Low-speed large-torque permanent magnet direct drive motor stator winding end part fixing structure and binding process

A winding end, permanent magnet direct drive technology, applied to the shape/style/structure of winding insulation, windings, electric components, etc., to achieve good mechanical strength and electrical insulation strength, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

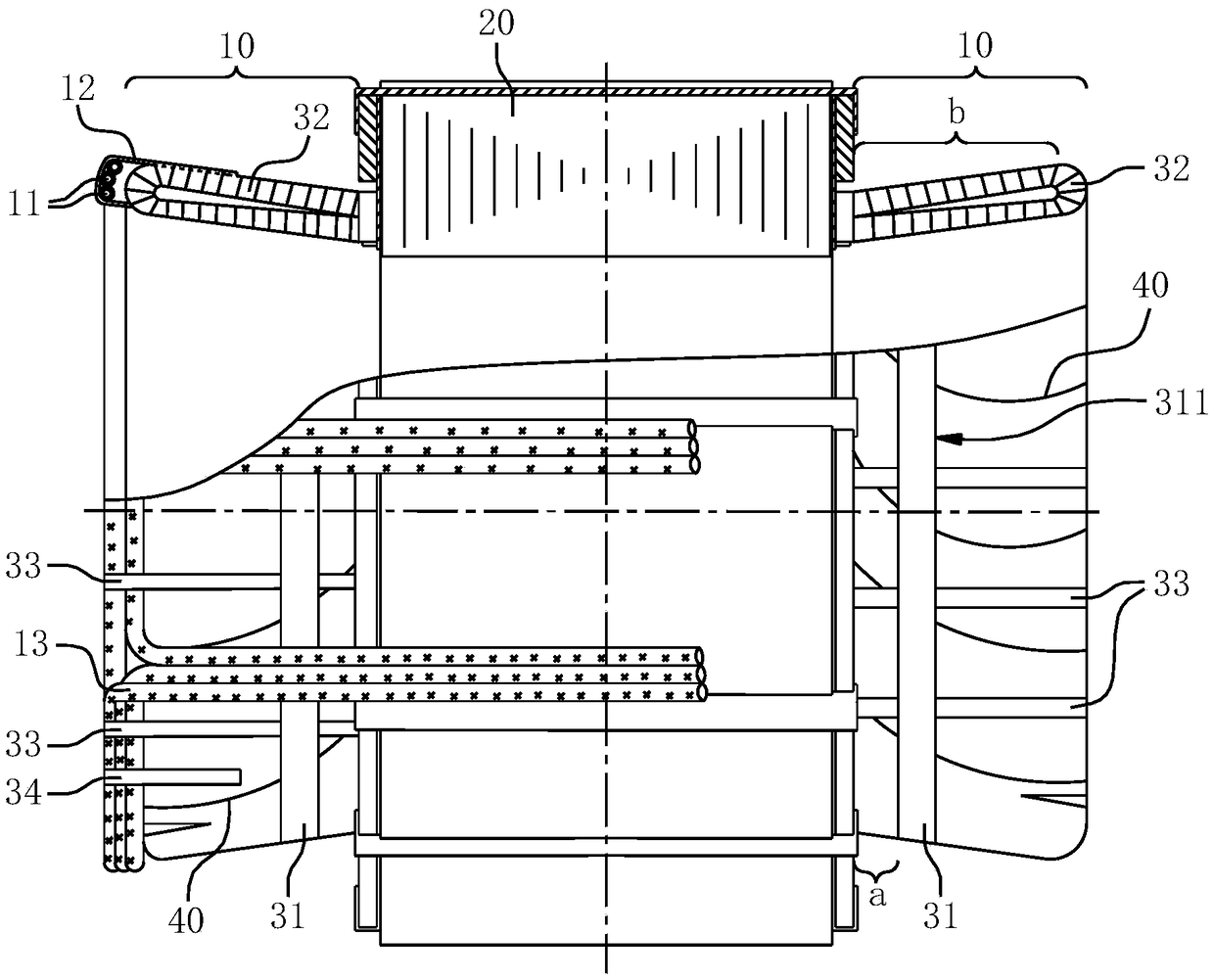

[0016] Attached below figure 1 , through the description of the embodiments, the specific implementation of the present invention will be further described in detail.

[0017] A binding process for a fixed structure at the end of a stator winding of a low-speed, high-torque permanent magnet direct drive motor, comprising the following steps:

[0018] Step A: After the wire embedding is completed, shape the wires at the end of the winding 10 so that the wires at the ends are close to each other and have a rounded shape. The inner diameter of the overall ring-shaped winding end 10 is larger than the inner and outer diameters of the stator core 20 smaller than the outer diameter of the stator core 20;

[0019] Step B: At the position where the winding end 10 is adjacent to the stator core 20, use a binding band 31 to wrap at least 2 turns along the circumferential direction of the winding end 10 and bind it to form an end hoop 311, and conduct a preliminary circumferential inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com