Patents

Literature

57results about How to "Significant safety benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

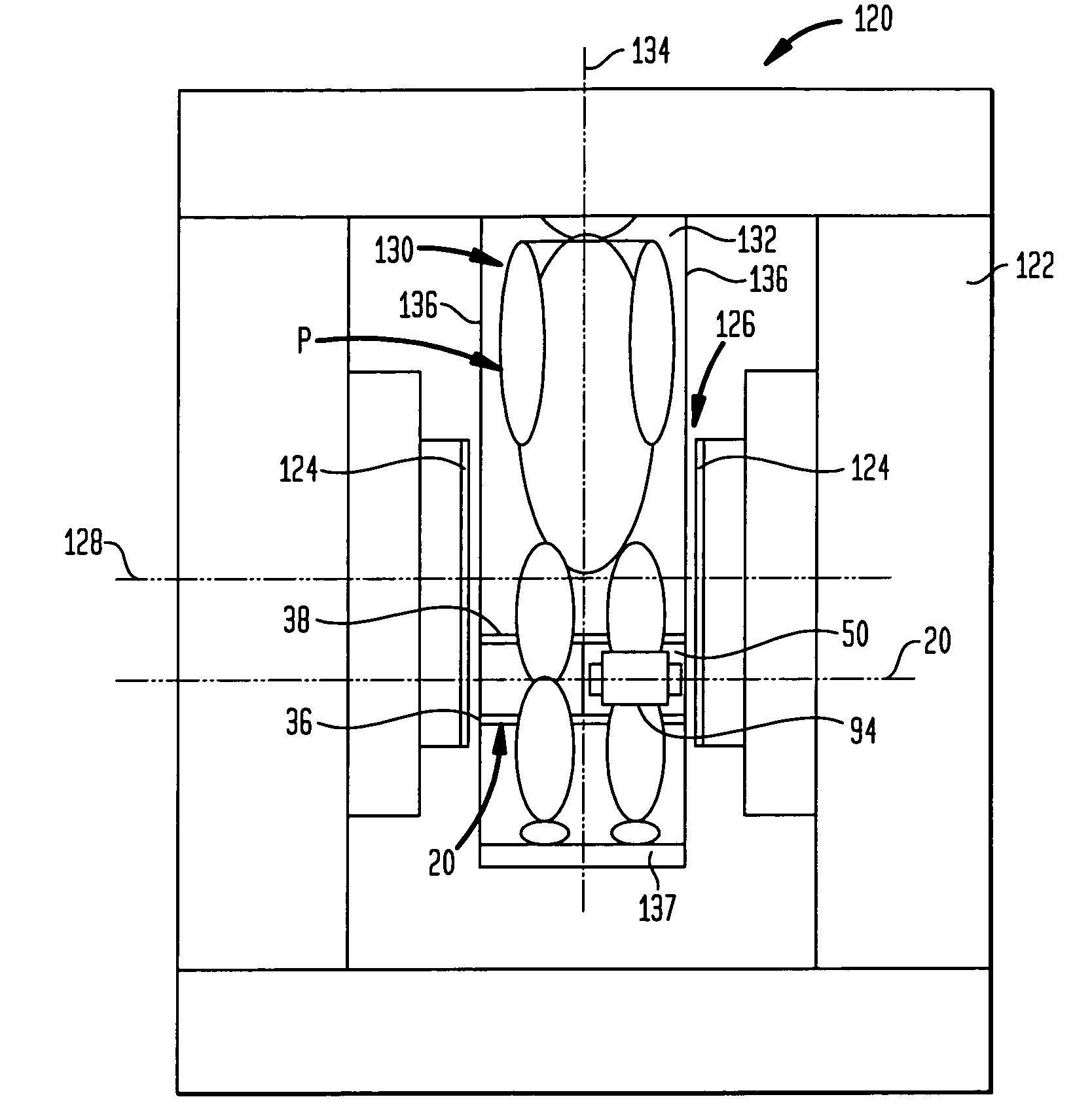

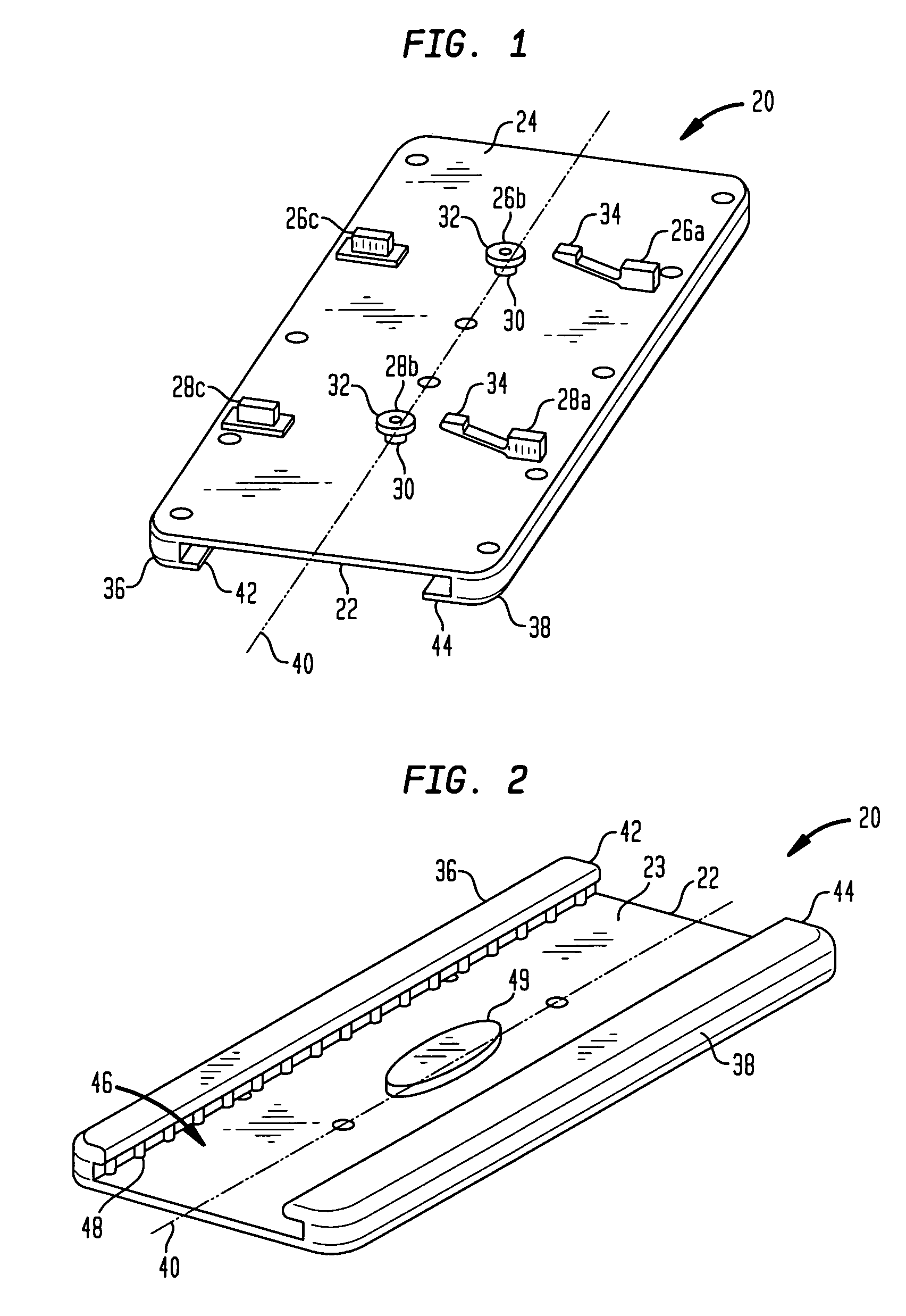

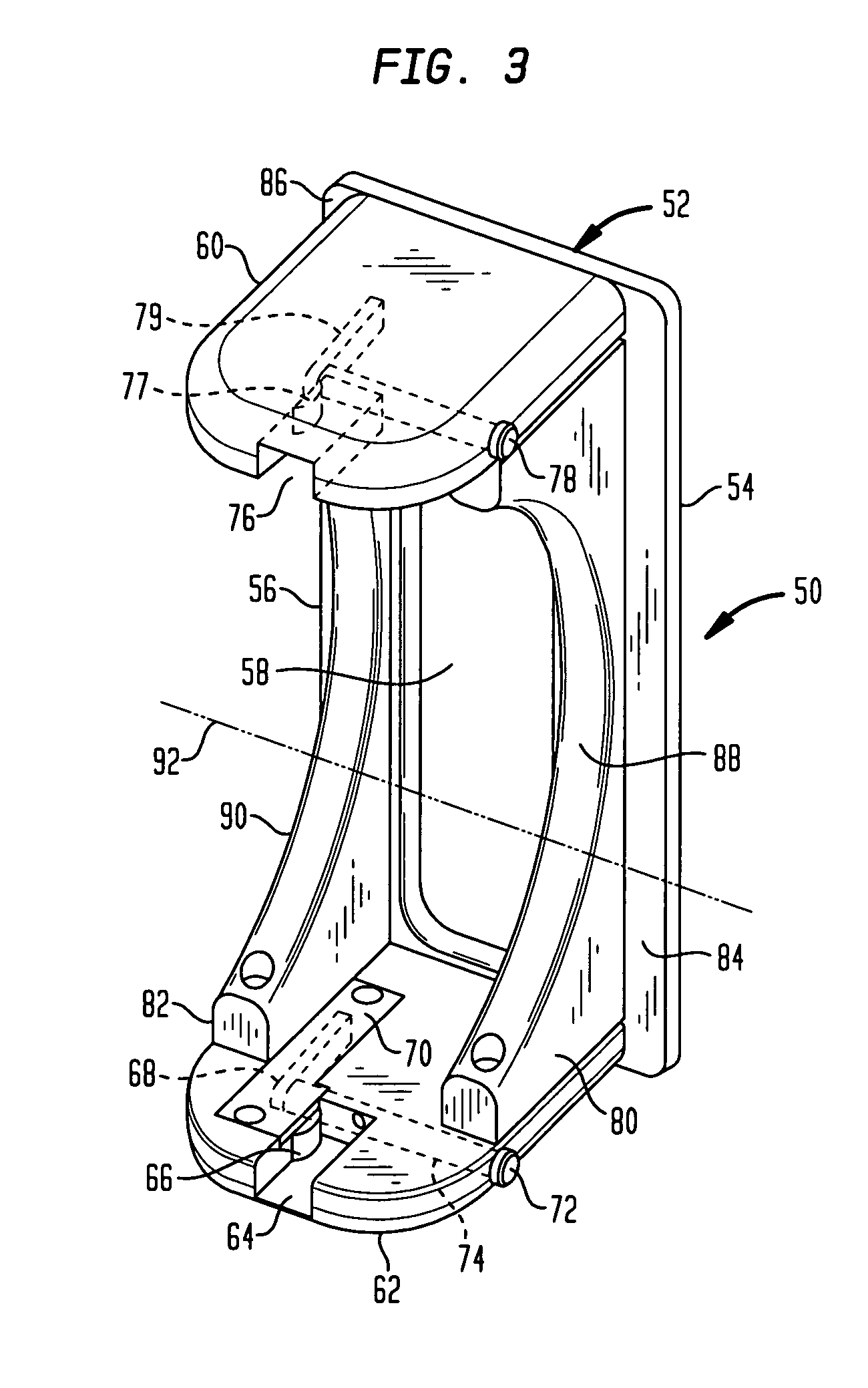

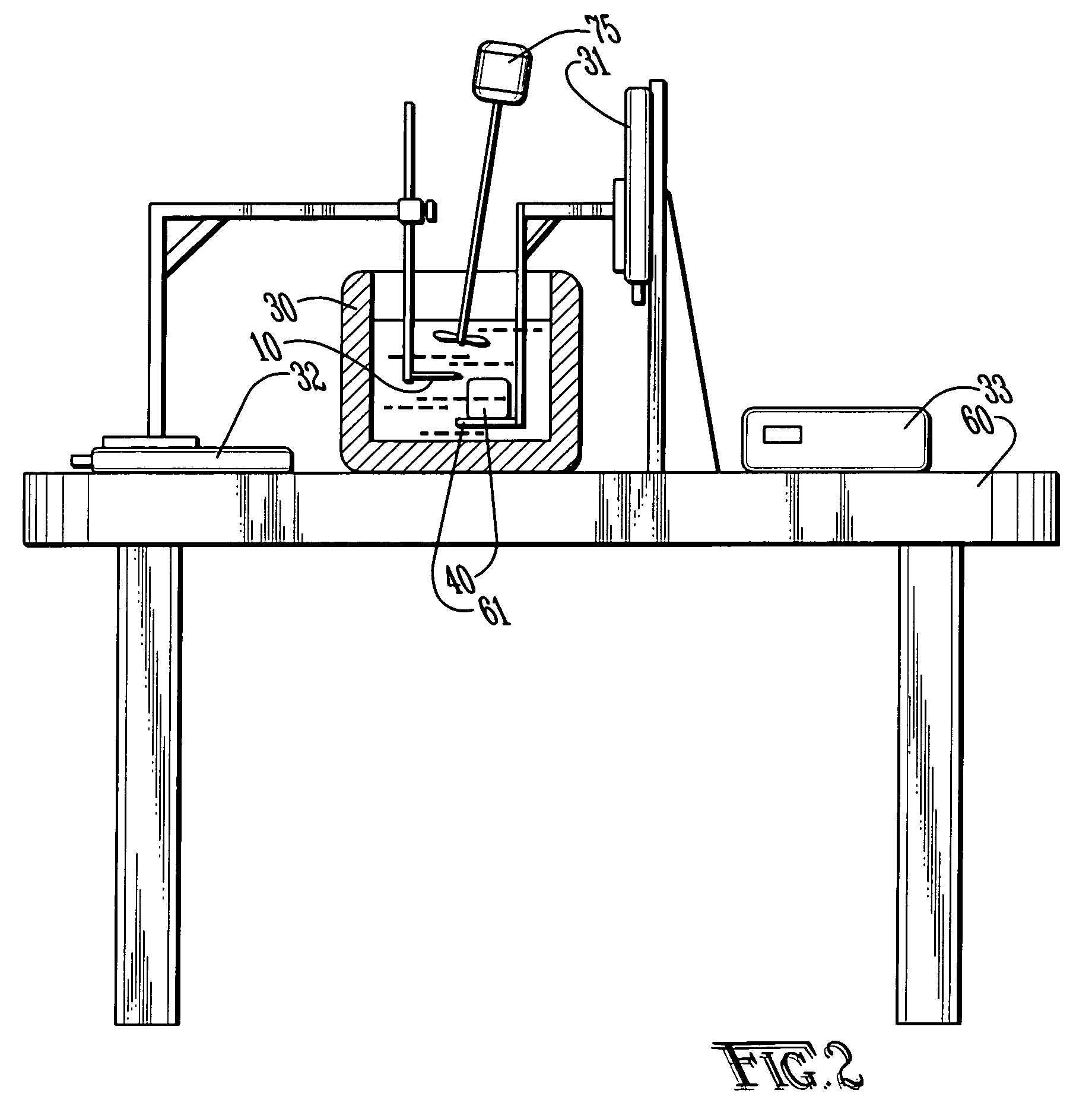

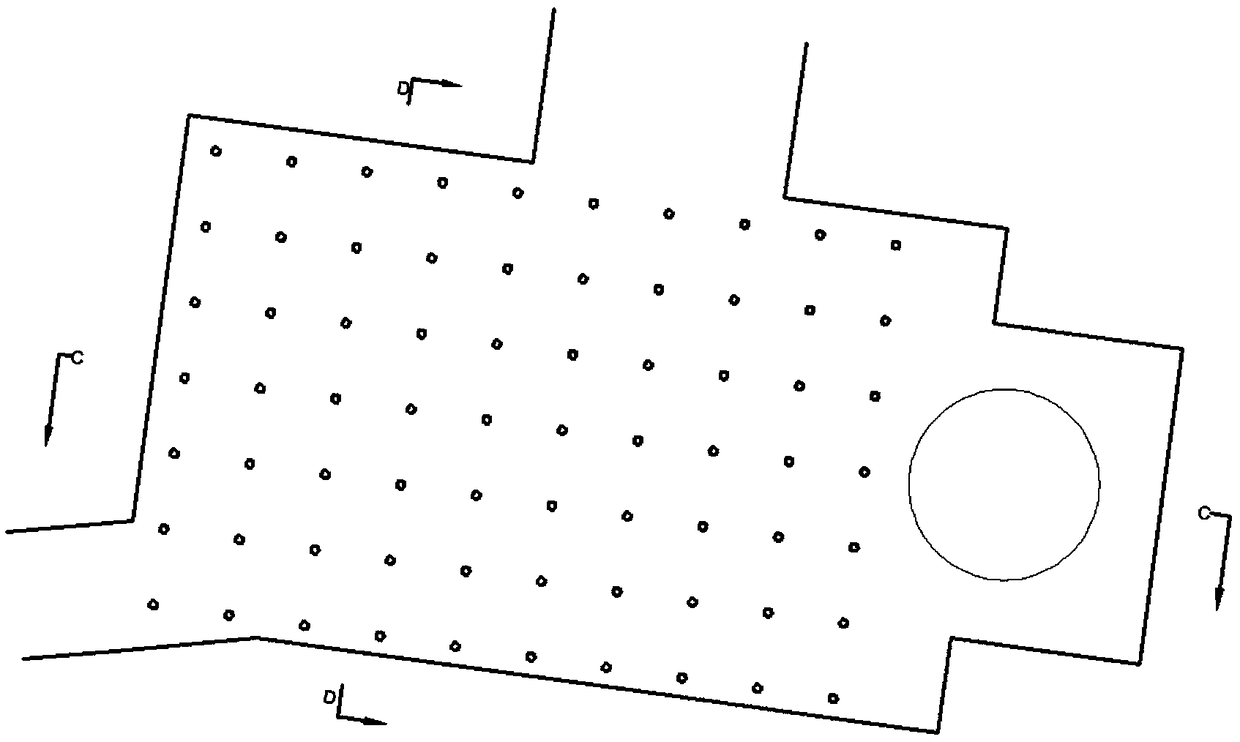

Magnetic resonance imaging with adjustable fixture apparatus

InactiveUS7693570B2Avoid supportSecure attachmentDiagnostic recording/measuringSensorsResonanceEngineering

A fixture such as a local receiver coil is secured to the patient support of a magnetic resonance imaging system so that the fixture remains in position relative to the support even when the support is in a vertical orientation. The positioning apparatus is arranged to allow adjustment of the fixture position, but to limit such adjustment so that the fixture cannot interfere with the poles or other elements defining the patient-receiving gap of the magnet during movement of the patient support.

