Patents

Literature

45results about How to "Improve electrical insulation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tung oil-modified water-based insulating paint

ActiveCN101724335AImprove electrical insulation strengthIncrease added valuePolyester coatingsWater basedElectrical conductor

The invention discloses a method for preparing a tung oil-modified water-based insulating paint. The method comprises the following steps that: firstly, 100 parts of polyalcohol reacts with 20 to 40 parts of poly-acid and 10 to 20 parts of maleic anhydride at the temperature of between 160 and 200 DEG C for 1 to 2 hours under the protection of the nitrogen gas to give an esterified liquid; secondly, 25 to 35 parts of the tung oil and 50 to 60 parts of maleic anhydride are added into the esterified liquid to react 2 to 6 hours at the temperature of between 190 and 210 DEG C under the protection of the nitrogen gas to form the esterified liquid, 15 to 25 percent of organic solvent by weight is added into the obtained esterified liquid and the mixture is neutralized by organic amine until the pH value is between 7.0 and 8.5 to form a polyester resin liquid modified by the tung oil; and finally, 10 to 30 weight percent of etherified amino resin and 0.1 to 0.3 weight percent of peroxide are added into the tung oil-modified polyester resin liquid and the obtained product is stirred and blended the for half an hour to 1 hour at room temperature to form the tung oil-modified water-based insulating paint. When the insulating paint is used, water is added in the insulating paint, the mixture is stirred and diluted to form a product with a solid content of 30 to 40 weight percent and the pH value of between 7 and 8, and the product is coated on a conductor to be solidified into a paint film at the temperature of between 120 and 130 DEG C.

Owner:合肥英索莱特新材料科技有限公司

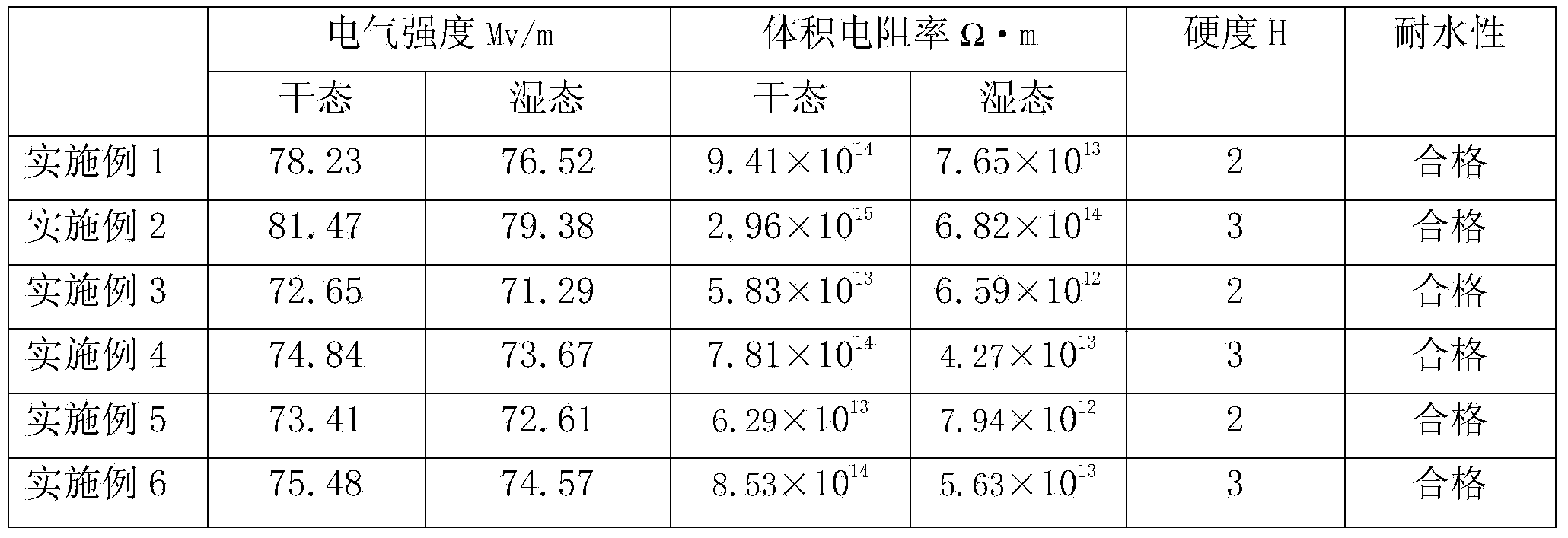

Vacuum casting method for epoxy resin

InactiveCN101847508AEfficient DryingImprove electrical insulation strengthCoils manufactureEpoxyTransformer

The invention relates to vacuum casting method for epoxy resin. The vacuum casting method is characterized by comprising the following concrete steps of: drying silicon micro powder for 8 hours at the temperature of 100+ / -5 DEG C; preheating a vacuum casting tank to 70+ / -5 DEG C; preheating a mixing tank to 40+ / -5 DEG C; adding epoxy resin, epoxy curing agent, silicon micro powder, color paste, a toughening agent and an accelerant into the mixing tank; heating the vacuum casting tank to 70 DEG C and vacuumizing after one hour; casting epoxy resin mixture in the mixing tank into a transformer coil mould and keeping 3-5 hours when the vacuum degree reaches 5mbar. The invention has the advantages of effectively improving the strength of electrical insulation materials, reducing and eliminating the internal and surface defects and reducing the production costs.

Owner:上海凯利电器厂有限公司

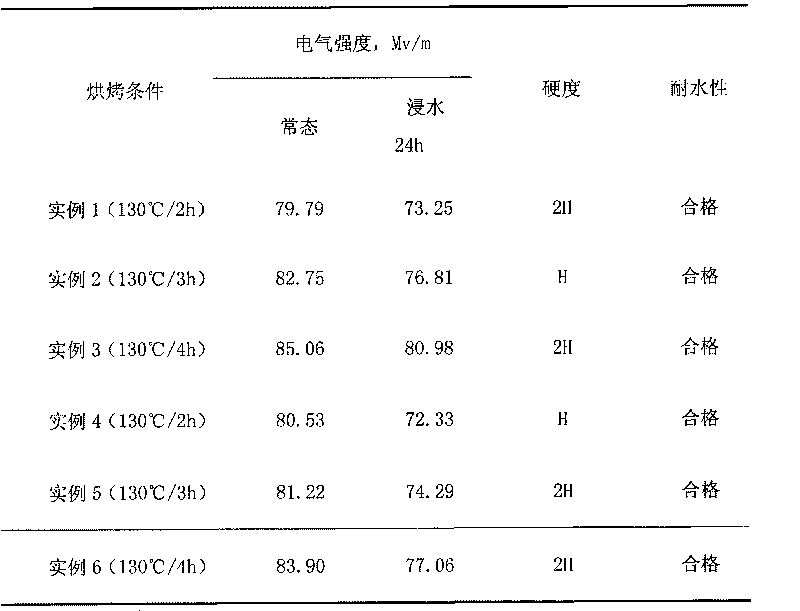

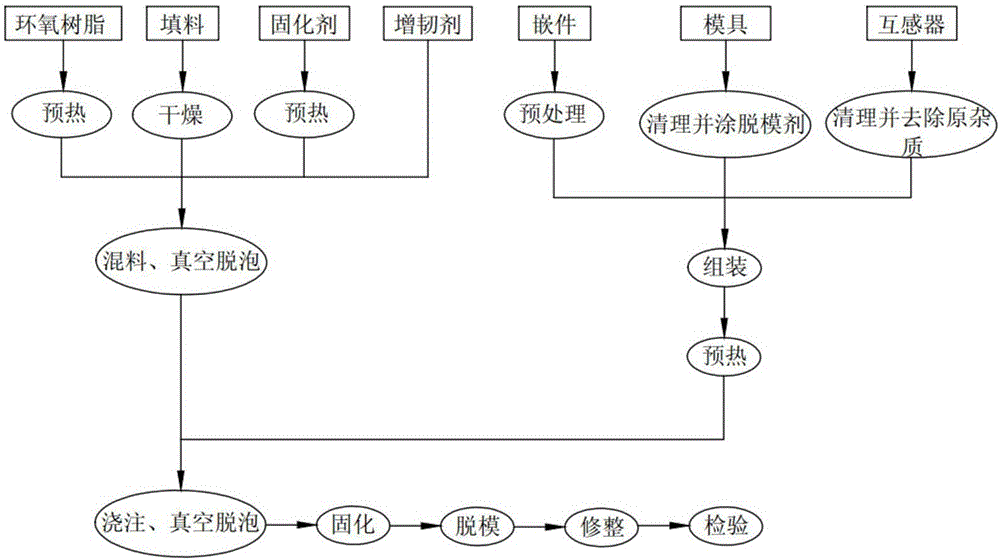

Pouring technology for all-fiber optical current transformer

The invention discloses a pouring technology for an all-fiber optical current transformer. Firstly, epoxy resin castables are obtained and then subjected to preheating and drying treatment; then the epoxy resin castables are placed in vacuum and subjected to mixing and defoaming treatment; a transformer semi-finished product is placed into a mould and preheated; finally, the defoamed epoxy resin castables are placed in vacuum and subjected to pouring defoaming treatment; and after pouring is completed, a mould is subjected to solidification demoulding treatment, and a transformer pouring body is obtained. The pouring technology for the all-fiber optical current transformer adopts a full-vacuum pouring technology and has a good applying effect on transformer type high voltage electric energy meter. Burdening, mixing and the whole process of pouring are all in a vacuum state so that bubbles in a pouring product can be reduced to a large extent, electric insulation strength and mechanical property of the product is improved, the yield of the product is improved, and the cost of the product and labor intensity are reduced. Epoxy resin has excellent electric insulation performance and high mechanical strength, heat resistance and chemical attack resistance are achieved, the cure shrinkage rate and the linear expansion coefficient are good, and dimensional stability and manufacturability are good.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

