Substation high-voltage chamber fully-closed operation system and control method

A technology for operating systems and high-pressure chambers, applied in heating and ventilation safety systems, substation/distribution device enclosures, control inputs involving air characteristics, etc. To improve the electrical insulation strength, improve the level of safe operation, and achieve significant safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

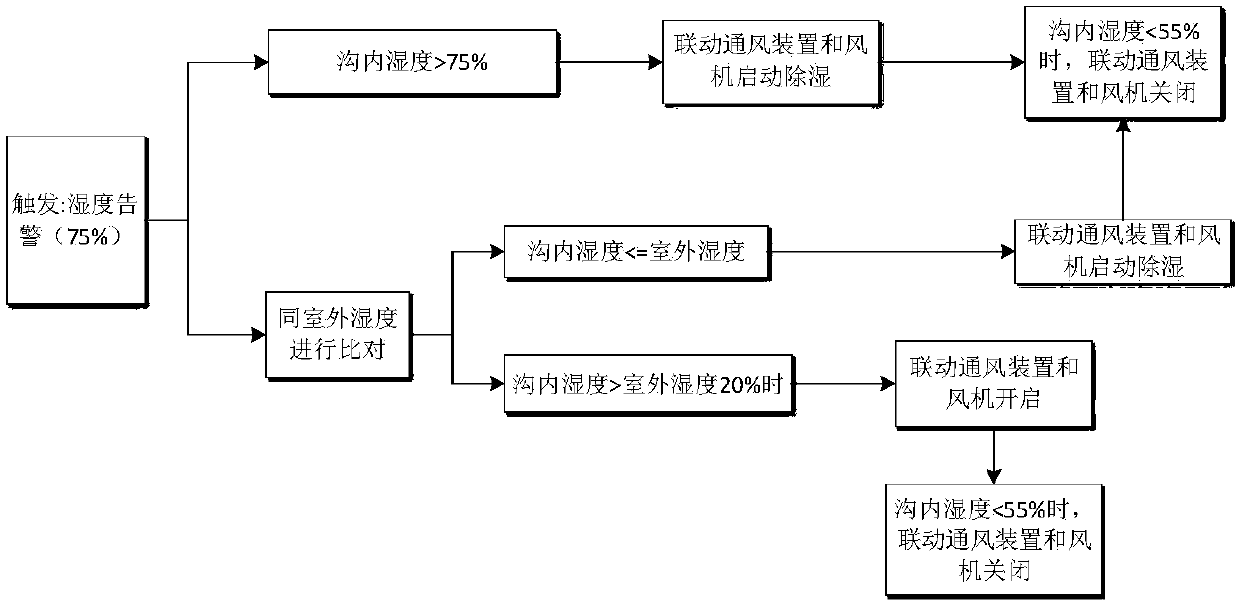

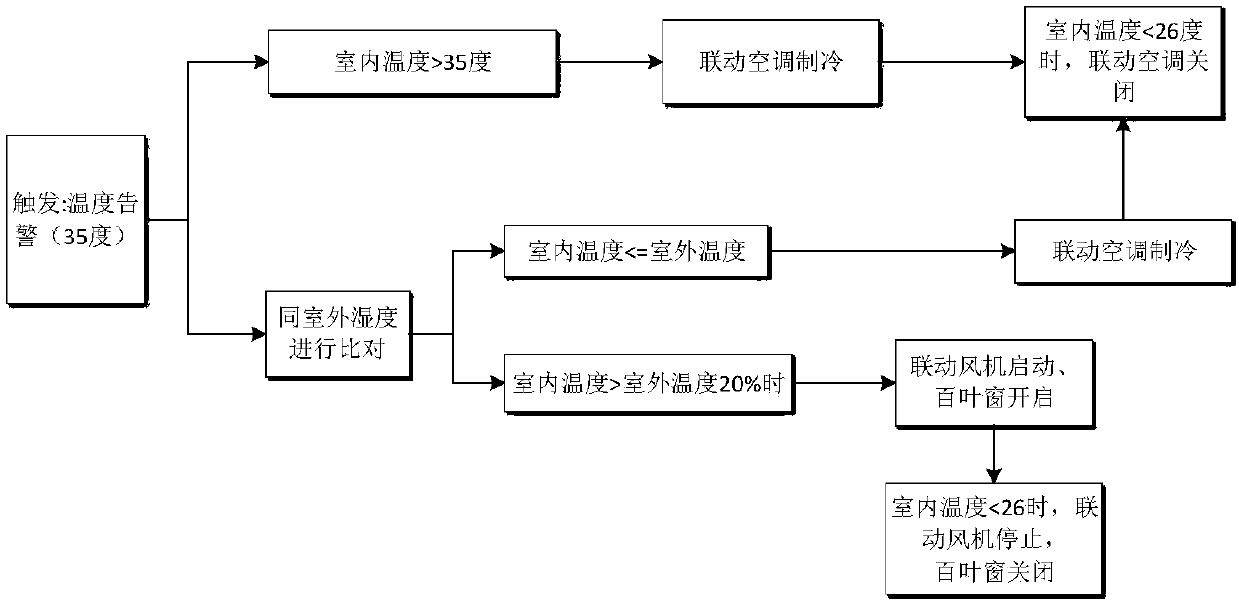

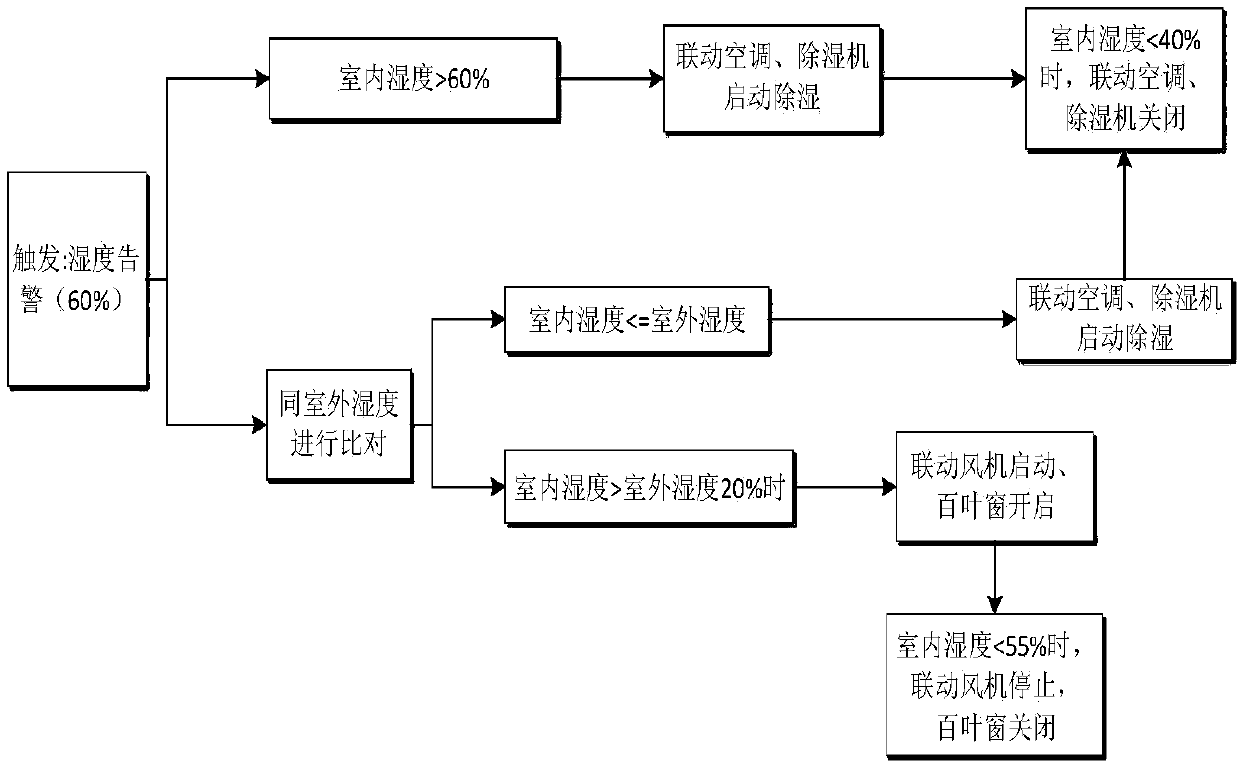

[0024] Such as Figure 1-Figure 3 The fully-sealed operation system of the high-voltage room of the substation shown in the figure includes a high-voltage room, which is characterized in that the high-voltage room is a fully-sealed structure, and electric shutters with electric control switches are installed at the vents of the high-voltage room; environmental active operation and maintenance is installed in the high-voltage room system; the environmental active operation and maintenance system includes an environmental monitoring device, a data processing module, and an environmental auxiliary device. The environmental monitoring device collects high-voltage indoor environmental information and transmits it to the data processing module. The data processing module adjusts the high-voltage indoor environment by controlling the environmental auxiliary device.

[0025] The environment monitoring device includes a temperature and humidity sensor, a bureau detector, and an arc sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com