Owner:FONAR

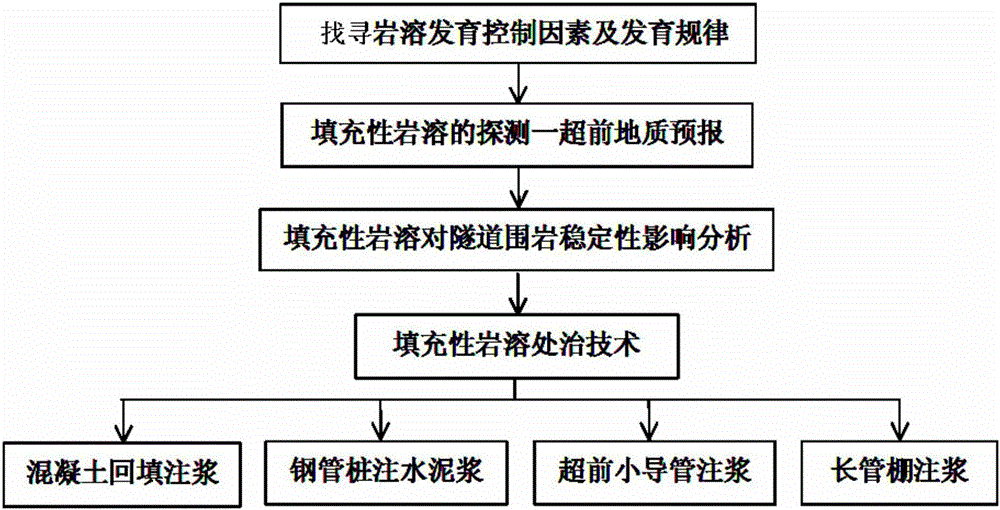

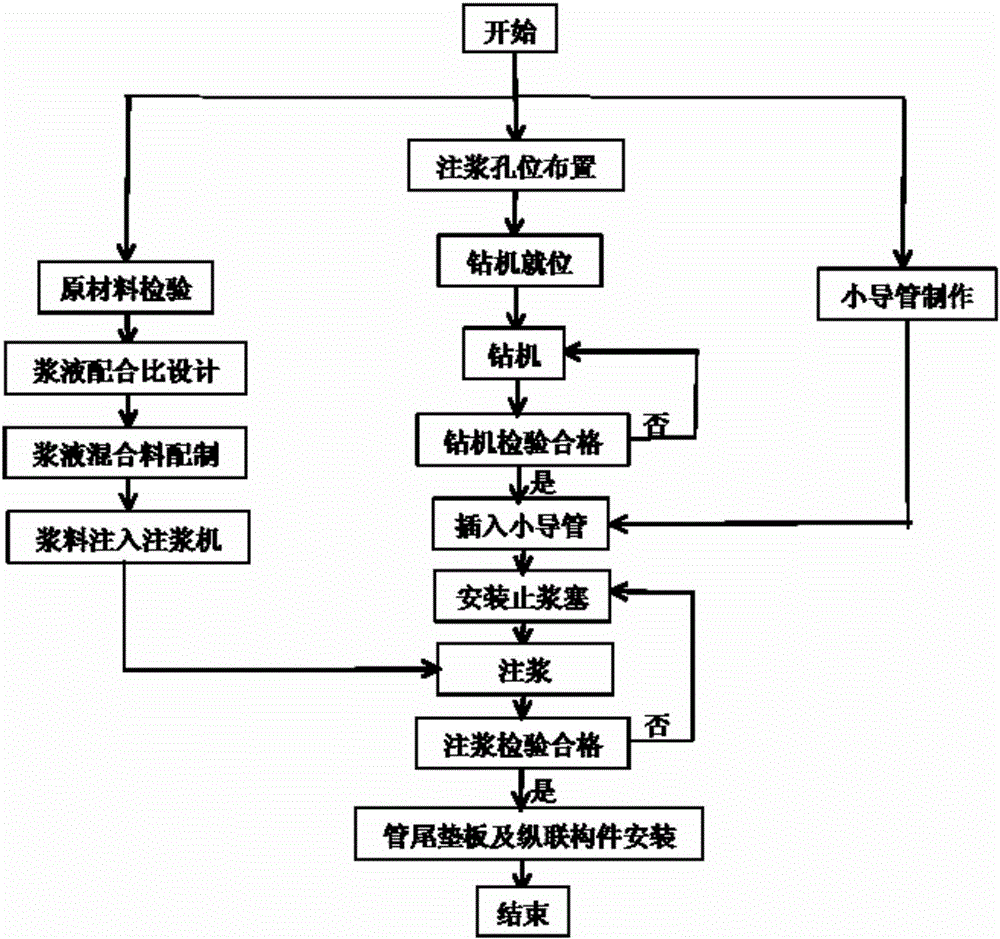

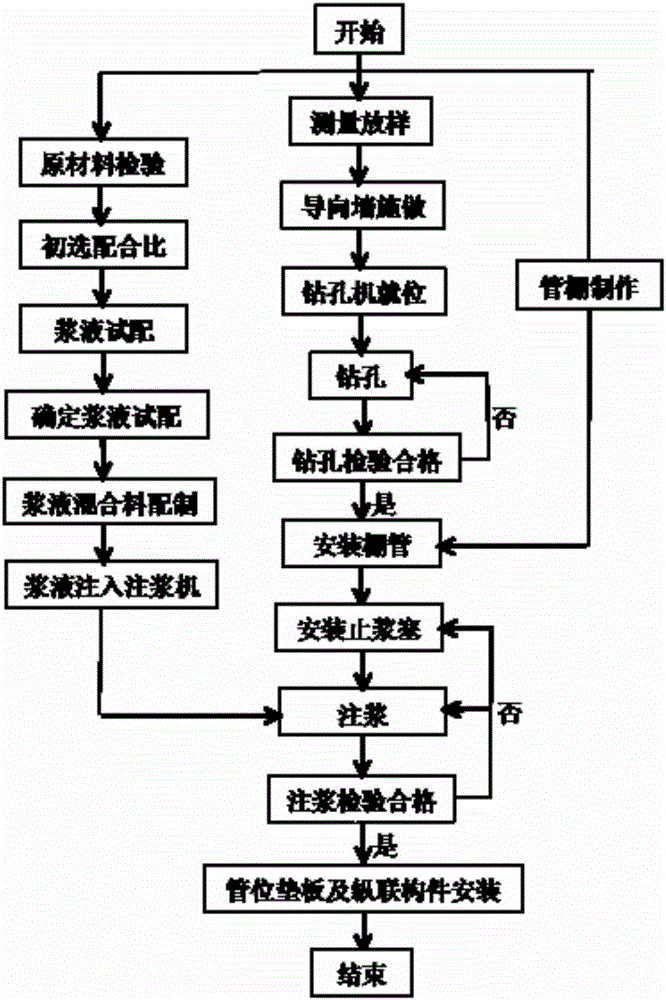

Construction treatment method of filling karst tunnel

InactiveCN106837353AReduce construction costsGrasp and implement in timeUnderground chambersTunnel liningRailway tunnelGeomorphology

The invention discloses a construction treatment method of a filling karst tunnel. The construction treatment method comprises the following steps that (a), a karst development control factor and a development principle are sought; (b), karst detecting is conducted for advance geology forecast; (c), analysis of influence of filling karst on stability of tunnel surrounding rocks is conducted; and (d), filling karst treatment is conducted. According to the construction treatment method of the filling karst tunnel, filling karst advance geology forecast, pre-reinforcement measures and the normal construction technical process of the tunnel are organically combined, and the safety risks of filling karst section tunnel construction are reduced or avoided by sufficiently using the means and methods such as advance geology forecast and pre-reinforcement. The construction treatment method is applied to tunnel filling karst construction of highways and railways, and meanwhile, the construction treatment method has imitative and referential significances on construction of the railways, the highways, municipal administrations and hydraulic tunnels (caves) with similar geological conditions.

Owner:CENT SOUTH UNIV +2

Tissue electro-sectioning apparatus

InactiveUS20050220674A1Increase the sectionIntense and localized fieldAutomatic control devicesAnalysis using chemical indicatorsFresh TissueGene and protein expression

An apparatus for sectioning fresh unfixed tissue into very thin layers with preserved tissue architecture, antigenicity, mRNA content, and amenable to 3-D computer reconstruction without mechanical or thermal damage by employing a sectioning tool having an electrode with an intense focused electrical field at an edge. A computer controlled x-y-z translation stage moves the sectioning tool through the tissue as defined by a predetermined program. The sectioning tool produces consecutive thin sections of fresh tissue for immunohistochemical and nucleic acids analyses without mechanical or thermal damage, ultimately allowing high-resolution volumetric reconstruction of gene and protein expression patterns of large tissue specimens. The geometry of the sectioning tool is selected so as to produce a spatially localized electrical field of sufficient intensity to sever molecular bonds or propagate flaws in tissue without mechanical cutting.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