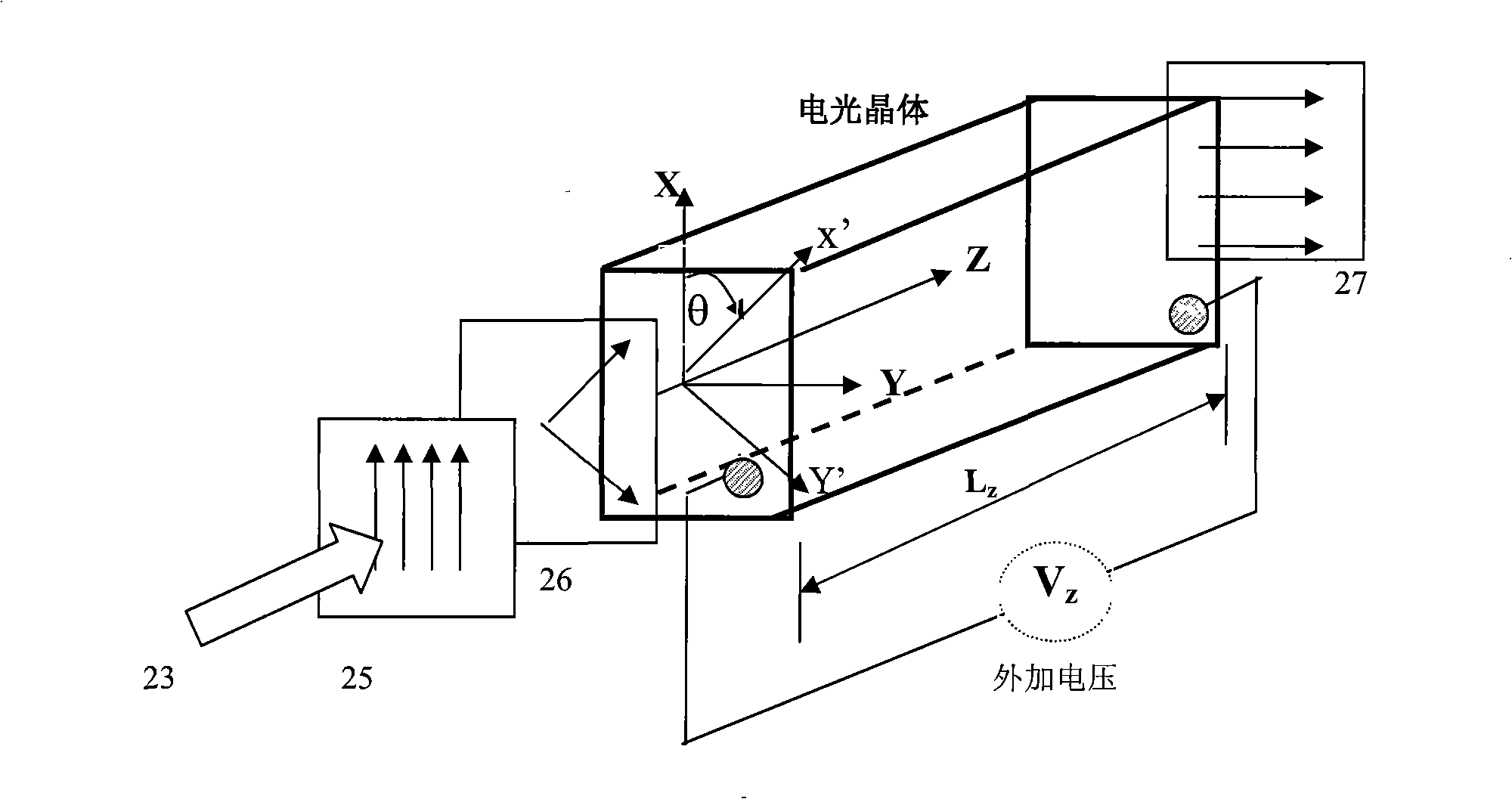

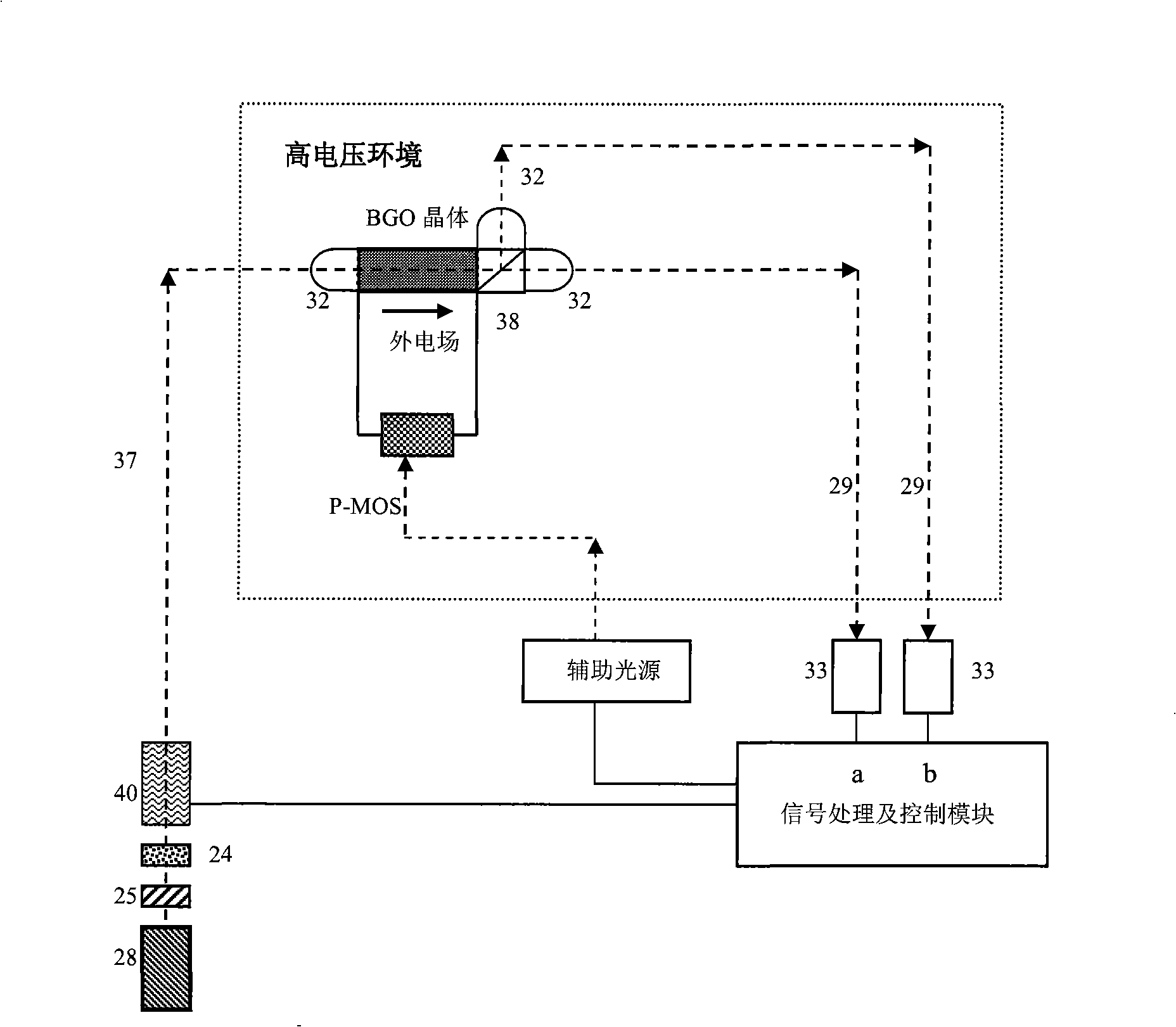

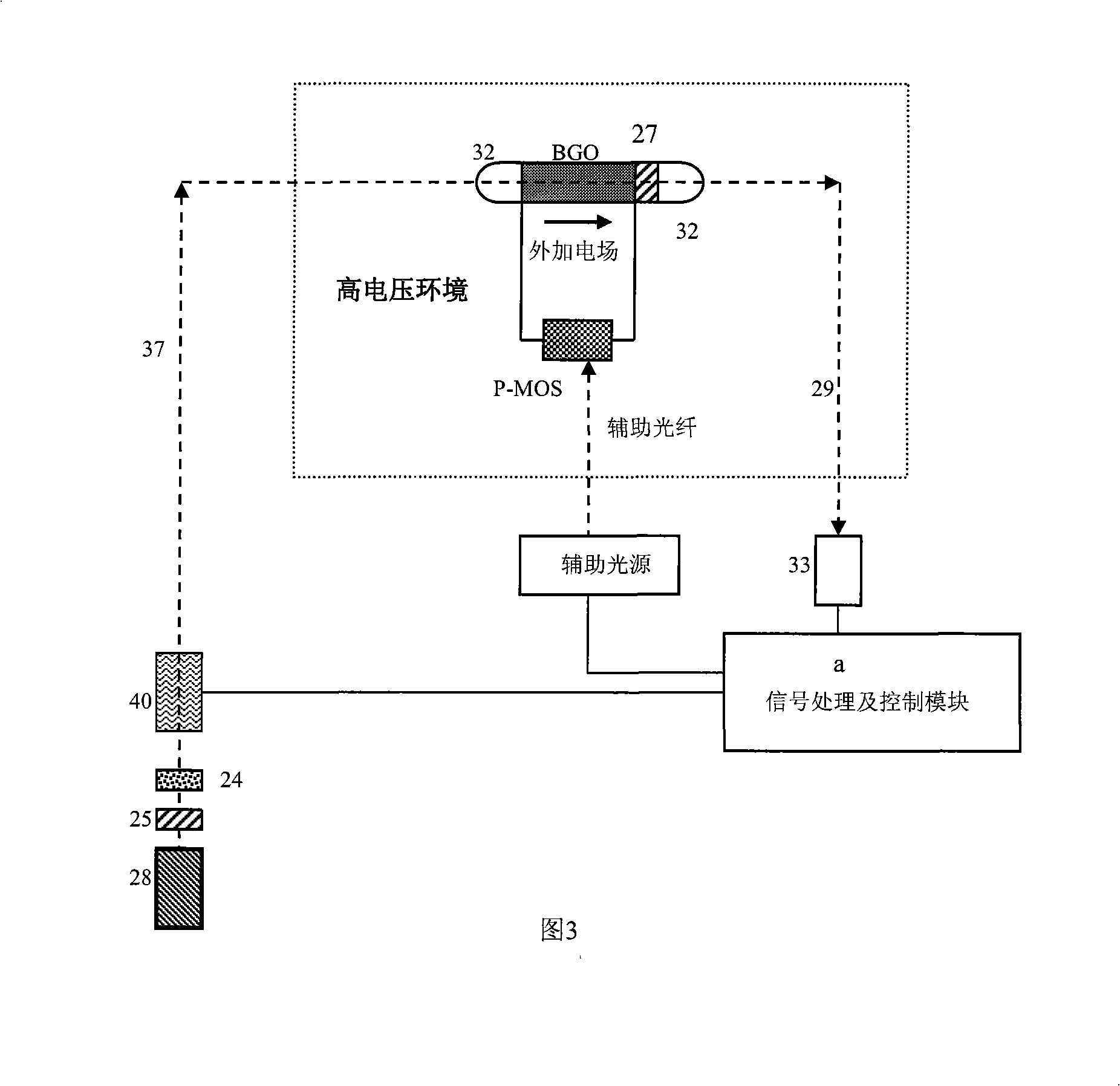

Minitype optical DC/AC electric field sensor

InactiveCN101408558AReduce distractionsMeasurement stabilityCurrent/voltage measurementVoltage/current isolationElectric field sensorHigh pressure

The invention provides a micro optical DC / AC electric-field sensor for eliminating the drift error of electric charges, capable of being used for measuring the voltage of a high-voltage DC transmission line by an optical method. Two transparent electrodes formed on an electro-optical crystal light-pass end surface used in an optical sensing module are electrically and compactly connected with two output terminals of an optical relay respectively. A secondary light source transmits the light beam that is open and is cut off periodically to a light beam collecting window of an the relay by auxiliary optical fiber under the coordinated control of a signal processing and control module, and the light beam that is open and is cut off periodically is used for controlling the breakover and the break of a circuit at the output end of the optical relay; the modulation to the DC electric field to be tested which is externally added on an electro-optical crystal can be realized, so that the DC electric field to be tested is periodically applied and eliminated on the electro-optical crystal. The error caused by space charge drift in the electro-optical crystal used when the DC electric field is measured can be controlled within bounds by the micro optical DC / AC electric-field sensor, thus realizing the long-term, stable, reliable and precise measurement on the DC electric field with the optical method.

Owner:湾世伟

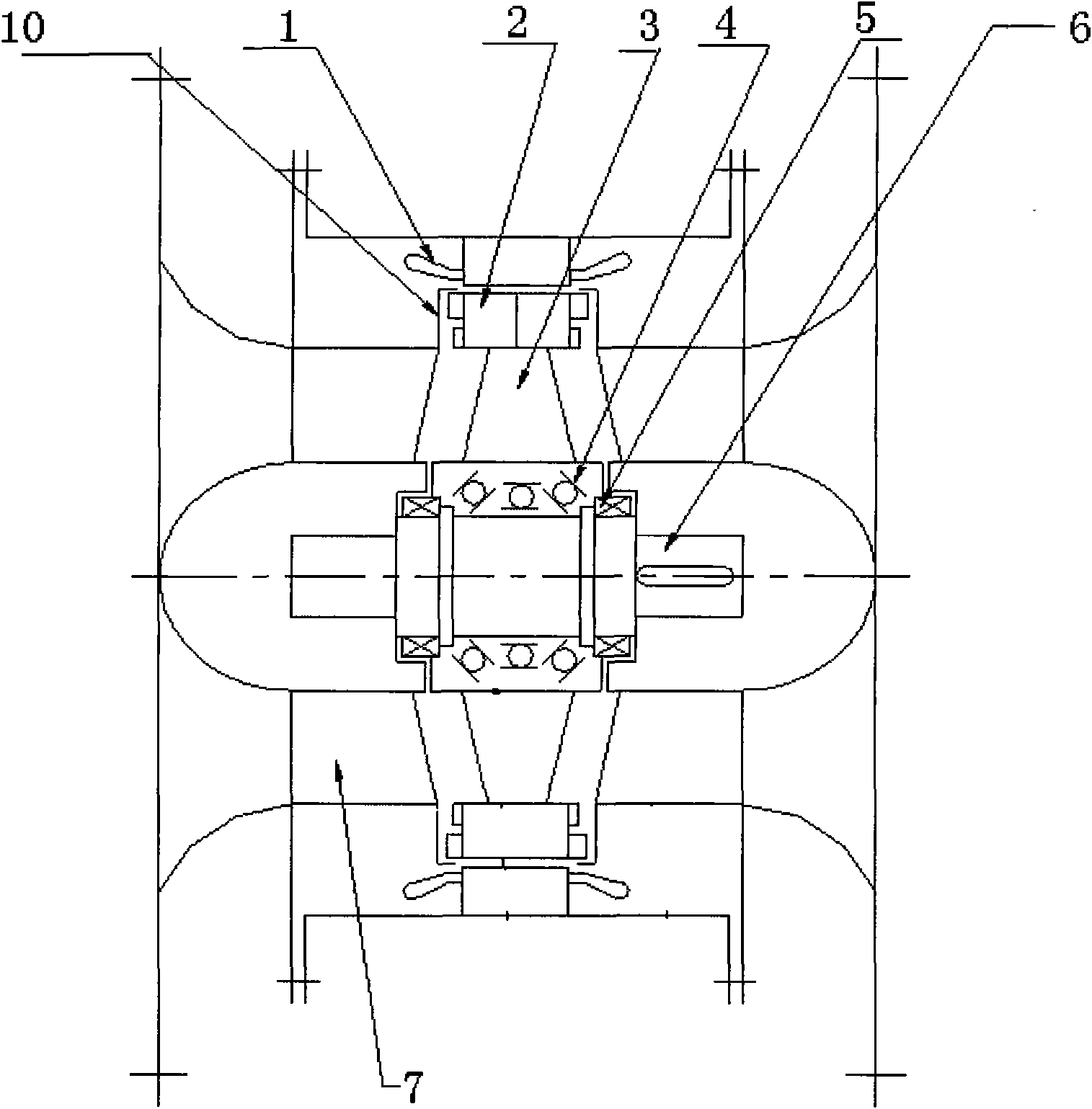

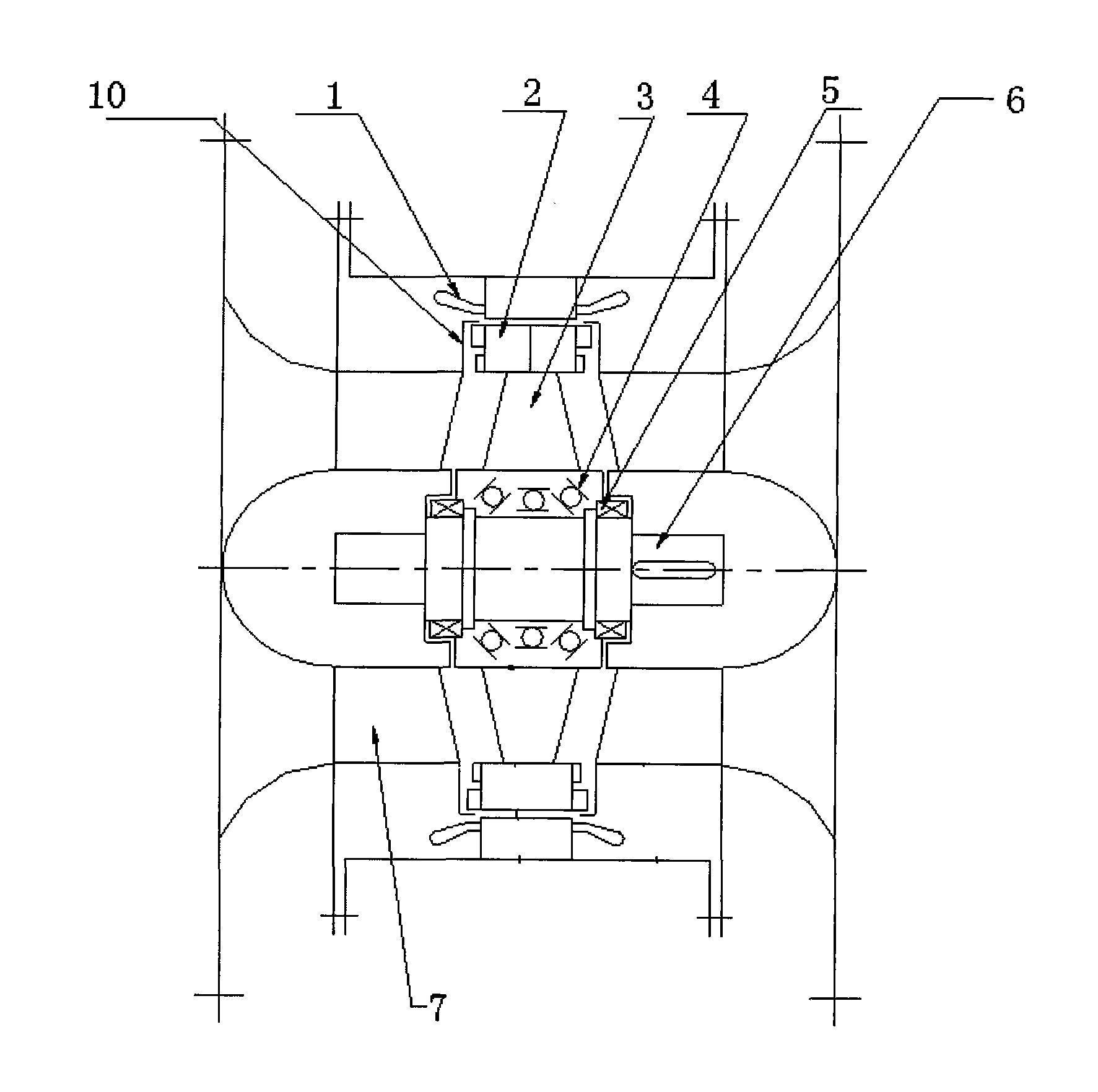

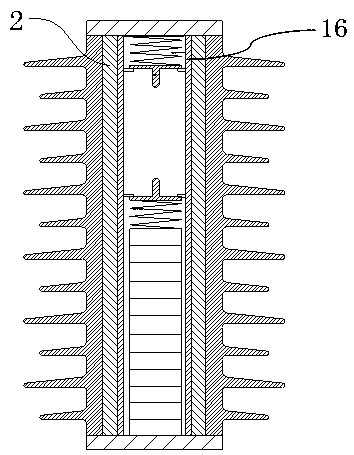

Novel fully-tubular electric submerged pump with shaft incapable of transferring torque

InactiveCN101787978AImprove electrical insulation strengthImprove reliabilityPump componentsPump installationsImpellerThrust bearing

The invention relates to a novel fully-tubular electric submerged pump with a shaft incapable of transferring torque; a submerged motor adopts wet stator winding structure, the impeller of a water pump is arranged in the inner cavity of a motor rotor, the vanes of the impeller are integrally welded with the inner circle of the motor rotor assembly by silicon steel plates through stacking, a radial bearing and a bidirectional thrust bearing are arranged in the inner seal bearing cavity of the motor rotor with the impeller, the motor rotor with the impeller is rotational and the shaft cannot rotate, and the inner rotational bearing cavity adopts dynamic seal structure. The invention has the beneficial effects that: the winding wire improve the electric insulation intensity of the electric submerged motor, so the reliability of the whole pump is improved, the vanes of the impeller are integrally welded with the inner circle of the motor rotor assembled by silicon steel plates through stacking to reduce the outer diameter of the motor rotor and improve the motor efficiency, the strength and rigidity requirements for the shaft are greatly reduced, the reliability is improved, the dynamic seal structure is compact and the seal effect is good, the axial length also can be reduced to realize compact structure, and the material consumption is also reduced.

