bag-autoclave molding technology. In the prepreg paving process, the copper strip is bonded to the laid and cured prepreg through a binder and the prepreg is paved and cured in two processes so that the prepreg is formed. The method bonds the pre-cured prepreg and the copper strip and solves the problem that the cured prepreg has no rigidity so that the copper strip is difficult tofix and the prepreg easily deforms in the copper strip bonding process.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

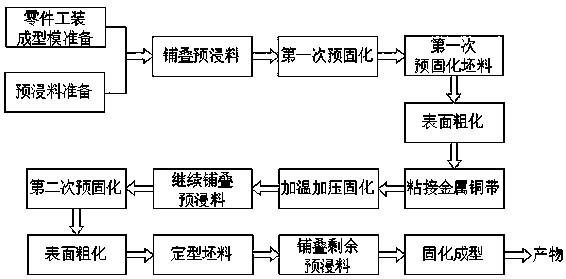

Modified polyurethane adhesive, composite waterproof adhesive strip comprising modified polyurethane adhesive, and preparation method and application thereof

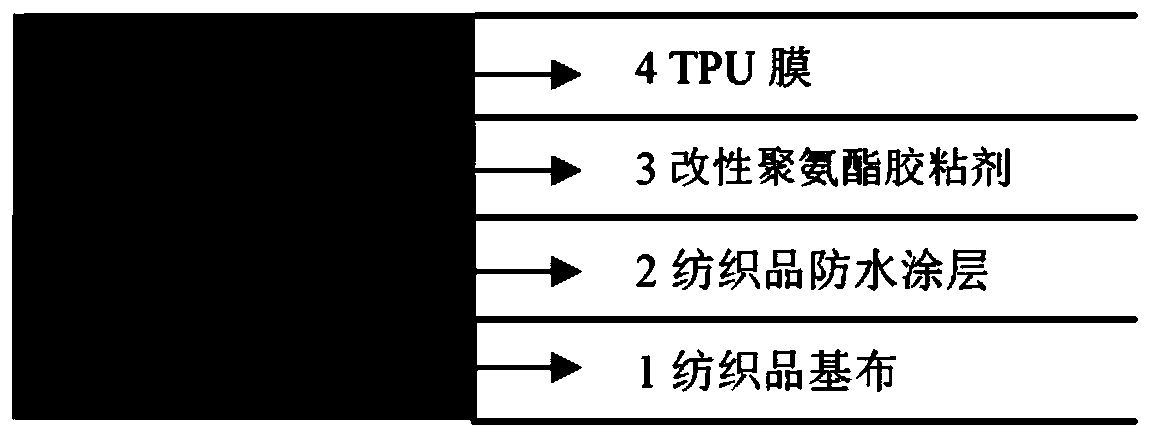

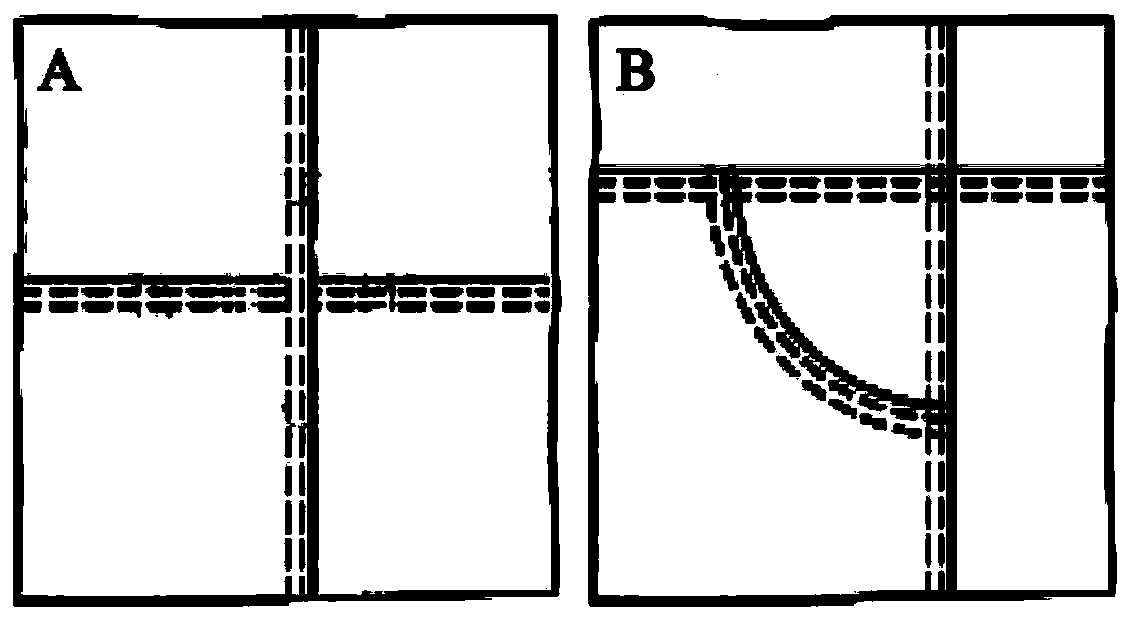

ActiveCN109796921AHigh bonding strengthAdhesive applicationNon-macromolecular adhesive additivesFilm/foil adhesivesPolyurethane adhesiveBond strength

The invention discloses a modified polyurethane adhesive, a composite waterproof adhesive strip comprising the modified polyurethane adhesive, a preparation method and an application thereof; the modified polyurethane adhesive is prepared from the following components in parts by weight: 80-120 parts of TPU particles, 8-30 parts of PES particles, 0.5-3 parts of polycarbodiimide, 0.5-5 parts of closed crosslinking agent, 0.5-5 parts of coupling agent and 0.1-1 part of antioxidant. The modified polyurethane adhesive is extruded by a casting machine and thermally compounded on one side of the TPUfilm to obtain the composite waterproof adhesive strip, and the composite waterproof adhesive strip is soft, good in elasticity, good in water washing resistance, dry cleaning performance and water pressure resistance, large in bonding strength to coatings such as TPE, hydrophilic PU, TPFE and the like of windproof and waterproof clothes; the composite waterproof adhesive strip is not capable offalling off at the edges, so that the composite waterproof adhesive strip can be applied to outdoor sports clothes, particularly windproof and waterproof clothes, and has a good application prospect.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

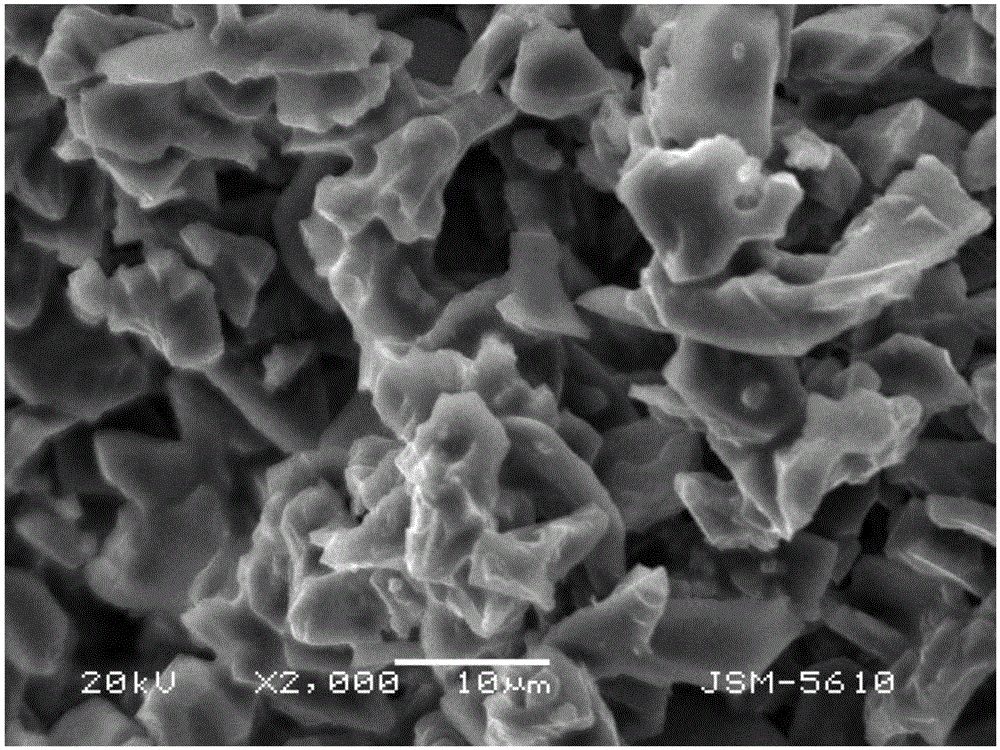

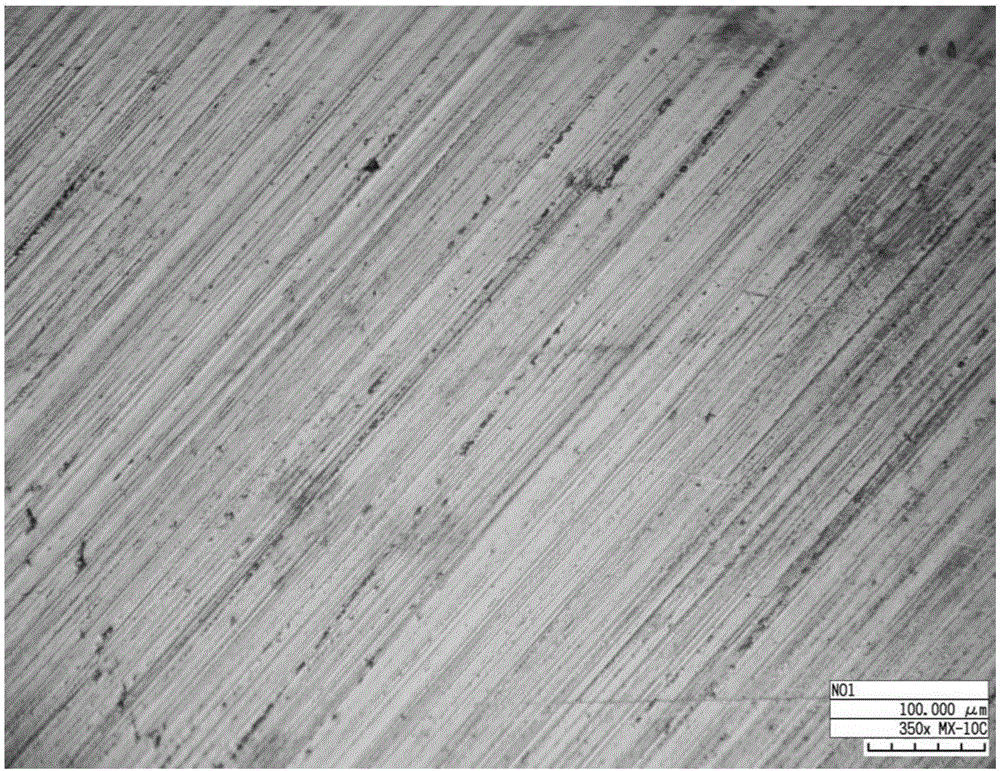

Preparation technology of cubic boron nitride accumulation abrasive material

ActiveCN106541339AHigh strengthSolve the problem of difficult wetting CBN abrasiveAbrasion apparatusGrinding devicesAdhesiveSingle crystal