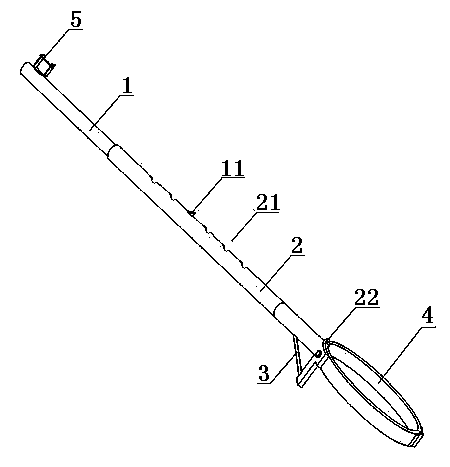

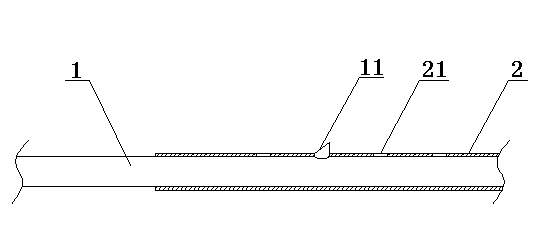

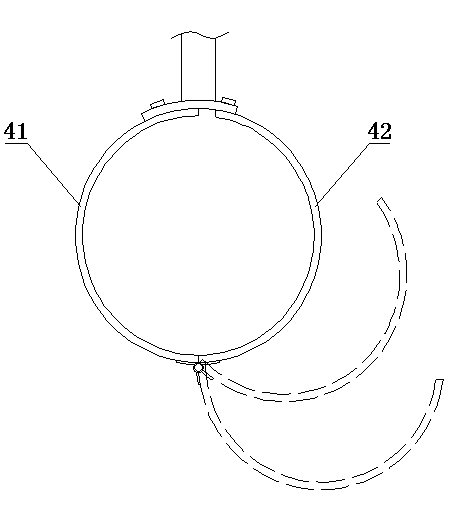

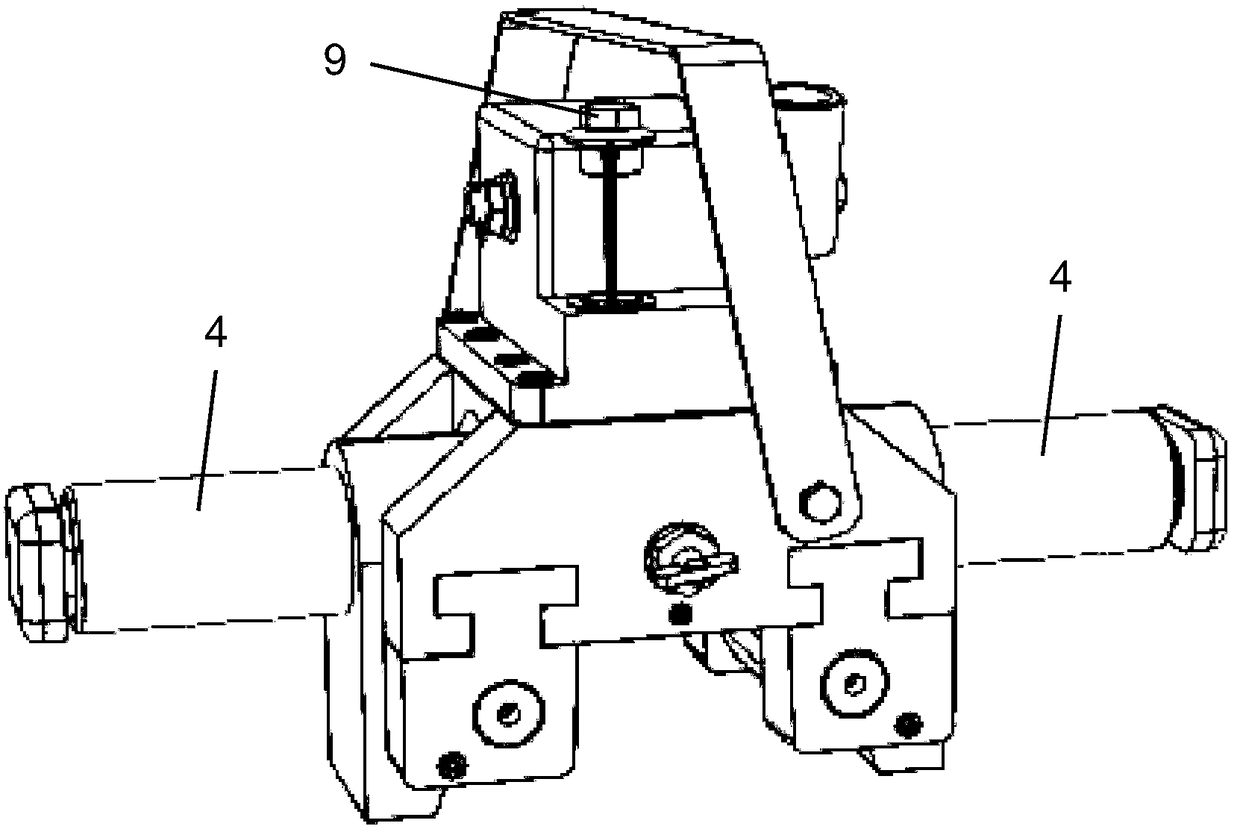

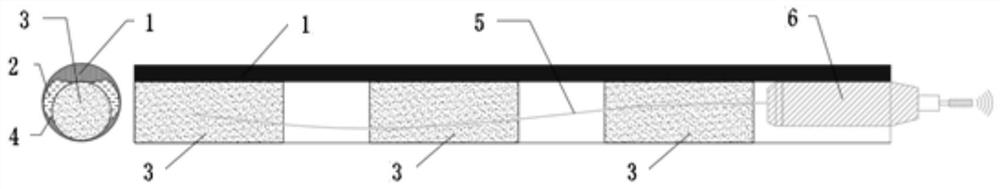

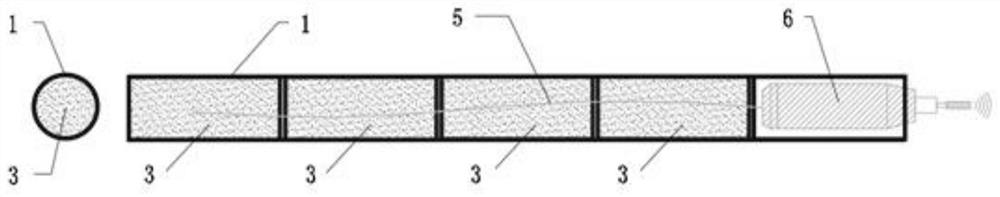

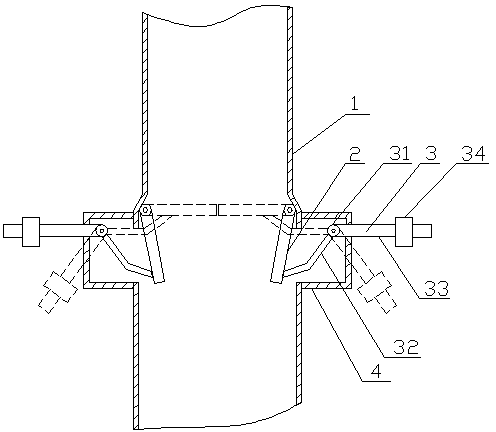

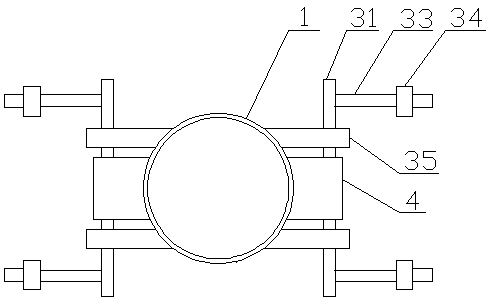

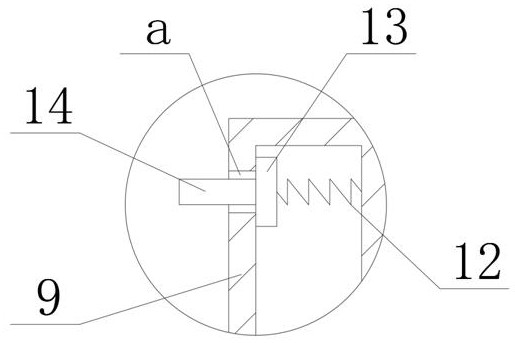

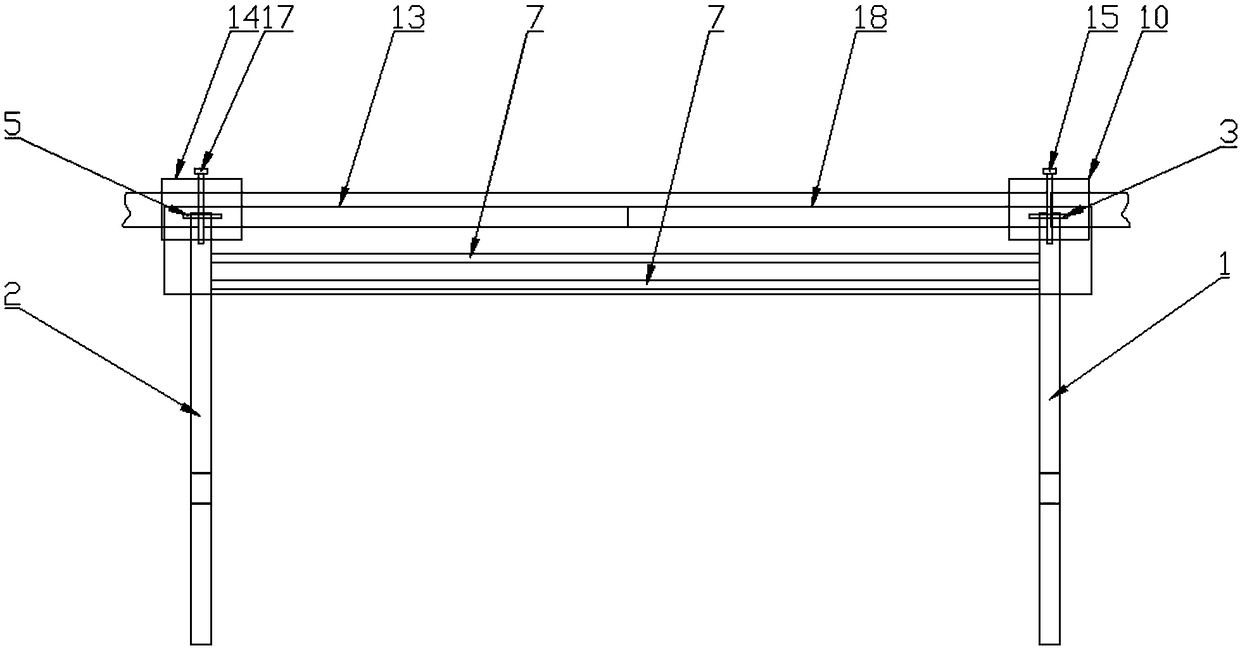

Live-working drainage wire bracket

InactiveCN103825219AEffectively fixedSimple structureApparatus for overhead lines/cablesEngineeringElectric power

The invention relates to a live-working drainage wire bracket which is characterized in that a plurality of through holes (21) are uniformly formed in a sleeve (2); the rear end of the sleeve (2) is connected with a fixing device (4) through a T-shaped plate (22); elastic pins (11) in match with the through holes (21) are arranged on a moving rod (1); a fixing clamp (5) is arranged at the end part of the moving rod (1); the fixing device (4) consists of a left semicircular bracket (41) and a right semicircular bracket (42); one end of the left semicircular bracket (41) is hinged with one end of the right semicircular bracket (42); the other end of the left semicircular bracket (41) is fixed on one side of the T-shaped plate (22); the other end of the right semicircular bracket (42) is slightly shrunk and is movably connected with the other side of the T-shaped plate (22), so that the right semicircular bracket (42) can be opened and conveniently fixed on a electric power pole. By adopting the bracket, a live-working drainage wire can be effectively fixed, the times of power outage are greatly reduced, and the reliability in power supply is improved.

Owner:STATE GRID SHANDONG QIHE POWER SUPPLY

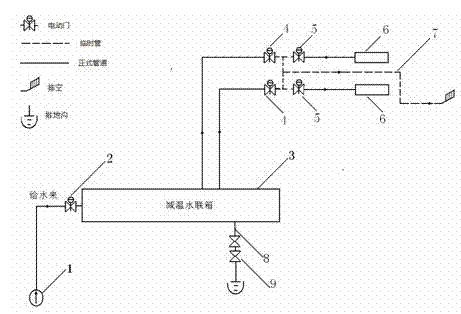

Washing method of power station boiler temperature reducing water system and washing pipeline connection structure

InactiveCN102777884AEffective flushingSignificant safety benefitsBoiler cleaning apparatusPower stationMotor drive

The invention discloses a washing method of a power station boiler temperature reducing water system and a washing pipeline connection structure. The washing method and the structure comprise a power station boiler temperature reducing water system. The method includes first increasing a temporary communication pipe on the power station boiler temperature reducing water system. The temporary communication pipe is located between two motor-driven doors connecting a temperature reducing water connection tank and a temperature reducing water pipeline of a temperature reducer. After the temporary communication pipe is connected, the washing steps comprise first way water washing, second way water washing and third way steam back washing. The washing method and the structure ensure that all temperature reducing water systems can be washed by a simple temporary system and the operation mode and ensure washing flow quantity and washing effect due to the fact that the inner diameter of a temporary pipe is larger than the inner diameter of the temperature reducing water pipeline.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

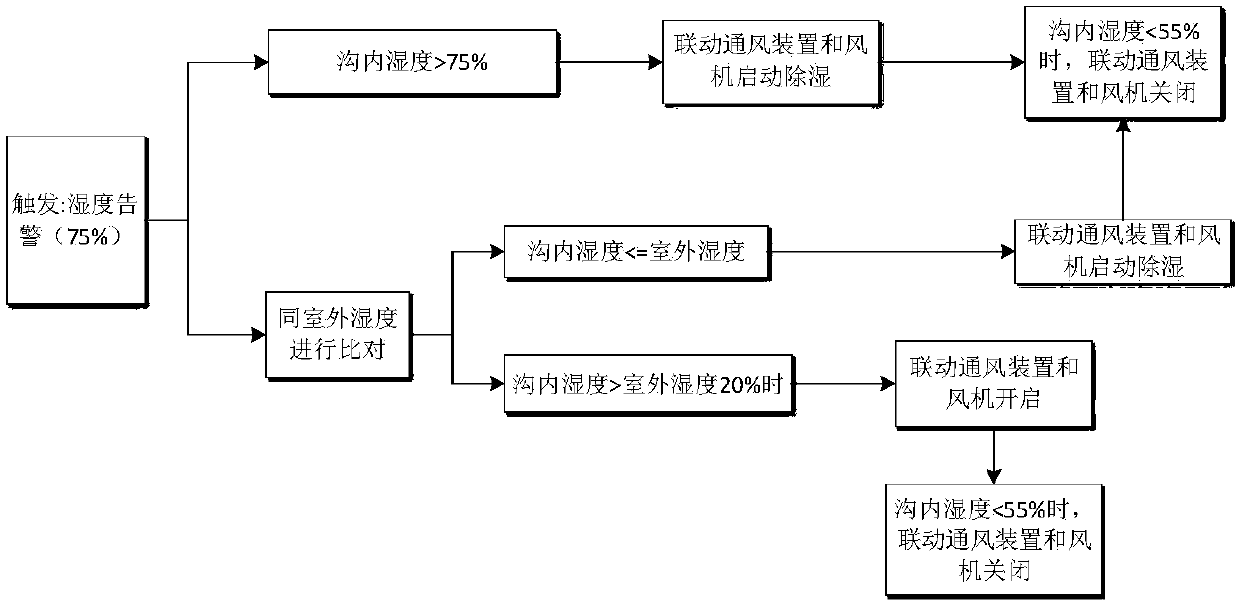

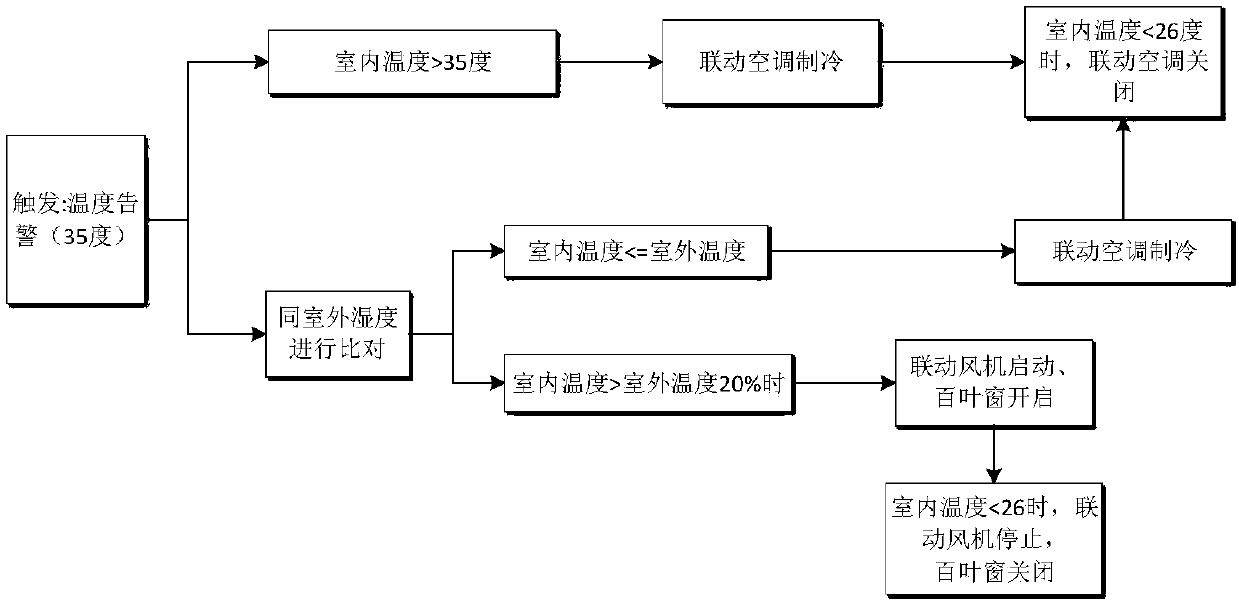

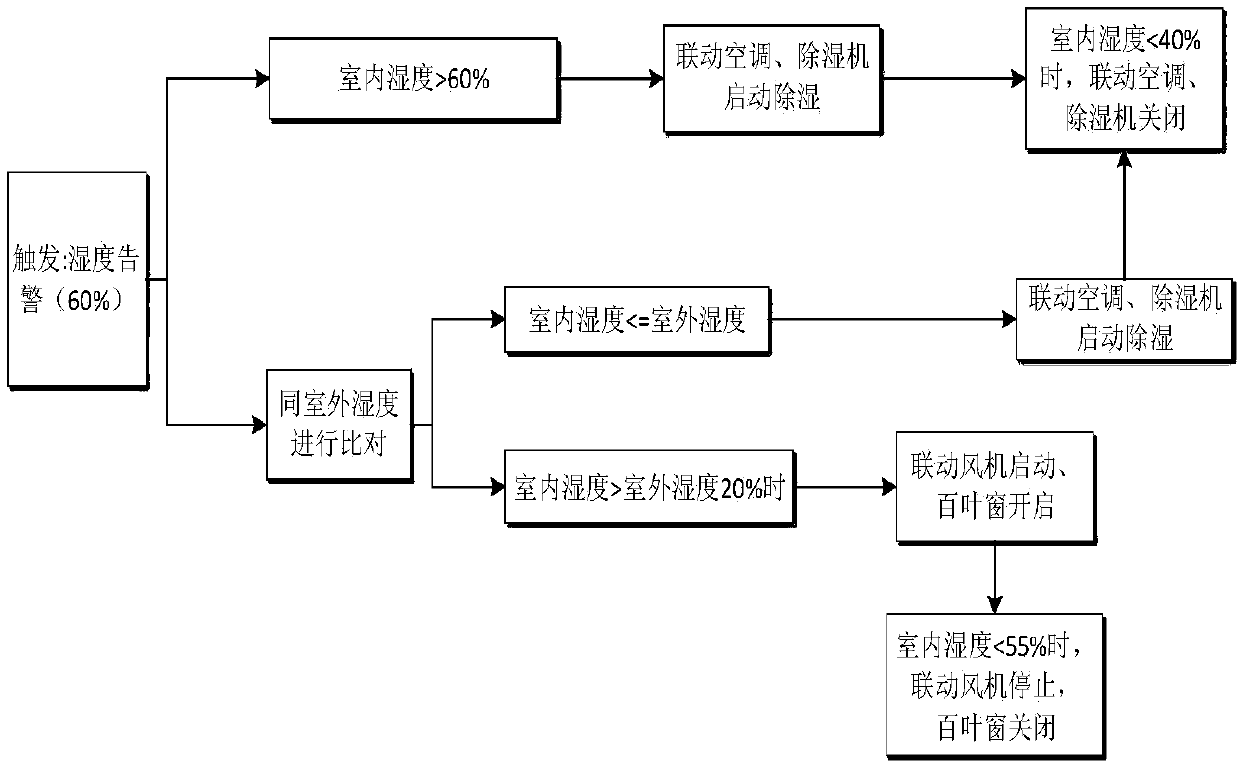

Substation high-voltage chamber fully-closed operation system and control method

PendingCN107726564AImprove electrical insulation strengthImprove the level of safe operationMechanical apparatusSpace heating and ventilation safety systemsHigh pressureEmbedded system

The invention relates to a substation high-voltage chamber fully-closed operation system and a control method. The system comprises a high-voltage chamber; the high-voltage chamber is a fully-closed structure; an electric blind window electrically controlled to open and close is mounted in a ventilation port of the high-voltage chamber; an environment active operation maintenance system is mountedin the high-voltage chamber, and comprises an environment monitoring device, a data processing module and an environment auxiliary device; the environment monitoring device collects high-voltage chamber internal environment information and sends to the data processing module; and the data processing module adjusts the environment in the high-voltage chamber through controlling the environment auxiliary device. Through intelligent control of the temperature and the humidity, the operation environment is optimized, the electric insulation intensity of switch cabinet equipment is improved, the bus and transformer damage risk caused by failures of the switch cabinet is reduced, the substation safety operation level is improved, and the safety benefit is prominent. The system can be applied tothe high-voltage chamber to eliminate the insulation reduction problem caused by damping and pollution of switch cabinet insulation pieces of small cabinet bodies.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

