Electrolytic capacitor paper

A technology for electrolytic capacitor paper and pulp, applied in the direction of electrolytic capacitors, capacitors, special paper, etc., can solve the problems of reducing plant fibers, limited beating degree of plant fibers, and difficulty in manufacturing capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

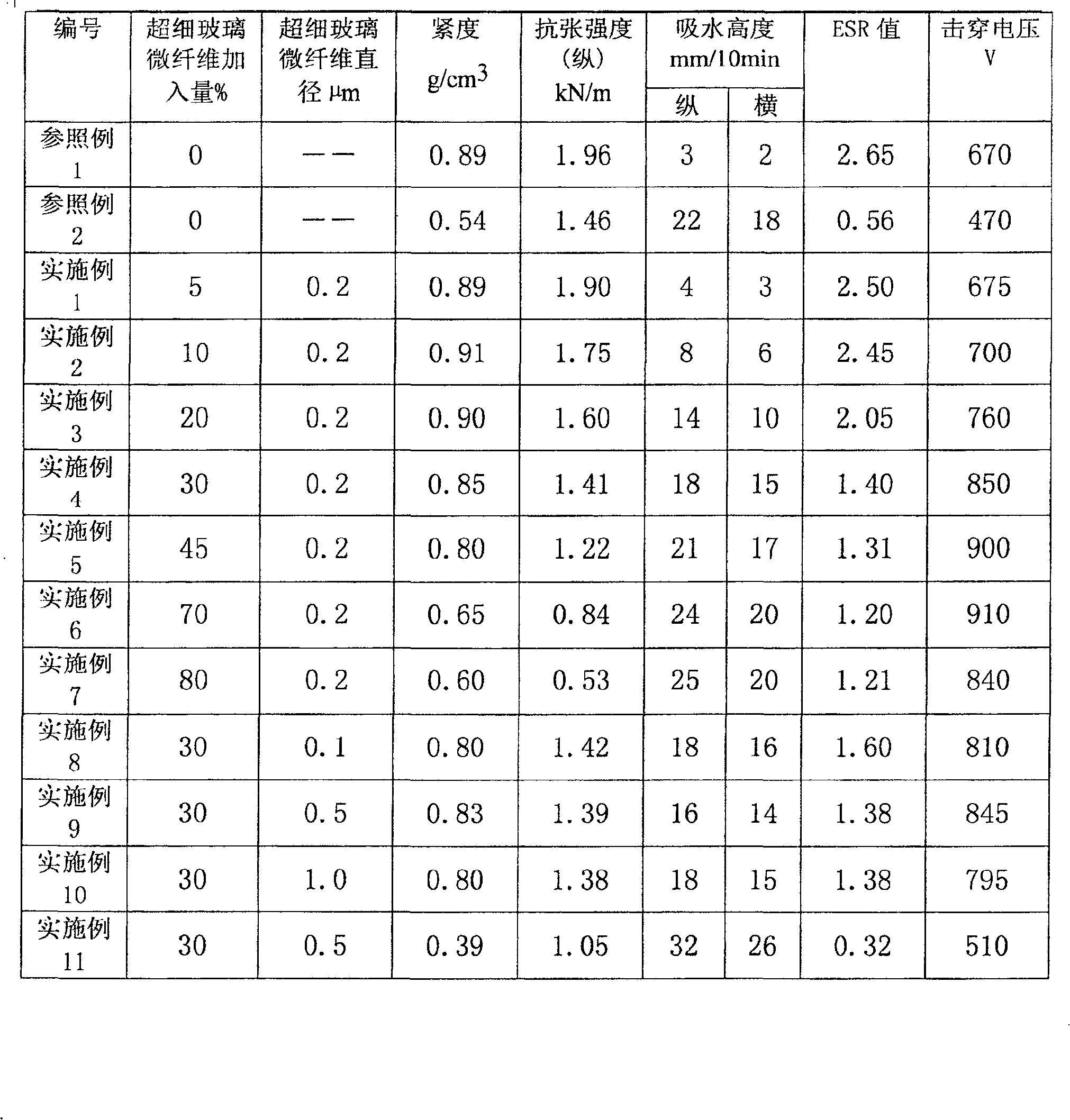

[0013] Reference example 1: The insulating wood pulp is beaten to 94°SR by a disc mill, and the wet weight is 3.0g, and paper is made by a fourdrinier paper machine. Coiling after drying, the paper has a thickness of 40μm and a tightness of 0.89g / cm 3 , the tensile strength is 1.96kN / m, the water absorption height is 3mm / 10min in the longitudinal direction, 2mm / 10min in the transverse direction, the loss ratio is 2.65, and the breakdown voltage is 670V.

example 2

[0014] Reference example 2: sisal pulp was beaten to 35 ° SR, wet weight 14.5g, papermaking with a cylinder paper machine. Coiling after drying, the paper has a thickness of 40μm and a tightness of 0.54g / cm 3 , the tensile strength is 1.46kN / m, the water absorption height is 22mm / 10min in the longitudinal direction, 18mm / 10min in the transverse direction, the loss ratio is 0.56, and the breakdown voltage is 470V.

Embodiment 1

[0015] Embodiment 1: Add 5% ultrafine glass microfibers of 0.2 μm provided by Nanjing Aixin Glass Microfiber Products Co., Ltd. to the slurry of Reference Example 1, and make paper in the same way. After measuring, the thickness of the paper is 40μm, tightness up to 0.89g / cm 3 , the tensile strength is 1.90kN / m, the water absorption height is 4mm / 10min in the longitudinal direction, 3mm / 10min in the transverse direction, the loss ratio is 2.50, and the breakdown voltage is 675V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com