The invention discloses a preparation technology of cubic boron nitride accumulation abrasive material. The preparation technology comprises the following steps: preparing an adhesive from titanium dioxide sol, water glass solution and boric acid; compounding the adhesive with yellow dextrin powder and cubic boron nitride abrasive material, carrying out ball-milling and sieving, and drying the sieved material to obtain dry pressing material of the cubic boron nitride accumulation abrasive material; carrying out compression moulding, drying, sintering and cooling on the dry pressing material of the cubic boron nitride accumulation abrasive material to obtain block of the cubic boron nitride accumulation abrasive material, and levigating the block to obtain the cubic boron nitride accumulation abrasive material. Compared with cubic boron nitride single crystal abrasive material, the cubic boron nitride accumulation abrasive material has more excellent grinding property.

Owner:HUNAN UNIV

Cutter for electrical adhesive tape

InactiveCN106966222ASolve the problem of cutting troubleSolve stickinessArticle deliveryAdhesive beltElectrical tape

The invention discloses a cutter for electrical tape, which comprises a tape fixing frame and a cutting device. The tape fixing frame includes a baffle, a connecting shaft and a rotating drum, the connecting shaft is fixed and vertically arranged at the center of the inner surface of the baffle, and the rotating drum Sleeved on the outside of the connecting shaft and connected with the connecting shaft in rotation; the cutting device includes a fixed plate, a bottom plate and a cutting plate, the fixed plate and the inner surface of the baffle are fixedly welded, the bottom plate and the fixed plate are vertically fixedly connected, and the upper surface of the bottom plate is provided with a bump and the cutting groove, the protrusion is located inside the cutting groove, a slide bar is arranged inside the fixed plate, and a spring is set on the outer end of the slide bar, and the cutting plate is connected with the slide bar through a buckle fixed on its side end, and the buckle is set on the slide The outer end of the rod and the lower surface of the cutting plate are fixed with a cutter matching the cutting groove structure, and the inner side of the cutter is provided with a through groove matching the bump structure; the present invention has the advantages of reasonable structure and convenient portability and use.

Owner:HENAN YAAN ELECTRICAL INSULATION MATERIAL PLANT CO LTD

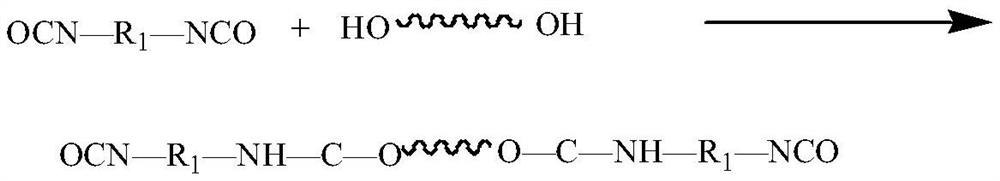

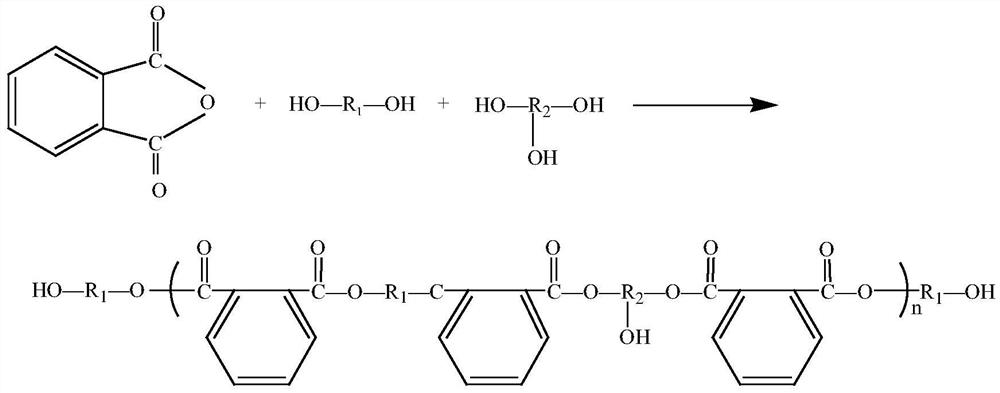

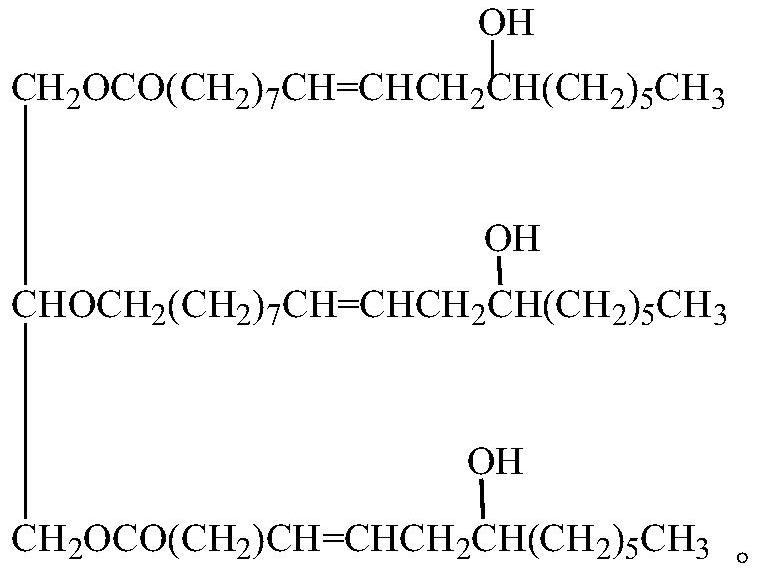

Two-component solvent-free polyurethane adhesive and preparation method thereof

PendingCN113583611ALow viscositySolve viscosityPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to the technical field of polyurethane adhesives, in particular to a two-component solvent-free polyurethane adhesive and a preparation method thereof. The two-component solvent-free polyurethane adhesive is composed of a component A and a component B according to the mass ratio of 1: 1 to 3: 2. The component A is an isocyanate-terminated prepolymer prepared through a reaction of polyisocyanate and polyether glycol. The component B is castor oil modified polyester polyol prepared by reacting castor oil with phthalic anhydride, small molecular dibasic acid and small molecular dihydric alcohol under the action of a catalyst. The two-component solvent-free polyurethane adhesive has low viscosity, high shear strength and high flame retardant property, and overcomes the defects of poor adhesive strength and poor high temperature resistance of a polyurethane adhesive in a flexible package.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