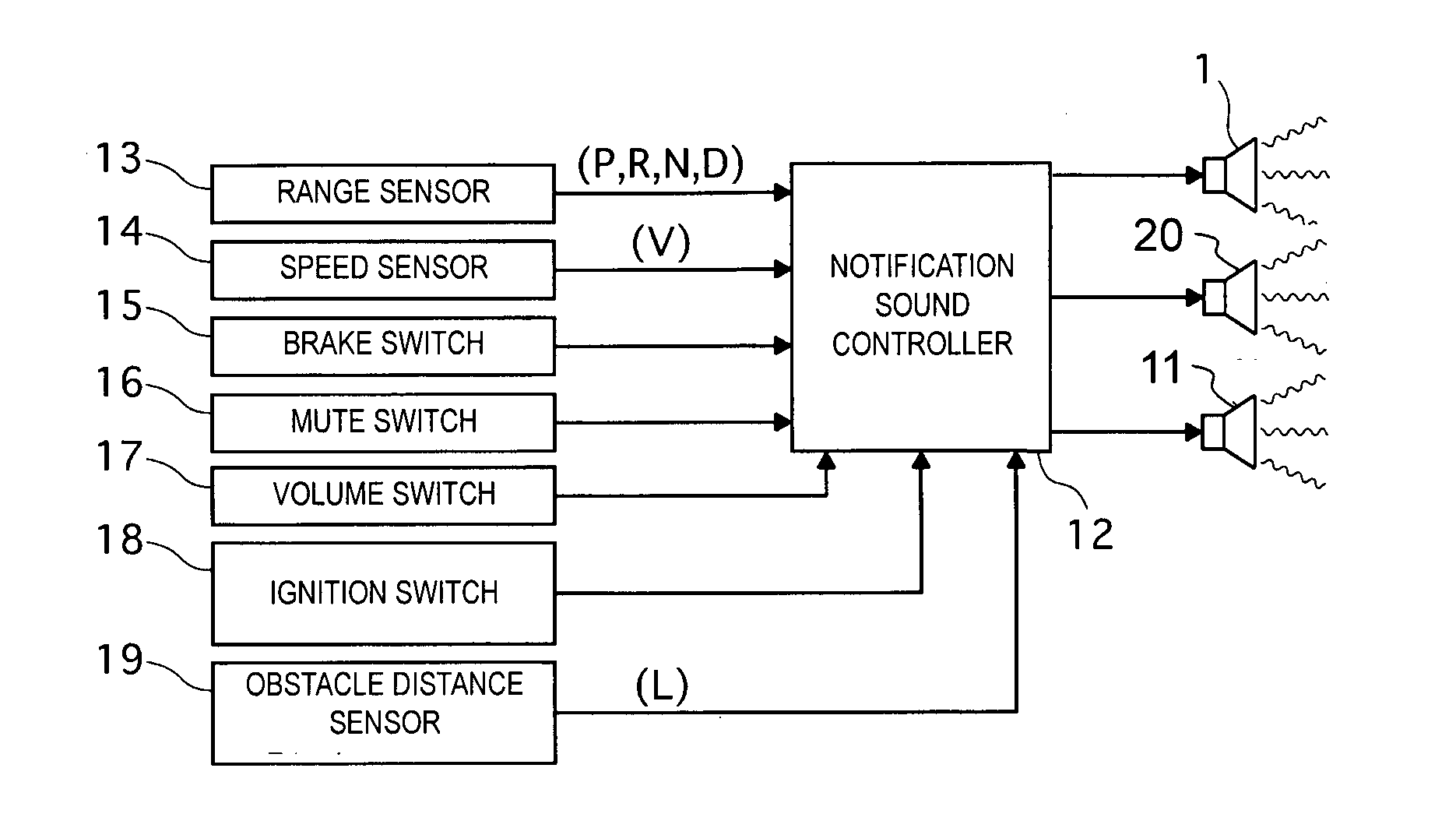

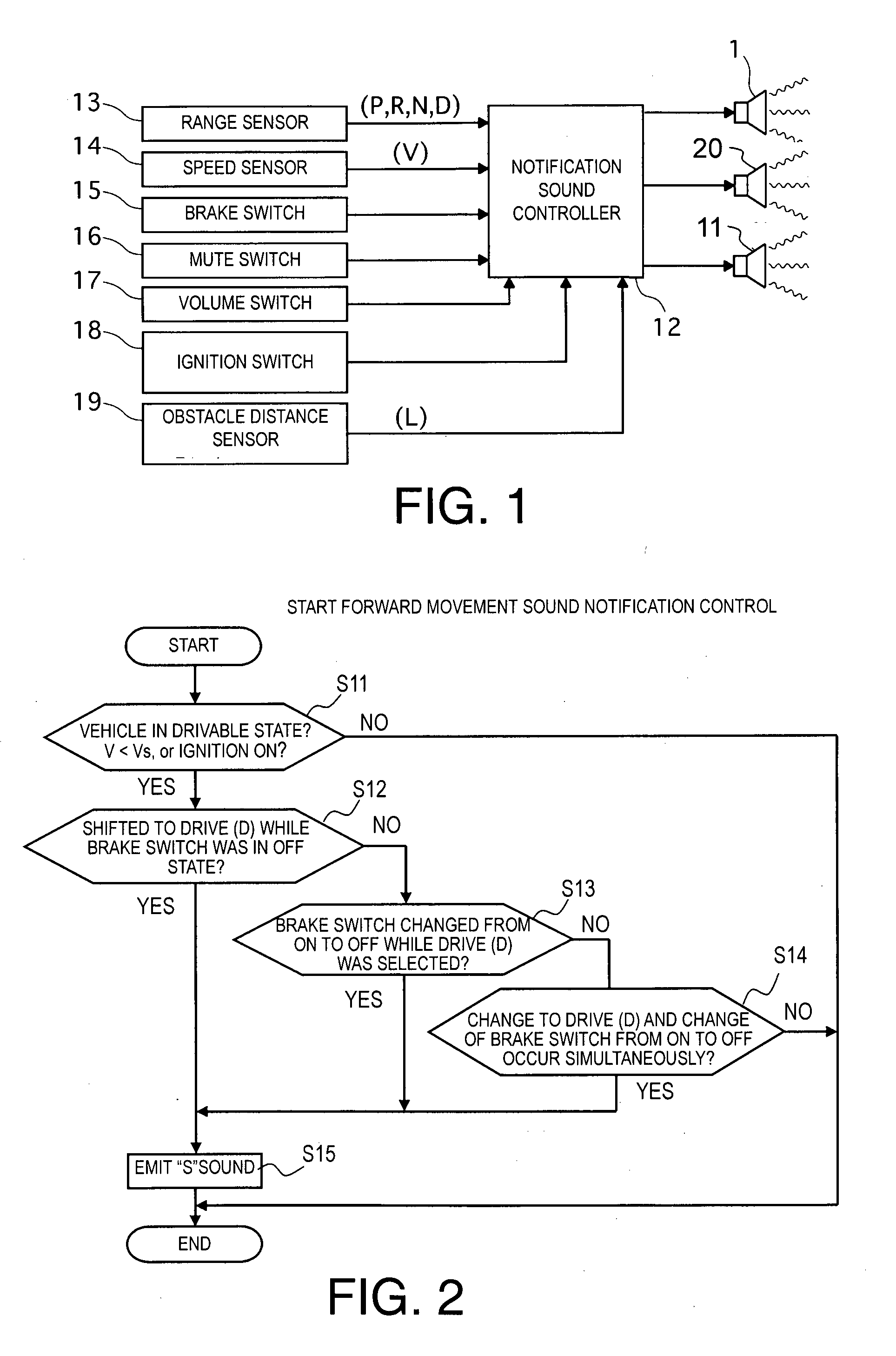

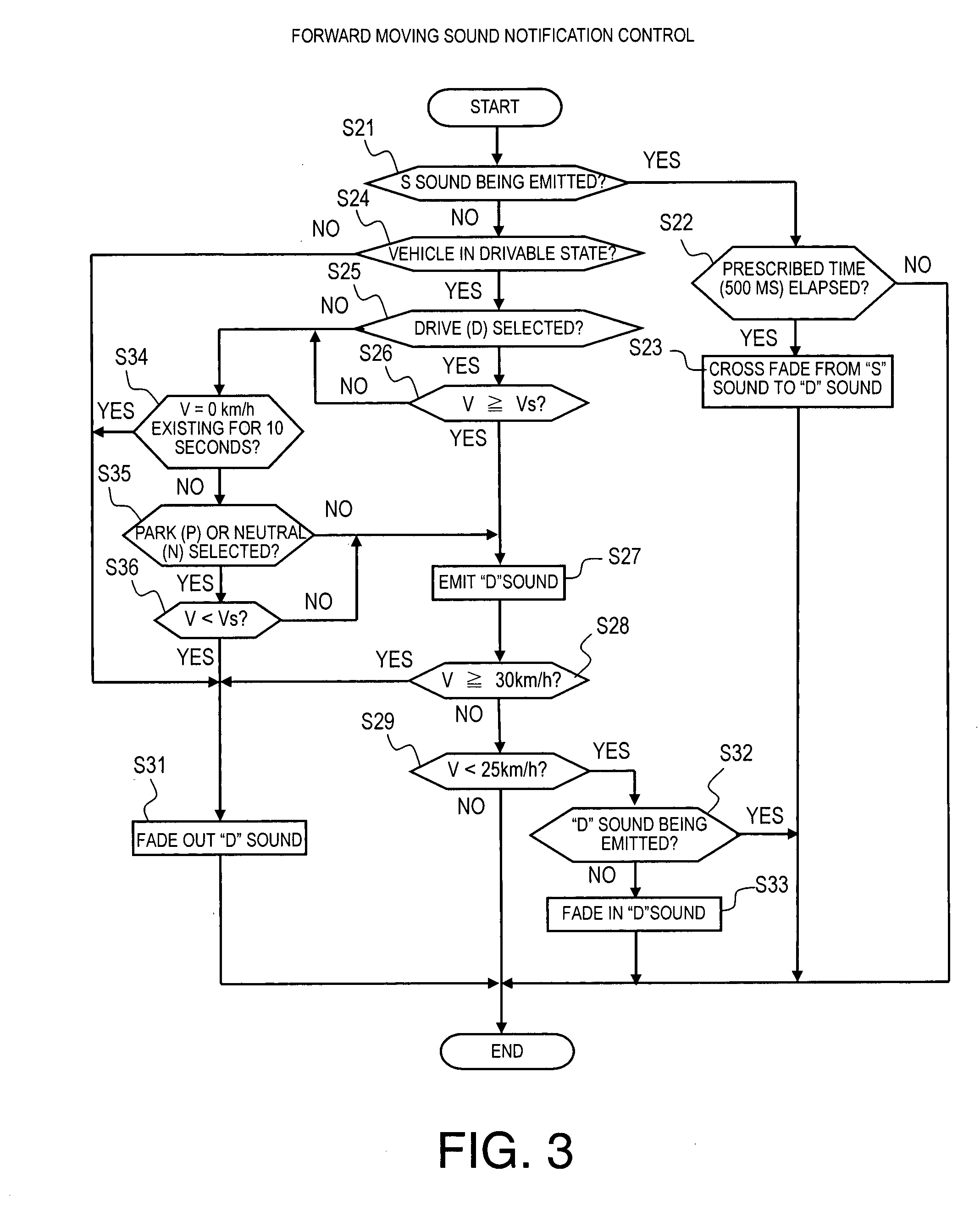

Vehicle notification sound emitting apparatus

ActiveUS20120296520A1Quickly recognizeLarge safety benefitAcoustic signal devicesDigital data processing detailsEngineeringSecond sound

A vehicle notification sound emitting apparatus is basically provided with a first sound emitting device, a second sound emitting device and a notification sound control device. The first sound emitting device emits a first intermittent notification sound inside a cabin interior of a vehicle. The second sound emitting device emits a second intermittent notification sound outside of the cabin interior of the vehicle. The notification sound control device operates the first and second sound emitting devices to separately emit the first and second intermittent notification sounds in at least a partially overlapping pattern in response to occurrence of a vehicle condition to convey a same type of vehicle information to both inside and outside of the cabin interior of the vehicle. The notification sound control device includes a cabin interior-exterior notification sound synchronizing section that is configured to synchronize the first and second intermittent notification sounds.

Owner:NISSAN MOTOR CO LTD

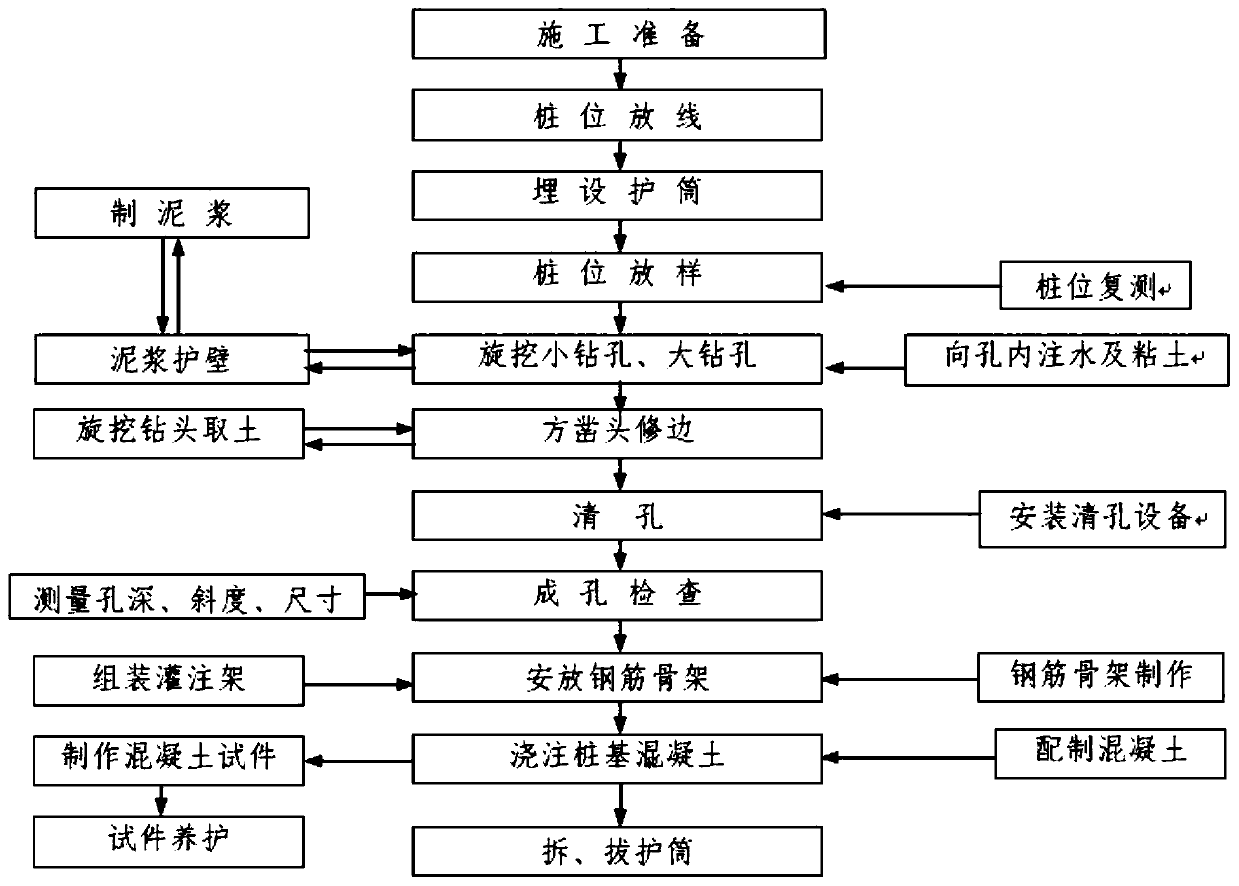

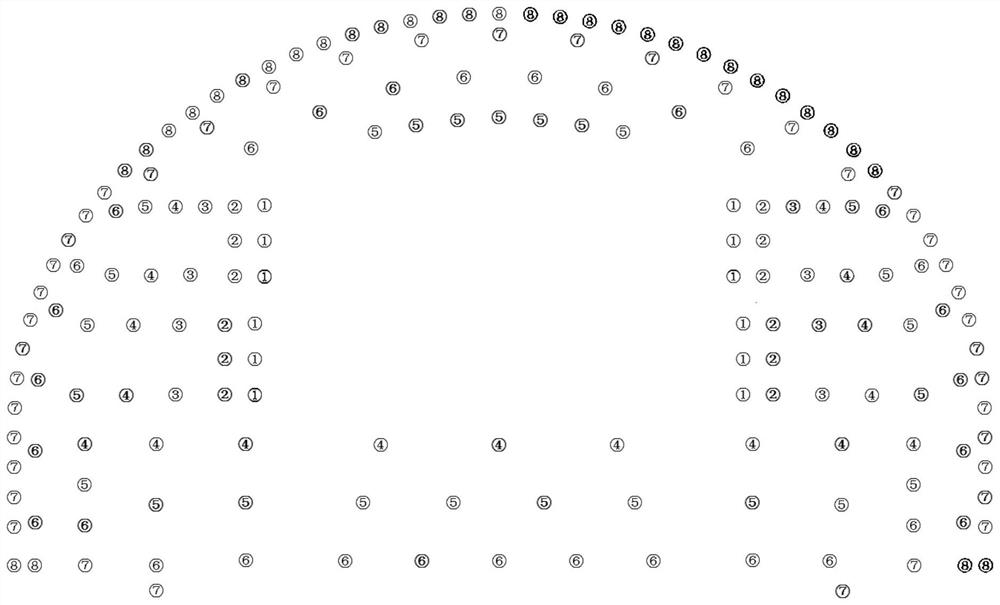

Construction method for excavating square piles through rotary excavating machine and square chiseling head combined

The embodiment of the invention discloses a construction method for excavating square piles through a rotary excavating machine and a square chiseling head combined. The construction method comprisesthe following steps that (1) pile casings are embedded; (2) pile positions are set out; (3) small drilled holes are subjected to rotary excavating; (4) large drilled holes are subjected to rotary excavating; (5) the square chiseling head conducts trimming and hole clearing, and the square chiseling head comprises a connecting part and a square pipe, wherein one end of the connecting part is detachably connected with a drill rod of the rotary excavating machine, one end of the square pipe is fixedly connected with the outer wall of the connecting part, a notch is formed in the other end of thesquare pipe, and the notch is provided with a plurality of bucket teeth at intervals; and (6) pile hole forming detection is conducted, reinforcement skeletons are mounted, pile foundation concrete ispoured, the pile casings are detachably and pulled, thus the square piles are formed, and square pile construction is completed. According to the construction method, by designing the square chiseling head, after the rotary excavating machine adopts a traditional rotary excavating drill bit to drill circular holes, the rotary excavating drill bit is replaced with the square chiseling head, the inner walls of the pile holes are trimmed, thus a mechanical trimming mode of the square chiseling head replaces an existing manual excavating mode, the construction duration is obviously shortened, andthe construction efficiency is improved.