Owner:TIANJIN GANQUAN GROUP

Novel photovoltaic assembly structure

InactiveCN103354249AImprove electrical insulation strengthSolve the cooling problemPhotovoltaic energy generationSemiconductor devicesPolyethylene glycolMetal sheet

The invention discloses a photovoltaic assembly structure of a photovoltaic building part. The structure successively comprises a glass layer, a solar cell and a backboard from top to bottom. A backboard material is a metal sheet, glass or composite sheet material. An insulation film layer is arranged between the solar cell and the backboard. The solar cell and the insulation film layer are connected through an EVA rubber sheet. The insulation film layer and the backboard are connected through the EVA rubber sheet or an adhesion agent. The insulation film layer is a polyimide, polyethylene glycol terephthalate and polypropylene film or an organic silicon film. By using the photovoltaic assembly structure of the photovoltaic building part of the invention, an insulating property is good, a heat dissipation effect is good and production manufacturing cost is low; structure intensity of the photovoltaic assembly is increased; simultaneously, problems that bonding of the related materials is difficult, the EVA is easy to age and weather-proof performance is poor are solved; the photovoltaic assembly structure and other materials can be combined and form the photovoltaic building part and other products.

Owner:合肥微纳电工有限公司

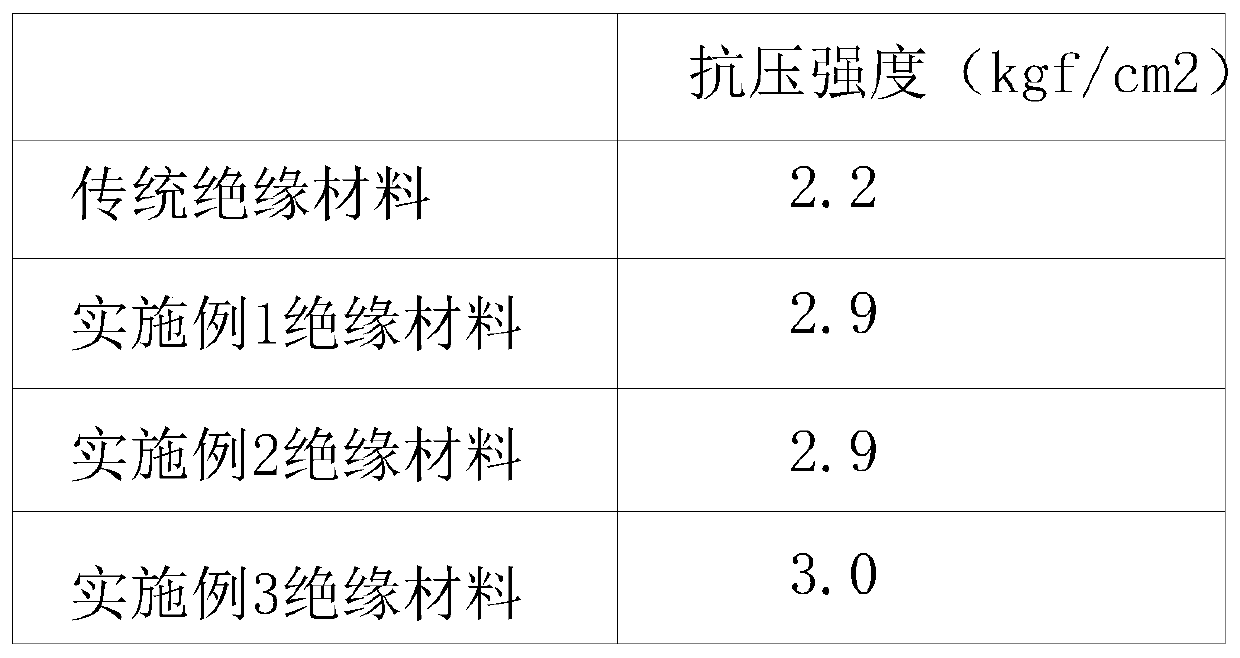

Electrolytic capacitor paper

ActiveCN1921040AImprove electrical insulation strengthGood chemical stabilitySpecial paperElectrolytic capacitorsFiberResist

The invention relates to an electrolytic capacitor paper, which has improved voltage-resist property and reduced consumption. Wherein, it is made from ultra-fine glass micro fiber in paper slurry; the amount of ultra-fine glass micro fiber is 5-80% of electrolytic capacitor paper; the diameter of ultra-fine glass micro fiber is 0.1-10 mum. The invention uses the ultra-fine glass micro fiber to improve the voltage-resist property, reduce the resistance, improve the electric property, improve the service life, and reduce the energy consumption.

Owner:浙江凯恩新材料有限公司 +1

Novel insulating cylinder processing method

InactiveCN103117141AImprove electrical insulation strengthSimple preparation processInsulatorsElectricityUltimate tensile strength

The invention relates to a novel insulating cylinder processing method. A die can be processed by a 1-3 mm sheet, and the size of an inner cavity of the die is adjustable. Preimpregnating epoxy digital mirror device (DMD) rolling materials are in thickness of 0.2mm, and the width of the preimpregnating epoxy DMD rolling materials are the same with the height of the insulating cylinder. The preimpregnating epoxy DMD rolling materials is utilized to roll on a foil winder and a coiler to the requested thickness (coiling effects of foil winder is better). The tail end is fixed stably by double faced adhesive tapes, and then the die is carried into an oasthouse to solidify. The solidification temperature is 130 degrees - 140 degrees. The solidification time is 3 hours -4 hours. After the solidification is cooled, screws can be adjusted by shrinking and the die is demolded. When two ends are in rubdown, the die can be used. The novel insulating cylinder processing method provides an insulating cylinder which is beautiful in appearance, excellent in insulating performance, extremely high in strength, simple in manufacturing crafts, low in cost, short in production cycle, good in laboring conditions for middle-high voltage electricity electric equipment.

Owner:KUNSHAN SPECIAL TRANSFORMER MFR

Carbon ceramic linear resistor, and preparation method of composite insulating layer on side surface of carbon ceramic linear resistor

ActiveCN111559913ASimple processNo pollution in the processResistor housing/enclosing/embeddingResistor manufactureGlazeMullite

The invention discloses a carbon ceramic linear resistor, and a preparation method of a composite insulating layer on the side surface of the carbon ceramic linear resistor. The preparation method ofthe composite insulating layer comprises the following steps: firstly, uniformly mixing bentonite, Zuoyun soil, calcined alumina and chromium oxide through ball milling to form high-resistance layer slurry, coating the side surface of an unsintered carbon ceramic resistor blank with the high-resistance layer slurry, and sintering together with a resistor to obtain a high-resistance layer on the side surface of the resistor; then uniformly mixing glass powder, mullite powder or calcined bauxite oxide, plastic clay and chromium oxide through ball milling to form glass glaze slurry, coating the surface of the high-resistance layer with the glass glaze slurry, and sintering to form the green and smooth insulating layer on the side surface of the resistor. The insulating layer prepared in the invention can obviously improve the endurance capacity of the carbon ceramic linear resistor to high-voltage and large-current impact, and prevent the resistor from flashover along the surface.

Owner:XI AN JIAOTONG UNIV +1

Pressure gel forming method for multi-winding current transformer

ActiveCN104299766AReduce labor intensityIncrease productivityTransformersInductances/transformers/magnets manufactureInjection pressureContraction rate

The invention discloses a pressure gel forming method for a multi-winding current transformer, and belongs to the technical field of electric manufacturing and electric equipment. According to the method, the traditional method that multiple windings are shielded respectively in a device correcting process is improved, the windings are combined and wrapped as a whole, and exhaust dead corners generated in the pouring process of the multi-winding current transformer are effectively avoided. In a transformer die preparation process, temperatures of different parts of a die are set, so that it is guaranteed that the curing process of gel materials which are injected firstly and the curing process of gel materials which are injected later basically keep consistent, and cracks generated due to an inconsistent curing contraction rate in the transformer are avoided. In the pressure gel forming process, viscosity of mixed materials is large, a certain period of time is needed when gas is exhausted from the inside of a product, and accordingly a staged material injection method is adopted. Besides, staged pressure maintaining can effectively avoid the situation that iron core magnetic permeability is reduced because of excessively large material injection pressure and accordingly error tests are not qualified, and therefore product quality and the pass percent are guaranteed.