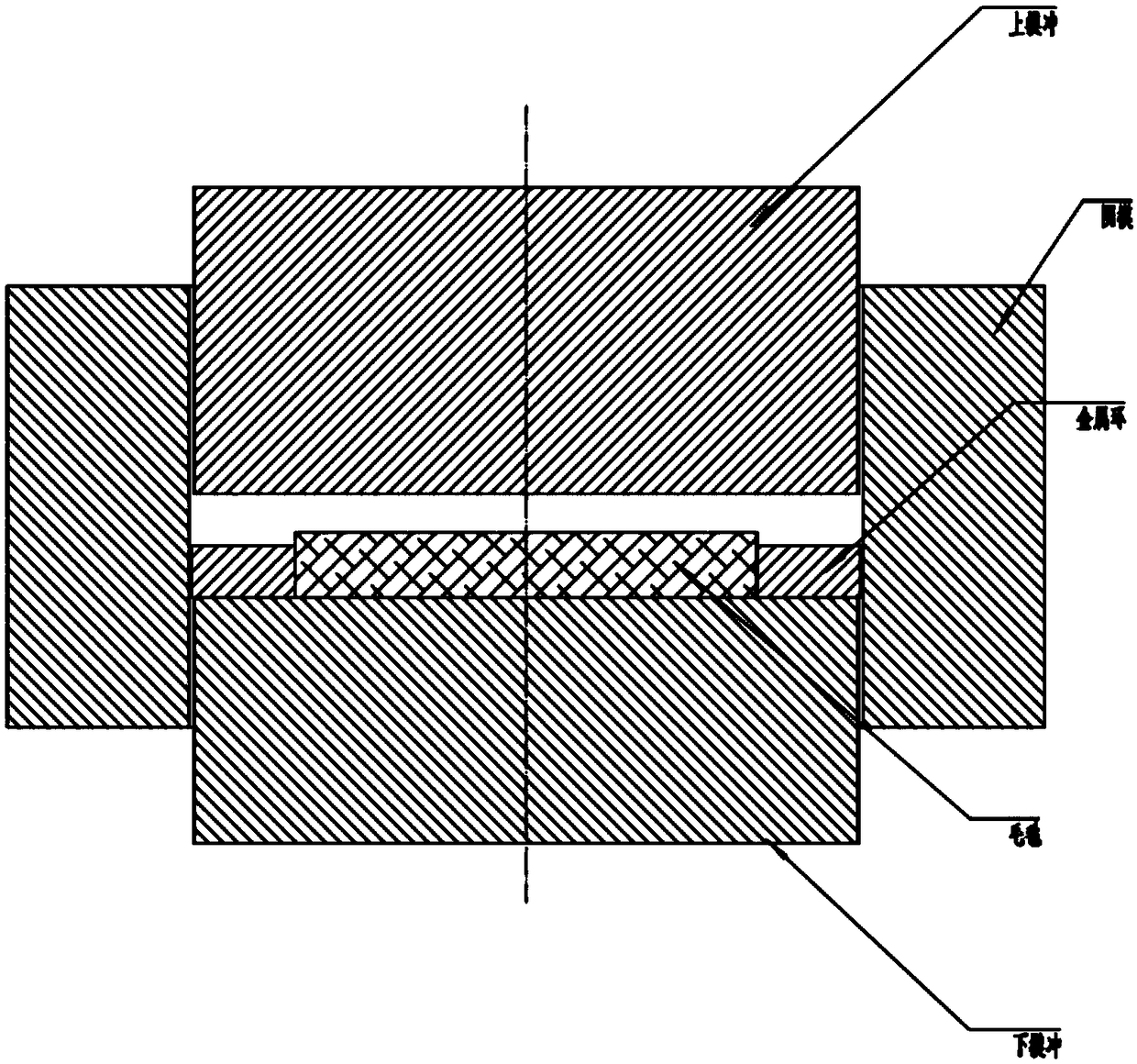

Method for preparing metal fiber sintered felt by spark plasma sintering

The invention relates to a preparation method of metal fiber sintered felt used in the fields of environmental protection, chemical industry, high-temperature dust removal, automobile tail gas purification, burners and the like. The preparation method comprises the steps that a sintered metal fiber felt and a conductive gasket are placed into a sintering cavity; vacuumizing is carried out; then spark plasma sintering is carried out for 5 to 15 min; cooling is carried out; products are obtained; and when the spark plasma sintering is carried out, the sintering temperature is controlled to be 900-1300 DEG C. The preparation method is the first attempt to rapidly and efficiently prepare the metal fiber sintered felt with high porosity, high air permeability and high mechanical properties by directly adopting a spark plasma sintering method. The quality of the obtained products is stable and controllable; and the operation is simple and is convenient for large-scale industrial application.

Owner:HUNAN HUITONG ADVANCED MATERIALS

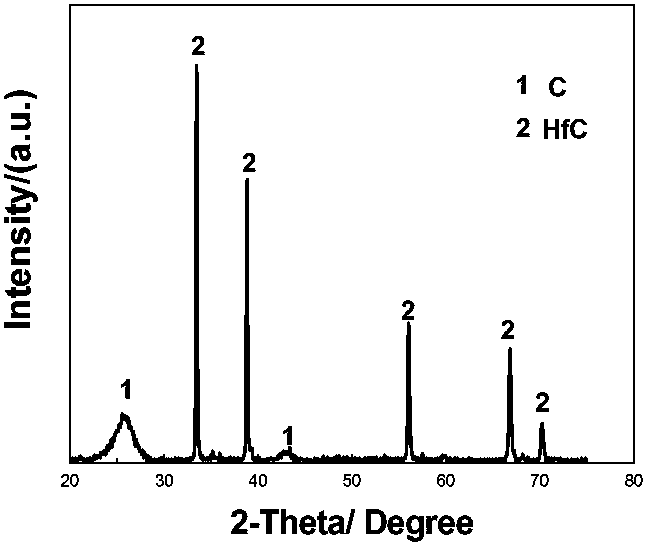

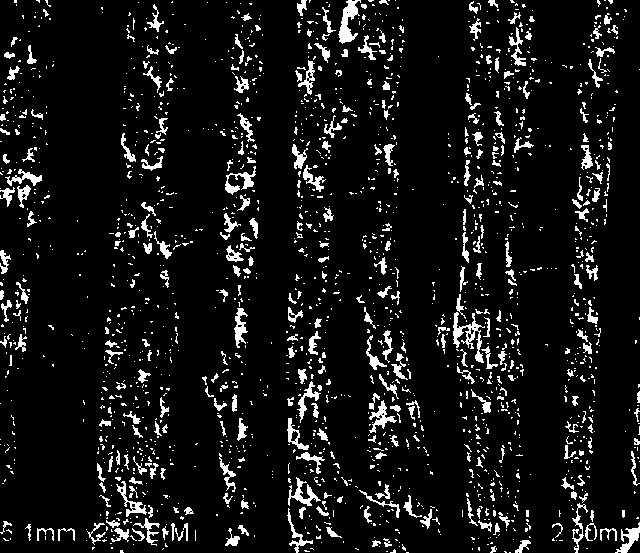

High-efficiency and low-cost near-net forming preparation method of C/C-HfC composite material

The invention provides a high-efficiency and low-cost near-net forming preparation method of a C / C-HfC composite material. The preparation method specifically comprises the following steps: (1) preparation of a carbon fiber preform with a fiber protection layer; (2) preparation of a porous C / C composite material preform; (3) preparation of soaking slurry; (4) preparation of coating slurry; and (5)preparation of the C / C-HfC composite material. Compared with the prior art, the preparation technology provided by the invention can solve the problem that residual metal after melt reaction infiltration is easy to adhere to the prepared composite material, and can realize the near-net forming of a C / C-HfC carbon-ceramic composite material; by combination of slurry soaking and surface slurry coating, the content of metal hafnium introduced into the C / C composite material can be reasonably controlled, and the process controllability is high; and the process is short in period and high in efficiency, and the prepared carbon-ceramic composite material is low in cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

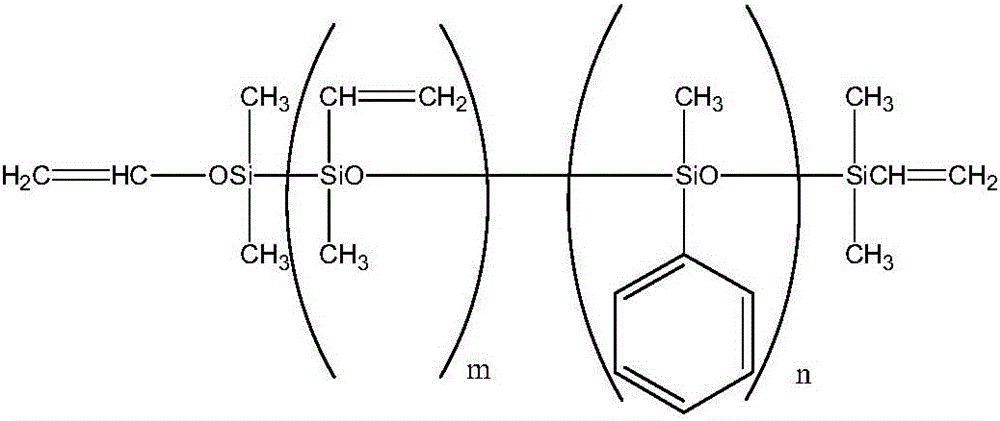

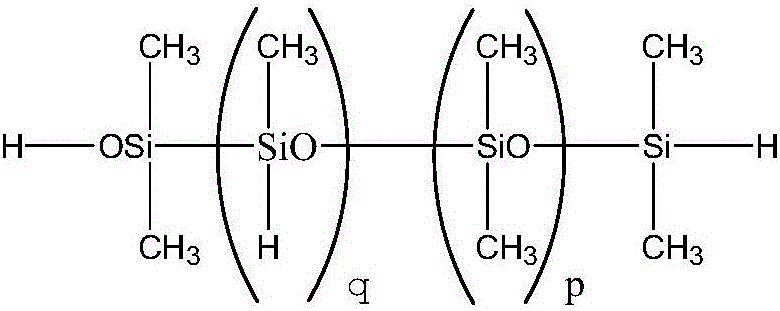

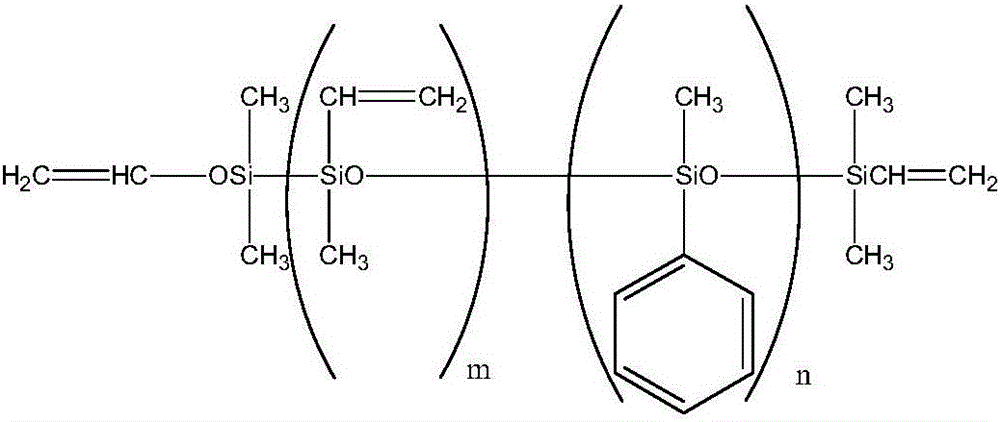

A kind of making method of silicone glove and polyorganosiloxane mixed solution

The invention relates to a manufacture method of silica gel gloves and a polysiloxane mixed liquor, belongs to the technical field of glove materials and products and aims at solving the problems of short operating time of raw materials and poor low-temperature resistance of the existing silica gel gloves. The mixed liquor comprises polysiloxane containing vinyl and polysiloxane containing a Si-H bond, and also comprises 0.3%-1.2% of platinum catalyst and 1.0%-3.0% of methyl vinyl cyclotetrasiloxane, wherein the weight ratio of the polysiloxane containing vinyl to the polysiloxane containing the Si-H bond is (8-12):1. The mixed liquor is taken as the raw material, and the silica gel gloves are prepared through steps of molding by pouring the pulp and / or steeping the pulp, vulcanizing and post-processing. The method can prolong the operating time of the raw material, so that the gloves resist high and low temperature; the method realizes preparation of the silica gel gloves by pouring and steeping, so that the gloves have flexible, comfortable and waterproof effects; when the method is used for preparing the silica gel gloves with linings, the linings have high bonding strength and are not easy to strip off.

