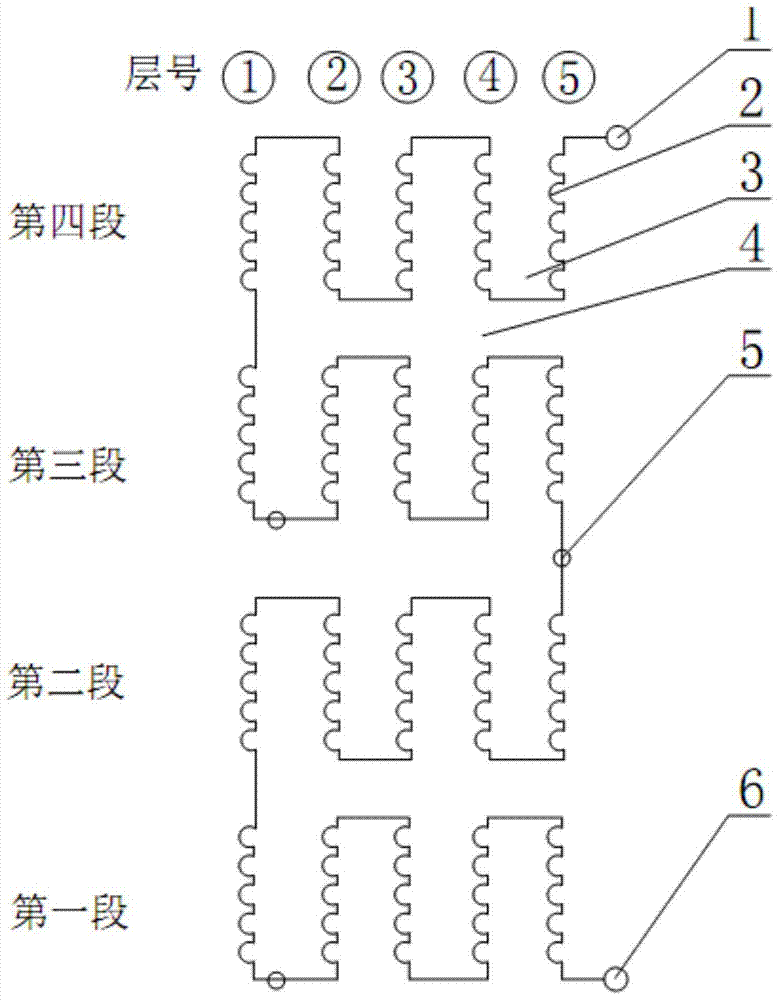

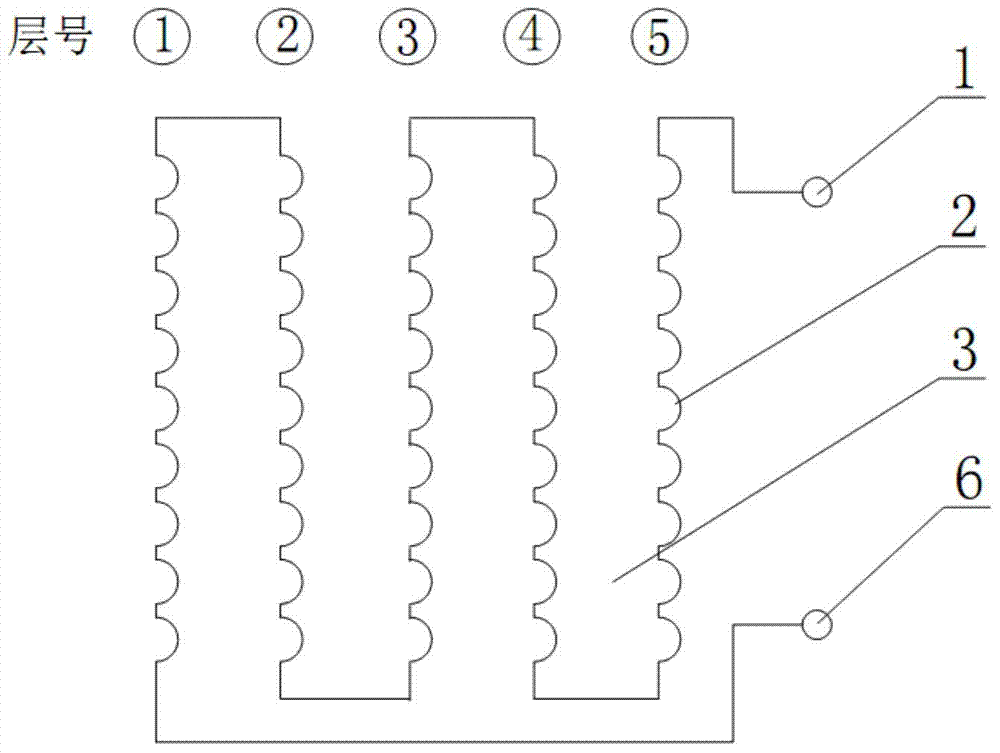

A reactor coil with reinforced interlayer insulation structure

An interlayer insulation and reactor technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of not effectively strengthening the end insulation, low coil filling factor, hidden quality problems, etc. High efficiency, stable product performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

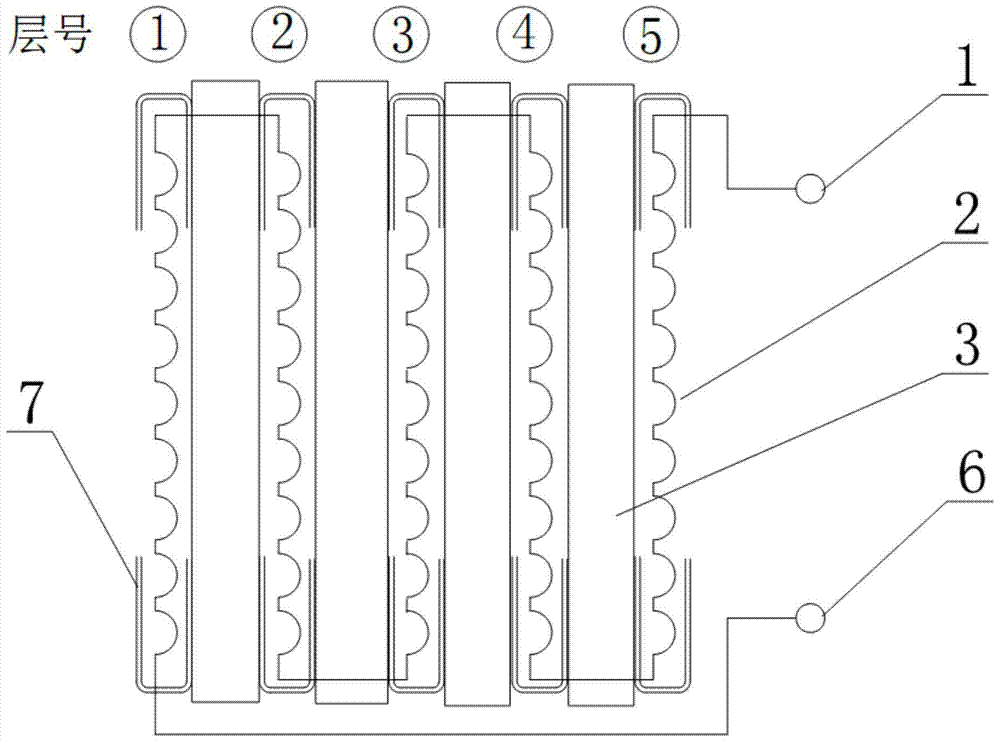

specific Embodiment approach

[0040] The specific implementation method: wrap the insulating film 7 on the entire circumference of the two ends of each layer of winding coil. Generally, each end of the winding coil is wrapped with the insulating film 7 of the entire circumference. It is divided into two sections along the circumference and wrapped respectively. overlay. First, prepare enough insulating film with a length longer than half of the circumference of the layer and a certain width for each layer of winding coil. When winding the beginning of each layer of winding coil, press half of the width of the insulating film along the entire circumference. After winding to a certain number of turns, turn the other half of the width of the insulating film upwards to cover the top of the turns. The insulating film is turned up in two sections along the circle, which is more convenient. In this way, the beginning of each layer of winding coil is completely wrapped by the insulating film on the entire circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com