Owner:德宏守精建筑劳务有限责任公司

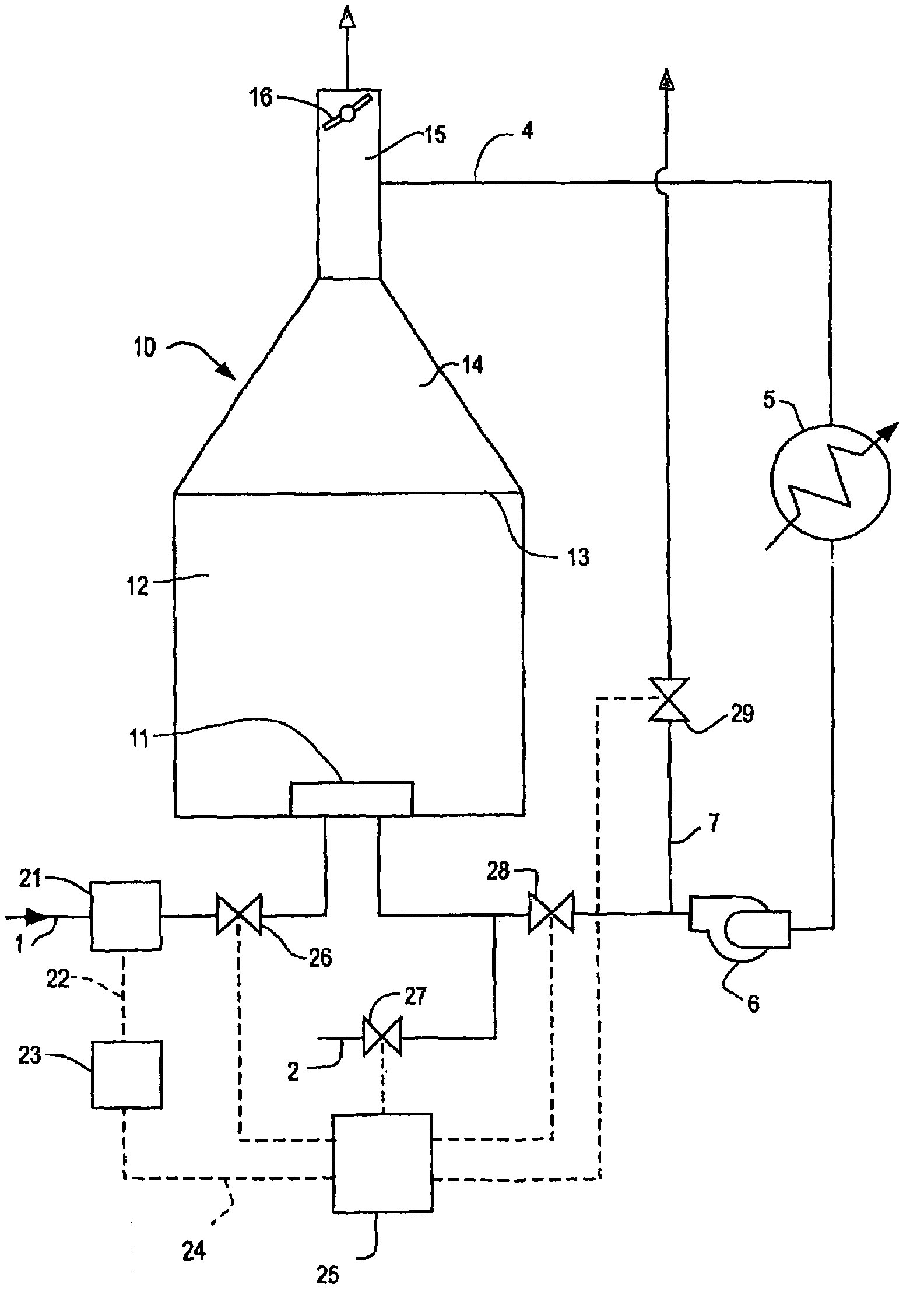

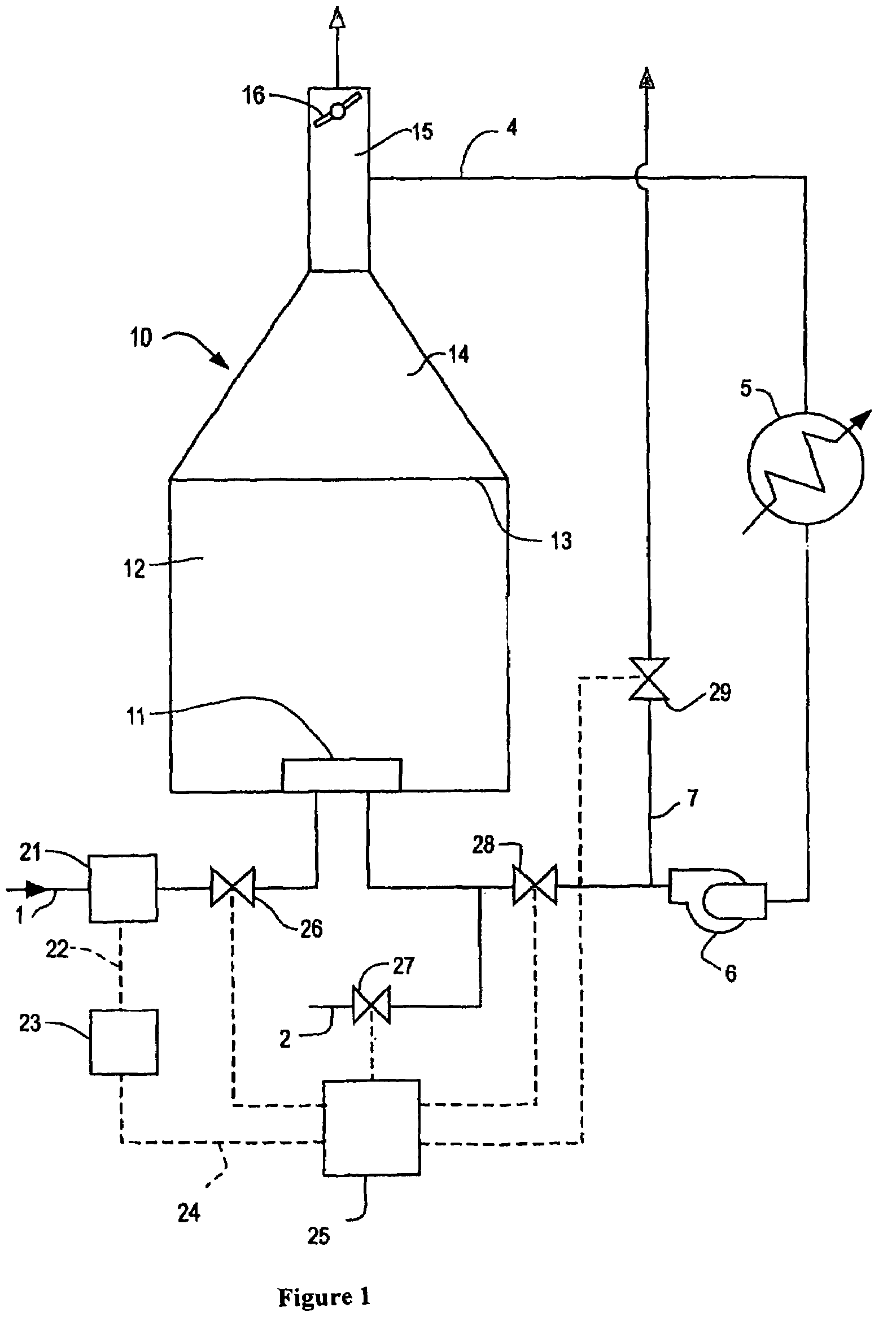

Method for combusting fuel in a fired heater

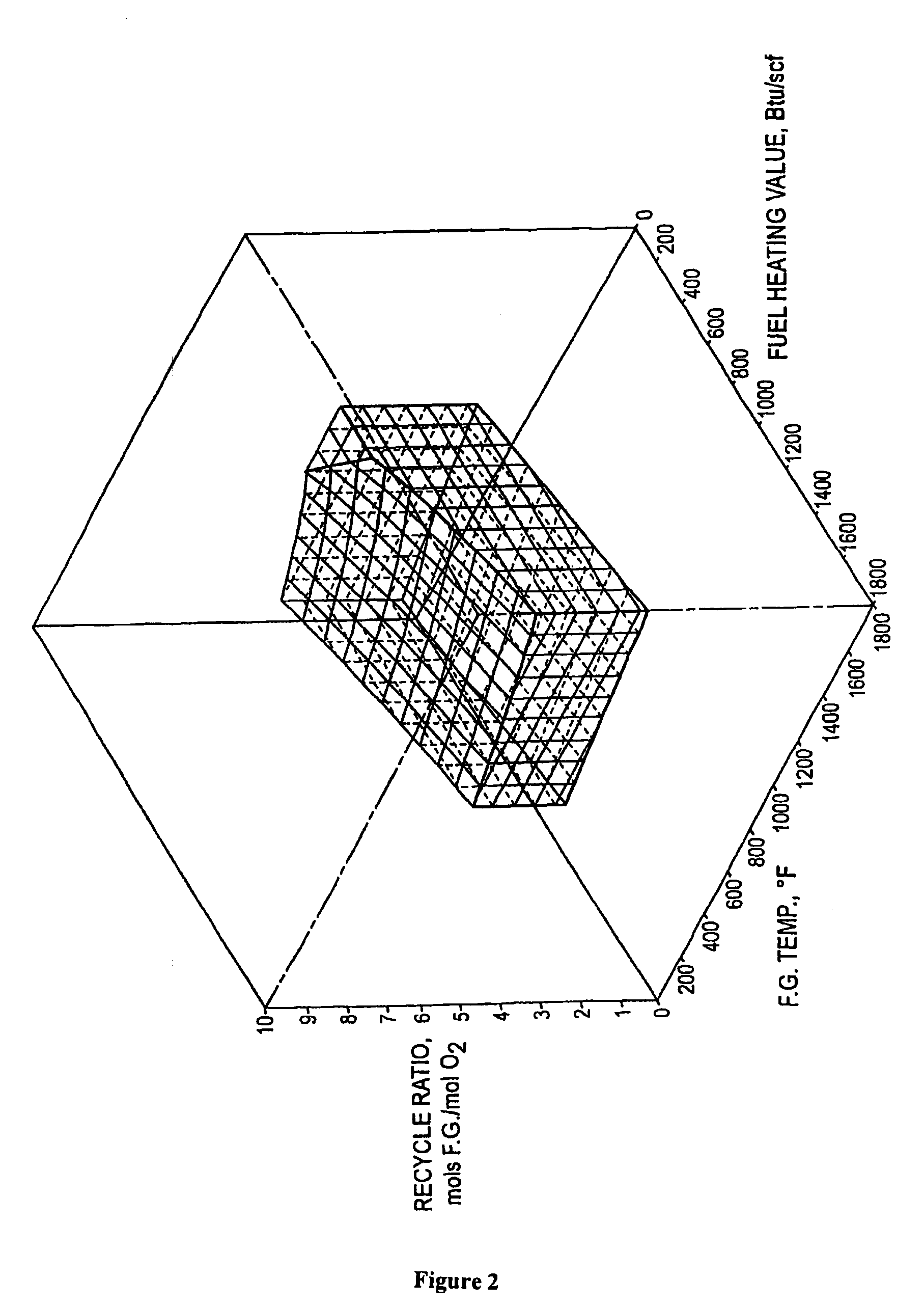

InactiveUS7467943B2Reduce unnecessary consumptionSubstantial cost-savingsDirect carbon-dioxide mitigationCombustion pretreatment/prehandlingThermodynamicsCombustor

A method for combusting fuel in a fired heater having one or more burners, the method. comprising: (a) combusting at least a portion of the fuel in the. presence of an oxidizer in the burners,. generating heat and producing a flue gas; and (b) recycling at least a portion. of the flue gas to. the burners;. wherein step (a) and step (b) are conducted in a manner such that the combusting takes place in a combustion regime represented. by 4,500−7554.8−933.72x+64.960x2+0.47705y−0.55680z1579.22,500; W wherein w represents a mole fraction of oxygen. in the oxidizer, x represents a recycle ratio of the flue as measured in moles of flue gas / mole of oxidizer; wherein y represents a temperature of the. flue gas in Fahrenheit recycled to the burners; and wherein. z represents a heating. value of the fuel in Btu / scf LHV.

Owner:BP CORP NORTH AMERICA INC

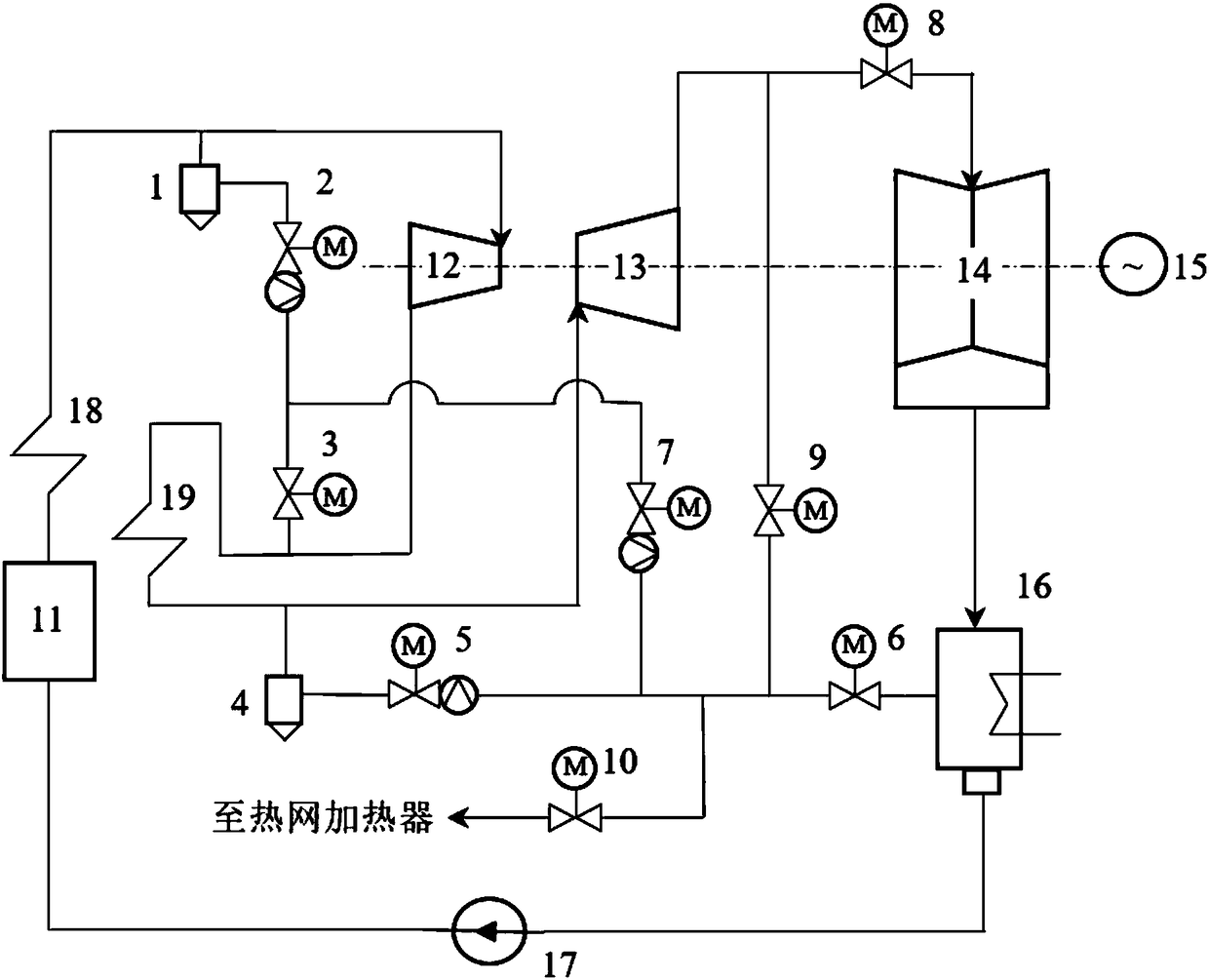

Generator set three-stage parallel serial connection bypass system and adjusting method thereof

PendingCN108301882AIncrease flexibilityIncreaseLighting and heating apparatusEngine componentsIsolation valveThree stage

The invention discloses a generator set three-stage parallel serial connection bypass system and an adjusting method thereof. The system comprises a high-pressure bypass system, a low-pressure bypasssystem and a low-low-pressure bypass system; the high-pressure bypass system comprises a high-pressure bypass filter, a high-pressure bypass valve and a high-pressure bypass isolation valve, the low-pressure bypass system comprises a low-pressure bypass filter, a low-pressure bypass valve and a low-pressure bypass isolation valve which are sequentially connected between a reheating steam heat segment pipeline and a condener, the low-low-pressure bypass system comprises a low-pressure cylinder isolation valve and a medium-pressure exhaust low-pressure bypass communication valve, the low-pressure cylinder isolation valve is arranged on an air guide pipe between a medium pressure cylinder and a low-pressure cylinder, an inlet pipeline of the medium-pressure exhaust low-pressure bypass communication valve is arranged on a medium-pressure cylinder exhaust pipeline, an outlet pipeline is arranged on a pipeline between the low-pressure bypass valve and the low-pressure bypass isolation valve,the high-pressure bypass system and the low-pressure bypass system are connected through a high and low pressure bypass communication valve, and a pipeline between the low-pressure bypass valve and the isolation valve is connected with a heat net heater through a low-pressure bypass heat supply adjusting valve.

