A kind of hollow copper flat wire and preparation method thereof

A copper flat wire and hollow technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, cable, etc., can solve the problems that the hollow copper flat wire cannot achieve electrical insulation strength, length is limited, and material loss is large, etc., to achieve Good electrical insulation strength, unlimited length and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

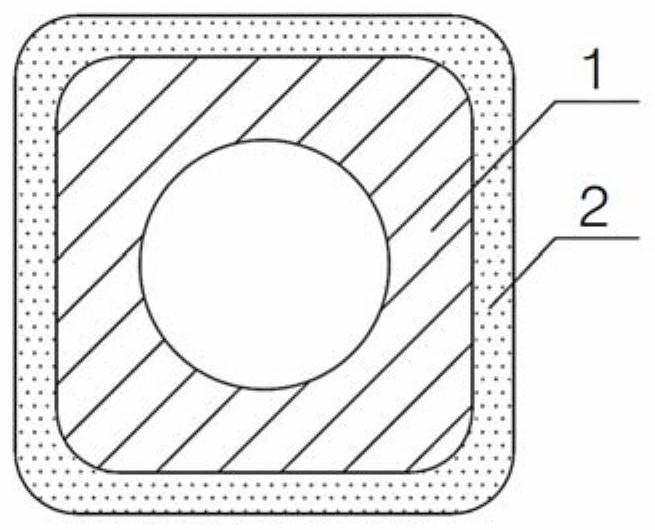

[0024] Such as figure 1 Shown: a hollow copper flat wire, comprising a hollow copper flat wire core 1, the hollow copper flat wire core 1 is provided with an insulating paint film 2, and its preparation method includes the following steps,

[0025] (1) Processing of hollow copper flat wire core 1: such as Figure 4 , 5 As shown, two pure copper rods 4 with a diameter of 9.5 mm are respectively passed through the extrusion wheel 5 and enter the material storage chamber 6 through the material guide plate. The temperature of the copper rod 4 is 550°C and the pressure is 1000MPa. The pure copper rod 4 is heated by the frictional force of continuous extrusion to form constrained pure copper. The constrained pure copper is combined in the storage cavity 6 through the mold 7 from the upper and lower directions. Get up and extrude into a hollow copper flat wire core 1;

[0026] (2) Cooling and drying: pass the extruded hollow copper flat wire core through the anti-oxidation protect...

Embodiment 2

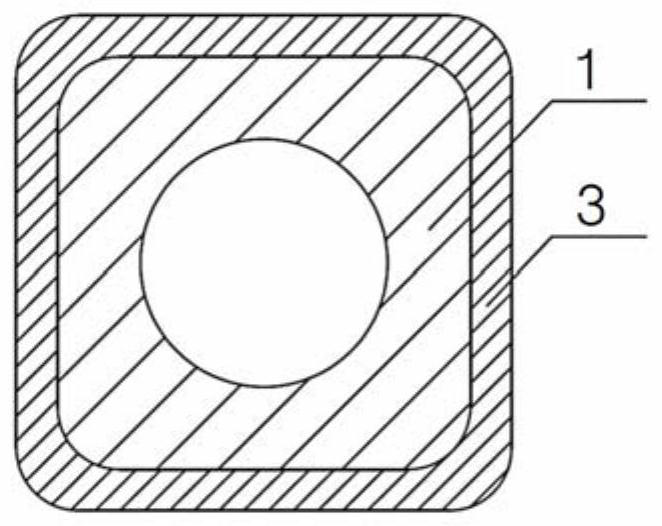

[0030] Such as figure 2 Shown: a hollow copper flat wire, comprising a hollow copper flat wire core 1, the hollow copper flat wire core 1 is provided with a thin film 3, and its preparation method includes the following steps,

[0031] (1) Processing of hollow copper flat wire core: such as Figure 4 , 5 As shown, two pure copper rods 4 with a diameter of 9.3 mm are respectively passed through the extrusion wheel 5 and enter the material storage chamber 6 through the material guide plate, and the rotating speed of the extrusion wheel 5 is set at 10 rpm. The temperature of the copper rod is 530°C and the pressure is 950MPa. The pure copper rod 4 is heated by continuous extrusion friction to form constrained pure copper. The constrained pure copper is combined in the storage chamber 6 through the mold 7 from the upper and lower directions. And extruded into a hollow copper flat core;

[0032] (2) Cooling and drying: Pass the extruded hollow copper flat wire core through the ...

Embodiment 3

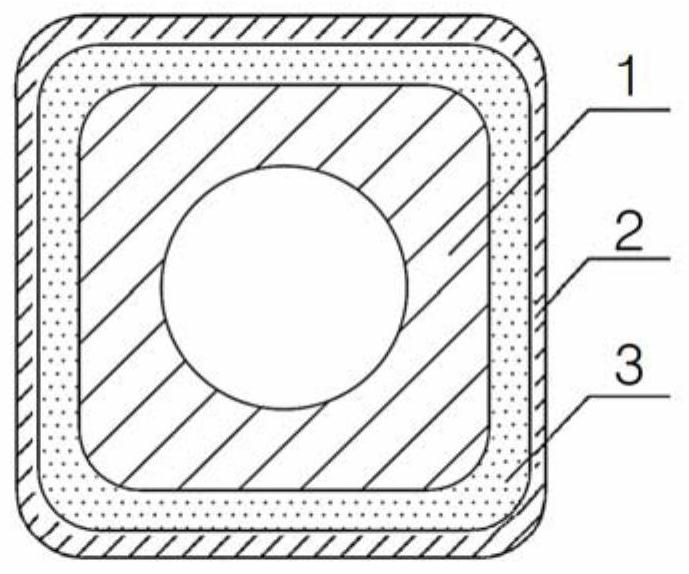

[0035] Such as image 3 Shown: a hollow copper flat wire, comprising a hollow copper flat wire core 1, an insulating paint film 2 is arranged outside the hollow copper flat wire core 1, and a film 3 is arranged outside the insulating paint film 2, and the preparation method thereof comprises the following steps,

[0036] (1) Processing of hollow copper flat wire core: such as Figure 4 , 5 As shown, two pure copper rods 4 with a diameter of 9.7 mm are respectively passed through the extrusion wheel 5 and enter the material storage chamber 6 through the material guide plate, and the rotational speed of the extrusion wheel is set at 15 revolutions per minute, and the pure copper in the material storage chamber The temperature of the rod is 570°C and the pressure is 1050MPa. The pure copper rod 4 is heated by the friction force of continuous extrusion to form a restrained pure copper. The restrained pure copper is combined in the storage chamber 6 through the mold 7 from the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com