Owner:STATE GRID CORP OF CHINA +1

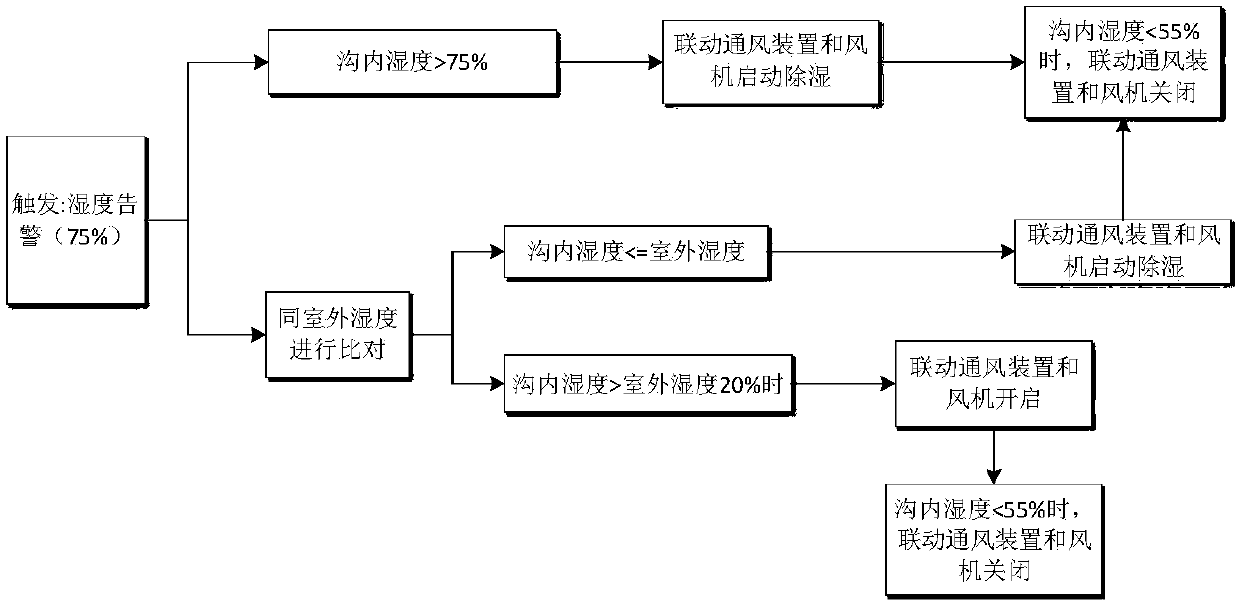

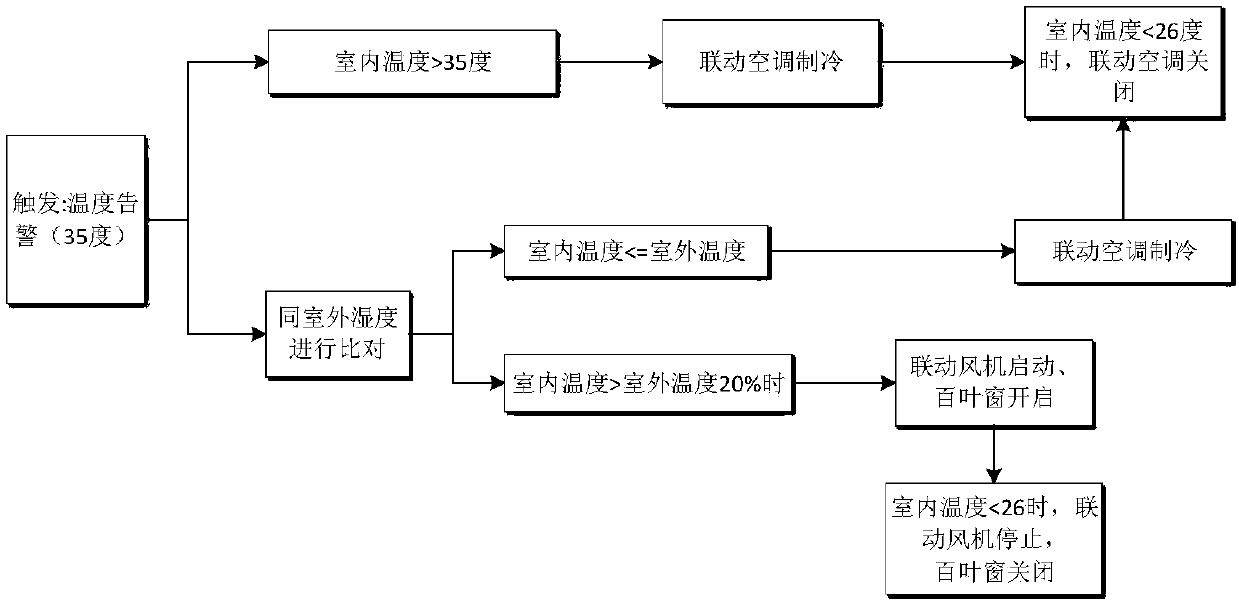

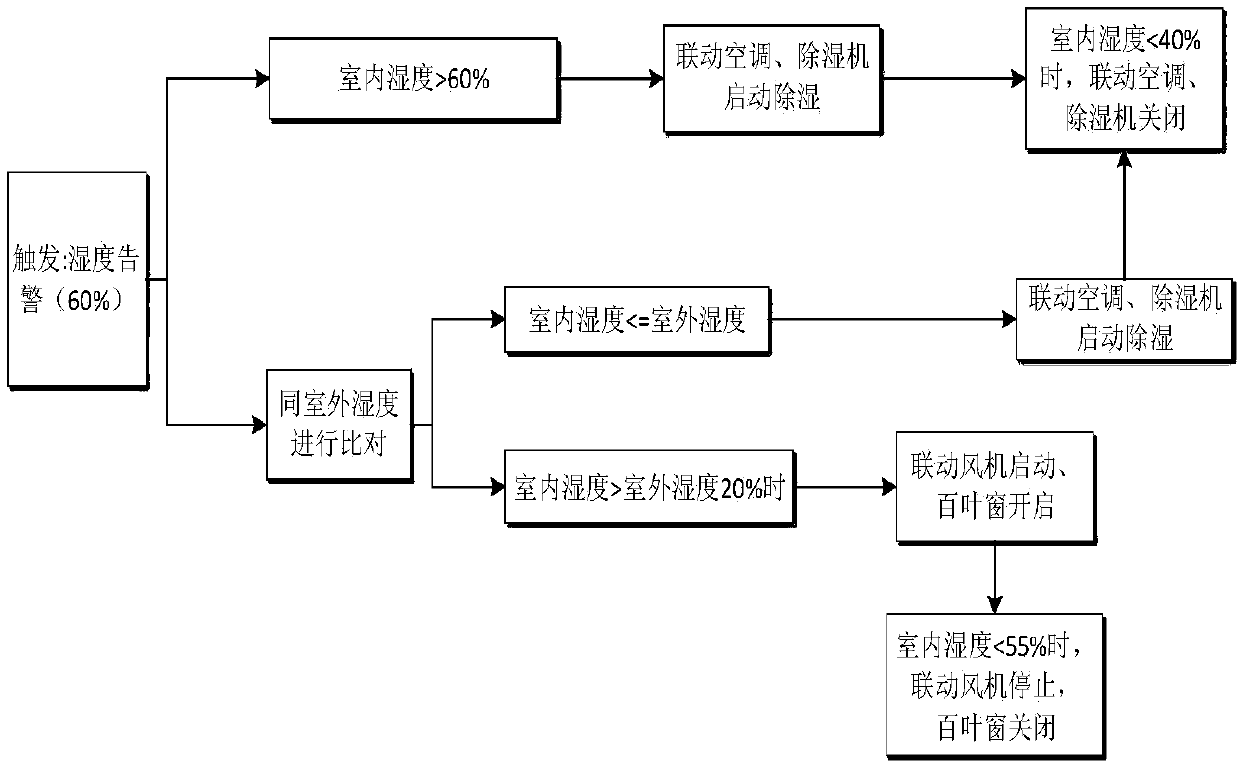

Substation high-voltage chamber fully-closed operation system and control method

PendingCN107726564AImprove electrical insulation strengthImprove the level of safe operationMechanical apparatusSpace heating and ventilation safety systemsHigh pressureEmbedded system

The invention relates to a substation high-voltage chamber fully-closed operation system and a control method. The system comprises a high-voltage chamber; the high-voltage chamber is a fully-closed structure; an electric blind window electrically controlled to open and close is mounted in a ventilation port of the high-voltage chamber; an environment active operation maintenance system is mountedin the high-voltage chamber, and comprises an environment monitoring device, a data processing module and an environment auxiliary device; the environment monitoring device collects high-voltage chamber internal environment information and sends to the data processing module; and the data processing module adjusts the environment in the high-voltage chamber through controlling the environment auxiliary device. Through intelligent control of the temperature and the humidity, the operation environment is optimized, the electric insulation intensity of switch cabinet equipment is improved, the bus and transformer damage risk caused by failures of the switch cabinet is reduced, the substation safety operation level is improved, and the safety benefit is prominent. The system can be applied tothe high-voltage chamber to eliminate the insulation reduction problem caused by damping and pollution of switch cabinet insulation pieces of small cabinet bodies.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Aqueous tung oil-based insulating paint and preparation method thereof

InactiveCN104356909AHigh glossImprove electrical insulation strengthFatty acid esterificationPolyurea/polyurethane coatingsEpoxyOrganic solvent

The invention discloses aqueous tung oil-based insulating paint which is prepared from aqueous tung oil / epoxy resin, a curing agent, a sealing agent and an organic solvent, wherein the aqueous tung oil / epoxy resin is prepared by performing diene addition reaction on tung oil with maleic anhydride (maleic anhydride) and performing esterification reaction with polyethylene glycol (PEG) in sequence, further performing ring-opening reaction with epoxy resin E-51, and by finally neutralizing till that the pH value is 8.0-8.5 by using organic alkali; the curing agent is a curing agent which is sealed by using the sealing agent; the solid content of the insulating paint is 70-75wt%. The aqueous tung oil-based insulating paint is diluted with water in a ratio of 1:1, is dipped on a copper piece, and is cured for 3-4 hours at 120-130 DEG C, so that a paint film is prepared. The insulating paint is high in insulation strength and good in comprehensive property.

Owner:HEFEI UNIV OF TECH

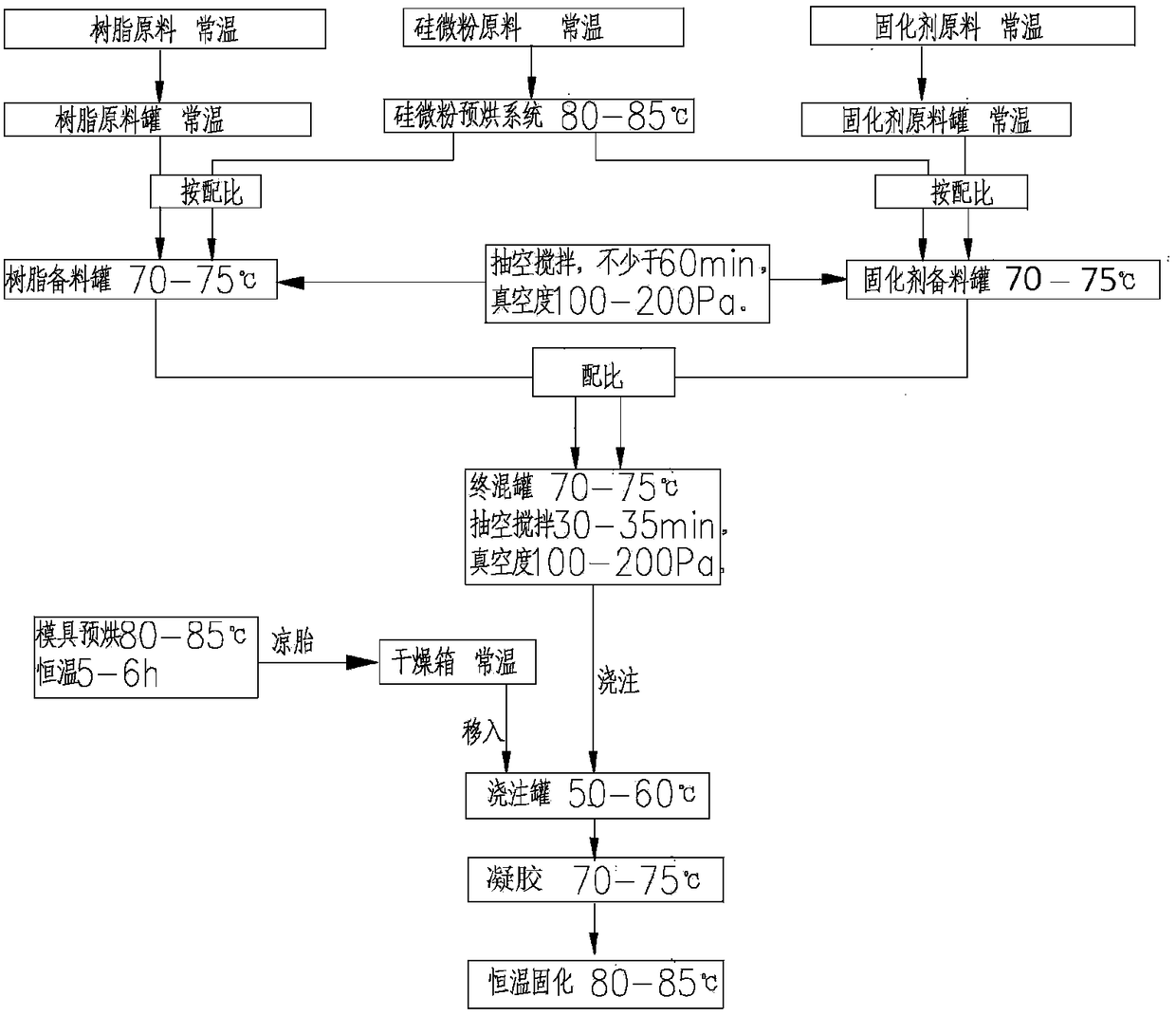

Vacuum pouring and gelating method for epoxy resin

ActiveCN108274670AHigh degree of curingImprove bindingEncapsulation/impregnationDomestic articlesEpoxyInductor

The invention provides a vacuum pouring and gelating method for epoxy resin, belonging to the technical field of preparation of a mutual inductor. The method comprises the steps: providing a final mixed material for epoxy resin pouring; conducting constant-temperature preheating and cooling a tire for a mould, and thus obtaining a cold-tire mould, wherein the mould comprises a coil winder and a mould base, and a thermal baffle plate is matted between the coil winder and the mould base; the temperature of the coil winder of the cold-tire mould is higher than the temperature of the mould base; under vacuum, pouring the final mixed material into the cold-tire mould, and thus obtaining a pouring model, wherein the temperature of the final mixed material is higher than the temperature of the mould base of the cold-tire mould and is lower than the temperature of the coil winder of the cold-tire mould; and orderly gelating and curing the pouring model. The method ensures that in the gelatingand curing process of the epoxy resin, the epoxy resin on the surface of the coil winder is gelated firstly and is cured from inside to outside. By the method, the mutual inductor has good electricalinsulation strength and tensile strength and high resin curing degree.

Owner:DALIAN NORTH INSTR TRANSFORMER GROUP

Vacuum drying method for power transformer body

InactiveCN103390488AShorten drying timeImprove drying efficiencyDrying using combination processesInductances/transformers/magnets manufactureFurnace temperatureTransformer

The invention relates to the technical field of transformer vacuum drying, in particular to a vacuum drying method for a power transformer body. The method comprises the following steps of (1), warming preheating processing: opening a steam valve of a heating calandria and warming the interior of a tank to enable the temperature to rise evenly, wherein the warming speed is 15 DEG C per hour, the warming time is 1-6 hours, and the furnace temperature is controlled to be 100-110 DEG C; (2), vacuumizing once per hour in the step (1), keeping the vacuum degree of 0.04 Mpa for 10-15 minutes, and stopping the vacuumizing and continuously heating; and (3) uniformly reducing the pressure in the vacuum tank evenly level by level after the preheating is finished, and keeping the vacuum degree of 0.02-0.05Mpa for 1-2 hours. According to the vacuum drying method for the power transformer body, vacuum drying processing is performed on the transformer body by heating a vacuum drying system, the drying time is short, the drying efficiency is high, the drying effect is good, and the electrical insulation strength and the product quality are effectively improved.

Owner:JIANGSU HENGTE GRP VALTTE ELECTRIC

A flame-retardant single-component moisture-cured silicone rubber and its construction method and application

ActiveCN107033599BExtended shelf lifeImprove electrical insulation strengthRubber materialPolymer science

The invention provides a flame-retardant single-component moisture-curable silicone rubber and a preparation method and application thereof and belongs to the field of organic silicon rubber materials. The preparation method of the flame-retardant single-component moisture-curable silicone rubber is characterized in that alpha,omega-hydroxyl-terminated polydimethylsiloxane serves as a basic resin, alkoxy silane serves as a cross-linking agent, organic tin serves as a catalyst, meanwhile reinforcing filler, increment filler, a fire retardant, hydroxyl scavenging agent and other components are adopted for matching, and the silicone rubber is obtained through vacuum kneading and mixing, extrusion and lamination and vacuum package. The silicone rubber is a single-component band-shaped or flaky material, is stable in appearance, has a certain initial strength and flexibility, and has good insulativity, weather resistance, heat resistance, acid-base resistance and flame retardant properties after moisture curing. The silicone rubber has good appearance and plasticity, can be attached in a planar mode, wound and bound, or be plugged, blocked and filled in joints and has the wide application prospect in the fields of cable damage repairing, insulated protection of exposed electrical connecting points and the like. The flame-retardant single-component moisture-curable silicone rubber is simple in preparation process and is especially suitable for industrial production, and the raw materials are wide in source.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