Owner:XIAN THERMAL POWER RES INST CO LTD

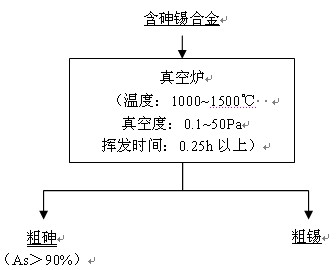

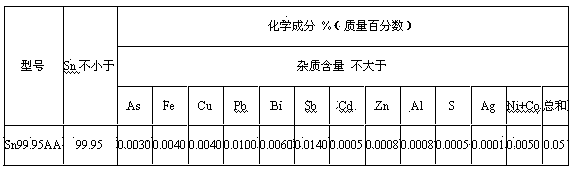

Method for removing arsenic impurities from tin

The invention relates to a method for removing arsenic impurities from tin. The method comprises the following steps of: adding an arsenic-containing tin alloy into a vacuum furnace, wherein arsenic elements in the tin are volatilized under the conditions that pressure in the furnace is in the range of 0.1-50Pa, the temperature in the furnace is between 1000 DEG C and 1500 DEG C, and the volatilization time of the arsenic-containing tin alloy is more than 0.25h; condensing the arsenic elements to obtain a metal arsenic; and separating the arsenic from the tin to obtain crude arsenic containing more than 90% of arsenic, wherein the removal rate of arsenic is greater than 90%. The invention provides a novel process for removing the arsenic from tin; the whole process is safe and controllable; and the method has the advantages of convenience for operation, high recovery rate of tin and arsenic, no need of adding chemical reagents and no pollution on the environment.