Owner:ZHEJIANG EAST ASIA GLOVE CO LTD

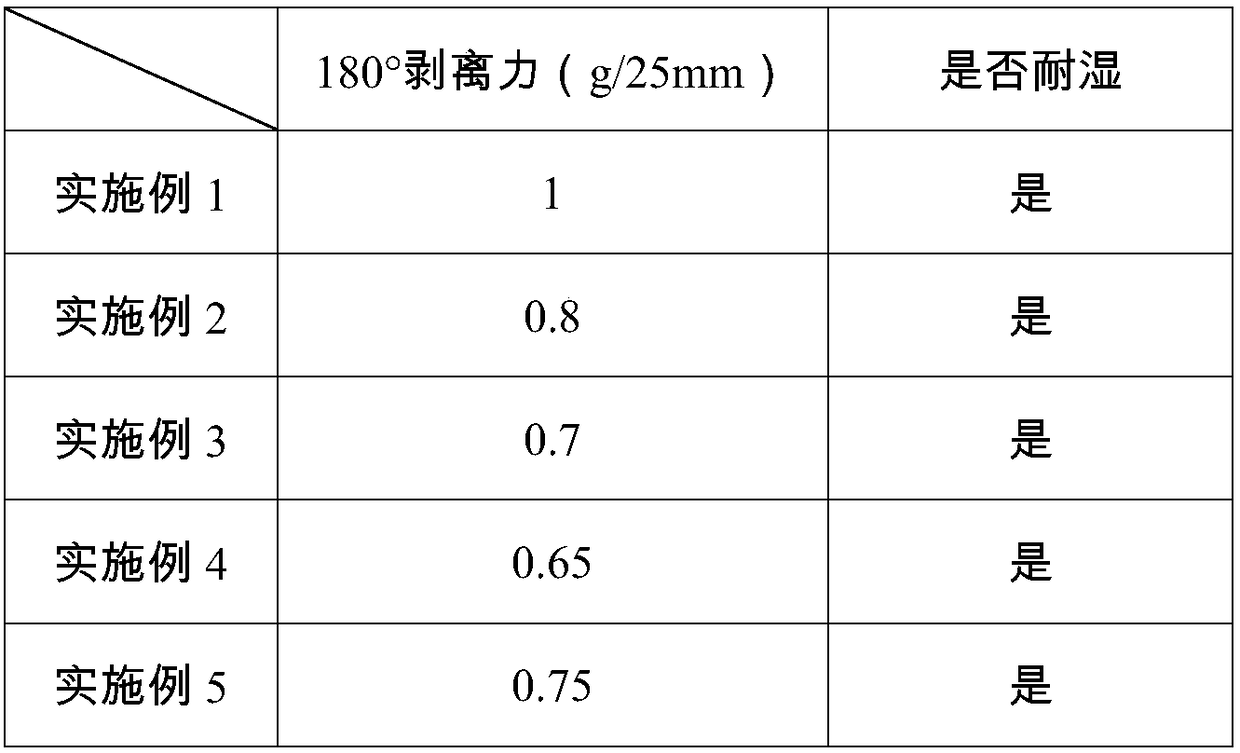

High performance two-component polyurethane pressure sensitive adhesive and preparation method and application thereof

InactiveCN108949088ALow viscositySmall peeling forcePolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesSolventPeel force

The invention discloses a high performance two-component polyurethane pressure sensitive adhesive and a preparation method and application thereof. The high performance two-component polyurethane pressure sensitive adhesive comprises a component (A) and a component (B). The component (A) is a glue liquid prepared from 10-12% by weight of a hard monomer, 24-30% by weight of a soft monomer, 2.5-4% by weight of a chain extender, 0.08-0.12% by weight of an organotin catalyst and 54-60% by weight of a solvent. The component (B) is an epoxy curing agent. The weight of the component (B) is 0.1% thatof the component (A). The high performance two-component polyurethane pressure sensitive adhesive has low adhesion, low peeling force and good moisture resistance.

Owner:WUXI HAITE NEW MATERIAL RES INST

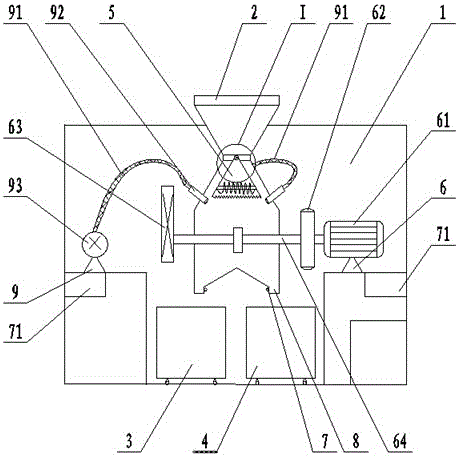

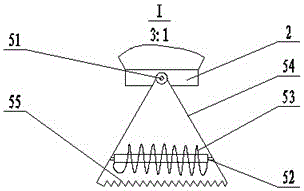

Novel riffle divider for material division

InactiveCN105928756ASolve the problem of shrinking operationsUniform dischargePreparing sample for investigationCouplingControl theory

The invention discloses a novel riffle divider for material division, belonging to the technical field of division equipment. The novel riffle divider for material division comprises a division cavity, a division shield, a feeder, a preserved-material bucket, a discarded-material bucket, a vibrator and a halving bucket, wherein the feeder is arranged on the upper side of the division cavity; the halving bucket is arranged at the lower side of the feeder; the preserved-material bucket and the discarded-material bucket are respectively arranged at the left and right sides of the halving bucket; the vibrator is mounted on the middle part of the halving bucket and comprises a motor, a shaft coupling, an eccentric wheel and a rotating shaft; and the shaft coupling is connected with the eccentric wheel through the rotating shaft. The riffle divider provided by the invention overcomes problems in rapid division operation when a variety of materials are great in moisture content and strong in bonding performance and the problems of bonding and blocking occurred in the process of division; the division operation in the invention can be carried out in a totally enclosed state, is free of cross pollution and dust leakage, and totally accords with requirements of environmental protection; and the riffle divider provided by the invention reduces labor intensity in operation and realizes uniform discharging of a material through vibration.

Owner:陈传海

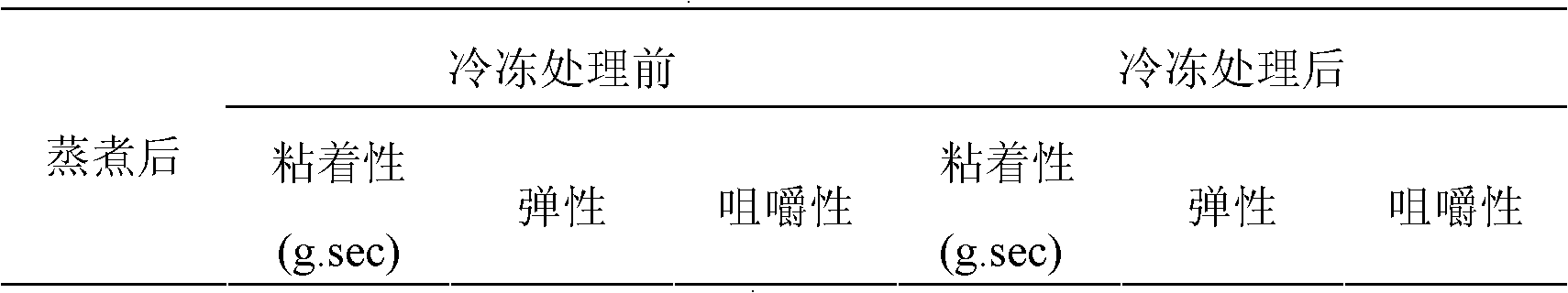

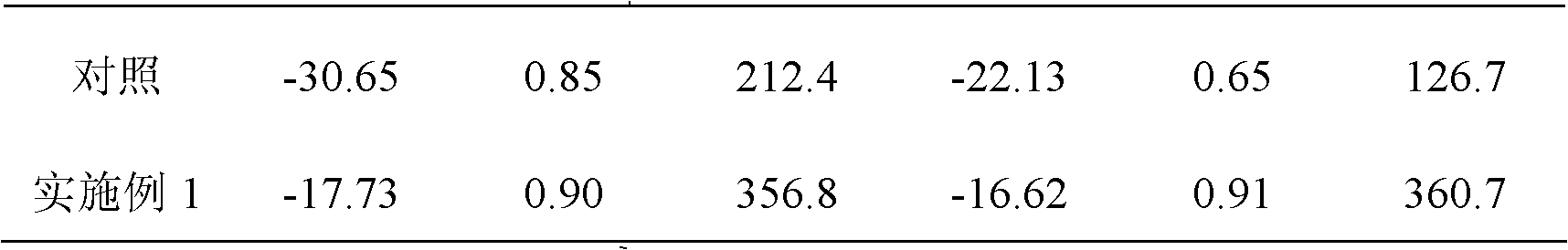

Making method of quick-freezing instant steamed vermicelli rolls

The invention discloses a making method of quick-freezing instant steamed vermicelli rolls. The making method comprises the following steps of: cleaning aging rice with water, soaking for 7-10h, pouring into a rice grinding machine for grinding into powder; in the terms of mass parts, dissolving 100 parts of rice flour, 1 part of raw potato powder and 5-30 parts of etherified and esterified arrowroot starch into water with the mass three times of the total mass, stirring into rice milk; pouring stirred rice milk on a steaming tray or cotton cloth, with the thickness being 1-1.5mm, then placing fillings on the rice milk, stewing until reaching medium to well done, then pulling out the steaming tray or cotton cloth, cutting sheet jelly and rolling into strips, coating anti-adhering grease on the surface of the strips; and placing the steamed vermicelli rolls coated with the grease in an environment of -40 DEG C for quick-freezing, enabling the temperature to reach -18DEG C and below within 30min, so that the quick-freezing instant steamed vermicelli rolls are made. According to the making method, the shelf life of the quick-freezing instant steamed vermicelli rolls is greatly prolonged while the elasticity and the chewiness and other edible indexes of the quick-freezing instant steamed vermicelli rolls are improved.

