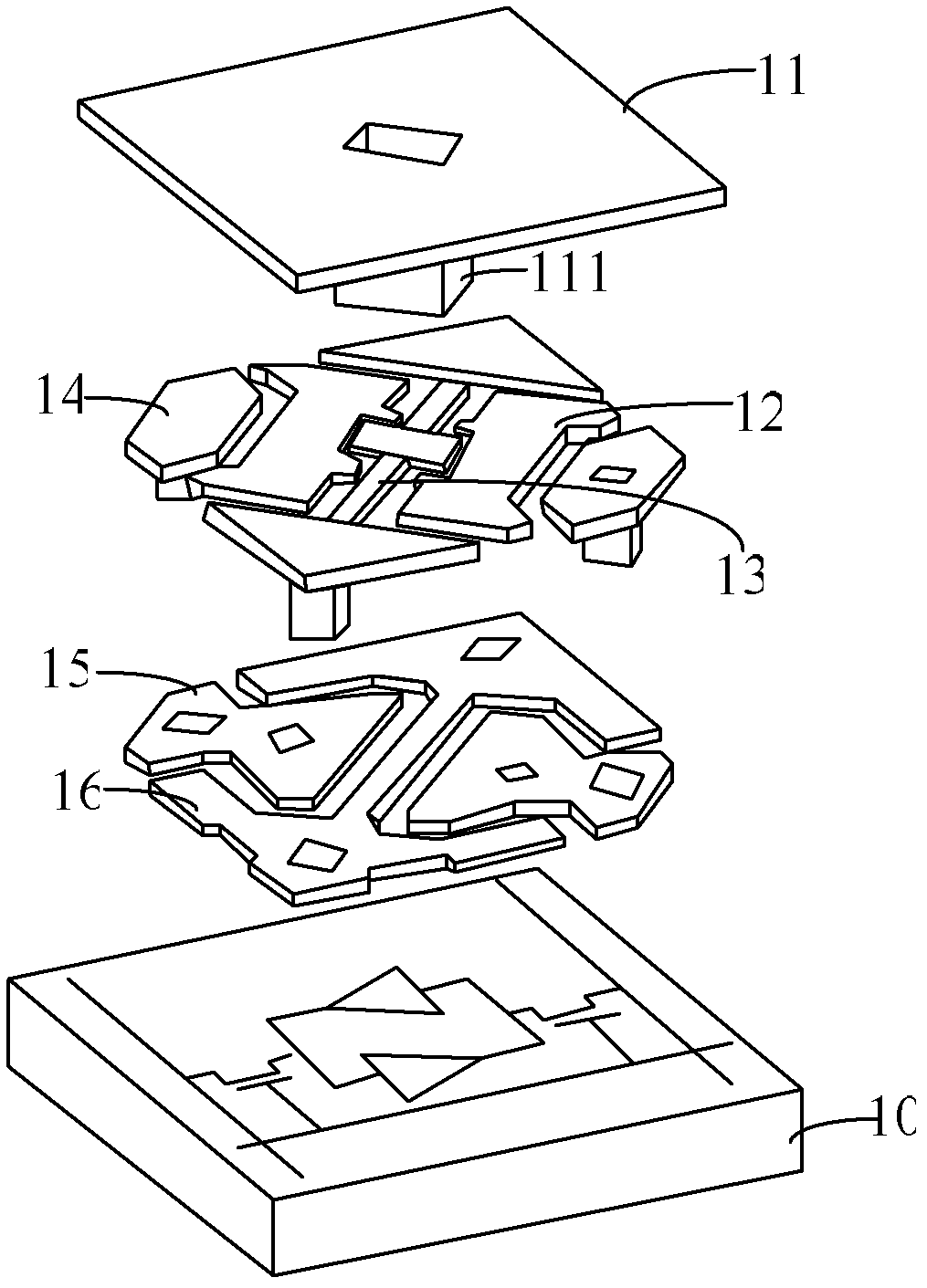

Digital micro-mirror device and forming method thereof

A digital micromirror device and digital micromirror technology, applied in the field of projectors, can solve the problems of high driving voltage, low yield, high power consumption, etc.