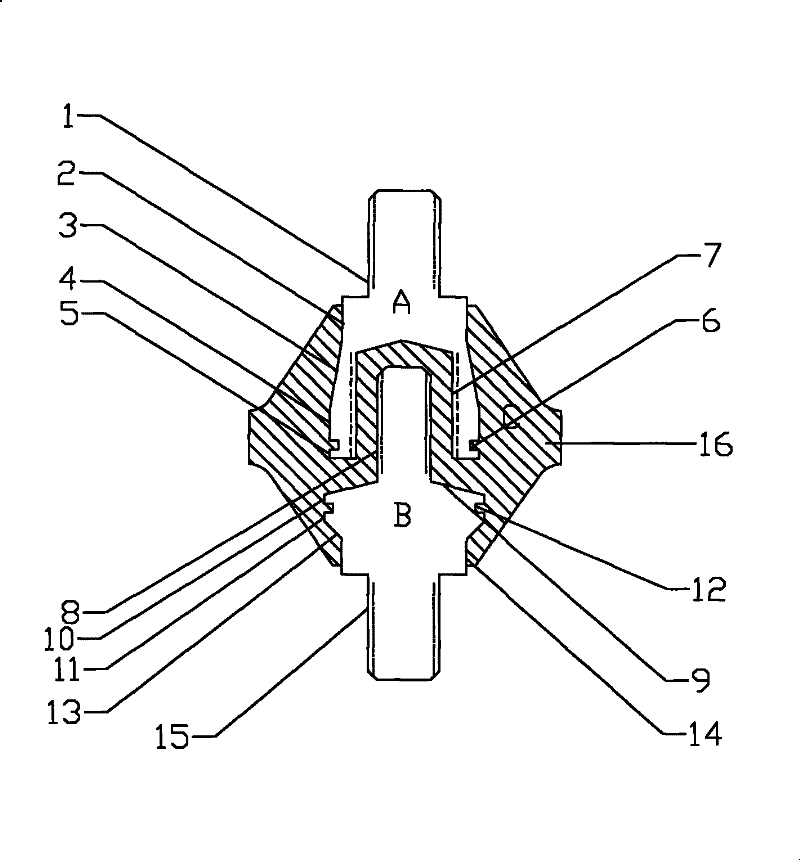

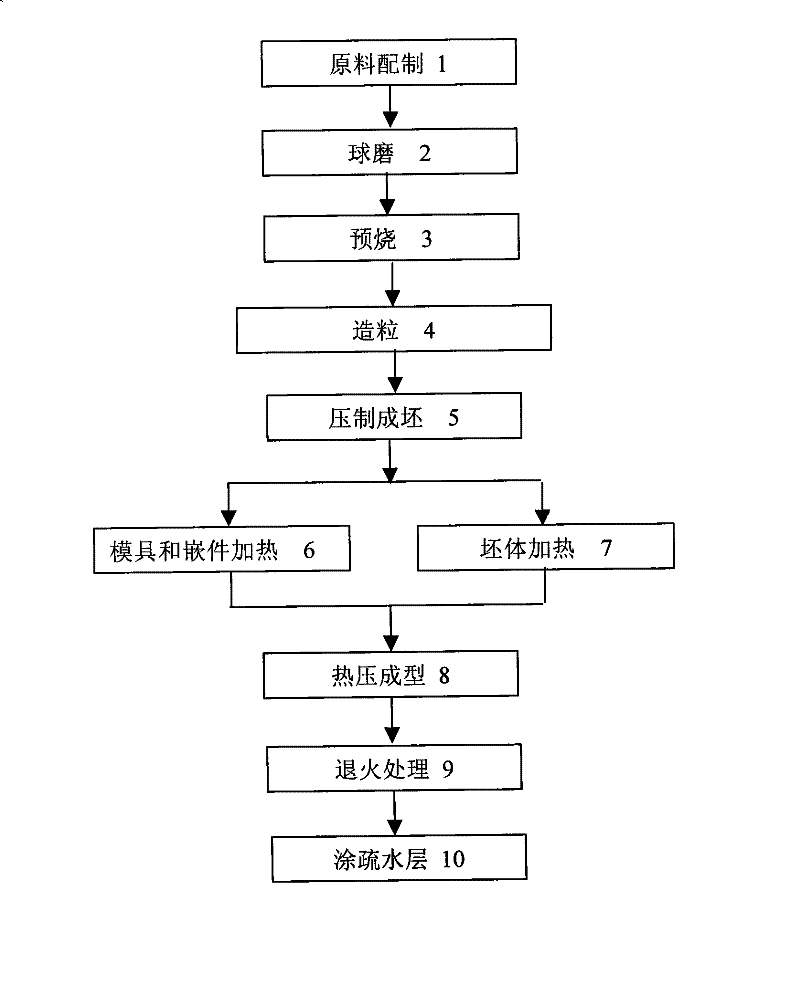

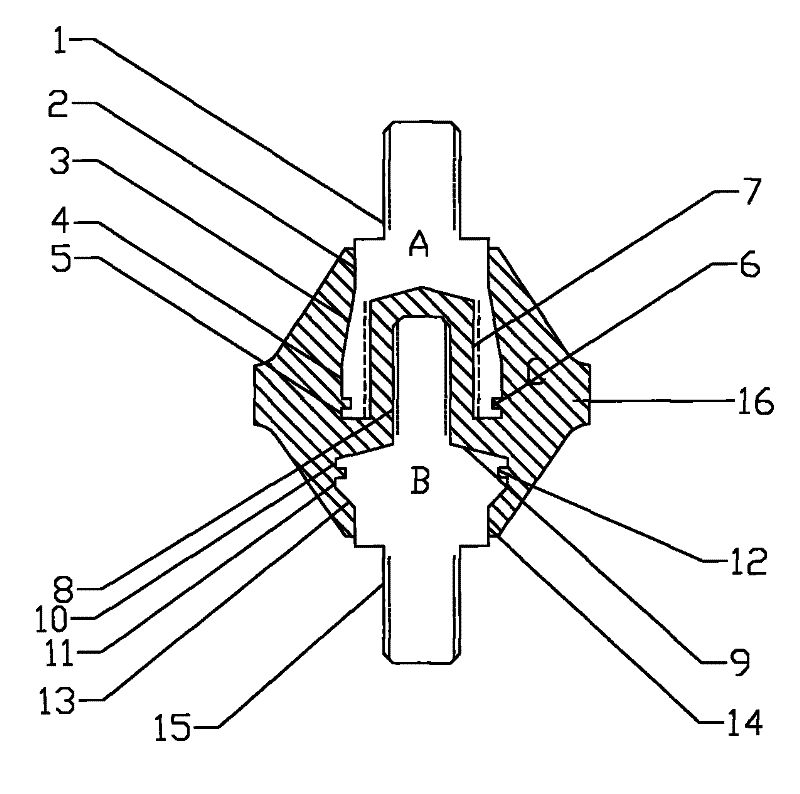

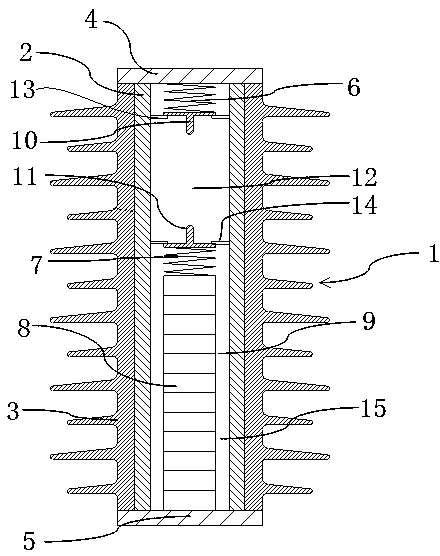

Mica ceramic insulator for novel high-speed power car and manufacturing method thereof

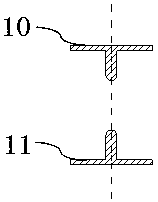

ActiveCN101746280BExtended service lifeImprove reliabilityTrolley linesAdditive ingredientTemperature resistance

The invention discloses a mica ceramic insulator for a novel high-speed power car and a manufacturing method thereof. The mica ceramic insulator mainly consists of a mica ceramic body and a metal connection terminal embedding piece, wherein the metal embedding piece comprises an upper and a lower independent terminals, the terminal is provided with an outer end and an inner end, the inner end is embedded inside the mica ceramic insulation body, one of the outer ends is installed on a fixed object, and the other end is connected with a conductive body. The mica ceramic insulator is produced ina hot-pressing method, i.e. the ingredients are pre-burned for 1 to 10 hours at the temperature of 750 to 1000 DEG C and are then pelletized into ceramic powder with the granularity of 10 to 100 meshes, the ceramic powder then is cooled to be a green body for hot-pressing, the mica ceramics and the metal terminal embedding piece are pressed and formed in a heated mould at a high temperature through a hot-press molding technology, and then the mica ceramic insulator product is prepared through the annealing and the coating treatment. The produced mica ceramic insulator has good insulation performance, good mechanical performance and high temperature resistance, and can completely satisfy the application requirement of the high-speed large-power AC power car.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

Composite insulated metallic oxide arrester

PendingCN108766697AExtended service lifeImprove use reliabilityOvervoltage protection resistorsElastomerMetal oxide surge arrester

The invention discloses a composite insulated metallic oxide arrester which comprises a hollow insulation pipe (2), an umbrella skirt sleeve (3), a first metal end plate (4), a second metal end plate(5), a first metal elastomer (6), a discharge gap structure, a second metal elastomer (7) and zinc oxide resistance pieces (8) which are arranged in a stacking manner; the first metal elastomer (6), the discharge gap structure, the second metal elastomer (7) and the zinc oxide resistance pieces (8) are axially arranged in the hollow insulation pipe from top to bottom; and the first metal elastomer, the discharge gap structure, the second metal elastomer and the zinc oxide resistance chips are all form gaps (9) with the hollow insulation pipe in a radial direction of the hollow insulation pipe.By adopting variable series gap composite insulated metallic oxide arrester, during normal running, lightning overvoltage and operation overvoltage allowed by running voltage and electrical equipmentcan not be applied to the zinc oxide resistance chips, so that the phenomena of electrical aging and thermal destruction caused by long-term electrification are avoided, and meanwhile, the problem ofarcs caused by sustaining current between adjacent series gaps after overvoltage disappears can also be prevented.

Owner:泰州学院

Method for preparing high-strength porcelain insulator blank by agitating type sanding

InactiveCN101780430AHigh mechanical strengthImprove electrical insulation strengthGrain treatmentsSeparation technologyHigh pressure

The invention relates to a method for preparing high-strength porcelain insulator blank by agitating type sanding, belonging to a continuous grinding process, and comprising the steps of high efficiency quick grinding by agitating type sanding, hydrocyclone separation and regrinding of coarse particles. In the invention, according to the requirements for hardness and fineness of raw materials, high efficiency quick grinding is carried out by agitating type sanding, thereby greatly improving the grinding efficiency, shortening the grinding time, reducing the scope of particle size distribution, and reducing the energy consumption of grinding. The hydrocyclone separation technology is adopted, particles achieving the fineness requirement are separated in time, and coarse particles which do not achieve the fineness requirement are returned to be reground, thereby preventing the raw materials from being overground, and eliminating the harmful coarse particles. The invention is suitable for grinding a single raw material and mixture of a plurality of raw materials, can effectively reduce the preparation cost of the high-strength porcelain insulator blank, and improves the mechanical strength, electrical insulation strength and operation reliability in a high-voltage fence of porcelain insulator products.

Owner:HUNAN UNIV

Method for preparing high-strength porcelain insulator blank by agitating type sanding

InactiveCN101780430BHigh mechanical strengthImprove electrical insulation strengthGrain treatmentsSeparation technologyHigh pressure

Owner:HUNAN UNIV

A New Processing Method for Insulating Cylinder

InactiveCN103117141BImprove electrical insulation strengthSimple preparation processInsulatorsElectricityUltimate tensile strength

The invention relates to a novel insulating cylinder processing method. A die can be processed by a 1-3 mm sheet, and the size of an inner cavity of the die is adjustable. Preimpregnating epoxy digital mirror device (DMD) rolling materials are in thickness of 0.2mm, and the width of the preimpregnating epoxy DMD rolling materials are the same with the height of the insulating cylinder. The preimpregnating epoxy DMD rolling materials is utilized to roll on a foil winder and a coiler to the requested thickness (coiling effects of foil winder is better). The tail end is fixed stably by double faced adhesive tapes, and then the die is carried into an oasthouse to solidify. The solidification temperature is 130 degrees - 140 degrees. The solidification time is 3 hours -4 hours. After the solidification is cooled, screws can be adjusted by shrinking and the die is demolded. When two ends are in rubdown, the die can be used. The novel insulating cylinder processing method provides an insulating cylinder which is beautiful in appearance, excellent in insulating performance, extremely high in strength, simple in manufacturing crafts, low in cost, short in production cycle, good in laboring conditions for middle-high voltage electricity electric equipment.

