Mica ceramic insulator for novel high-speed power car and manufacturing method thereof

A technology of ceramic insulators and electric locomotives, which is applied in the direction of overhead lines, etc., can solve the problems of difficult compaction and compactness of green bodies, poor product compactness, and short service life, and achieve high mechanical and electrical insulation strength, low manufacturing costs, and high product quality. The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

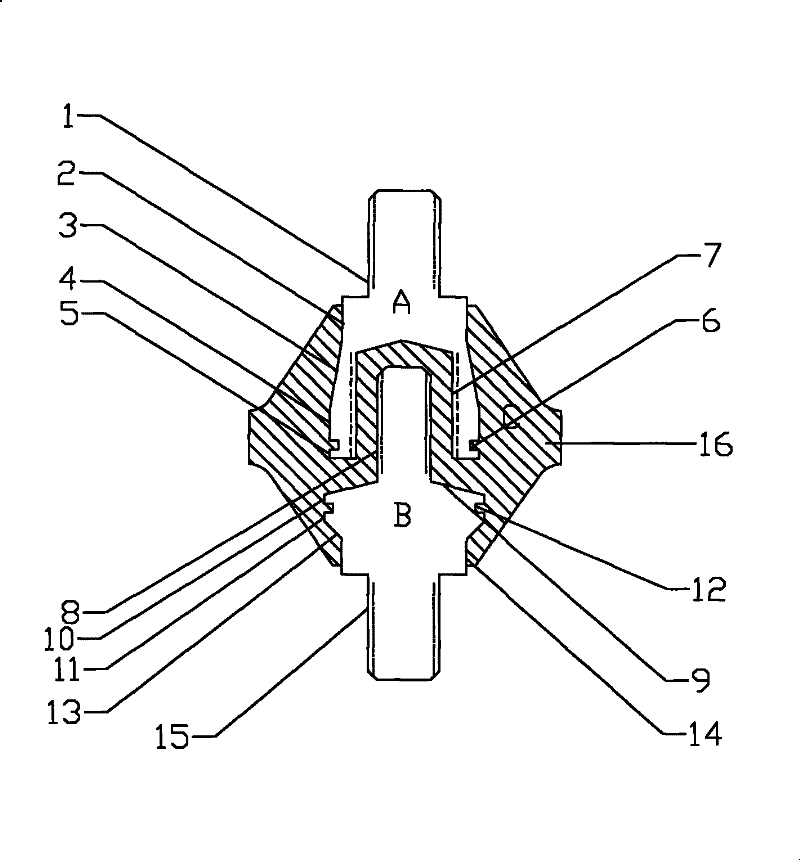

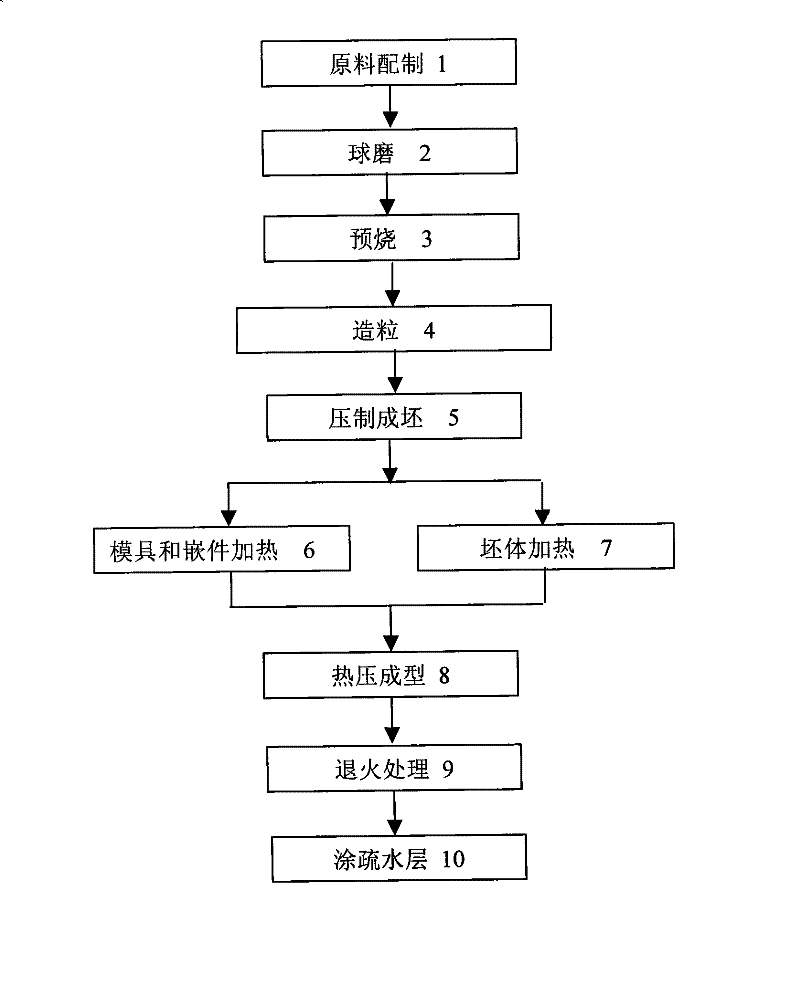

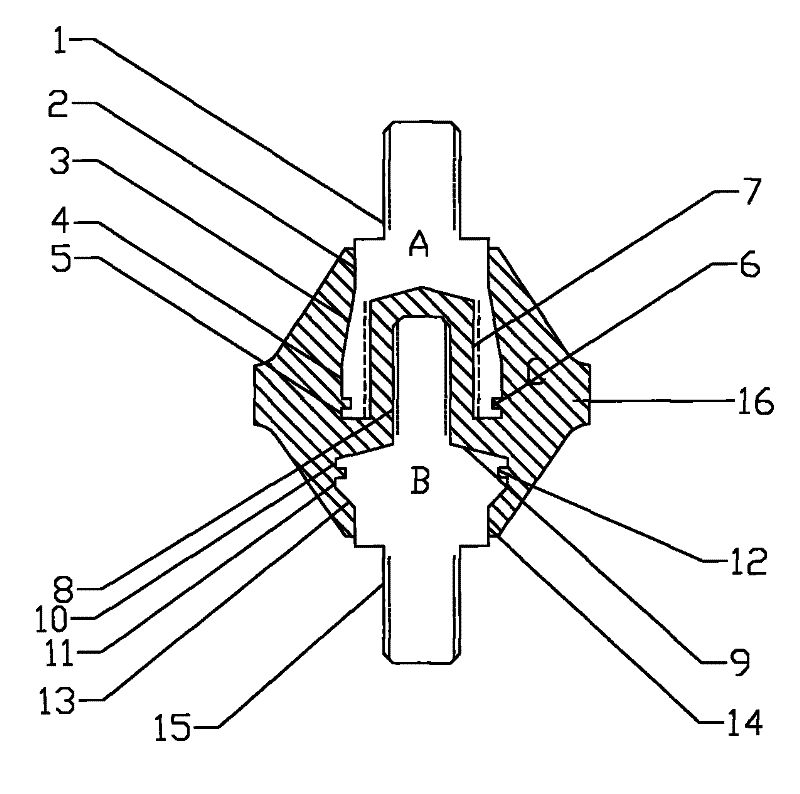

[0033]The technical solution of the present invention is to use the mica ceramic ingredients with good electrical insulation properties to firmly fix the metal inserts in the ceramic insulator by hot pressing technology to form a mica ceramic insulator for high-speed electric locomotives, so this product It is mainly composed of two parts: an electrically insulating ceramic body and a metal connecting pole, that is, a metal insert. Among them, the insulating ceramic body is mainly composed of synthetic mica powder and electrical glass powder, while the metal connecting pole can be designed according to the needs of the installation environment, and the material can be selected from various metal materials such as stainless steel or ordinary steel. The metal insert includes two independent poles, upper and lower. The two poles are divided into outer and inner ends. The inner end is embedded in insulating ceramics. The outer end of the lower pole is installed through external or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com