Layer coil for oil-immersed distribution transformer and manufacturing method of layer coil

A distribution transformer, oil-immersed technology, applied in the field of transformers, can solve the problems of reduced insulation strength, complex coil process, easy to affect coil heat dissipation, etc., and achieve the effect of improving electrical insulation strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

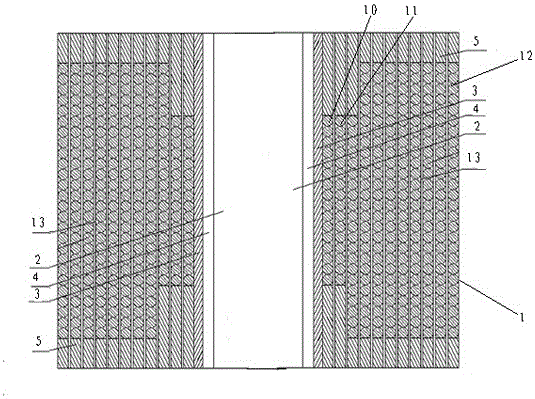

[0020] like figure 1 As shown, a layered coil for an oil-immersed distribution transformer in this embodiment includes several layers of low-voltage coils 2 and high-voltage coils 1 wound in sequence inside and outside, and a main coil is formed between the high-voltage coil 1 and the low-voltage coil 2. Empty channel, characterized in that: the high-voltage coil 1 is wound on the outside of the main air channel, and the high-voltage coil 1 is wound with the first layer coil 10, the second layer coil 11 to the Nth layer sequentially from the inside to the outside Coils 12 and interlayer insulating layers 13 are respectively provided between two adjacent coils of the high-voltage coil 1. The upper and lower ends of the high-voltage coil 1 are respectively provided with a stepped insulating layer 5, and the thickness of the inner insulating layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com