Owner:KUNSHAN SPECIAL TRANSFORMER MFR

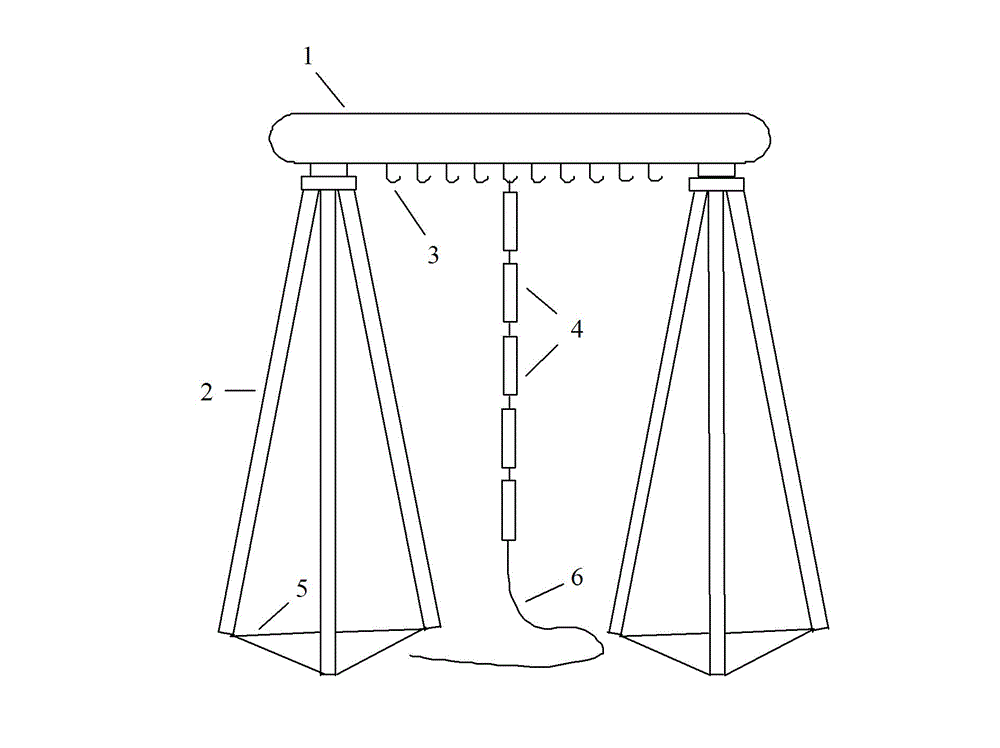

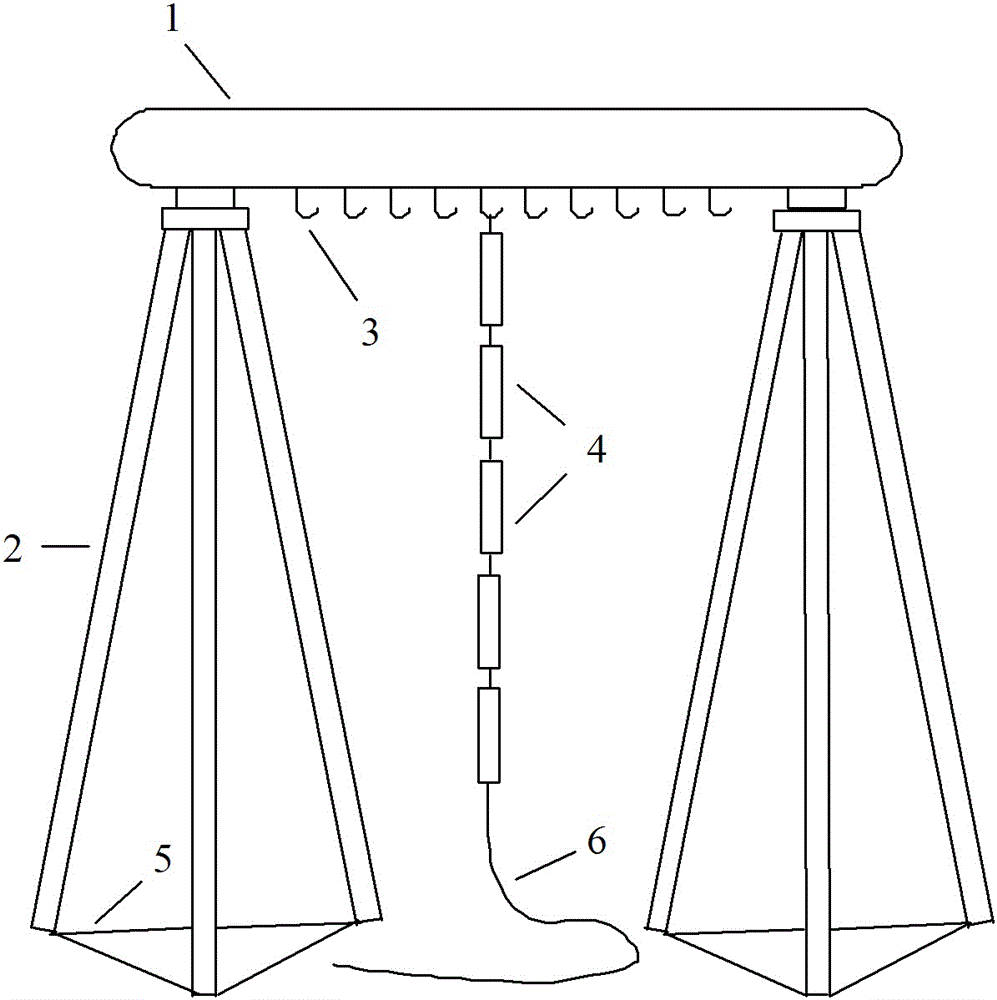

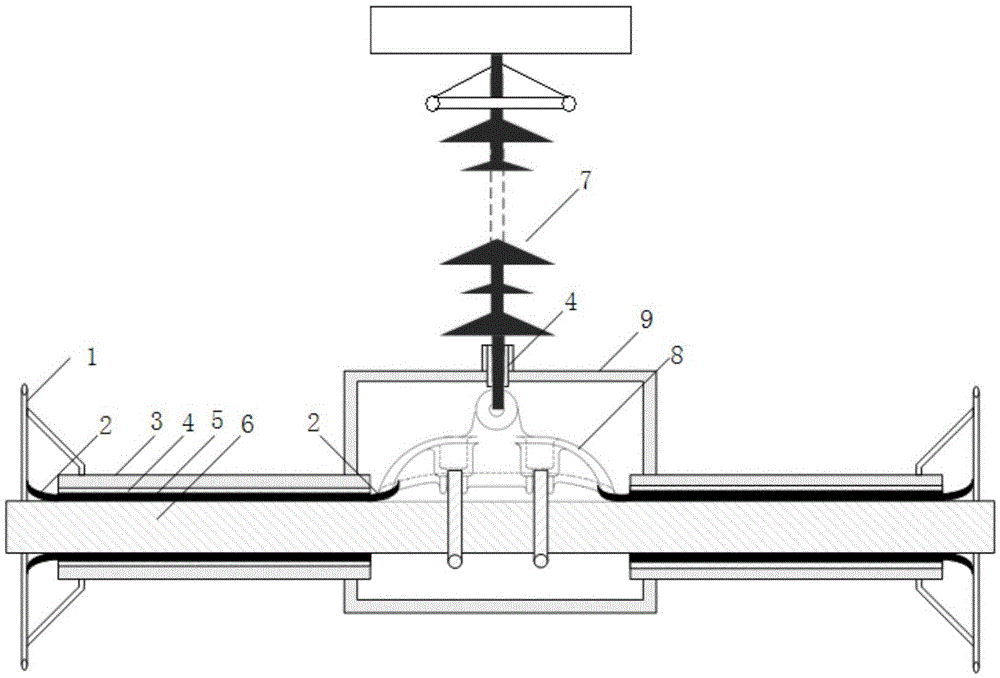

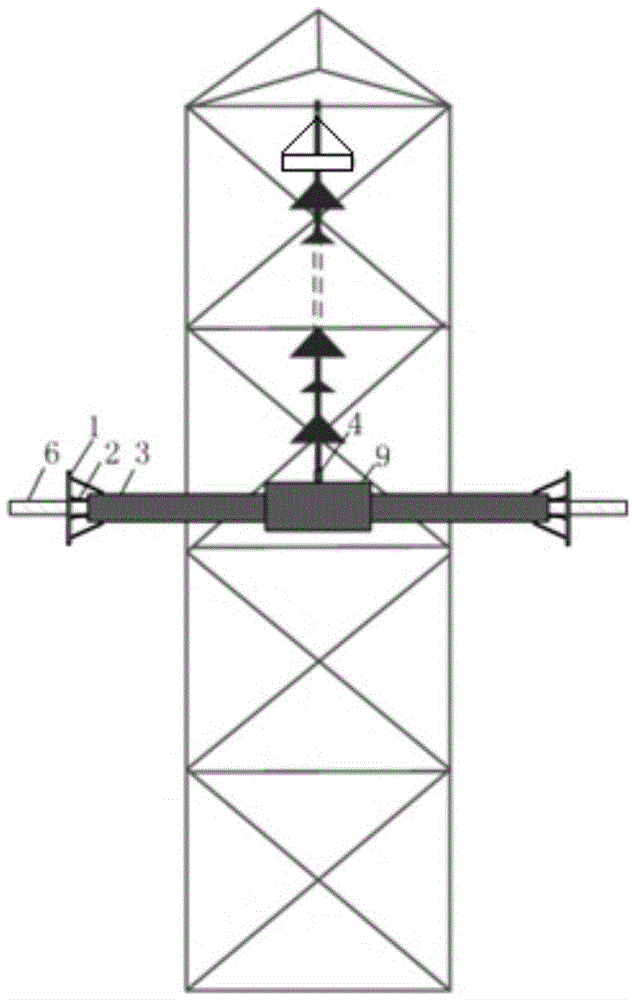

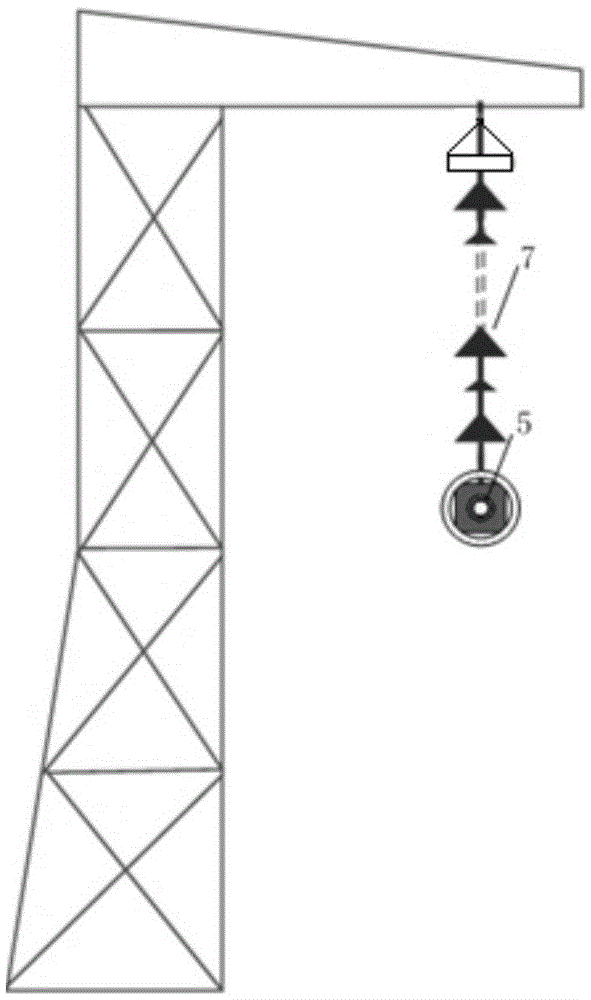

Adjustable high-voltage capacitor device

ActiveCN102915842ARealize concatenationCapacitance continuous adjustmentMultiple capacitorsMechanical engineeringElectric Capacitance

The invention relates to a suspended adjustable high-voltage capacitor device which is particularly capable of regulating capacitance in an approximately stepless manner. The suspended adjustable high-voltage capacitor device comprises a conducting rod and a high-voltage capacitor; and a voltage-sharing conducting rod is connected with an insulating tripod, and a hook is arranged on the voltage-sharing conducting rod and connected with the high-voltage capacitor. The insulating tripod is made of insulating resin with good mechanical strength and electrical insulation strength, thereby providing suspension space to series capacitors and ensuring that the ground insulation strength of the voltage-sharing conducting rod can meet relevant specification requirements. Die to the series and parallel combined connections of the high-voltage capacitors with different capacitances, the capacitance of the whole capacitor device can be approximately continuously adjusted within a very wide range. The capacitance can be approximately continuously adjusted within the range of 0-10000 pF, and the fineness of adjustment can reach 100 pF. The capacitance of the capacitor device can be adjusted in the approximately stepless manner, the overall withstand voltage can reach 300 kV, and due to the separated structure, the adjustable high-voltage capacitor device can be conveniently transported, assembled and used on site.

Owner:LIAONING ELECTRIC POWER COMPANY LIMITED POWER SCI RES INSTION +2

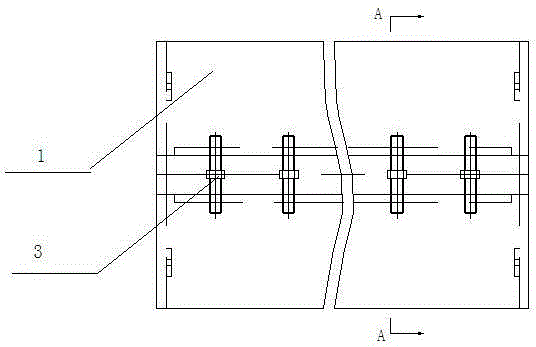

Plasma generating device

InactiveCN110876223AIncrease distanceImprove insulation performancePlasma techniquePlasma technologyEngineering

The invention relates to the technical field of plasmas, and specifically relates to a plasma generating device. The device comprises a high-voltage discharge tub, a grounding discharge tube, a high-voltage-side insulating support plate and a grounding-side insulating support plate, wherein the high-voltage discharge tube and the grounding discharge tube are respectively provided with wiring terminals; the high-voltage-side insulating support plate and the grounding-side insulating support plate are respectively provided with through wiring through holes, the wiring terminal of the high-voltage discharge tube is fixed on the high-voltage-side insulating support plate and is connected with a high-voltage power supply through the wiring through hole of the high-voltage-side insulating support plate, the grounding discharge tube is fixed on the grounding-side insulating support plate and is grounded through the wiring through hole of the grounding-side insulating support plate, and the high-voltage-side insulating support plate and the grounding-side insulating support plate are arranged on two opposite sides. According to the plasma generating device, the insulating property of the plasma generating device can be remarkably improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

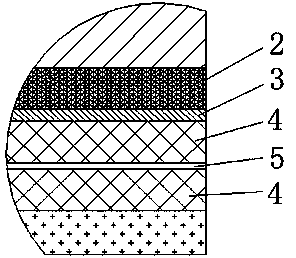

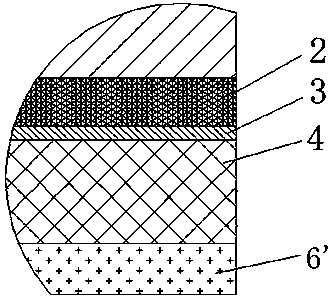

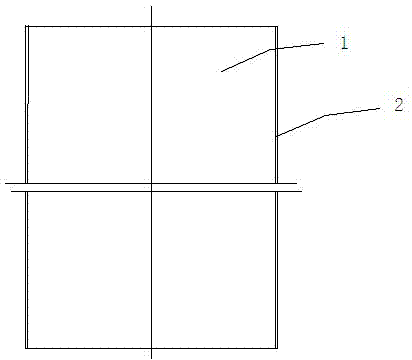

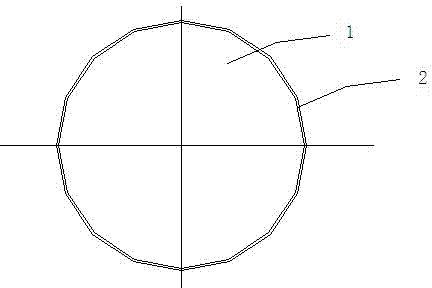

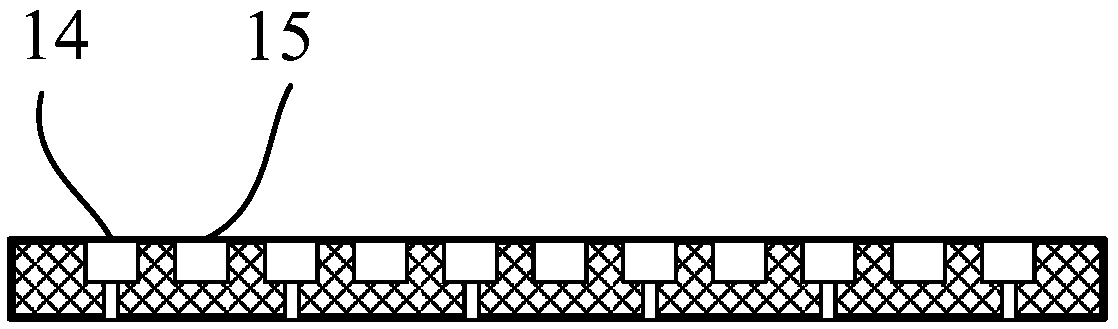

A kind of hollow copper flat wire and preparation method thereof

ActiveCN111613369BImprove adhesionGood electrical insulation Strong adhesionDetails of conductive coresFlexible cablesThin membraneEngineering

The invention belongs to the technical field of cables and wires, and specifically relates to a flat copper hollow wire and a preparation method thereof. The flat copper flat wire includes a flat copper hollow core, and an insulating paint film (2 ) or film; the preparation method includes the following steps: (1) processing hollow copper flat wire core; (2) cooling and drying; (3) processing insulating paint film; (4) processing film wrapping. The invention has high machining dimensional accuracy (tolerance ±0.03mm), low manufacturing cost, unlimited length, high surface current density, good electrical insulation strength, and can withstand the test of various environmental factors. The outsourcing insulating varnish and The film has stable performance, strong adhesion, can withstand various subsequent processing, and has good processing performance; the structure is simple and compact, which is conducive to reducing the volume of the coil, reducing the amount of copper used, and can effectively reduce costs.

Owner:WUXI TOLY ELECTRIC WORKS

Adjustable high voltage capacitor device

ActiveCN102915842BRealize concatenationCapacitance continuous adjustmentMultiple capacitorsHigh voltage capacitorsEngineering

The invention relates to a suspended adjustable high-voltage capacitor device, especially capable of approximately "steplessly" adjusting the size of the capacitor. It includes a conductive rod and a high-voltage capacitor; the voltage-equalizing conductive rod is connected with an insulating tripod, and a hook is arranged on the voltage-equalizing conductive rod, and the hook is connected with the high-voltage capacitor. The insulating tripod is made of insulating resin, which has good mechanical strength and electrical insulation strength, provides suspension space for series capacitors and ensures that the insulation strength of the equalizing conductive rod to the ground meets the requirements of relevant regulations. Through the series-parallel connection of high-voltage capacitors with different capacitance values, the approximate continuous adjustment of the capacitance of the overall capacitor device in a relatively wide range is realized. It can realize approximately continuous adjustment of capacitance within the range of 0-10000pF, and the adjustment fineness can reach 100pF. The approximate stepless adjustment of the capacitance of the capacitor device is realized, and the overall withstand voltage can reach 300kV, and the invention adopts a split structure, which is convenient for transportation and on-site assembly and use.