- Summary

- Abstract

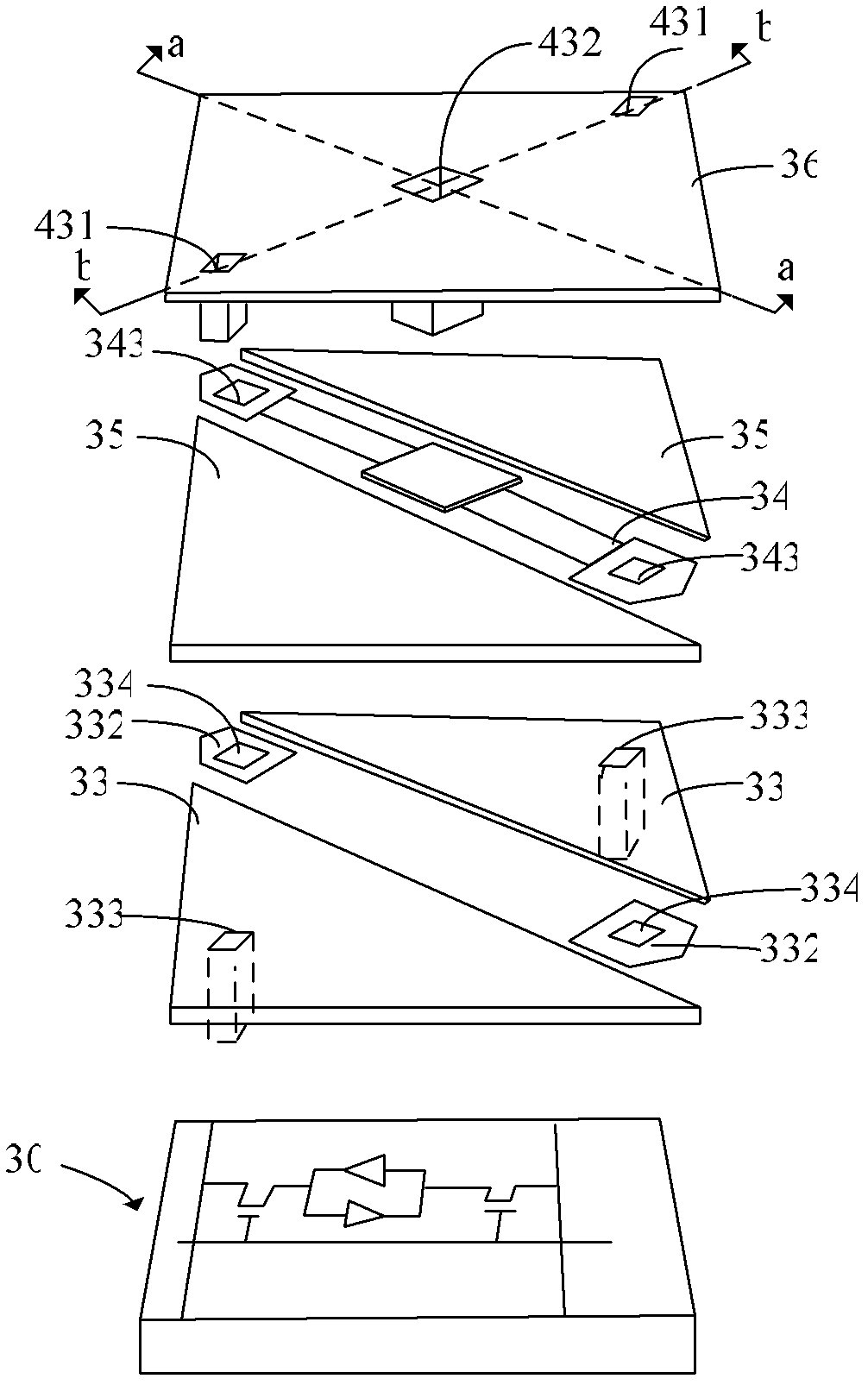

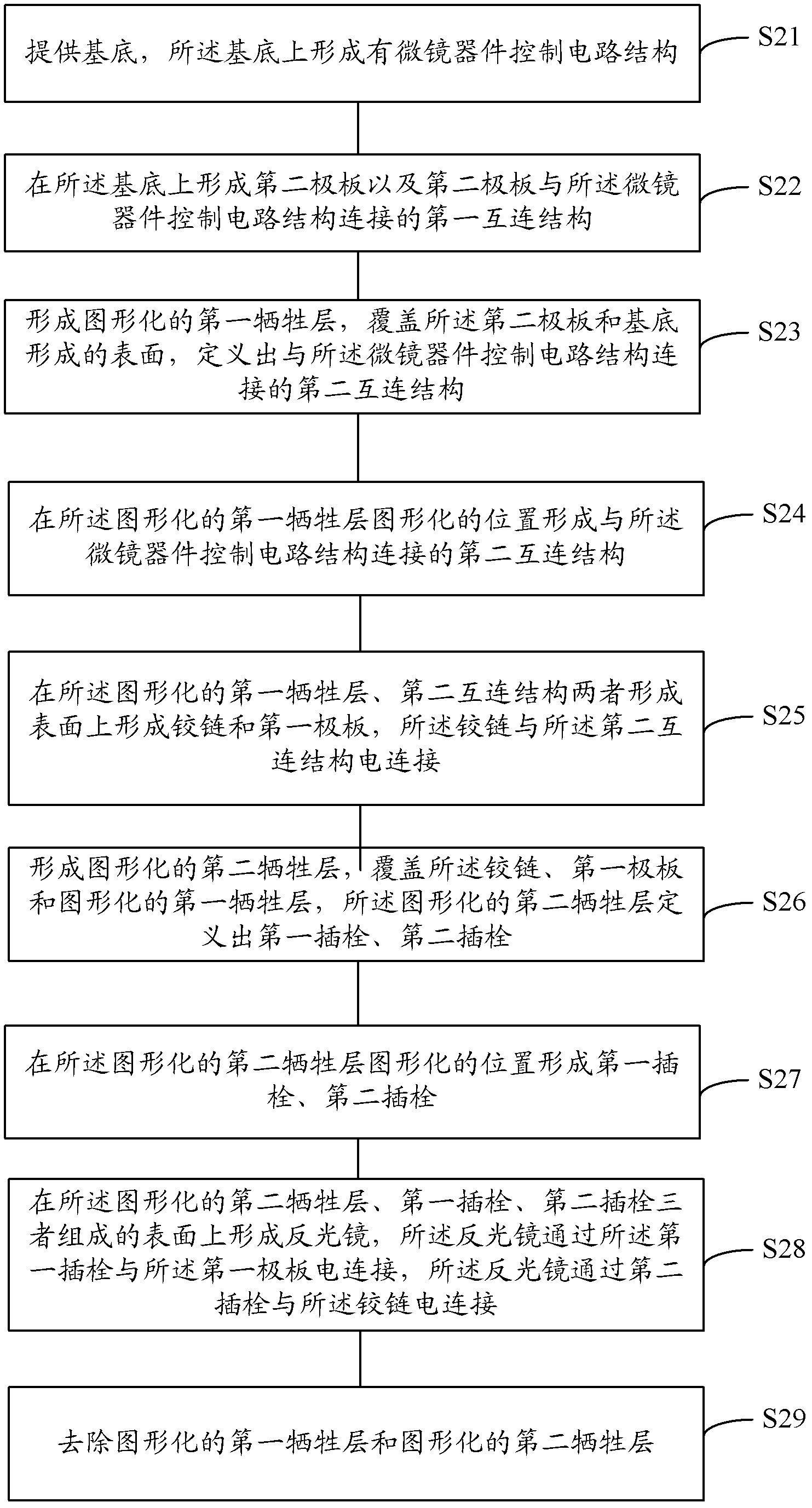

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The digital micromirror device of the invention has a simple structure. Moreover, in a specific embodiment, the hinge includes a conductive layer and a dielectric layer. Due to the existence of the dielectric layer, the strength of the dielectric layer is greater than the strength of the conductive layer. Compared with the hinge that only includes the conductive layer in the prior art, the strength of the hinge is improved. Thereby, the reliability of the hinge can be increased (that is, the number of times the hinge can be turned).

[0095] Further, in the present invention, the first pole plate located above the second pole plate also includes a conductive layer and a dielectric layer, the dielectric layer is close to the second pole plate, and the conductive layer is far away from the second pole plate. In the polar plate, the dielectric layer has compressive stress relative to the conductive layer, and the conductive layer has tensile stress relative to the dielectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com