Owner:SOUTH CHINA UNIV OF TECH

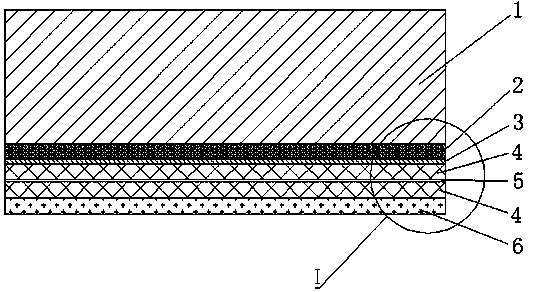

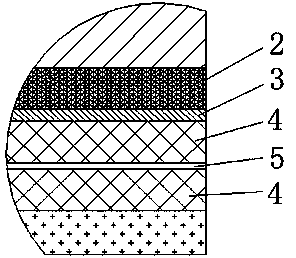

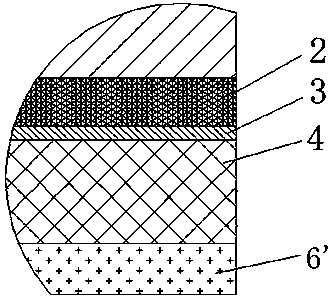

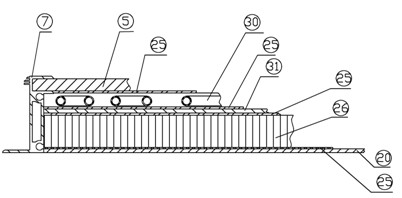

High-bandwidth ultrasonic transducer and preparation method thereof

ActiveCN112958420AHigh bandwidthImprove image qualityMechanical vibrations separationUltrasonic beamHigh bandwidth

The invention relates to the technical field of ultrasonic transducers, in particular to a high-bandwidth ultrasonic transducer and a preparation method thereof. The high-bandwidth ultrasonic transducer comprises matching layers, a backing layer, a plurality of piezoelectric array elements arranged in an array mode and an acoustic lens used for ultrasonic beam focusing; each piezoelectric array element is provided with a first electrode surface and a second electrode surface arranged in a plane mode, the second electrode surface is an emitting surface and is perpendicular to the polarization direction, and the distance between the first electrode surface and the second electrode surface changes regularly; the backing layer, the piezoelectric array elements, the matching layers and the acoustic lens are sequentially arranged; and the first electrode surfaces are attached to the backing layer, and the second electrode surfaces are attached to the matching layer. According to the high-bandwidth ultrasonic transducer, a piezoelectric unit is of a variable-thickness structure, after excitation voltage is applied, the parts, with different thicknesses, of the piezoelectric array elements vibrate at different frequencies, therefore, the bandwidth of the ultrasonic transducer is widened, the imaging quality and detection accuracy of the ultrasonic transducer are improved, and the ultrasonic transducer can be applied to harmonic imaging.

