Flue gas waste heat recovery device

A waste heat recovery device and recovery device technology, applied in the field of flue gas waste heat recovery, can solve the problems of user inconvenience, inconvenient cleaning operations, and affecting the use of flue gas waste heat recovery devices, and achieve the effects of prolonging the service life and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

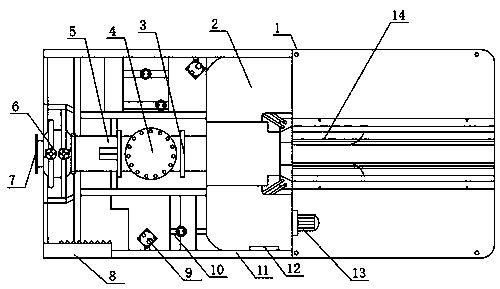

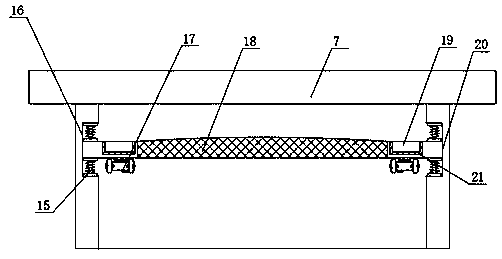

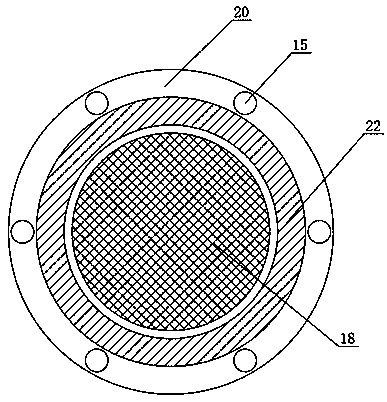

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: the flue gas waste heat recovery device, including a filter device, the filter device includes an air inlet 7, and an integrated movable groove 16 is provided on both sides of the air inlet 7, and the two sides of the movable groove 16 are passed through bolts The connection spring 15 is fixed, and the connection ring plate 20 is connected by bolts between the connection springs 15. The bottom of the connection ring plate 20 is fixed with a vibrator 17 by bolts relative to the inner side of the connection spring 15, and the top of the vibrator 17 is relatively connected to the connection ring plate 20. The surface is provided with a ring groove 22, and the inside of the ring groove 22 is connected with a collection box 19 by snap-fitting. The bottom of the collection box 19 is pasted with a magnetic block 21, and the middle part of the connecting ring plate 20 is fixed with a filter screen 18 b...

Embodiment 2

[0028] see Figure 1-Figure 5 , the present invention provides a technical solution: a flue gas waste heat recovery device, including a filter device and a cleaning device, the filter device includes an air inlet 7, and there are movable grooves 16 with an integrated structure on both sides of the air inlet 7, and there are two movable grooves inside the movable groove 16. The connecting spring 15 is fixed on the side by bolts, and the connecting ring plate 20 is connected by bolts between the connecting springs 15. The bottom of the connecting ring plate 20 is fixed with a vibrator 17 by bolts relative to the inner side of the connecting spring 15, and the top of the vibrating machine 17 is connected to the connecting spring 15. A ring groove 22 is opened on the surface of the ring plate 20, and the inside of the ring groove 22 is connected with a collection box 19 by snap-fitting. The bottom of the collection box 19 is pasted with a magnetic block 21, and the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com