Owner:KUNMING UNIV OF SCI & TECH +1

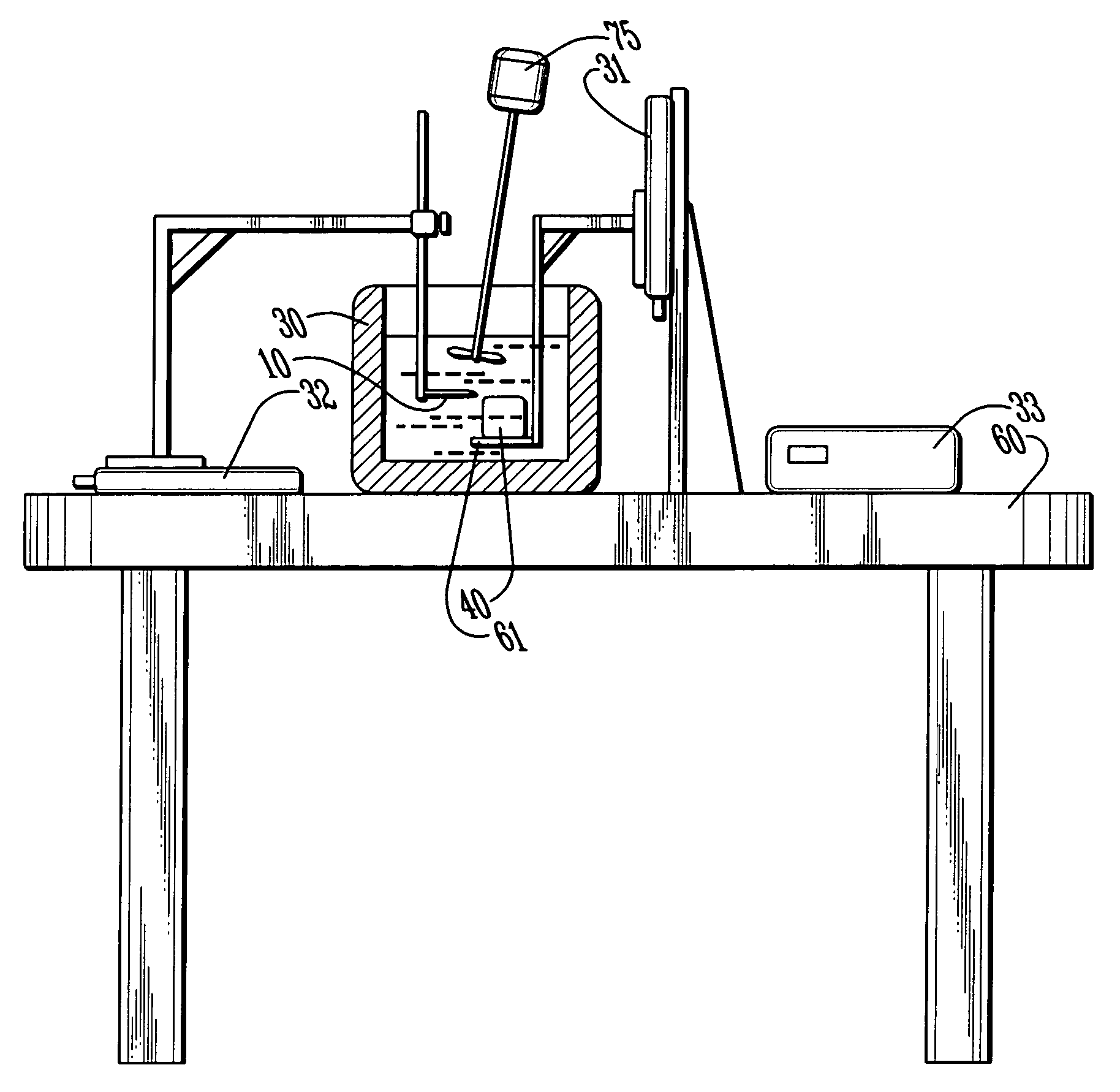

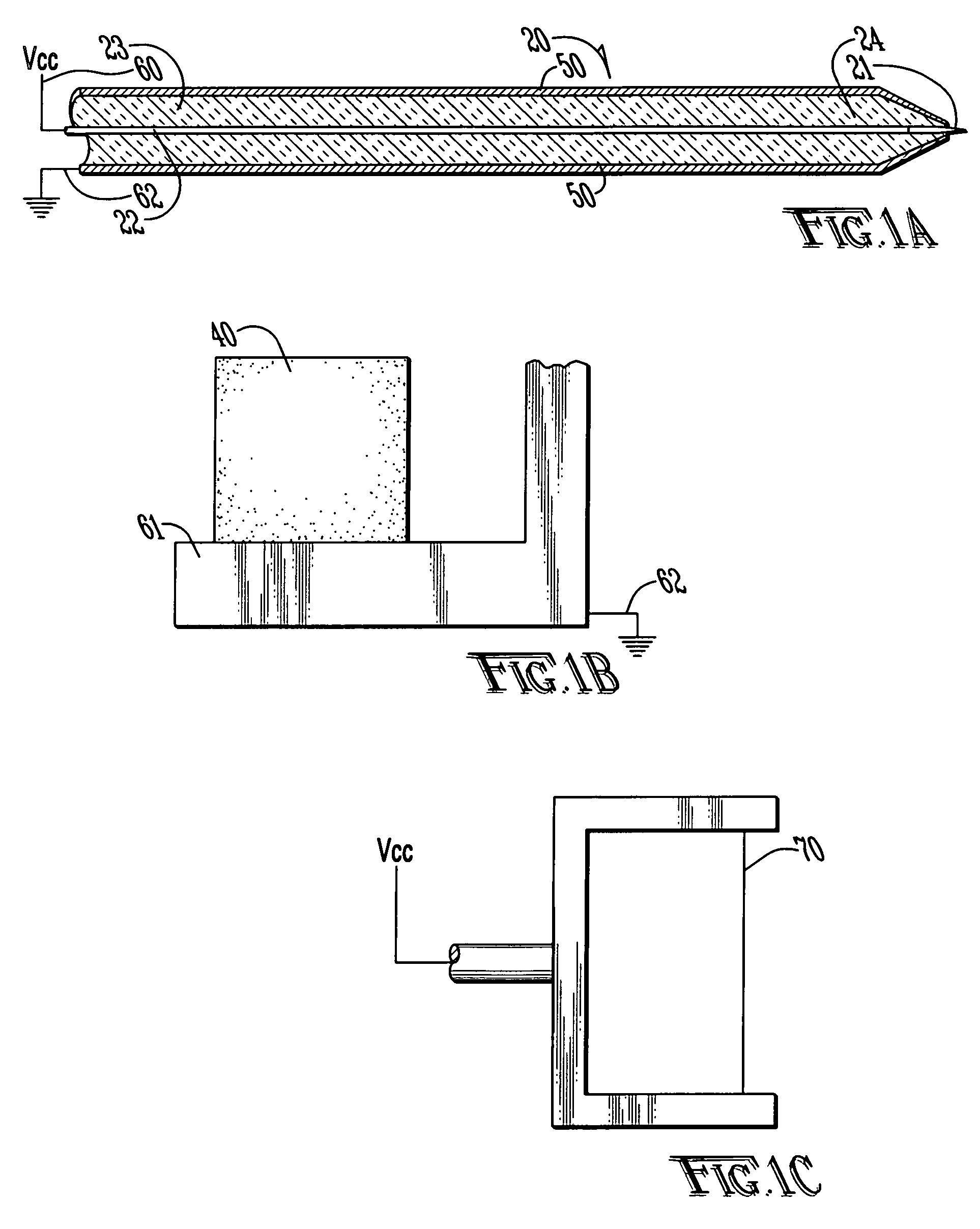

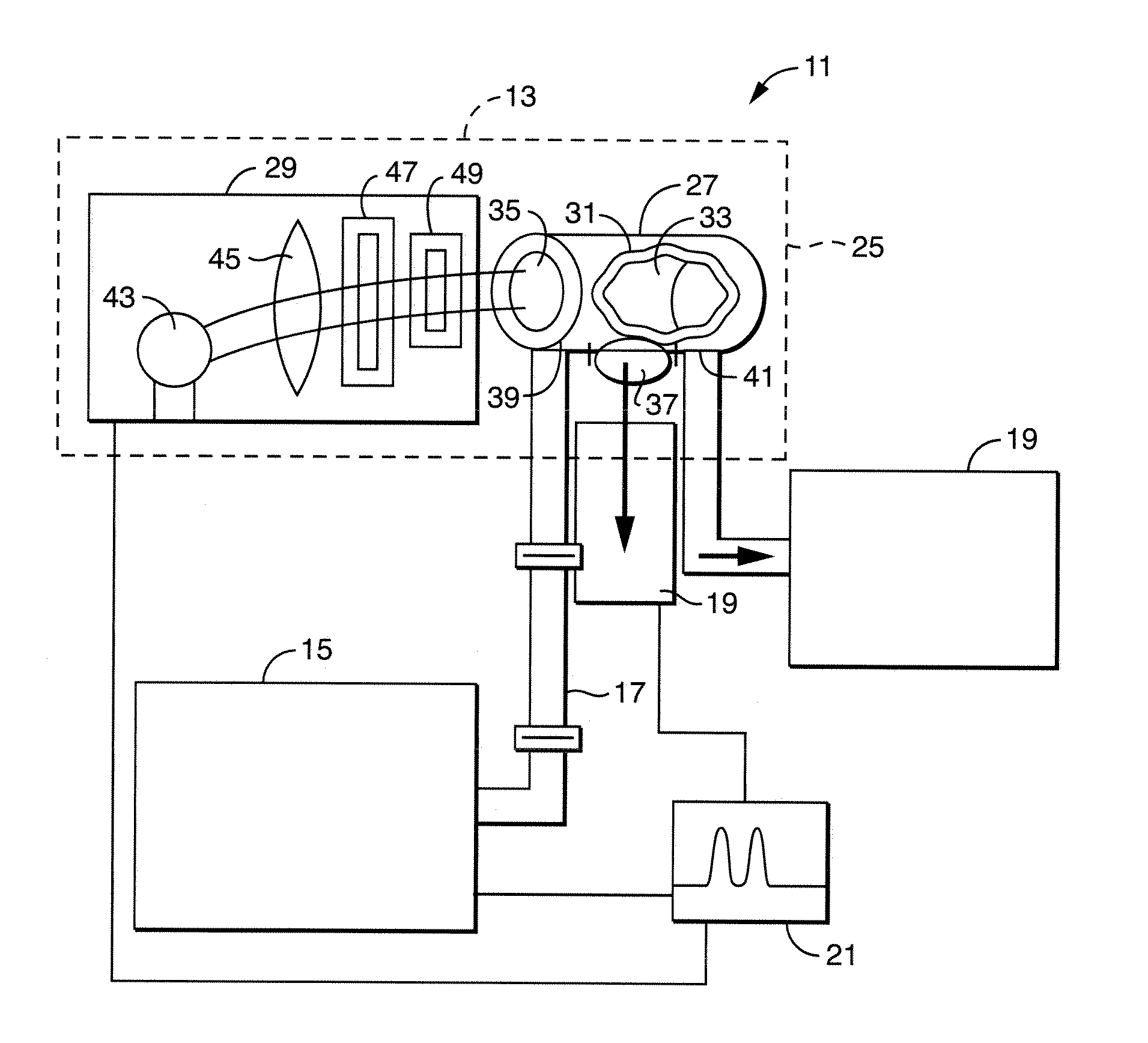

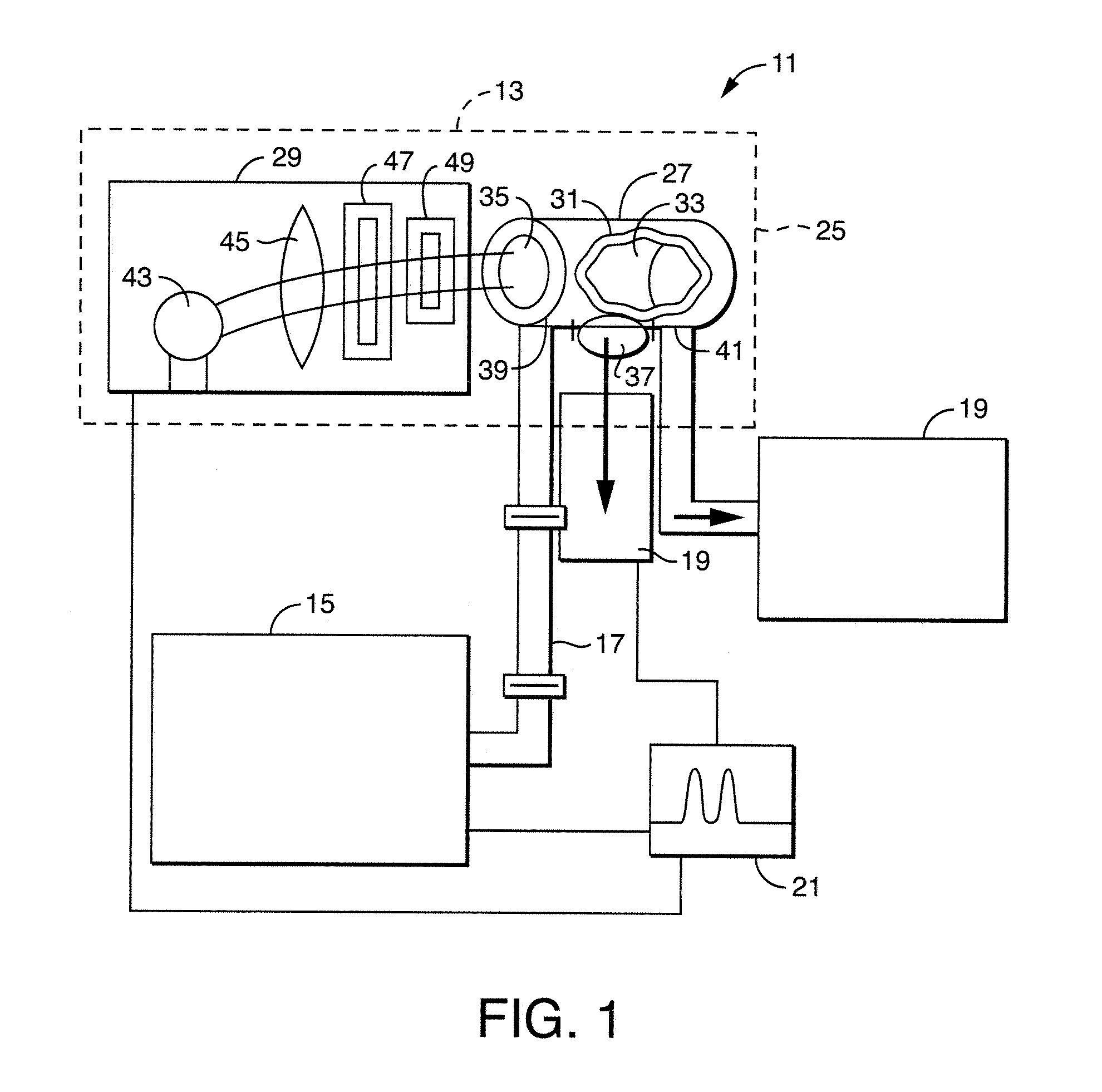

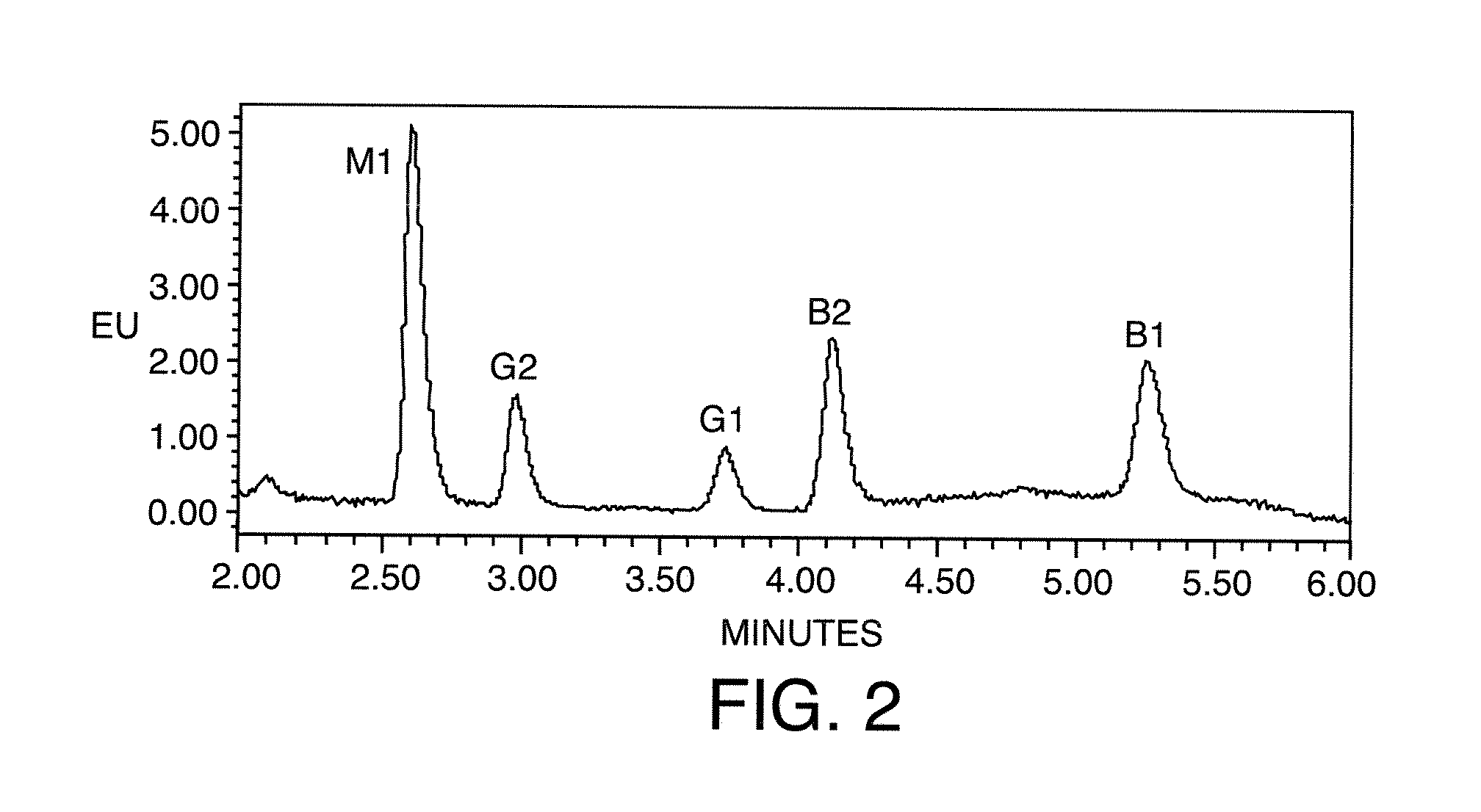

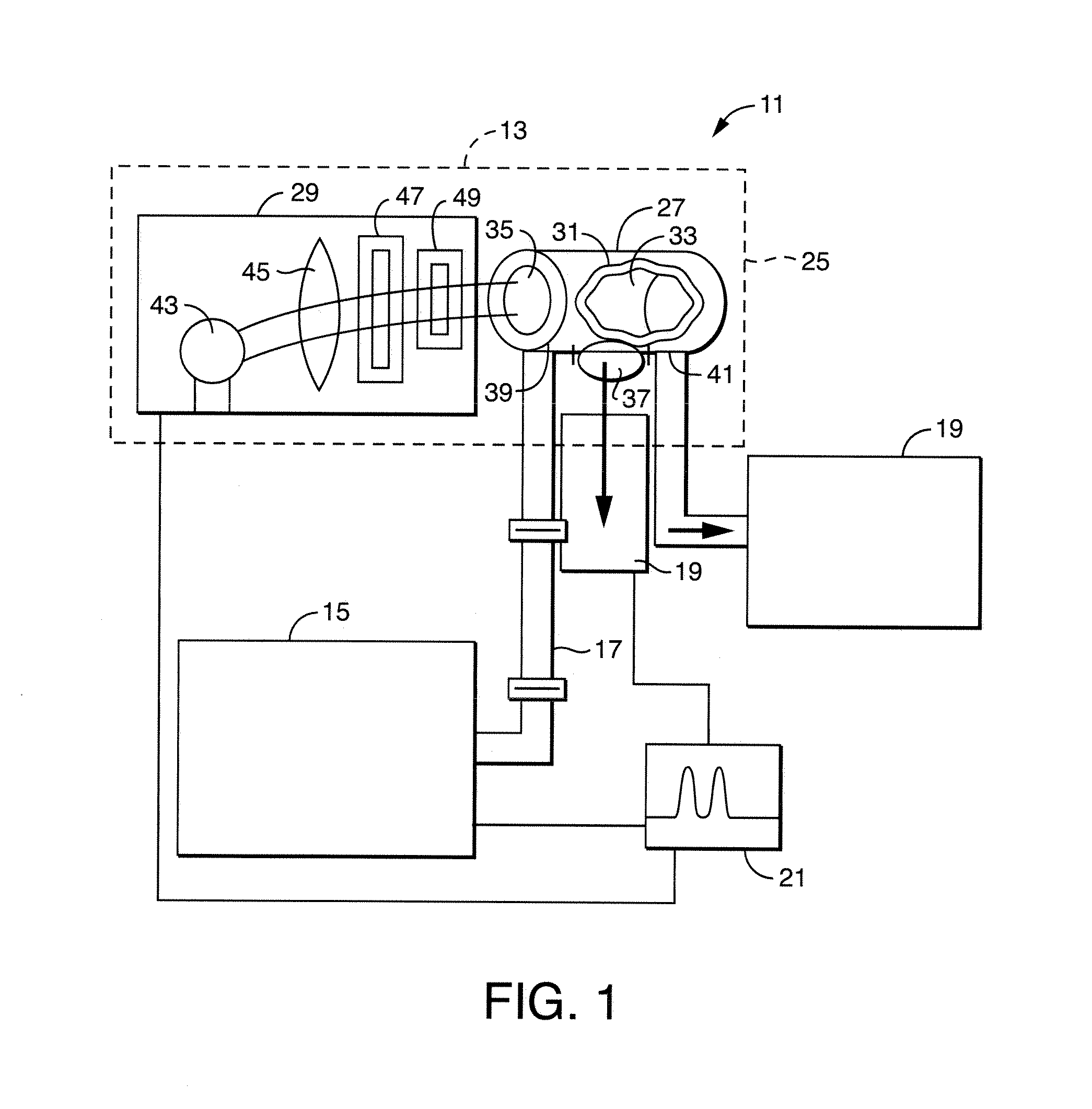

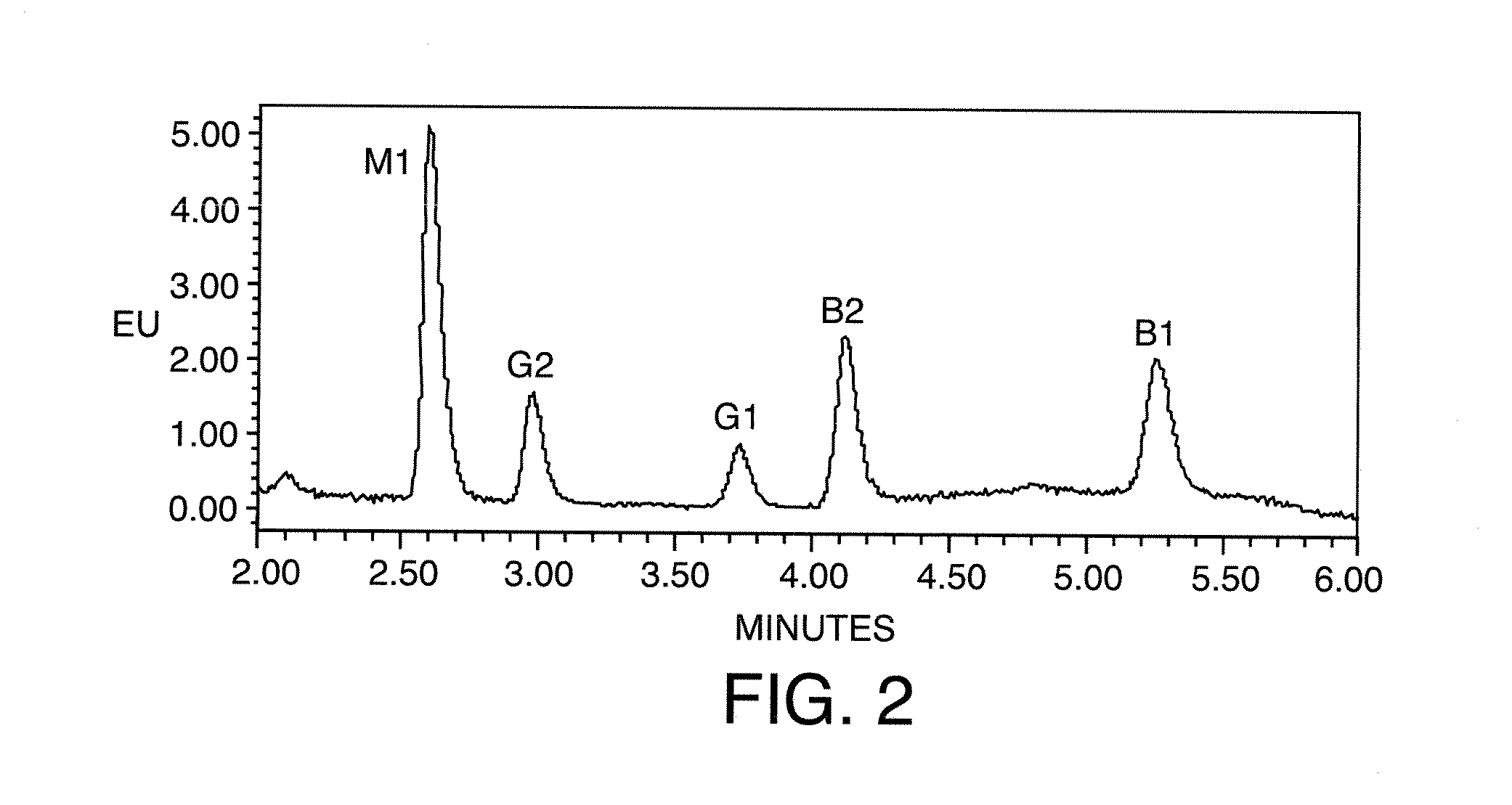

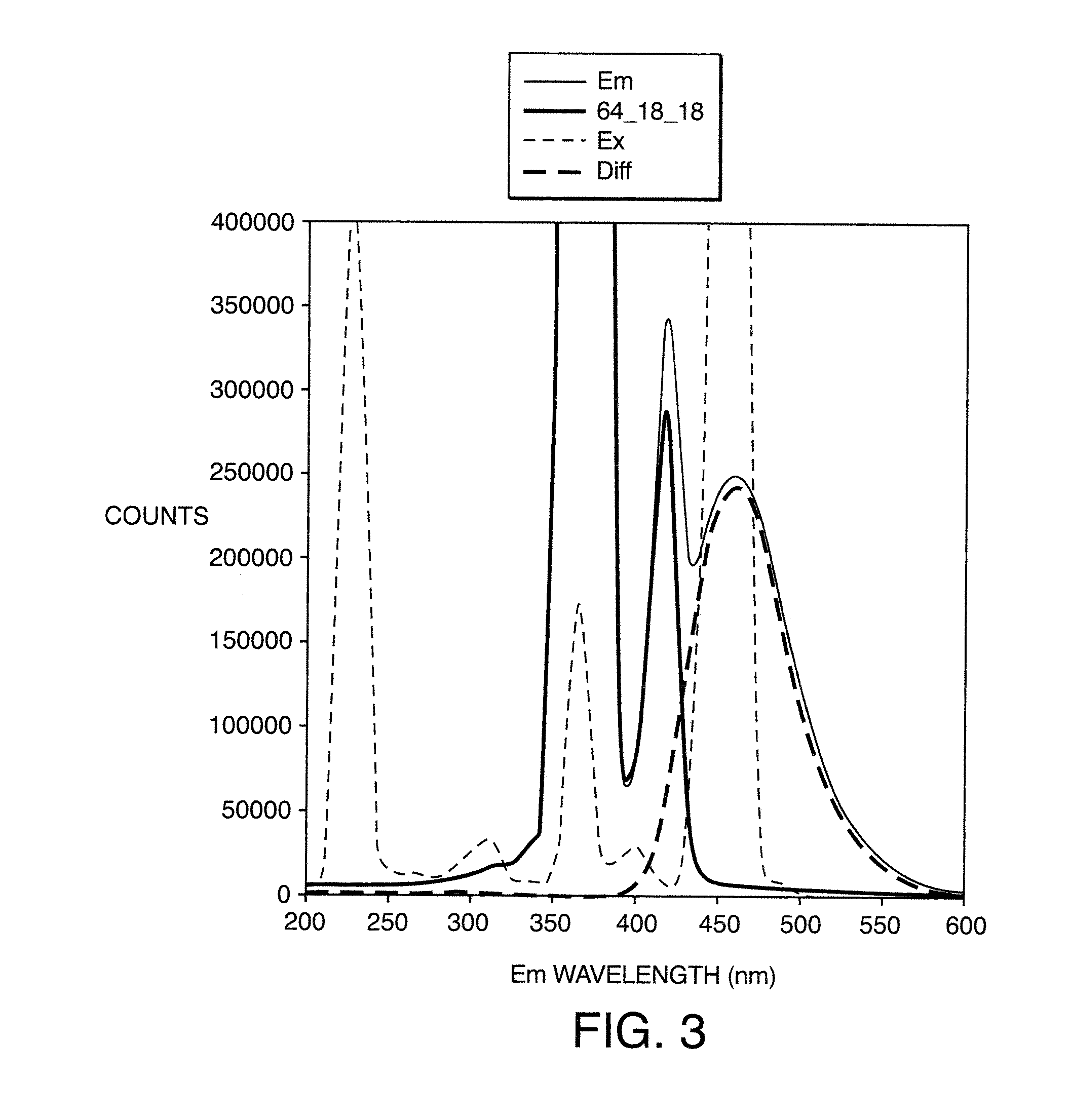

Apparatus and methods for performing photoreactions and analytical methods and devices to detect photo-reacting compounds

ActiveUS8524502B2Significant safety benefitsGroup 1/11 element organic compoundsSamplingMedicineOptical communication

The present invention is directed to devices and methods for performing photoreactions of photo-reacting compounds in solution. The invention features a vessel defining a chamber and a light source. The chamber has a chamber volume, a first window, an inlet and an outlet. The inlet is placed in fluid communication with a source of photo-reacting compounds in solution. The first window is transparent to light transmission and is placed in optical communication with a light source to receive photons. The chamber receives a solution of one or more photo-reactive compounds over time to define a dwell time. The device further includes a light source, in optical communication with the first window, for emitting photons which photons are received by the first window and transmitted into the chamber.

Owner:WATERS TECH CORP

Apparatus And Methods For Performing Photoreactions And Analytical Methods And Devices To Detect Photo-Reacting Compounds

ActiveUS20110263033A1Significant health safety benefitEfficient processingGroup 1/11 element organic compoundsComponent separationMedicineOptical communication

Embodiments of the present invention are directed to devices and methods for performing photoreactions of photo-reacting compounds in solution. The invention features a vessel and a light source. The vessel has at least one wall defining a chamber. The chamber, for performing photoreactions, has a chamber volume, a first window, an inlet and an outlet. The inlet and outlet are in fluid communication with a source of photo-reacting compounds in solution. The first window is transparent to light transmission and is placed in optical communication with a light source to receive photons. The chamber is for receiving a solution over time to define a dwell time. The solution potentially has one or more photo-reactive compounds having a concentration. The device further comprises a light source, in optical communication with the first window, for emitting photons which photons are received by the first window and transmitted into the chamber.