Owner:SHENZHEN UNIV

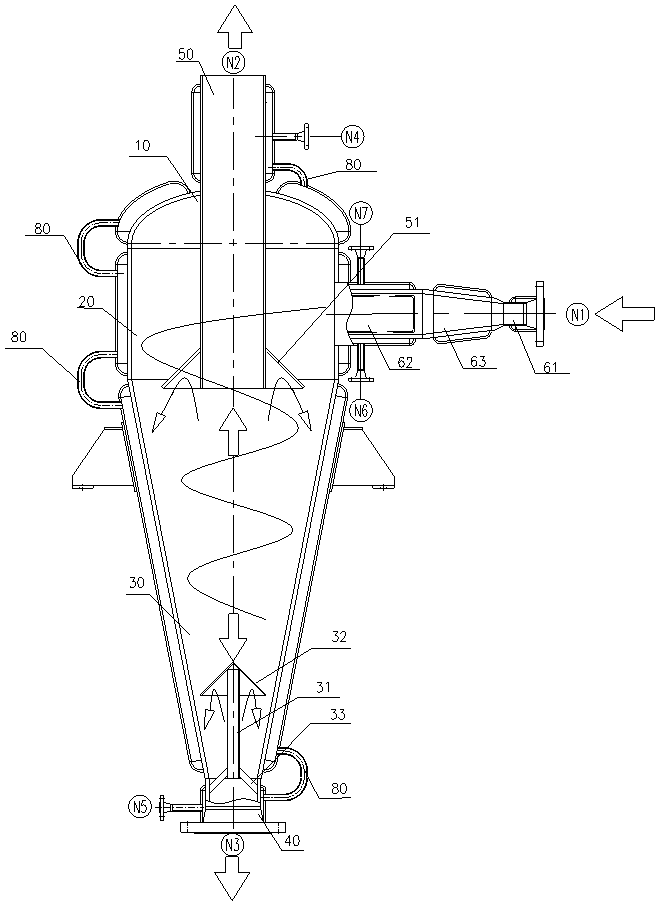

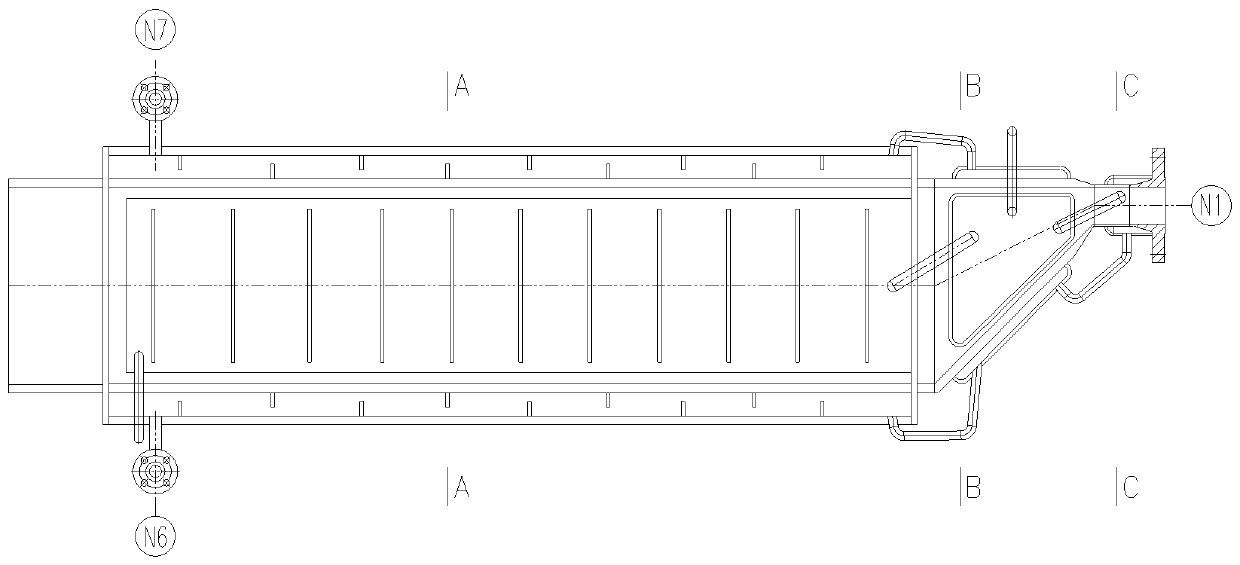

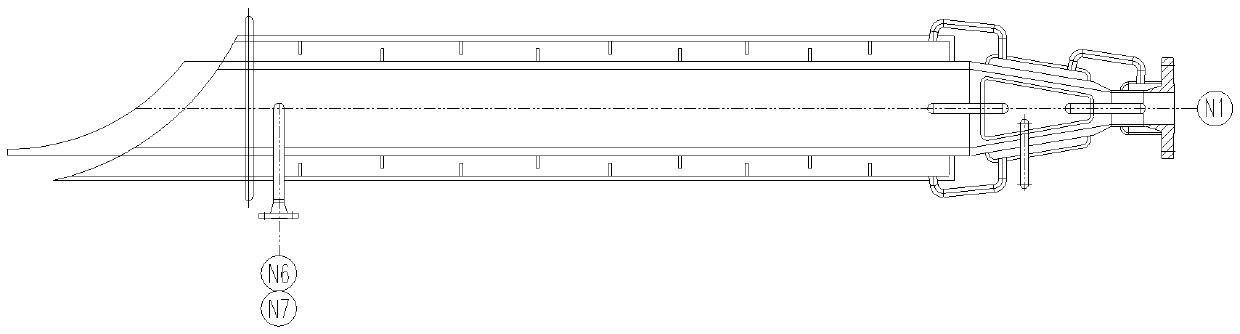

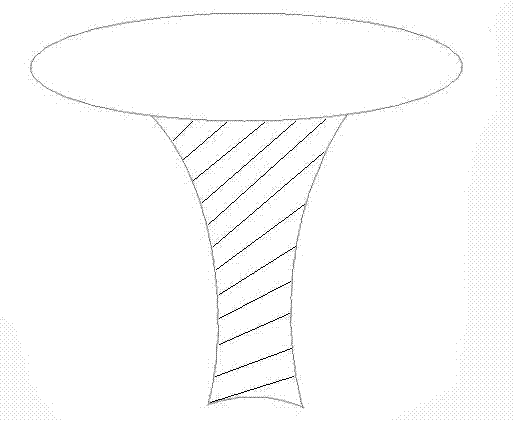

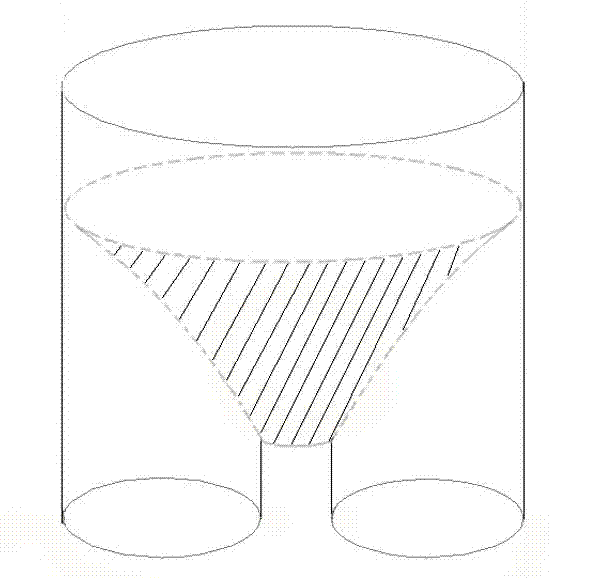

High-freezing-point medium gas-liquid separator with labyrinth-type gas inlet pipe heat-preserving device

ActiveCN109603316AImprove liquiditySolve the stickinessDispersed particle separationCycloneVapor–liquid separator

The invention relates to the technical field of gas-liquid separation devices in chemical engineering equipment, specifically to a high-freezing-point medium gas-liquid separator with a labyrinth-typegas inlet pipe heat-preserving device. The high-freezing-point medium gas-liquid separator successively comprises an elliptical seal head, a cyclone drum body and a cyclone cone body from top to bottom, wherein the elliptical seal head, the cyclone drum body, the cyclone cone body, a liquid discharging pipe and an exhaust pipe located at the exterior of the elliptical seal head are respectively sleeved by a heat-preserving sleeve to form heat-preserving cavities; a connecting circular pipe is arranged between adjacent heat-preserving cavities; a tangential gas inlet pipeline is arranged at one side of the drum body of the cyclone drum body and comprises a gas inlet circular pipe, a cone pipe and a rectangular pipe; four side surfaces of the cone pipe are respectively provided with a conepipe heat-preserving chamber; and four side surfaces of the rectangular pipe are respectively provided with a rectangular pipe heat-preserving chamber. According to the invention, heat-conductive oilenters from the heat-conductive oil inlet of a gas inlet pipe, respectively passes through the heat-preserving chambers located on four side surfaces of the cone pipe, the circular pipe heat-preserving chamber and the heat-preserving chambers located on four side surfaces of the rectangular pipe, and finally flows out from the heat-conductive oil outlet of the gas inlet pipe.

Owner:EAST CHINA ENG SCI & TECH

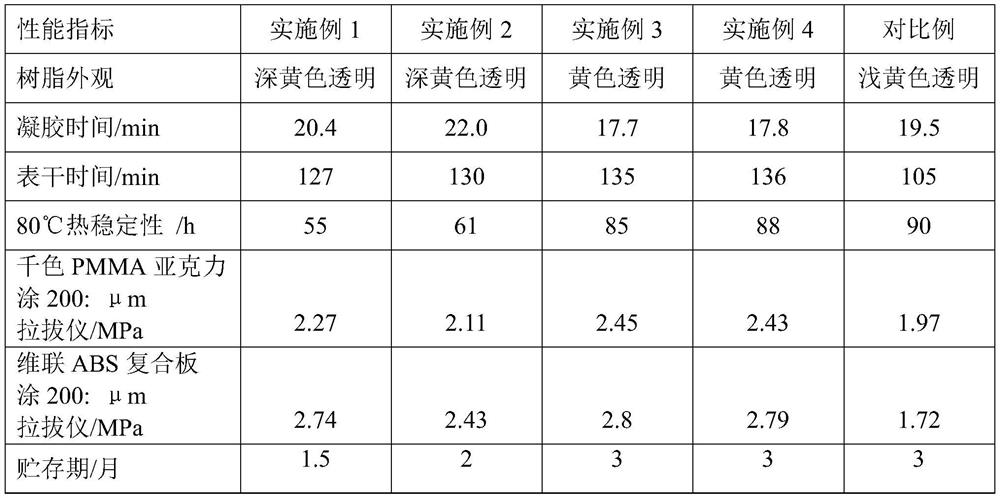

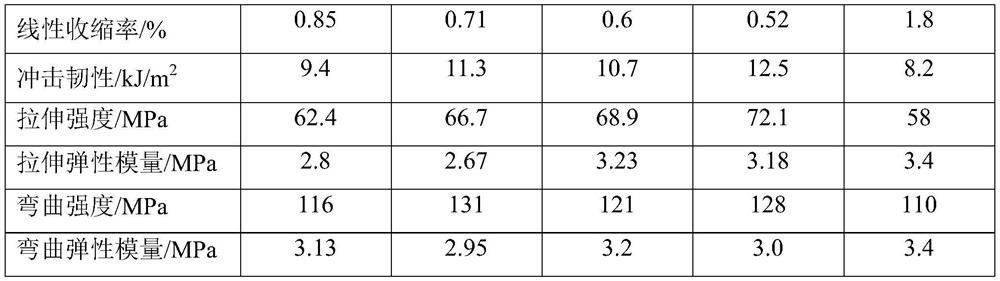

Amino-modified unsaturated polyester resin

ActiveCN111662540AGood flexibilityGood adhesionMacromolecular adhesive additivesPolymer sciencePolymethyl methacrylate

The invention discloses amino-modified unsaturated polyester resin which is synthesized by a reaction among the following components: saturated binary acid or anhydride, unsaturated binary acid or anhydride, polyhydric alcohol, an amino compound, an active diluent, a polymerization inhibitor and paraffin. According to the amino-modified unsaturated polyester resin disclosed by the invention, the shrinkage rate can be effectively reduced, the flexibility and the bonding force of the resin are improved, and particularly, the bonding force of PMMA (polymethyl methacrylate) acrylic and ABS (acrylonitrile butadiene styrene) composite boards can be greatly improved, so that the problems of poor bonding force, high shrinkage rate and poor impact toughness of the existing unsaturated polyester resin products are solved.

Owner:ZHAOQING FUTIAN CHEM IND

Epoxylite low temperature cured type high strength adhesive

InactiveCN106928891ASolve densitySolve the stickinessNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryAdhesive

The invention discloses an epoxylite low temperature cured type high strength adhesive. The epoxylite low temperature cured type high strength adhesive is prepared from, by weight, modified bisphenol A epoxy resin, modified bisphenol F epoxy resin, an -SH group modified amine curing agent, 692 epoxy active diluent, a silane coupling agent and a special accelerant. According to the epoxylite low temperature cured type high strength adhesive, the problems are solved that a common epoxylite adhesive is not sufficient in curing cross-linked density and poor in adhesive force in a low temperature environment, can be cured from a low temperature (15 DEG C) to a normal temperature, can reach high cross-linking density as usual without post curing, is small in smell, is extremely low in toxicity and good in toughness, is not fractured at the low temperature, can maintain a good constitutive property after being cured, thus guarantee structural stability, has good adhesive strength both for most metal and non-metal building materials, is used in the low temperature environment, is matched with carbon fiber for curing construction and adhesive curing for waterproofing, anti-corrosion paints and other low temperature application occasions, and is widely applied to many fields of electron, buildings, chemical building materials and the like.