Owner:LIAONING ELECTRIC POWER COMPANY LIMITED POWER SCI RES INSTION +2

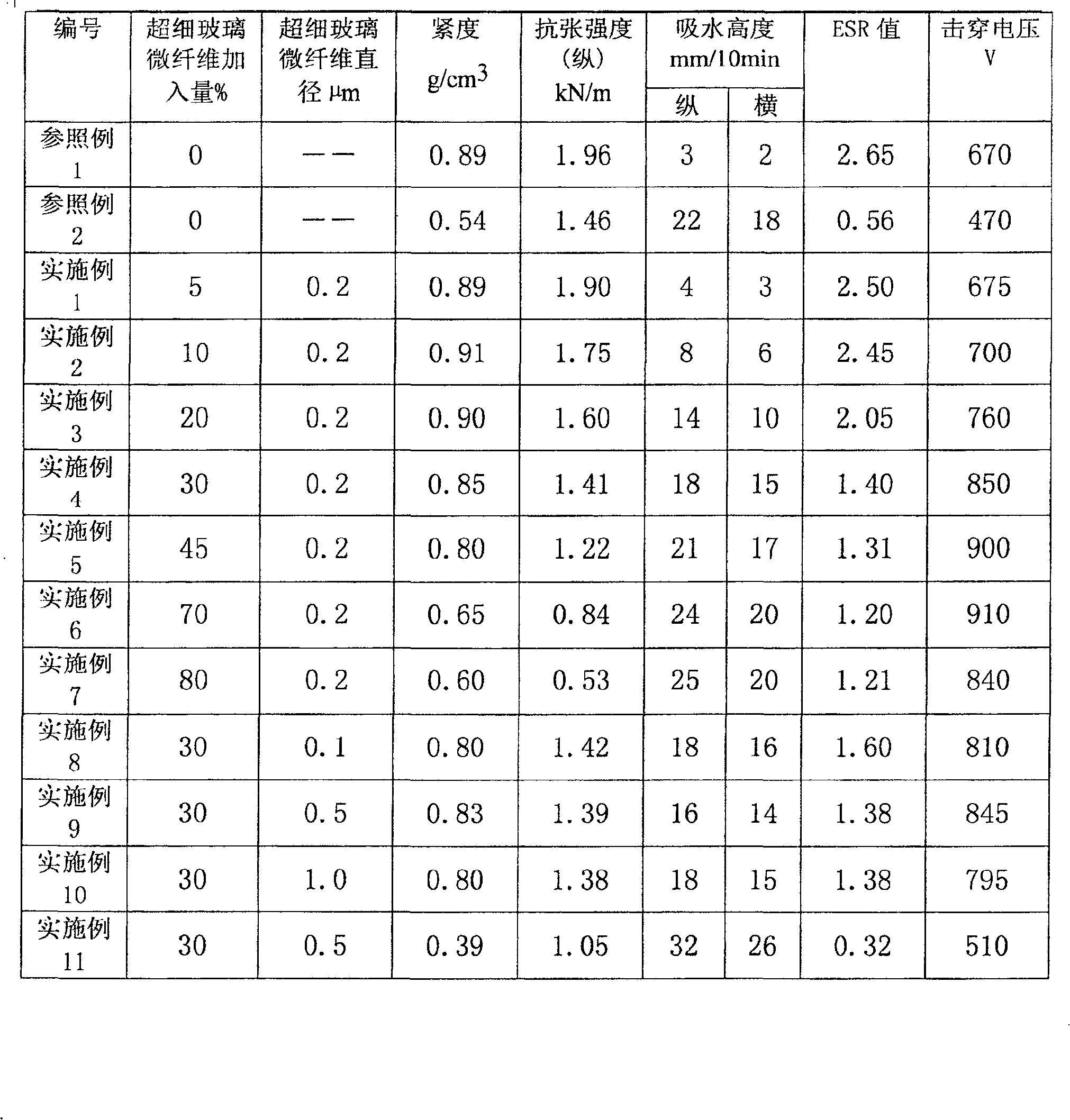

Fire-resistant insulating material with mechanical strength and preparation method

InactiveCN111574113AHigh mechanical strengthGuaranteed mechanical propertiesCarbide siliconGlass fiber

The invention discloses a fire-resistant insulating material with mechanical strength and a preparation method thereof. The fire-resistant insulating material is prepared from the following raw materials in parts by weight: 100-200 parts of mica powder, 20-30 parts of alkali-free glass fibers, 20-30 parts of glass fibers, 50-60 parts of a binder, 30-40 parts of methylbenzene, 20-40 parts of a polyether ammonium curing agent and 10-20 parts of aluminum hydroxide powder. The mica powder is a powdery mixture which is composed of mica, aluminosilicate, carbonate and a high-heat-resistance inorganic mineral having undergone grinding and smashing and uses the ground and smashed mica as a main component. The high-heat-resistance inorganic mineral is one or more selected from a group consisting ofa clay material, a high-aluminum material, a corundum material, a silicon material, a magnesium material and a silicon carbide material. The ire-resistant insulating material of the invention has thetechnical effects of high heat resistance and high mechanical strength.

Owner:天津市海纳源科技有限公司

Electrolytic capacitor paper

ActiveCN100552840CImprove electrical insulation strengthGood chemical stabilitySpecial paperElectrolytic capacitorsElectrolysisUltra fine

The invention relates to an electrolytic capacitor paper, in particular to an electrolytic capacitor paper for enhancing voltage resistance and reducing loss. The electrolytic capacitor paper is made by adding ultrafine glass microfibers into papermaking slurry, the addition of the ultrafine glass microfibers is 5% to 80% of the weight of the electrolytic capacitor paper, and the diameter of the ultrafine glass microfibers is 0.1μm~10μm. The invention adopts adding ultra-fine glass microfibers into the slurry in the conventional electrolytic capacitor paper manufacturing process. Utilize the unique properties of ultra-fine glass microfibers to improve the voltage resistance of electrolytic capacitor paper, reduce its impedance, improve electrical performance, increase the life of electrolytic capacitors, and reduce the power loss of electrolytic capacitors.

Owner:浙江凯恩新材料有限公司 +1

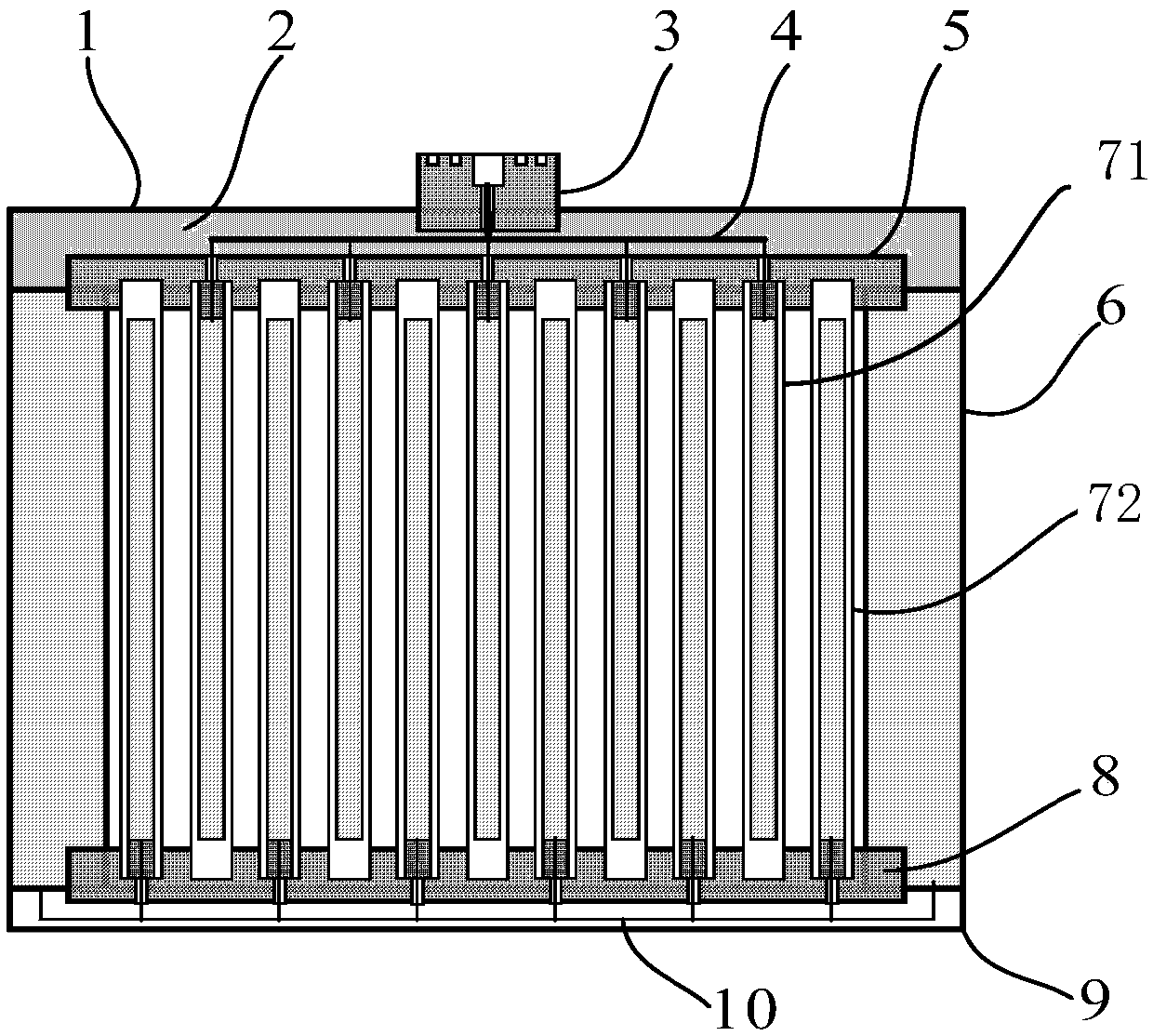

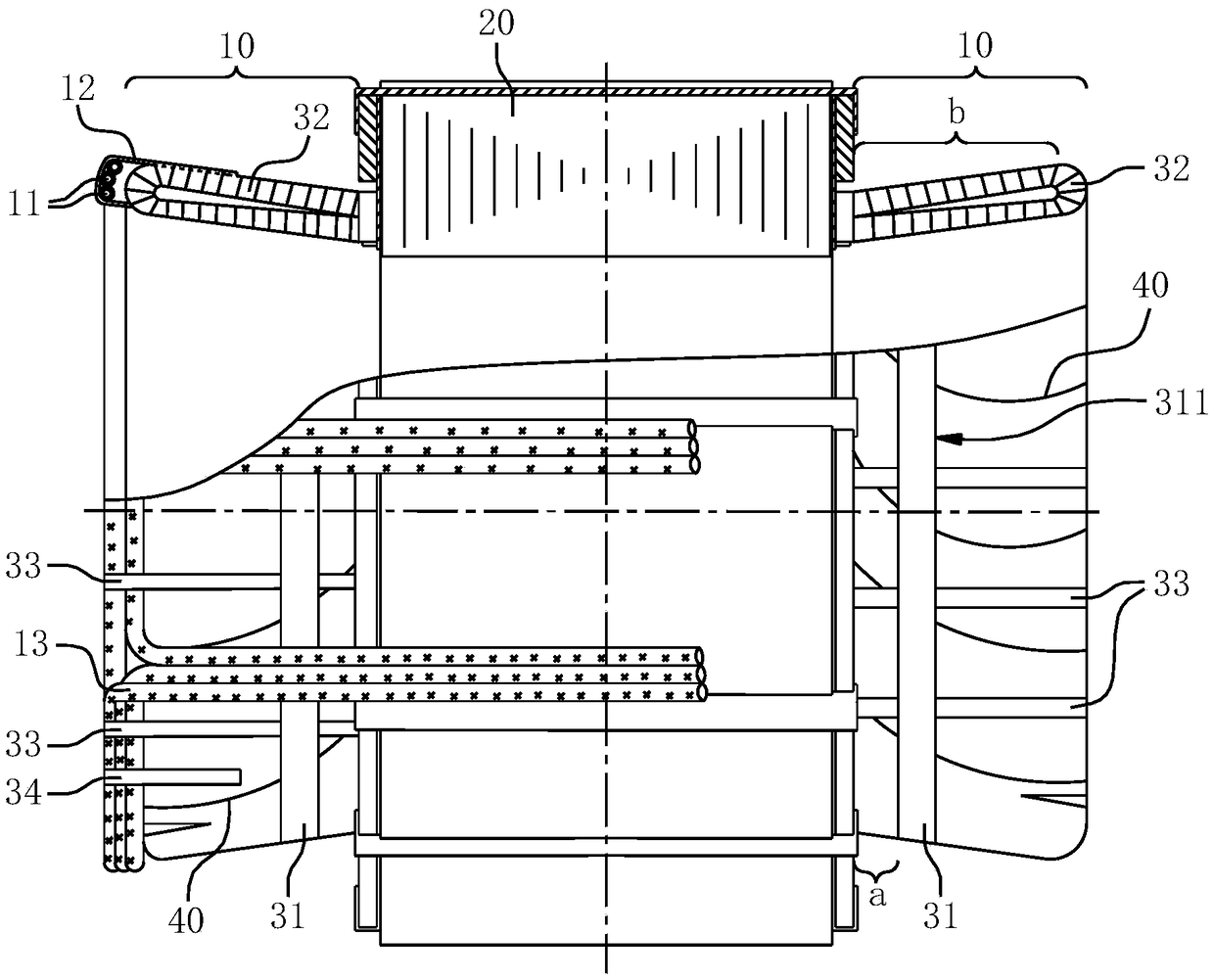

Low-speed large-torque permanent magnet direct drive motor stator winding end part fixing structure and binding process

PendingCN108696029AHigh mechanical strengthImprove electrical insulation strengthWindings insulation shape/form/constructionManufacturing dynamo-electric machinesLow speedEngineering

The winding acquired by the low-speed large-torque permanent magnet direct drive motor stator winding end part binding process has the following fixing structure: the wire body of each turn of coil located outside a stator iron core wire embedding groove body is completely coated by an insulating material; the insulating material fills the place between adjacently-arranged heterogeneous coils; insulating paper is adopted in the embodiment of the invention, and in other embodiments, other insulating materials can also be used for filling; multiple turns of coils crossing adjacent two wire embedding groove wall end surfaces are bound and fixed by an insulating band; the periphery around the end part of the winding is coated with an end hoop; and a bridge crossing wire and a leading out wireform a ring-shaped wire harness to be fixed on the periphery of the end part of the winding. The winding end part has good mechanical strength and electrical insulation strength, and the reliability,the stability and the durance of the low-speed large-torque permanent magnet direct drive motor can be greatly enhanced.