Owner:CARBON COMPOSITESTIANJIN CO LTD

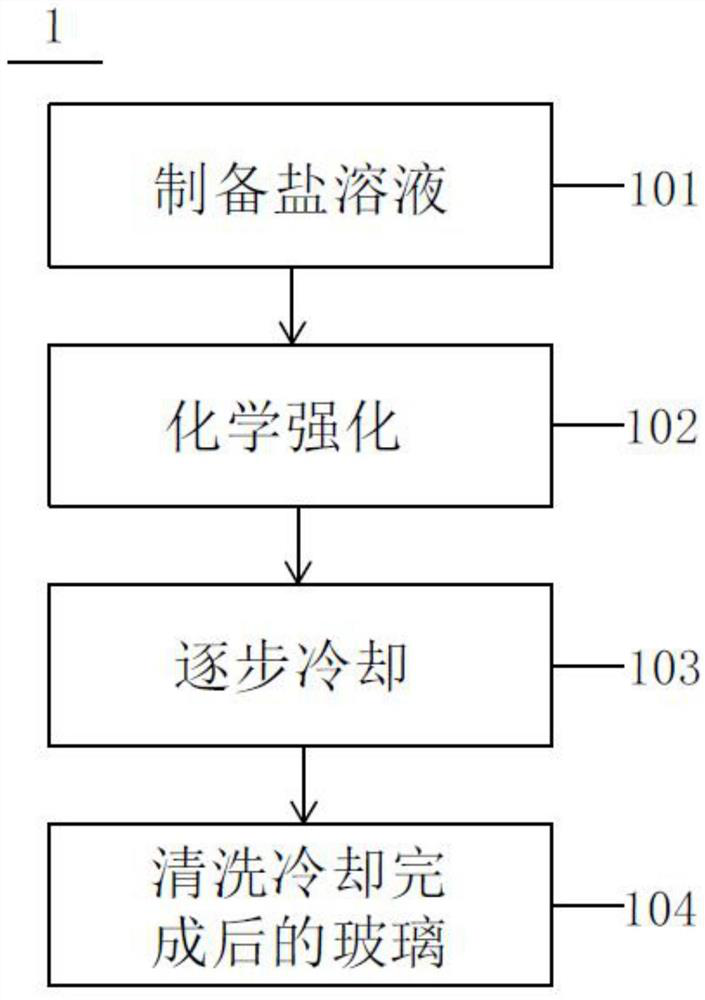

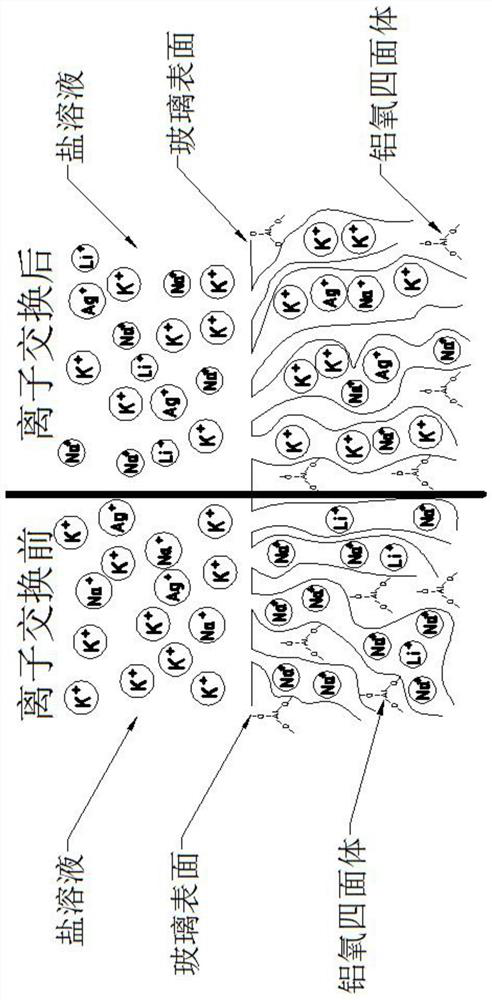

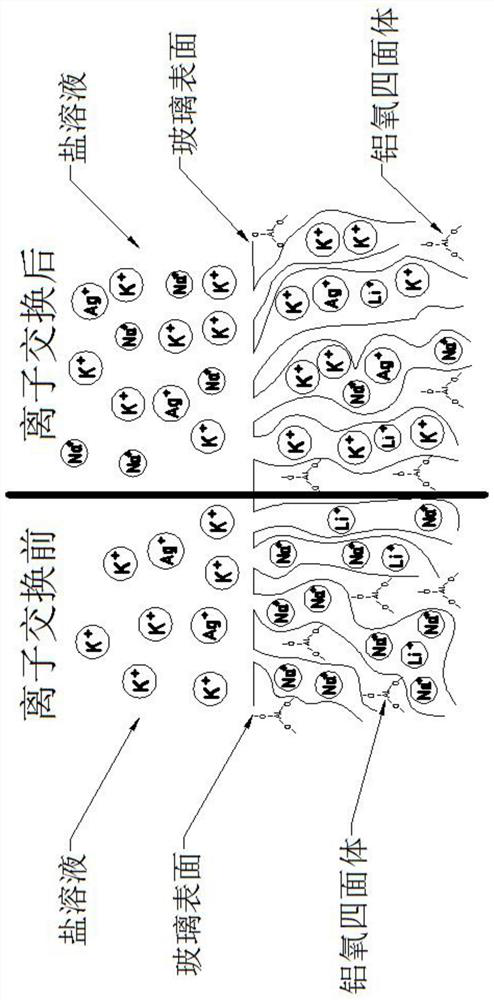

Preparation method of high-transmittance and high-strength antibacterial glass

InactiveCN111807718AGuaranteed antimicrobial propertiesGuaranteed StrengthPotassium nitratePotassium nitrite

The invention relates to a preparation method of high-transmittance and high-strength antibacterial glass. The method comprises the following steps: forming a salt solution, wherein the mass ratio ofpotassium nitrate in the salt solution is 40%-80%, the mass ratio of potassium nitrite is 10%-20%, the mass ratio of sodium nitrate is 15%-20%, the mass ratio of sodium nitrite is 5%-10%, the mass ratio of silver nitrate is 0.005%-0.08%, the mass ratio of aluminum oxide is 1%-7%, the mass ratio of potassium hydroxide is 1%-3%, the mass ratio of silicon oxide is 1%-5%, and the mass ratio of other substances is 0.15%-1.5%; immersing glass to be reinforced into the salt solution to chemically reinforce the glass; and taking out the chemically reinforced glass, and gradually cooling the chemicallyreinforced glass to room temperature. According to the method, the proportions of KNO3, KNO2, NaNO3, NaNO2 and AgNO3 in the salt solution are reprepared, so that K<+>, Na<+> and Ag<+> can be fully exchanged with alkali metals Na<+> and Li<+> in the glass, and the antibacterial and high-strength properties of the glass are guaranteed.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

Environment-friendly adhesive and preparation method thereof

InactiveCN105255414ASolve the stickinessSolve environmental problemsMineral oil hydrocarbon copolymer adhesivesAldehyde/ketone condensation polymer adhesivesEpoxyPolymer science

The invention relates to an environment-friendly adhesive and a preparation method thereof, belonging to the technical field of high polymer materials. The environment-friendly adhesive is prepared from the following raw materials in parts by weight: 20-30 parts of SBS, 10-20 parts of SEBS, 3-5 parts of C5 petroleum resin, 3-5 parts of C9 petroleum resin, 3-5 parts of rosin resin, 2-3 parts of tertiary butyl phenolic resin, 1-5 parts of novolac epoxy resin, 3-5 parts of terpene resin, 30-40 parts of gasoline, 5-10 parts of cyclohexane, 5-10 parts of ethyl acetate, 10-20 parts of acetone and 5-10 parts of methylcyclohexane. By matching SBS and SEBS with the other raw materials, the environment-friendly adhesive has an ideal adhesion effect on polar materials and is free from toxicity and environmentally friendly.

Owner:CHENGDU JINHUI TECH

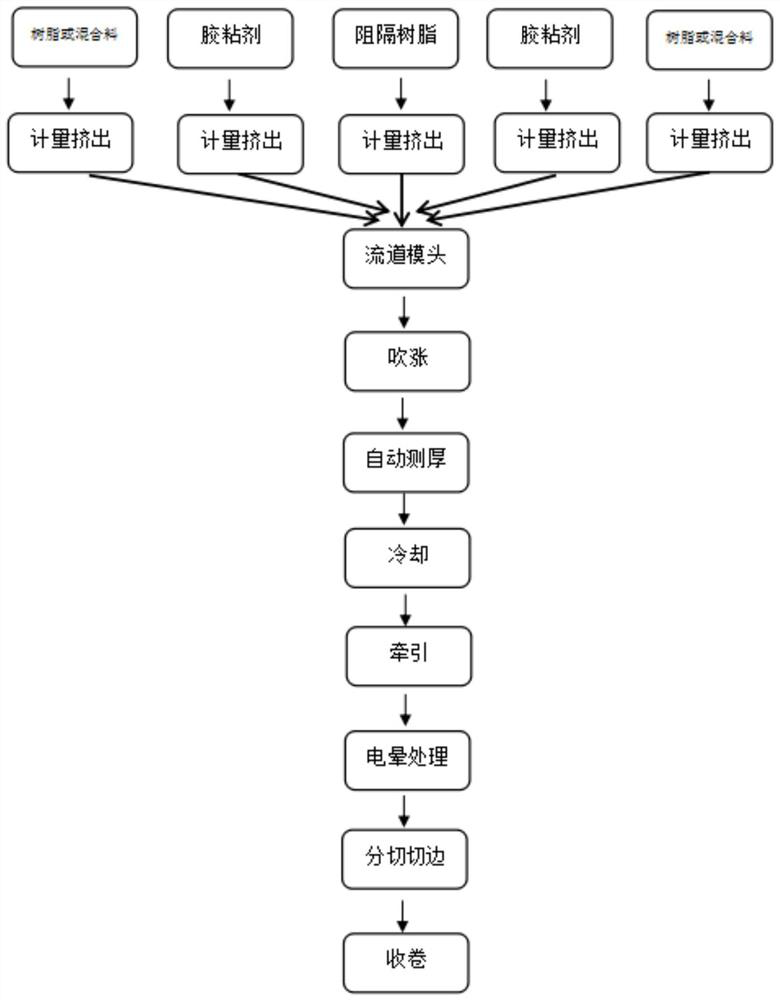

Hot melt adhesive for high-performance polypropylene barrier film as well as preparation method and application of hot melt adhesive

ActiveCN114032049AGood adhesionNo irritating smellNon-macromolecular adhesive additivesSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a hot melt adhesive for a high-performance polypropylene barrier film as well as a preparation method and application of the hot melt adhesive. The hot melt adhesive is prepared from 10 to 30 parts of maleic anhydride grafted polypropylene, 35 to 60 parts of polypropylene-random-copolymer, 0 to 20 parts of low-density polyethylene, 10 to 30 parts of metallocene polyolefin plastomer, 0 to 5 parts of PP grafted maleic anhydride wax and 0.1 to 0.5 part of antioxidant. Through component optimization, the hot melt adhesive has the characteristics of excellent bonding performance, no pungent smell and few crystal points, and solves the problems of poor bonding force, strong smell and many crystal points of the hot melt adhesive for the domestic polypropylene barrier film.

Owner:合诚技术股份有限公司

Preparation method of mould-proof clean type glass cement

InactiveCN107603555AIncrease consumptionLow toxicityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEscherichia coliPolyurethane adhesive

The invention discloses a preparation method of mould-proof clean type glass cement and belongs to the technical field of glass cement preparation. According to the preparation method disclosed by theinvention, hydroxyl of castor oil polyalcohol generates dehydration condensation with the isocyanate group of toluene diisocynate; a small part of unreacted castor oil in prepolymer is adsorbed on the surface of a polyurethane adhesive film and is oxidized by air to form a colorless and flexible film; water chestnut peels are waste in water chestnut processing; by mixing the extract of water chestnut peels in the glass cement, the reproduction and growth of staphylococcus aureus, escherichia coli and various mycete can be inhibited; through network interpenetration between castor oil polyurethane and methyl silicone rubber, an IPN adhesive is prepared so that the surface of a base material is cleaned; the penetrating network structure is combined more tightly, and the glass cement does not drop easily after curing; moreover, a hydrogen bond is formed on the surface of the base material such as silicone rubber and glass, the molecular interaction force is enhanced, the adhesive property is improved, and the problem of infirm bonding or drop after curing of the glass cement due to the unclean surface of the bonding base material is solved.

Owner:高俊

Dustproof underpants

The invention relates to dust-proof underpants. The dustproof underpants are characterized in that fabric with a dustproof, moisture-permeable and air-permeable microporous membrane is applied to the fabric or partial fabric of the dustproof underpants, the aperture of the microporous membrane is between 0.01 mu m and 10 mu m, outside dust can be blocked effectively, the fabric with the dustproof, moisture-permeable and air-permeable microporous membrane is added, and a 'closed' space or a relatively 'closed' space is formed at some parts such as a genital organ and an anus and the peripheral part, thus the dust-caused problems that the genital organ and the anus parts and the peripheral part are easy to be dirty, have peculiar smell, tickle and be sticky and greasy, virus infection is caused, bacteria are proliferated and pores are blocked can be effectively solved.

Owner:李双利

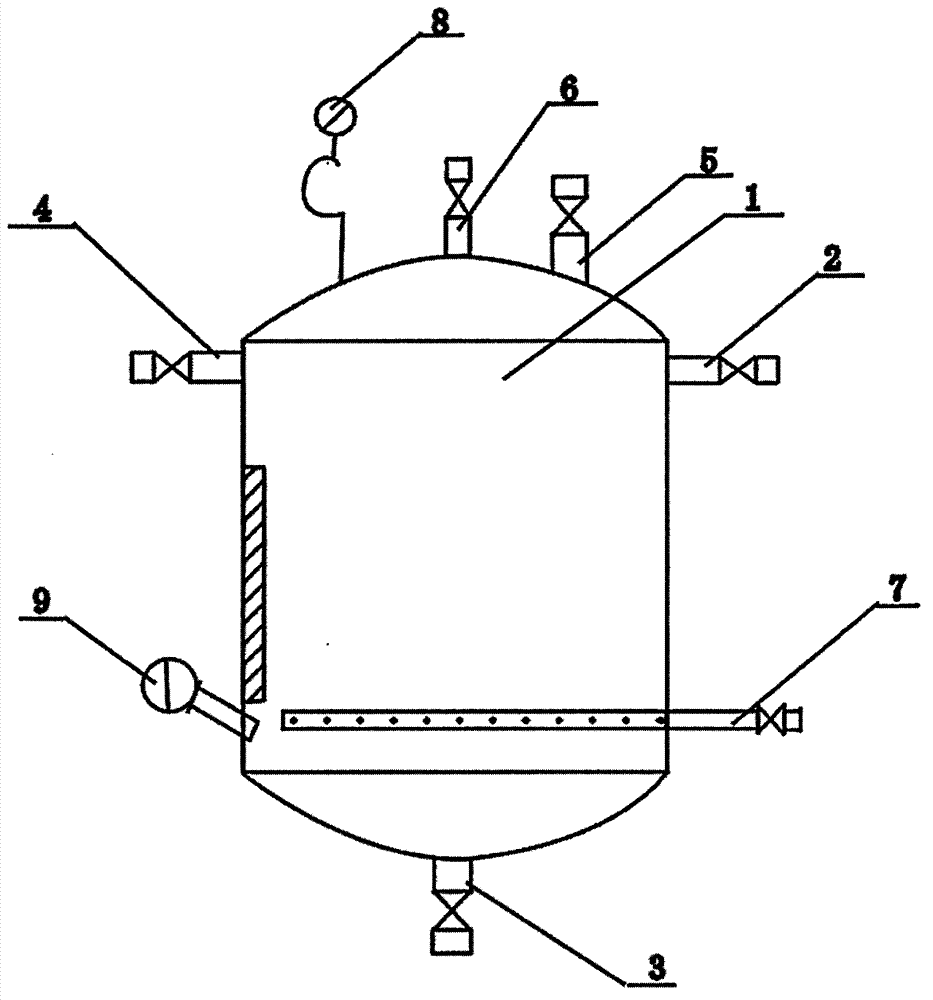

Special pressure filter tank for filter press

InactiveCN102961907AReduce viscositySolve the stickinessFiltration separationBiochemical engineeringFilter press

The invention relates to a special pressure filter tank for a filter press, comprising a tank body (1), wherein the top of the tank body (1) is provided with an exhaust pipe (5), a compression air inlet pipe (6) and a pressure gauge (8), and the exhaust pipe (5) and the compression air inlet pipe (6) are respectively provided with a valve; the upper part of the tank body (1) is provided with a feeding pipe (2) with a valve and an overflow pipe (4) with a valve; the lower part of the tank body (1) is provided with a steam heating pipe (7) with a valve, the steam heating pipe (7) is directly connected with the inside of the tank body, the part of the steam heating pipe (7), which is arranged inside the tank body, is provided with a steam spray hole, and the lower part of the tank body (1) is also provided with a temperature gauge (9); and the bottom of the tank body (1) is provided with a discharging pipe (3) with a valve. The special pressure filter tank for the filter press, provided by the invention, is mainly used for heating materials with higher viscidity before pressure filtering to reduce the viscidity of the materials and then feeding the materials into the filter press for pressure filtering, so that the problem of higher viscidity during material pressure filtering is solved, then, the pressure filtering efficiency is increased greatly, and the energy consumption is reduced.

Owner:陈广海

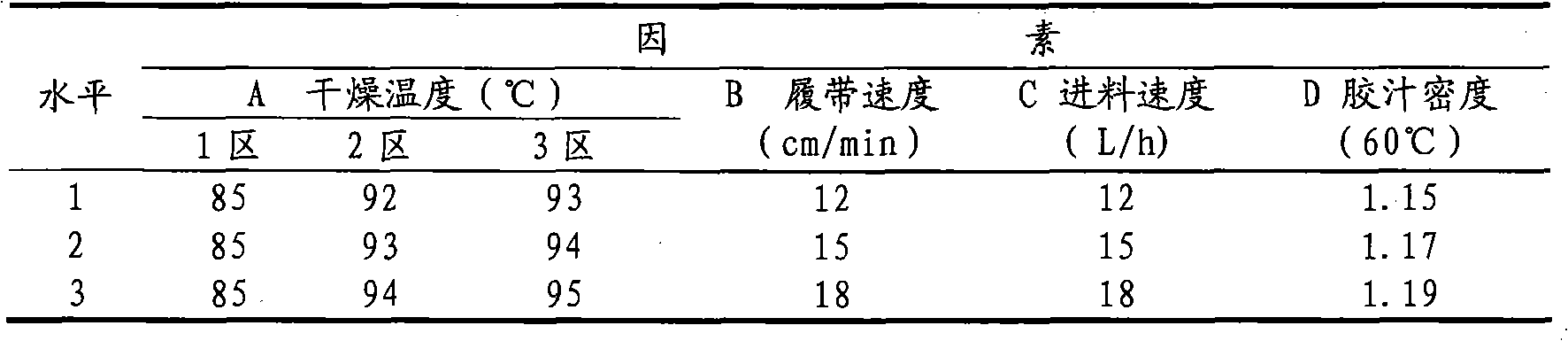

Method for drying gelatin type traditional Chinese medicine

ActiveCN102109273AEasy gelatinizationKeep dryDrying using combination processesUnknown materialsHigh probabilityEngineering

The invention discloses a method for drying a gelatin type traditional Chinese medicine, and belongs to the field of traditional Chinese medicines. The method for drying the gelatin type traditional Chinese medicine comprises the following steps of: conveying a gelatin type extract to drying equipment at a feeding speed of between 10 and 20L / h and drying in the drying equipment under vacuum under the following conditions: the crawler transmission speed is 10 to 20cm / min, and the heating temperature of a heater is 60 to 100 DEG C; and crushing the dried material into grains. By the method for drying the gelatin type traditional Chinese medicine, the defects of high viscosity, high probability of agglomeration, high probability of gelatinization and the like existing in a drying process of the gelatin type traditional Chinese medicine can be effectively solved; and the method has the advantages of low drying temperature, high drying efficiency, high product quality, closed operating environment, continuous mass production and the like.

Owner:SHAN DONG DONG E E JIAO

Yam sweet dumpling and preparation method thereof

The invention discloses a yam sweet dumpling and a preparation method thereof. The yam sweet dumpling is prepared from raw materials in parts by weight as follows: a yam sweet dumpling wrapper: 100-150 parts of glutinous rice flour, 2-5 parts of quick-frozen oil and 90-110 parts of water; yam sweet dumpling stuffing: yams or a mixture of the yams and one of Chinese wolfberries and red dates. The preparation method comprises steps as follows: Step 1, a preparation process of the yam sweet dumpling wrapper; Step 2, a preparation process of the yam sweet dumpling stuffing. According to the yam sweet dumpling and the preparation method thereof, processes distinct from traditional sweet dumpling processes are adopted, so that the steaming time is shortened, and few microelements of the yams are lost. The problem of high viscosity of the steamed yams is solved, the stuffing does not leak during cooking of the sweet dumpling prepared by a machine, and the stuffing is more sweet and delicious under the condition that the taste and the flavor of the yams are not changed.

Owner:焦作市欣冻食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com