Owner:ANHUI WANNAN ELECTRIC MACHINE

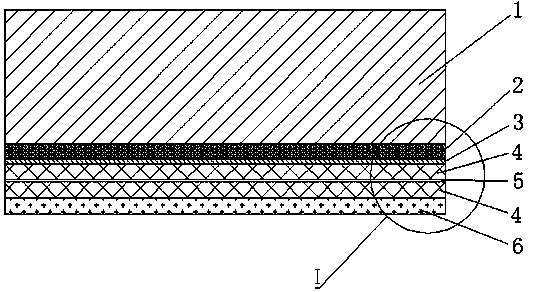

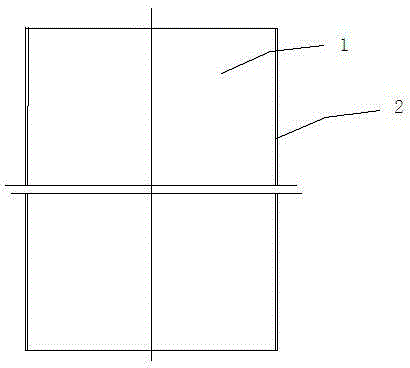

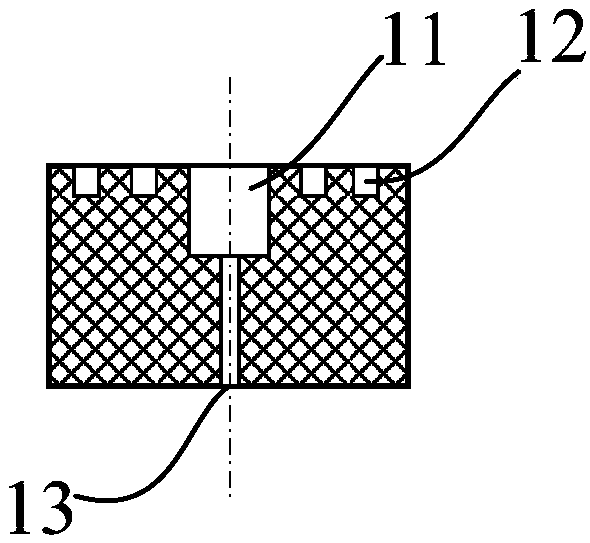

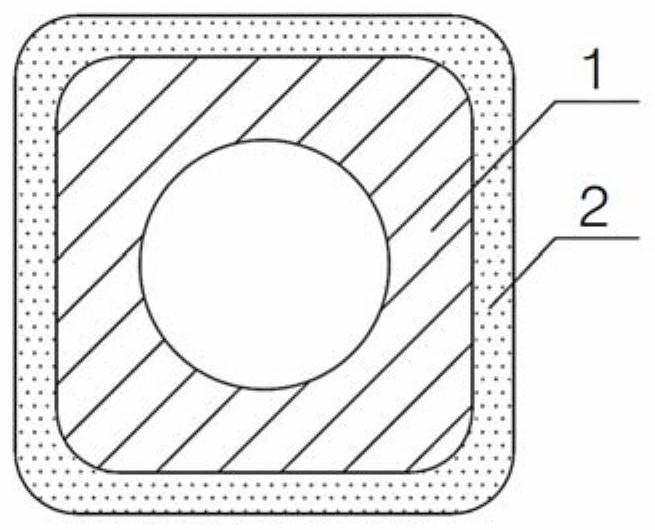

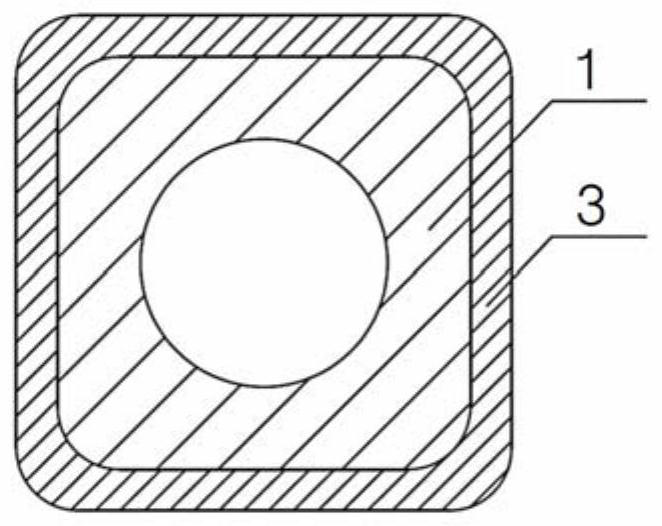

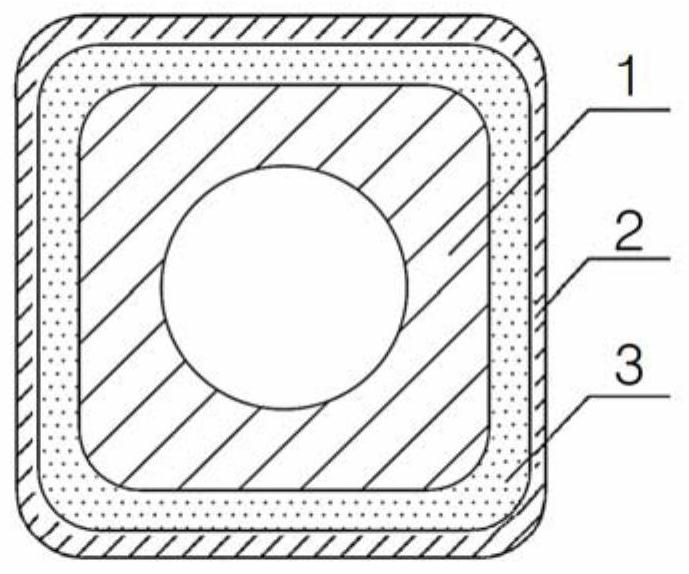

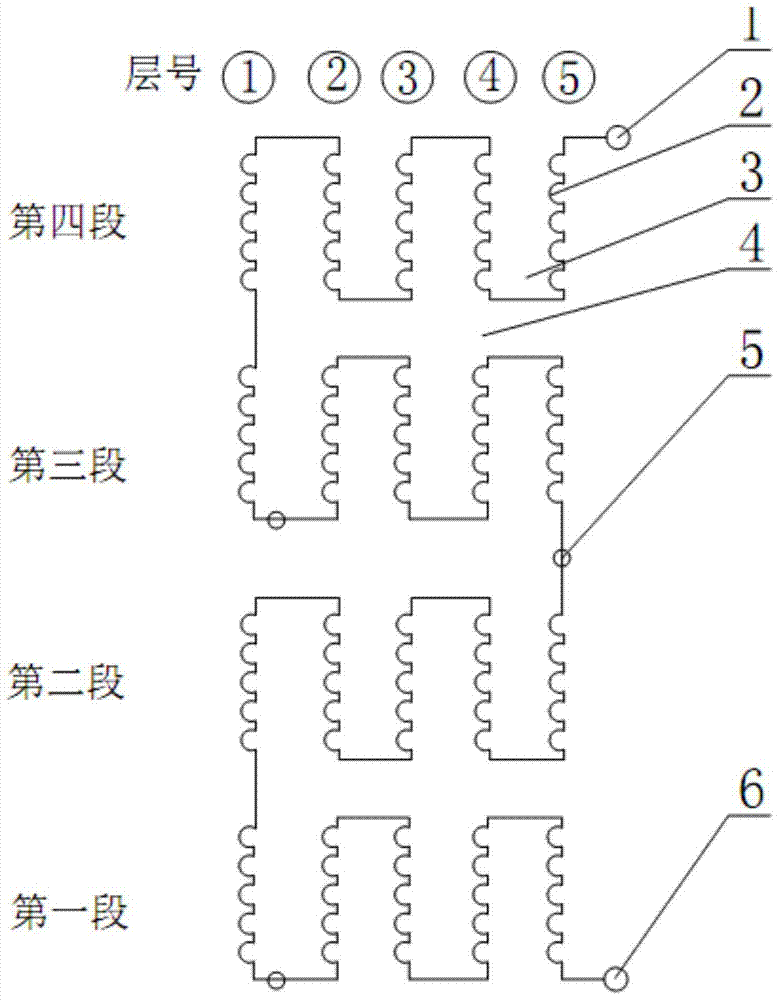

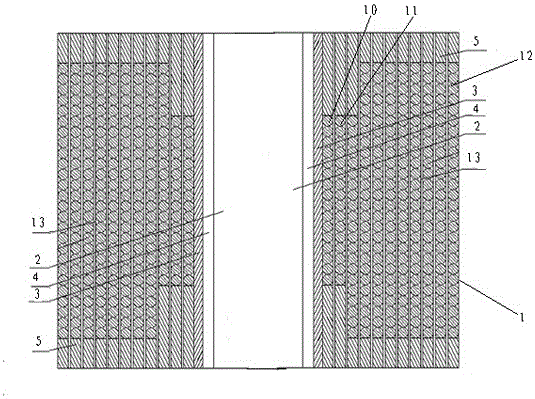

A reactor coil with reinforced interlayer insulation structure

InactiveCN105118635BImprove insulation performanceImprove electrical insulation strengthTransformers/inductances coils/windings/connectionsInter layerUltimate tensile strength

The invention discloses electric reactor coils of a reinforced interlayer insulation structure. The electric reactor coils of the reinforced interlayer insulation structure comprise multiple layers of winding coils, interlayer insulation and insulating films, wherein the multiple layers of the winding coils are arranged around an electric reactor magnetic leg in a spaced and enveloping mode, each layer of the winding coil is arranged in a spaced and overlaid mode, and all the layers of the winding coils are connected with one another in series; the interlayer insulation is arranged between the two adjacent layers of the winding coils, the insulating films are arranged at the head end and the tail end of each layer of the winding coil in a covering mode, the insulating films are each shaped like a rectangle, each insulating film is folded in half along the center line in the width direction, each center line portion abuts against the end of each layer of the winding coil, and the two folded edges of each insulating film extend to the interior of the corresponding winding coil for a certain distance and wrap multiple numbers of coils at the end of each layer of the winding coil. According to the electric reactor coils of the reinforced interlayer insulation structure, the technical problem that interlayer breakdown occurs at the two ends of the coils is solved, and the insulating strength of the coils is improved.

Owner:KUNSHAN SPECIAL TRANSFORMER MFR

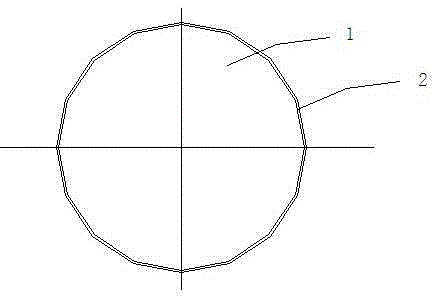

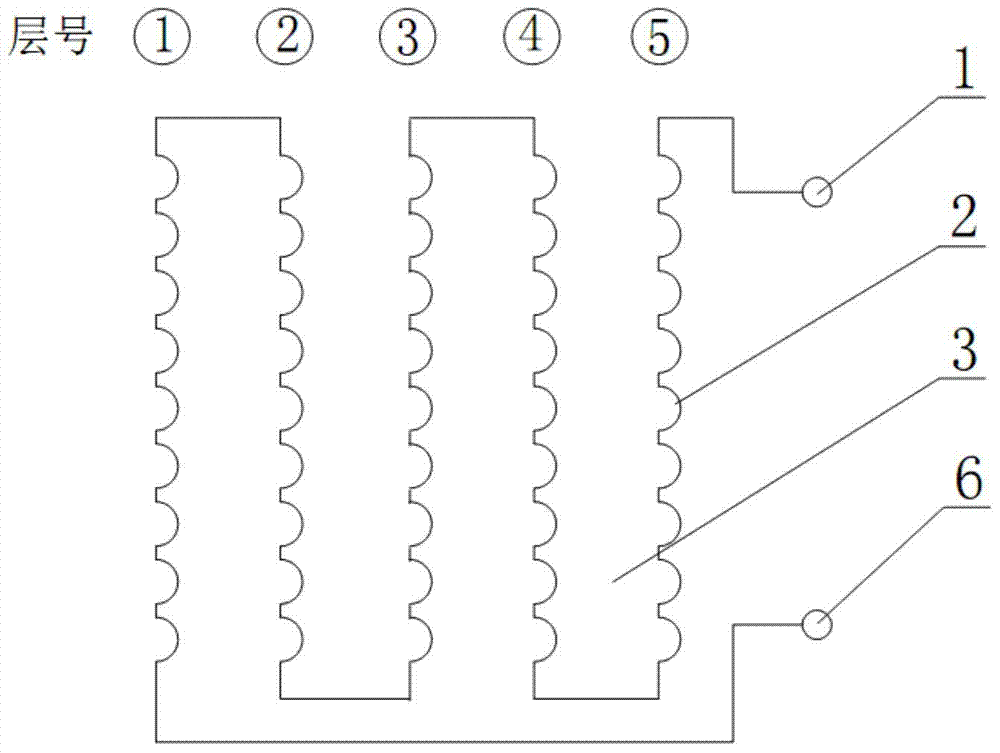

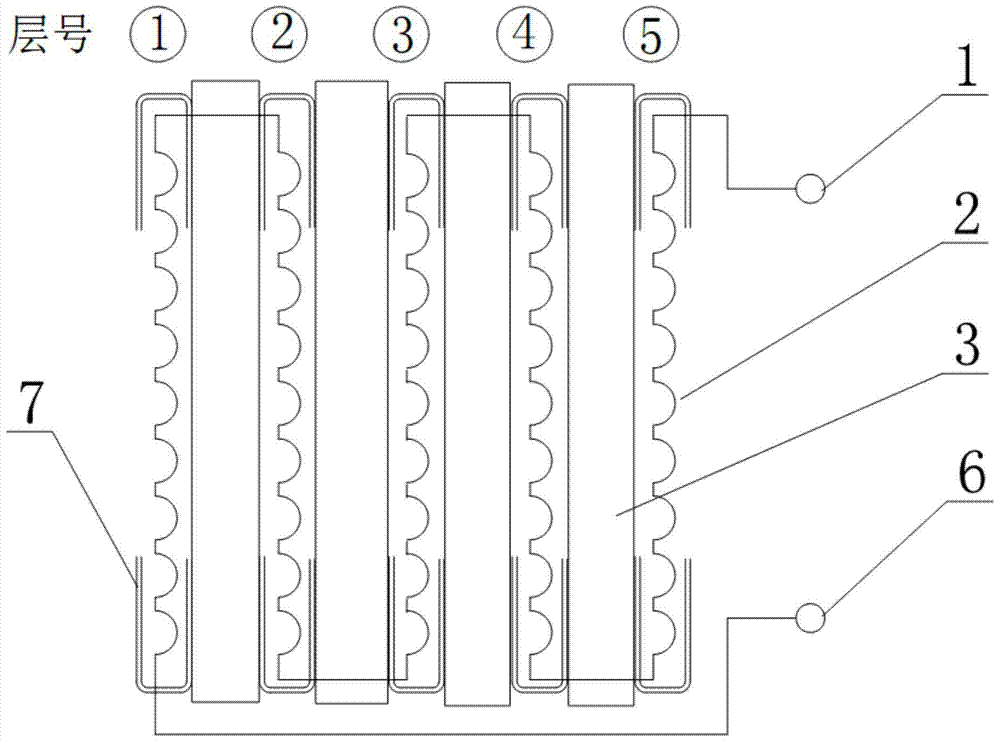

Layer coil for oil-immersed distribution transformer and manufacturing method of layer coil

InactiveCN105931822AAffect heat dissipationImprove electrical insulation strengthTransformers/inductances coils/windings/connectionsCoils manufactureDistribution transformerLow voltage

The invention relates to a layer coil for an oil-immersed distribution transformer and a manufacturing method of the layer coil. The layer coil comprises multiple layers of low-voltage coils and high-voltage coils, which are sequentially wound from the inside to the outside, wherein a main empty path is formed between the high-voltage coils and the low-voltage coils; the high-voltage coils are wound on the outer side of the main empty path; the high-voltage coils are sequentially wound by a first layer of coil, a second layer of coil and an Nth layer of coil from the inside to the outside; an interlayer insulating layer is arranged between two adjacent coils of the high-voltage coils; stepped insulating layers are arranged at the upper ends and the lower ends of the high-voltage coils; and the thickness of the insulating layer at the inner side is greater than that of the insulating layer at the outer side. The layer coil for the oil-immersed distribution transformer has the beneficial effect that the electric insulation strength between the high-voltage coils and the low-voltage coils is improved.

Owner:STATE GRID CORP OF CHINA +1

A protection device against wind and deflection flashover for transmission lines

ActiveCN103997007BImprove electrical insulation strengthAvoid mechanical strengthDevices for damping mechanical oscillationsInsulated cablesPartial fieldEngineering

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com