Owner:WATERS TECH CORP

Medium-length hole controlled blasting construction method of underground large chamber

InactiveCN109322683ASolve problems in basic constructionImprove blasting efficiencyUnderground chambersArchitectural engineeringEngineering

The invention discloses a medium-length hole controlled blasting construction method of a underground large chamber. The medium-length hole controlled blasting construction method comprises the following steps that the size of the large chamber is determined; undercutting roadway construction is conducted; chamber expansion brushing and drilling are conducted; courtyard cutting construction is conducted; upward medium-length hole construction is conducted; explosive is mounted in the medium-length hole; medium-length hole blasting is conducted; deslag is conducted; and whitewashing and supporting are conducted, and the large chamber is formed. The medium-length hole controlled blasting technology is adopted, blasting efficiency is greatly improved, the method of early centralized drillingand later unified blasting is adopted, the circulation of drilling-blasting-deslag-drilling is not required to be conducted frequently by workers, and therefore working efficiency is improved. Compared with a traditional chamber layered construction method, the cost of the method is reduced by half, construction efficiency is doubled, the construction period is shortened by half, security is greatly improved, and safety benefits are obvious.

Owner:临沂会宝岭铁矿有限公司

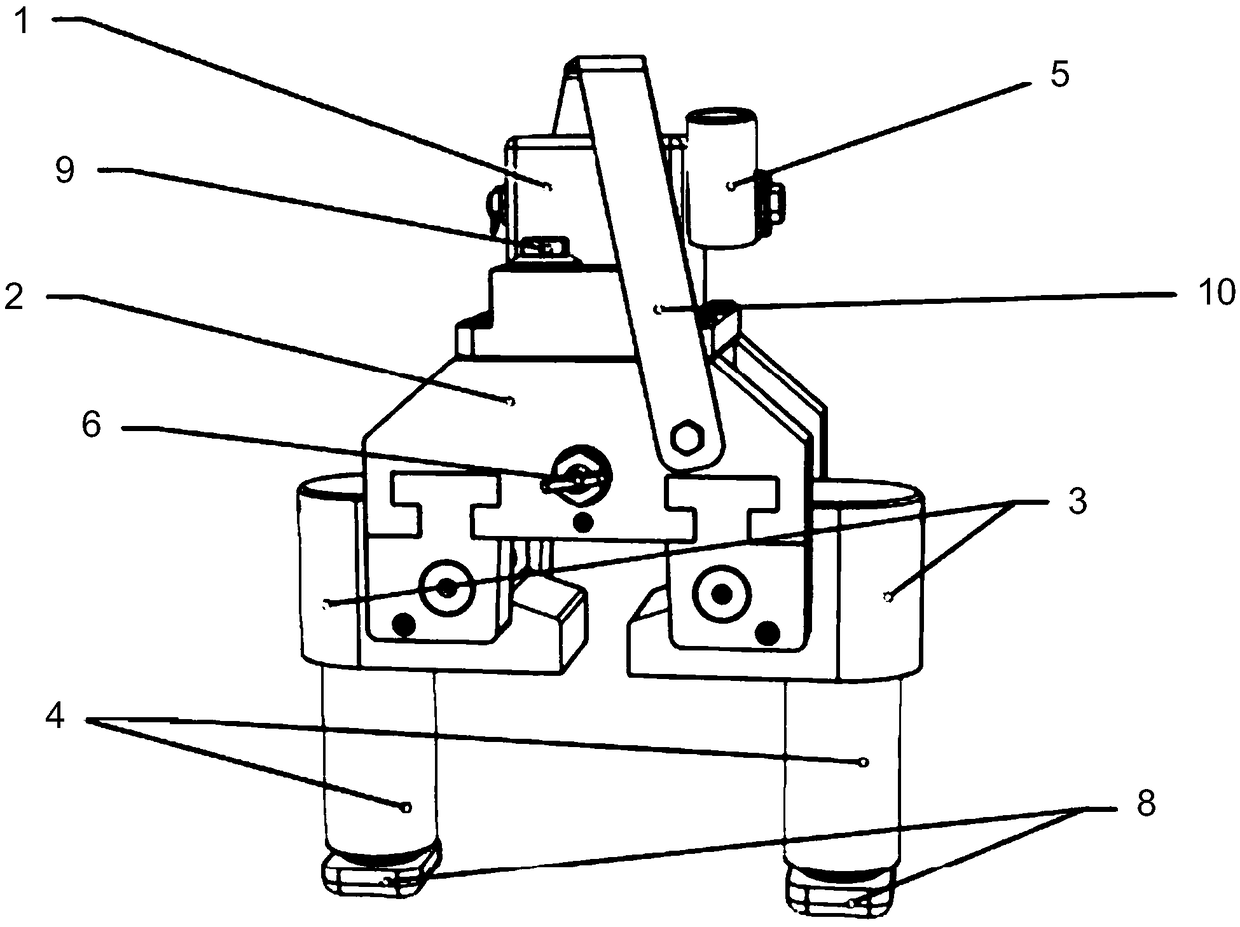

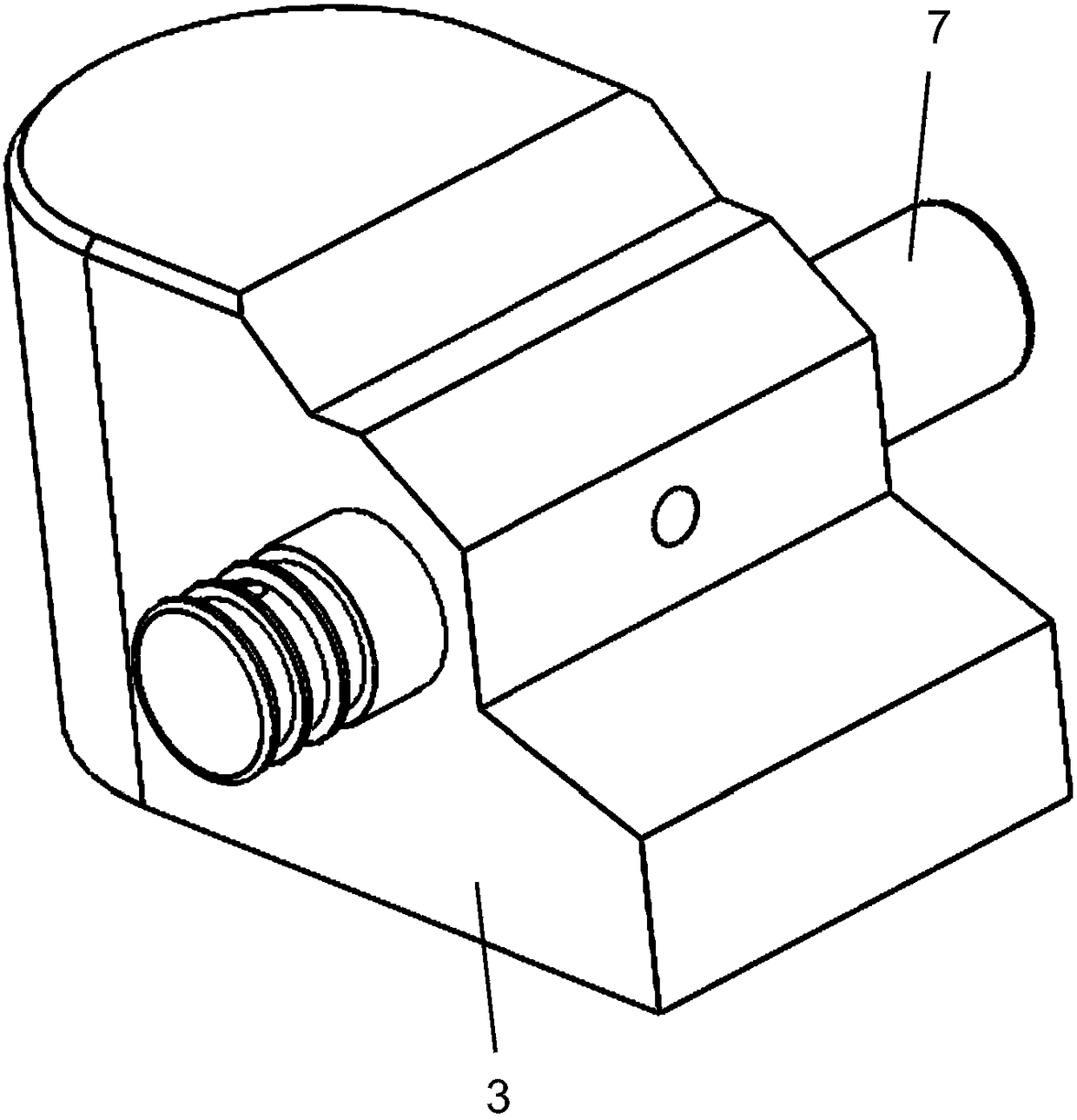

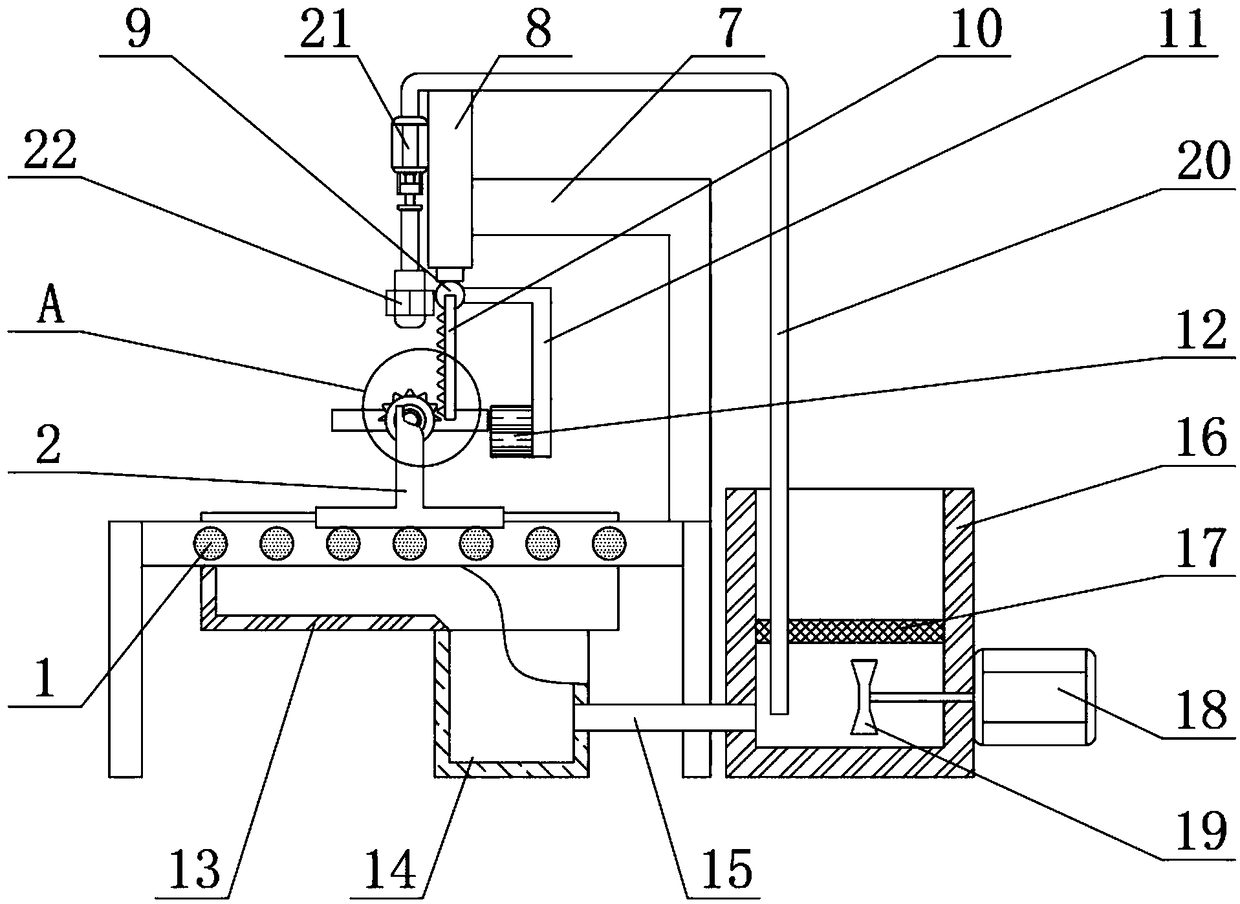

Hydraulic railhead track jack and use method thereof

The invention discloses a hydraulic railhead track jack and a use method thereof. The hydraulic railhead track jack comprises an oil tank and a base; the oil tank is arranged at the top of the base; alifting handle is connected to the oil tank; a manual oil return valve is also arranged on the base; a track lifting structure is arranged at the bottom of the base; the track lifting structure comprises a pair of track lifting hooks symmetrically arranged; hook heads of the two track lifting hooks are also oppositely arranged; rotating shafts are arranged on the track lifting hooks; the interiors of the rotating shafts are in communication with the oil tank; the track lifting hooks are connected to the bottom of the base through rotating shafts so that the track lifting hooks turn over to the external sides for 90 degrees to rotate around the rotating shafts; a hydraulic oil cylinder is connected to each track lifting hook; the two hydraulic oil cylinders are also symmetrically arranged;and rotatable feet are connected to piston ends of the hydraulic oil cylinders. The hydraulic railhead track jack can be applicable to but not limited to the track lifting operations of broad-gauge sleeper slabs under a situation of a small space.

Owner:上海瑞纽机械股份有限公司

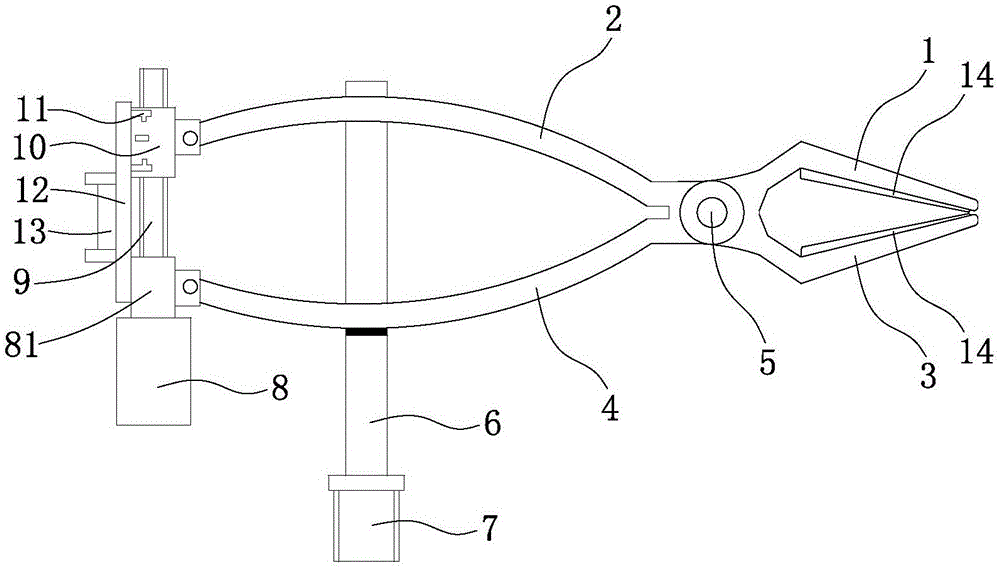

Live-line insulator W-shaped pin electric pin remover

ActiveCN105162040ANo falling from high altitudeReduce workloadApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention discloses a live-line insulator W-shaped pin electric pin remover, belonging to the power maintenance tool technology field and solving the problem that the prior art removes the pin through manual operation like beating up the W-shaped pin, which can mistakenly damage the insulator and is not easy to operate. The live-line insulator W-shaped pin electric pin remover comprises an upper clamping sheet and a lower clamping sheet; the upper sheet and the lower sheet are hinged together through a rotation shaft; the rotation shaft is provided with a spring; the upper sheet comprises an upper clamping head and an upper clamping handle; the lower clamping sheet comprises a lower clamping head and a lower clamping handle; the lower clamping handle is connected to a top of an insulation operation rod through a connection rod; the live-line insulator W-shaped pin electric pin remover also comprises an electric driving device comprising a motor, a screw rod connected to the output terminal of the motor and a nut sleeving the screw rod; the end of the lower clamping handle is fixed through a fixing block on the outer wall of the motor; and the end of the upper clamping handle is fixed on the nut.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO +1

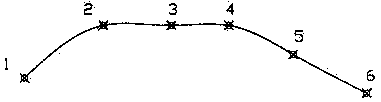

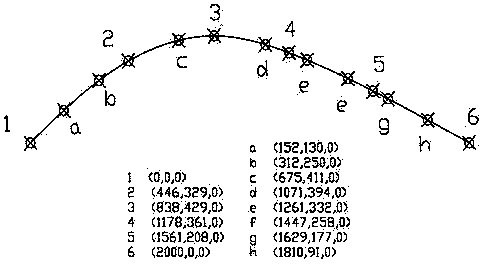

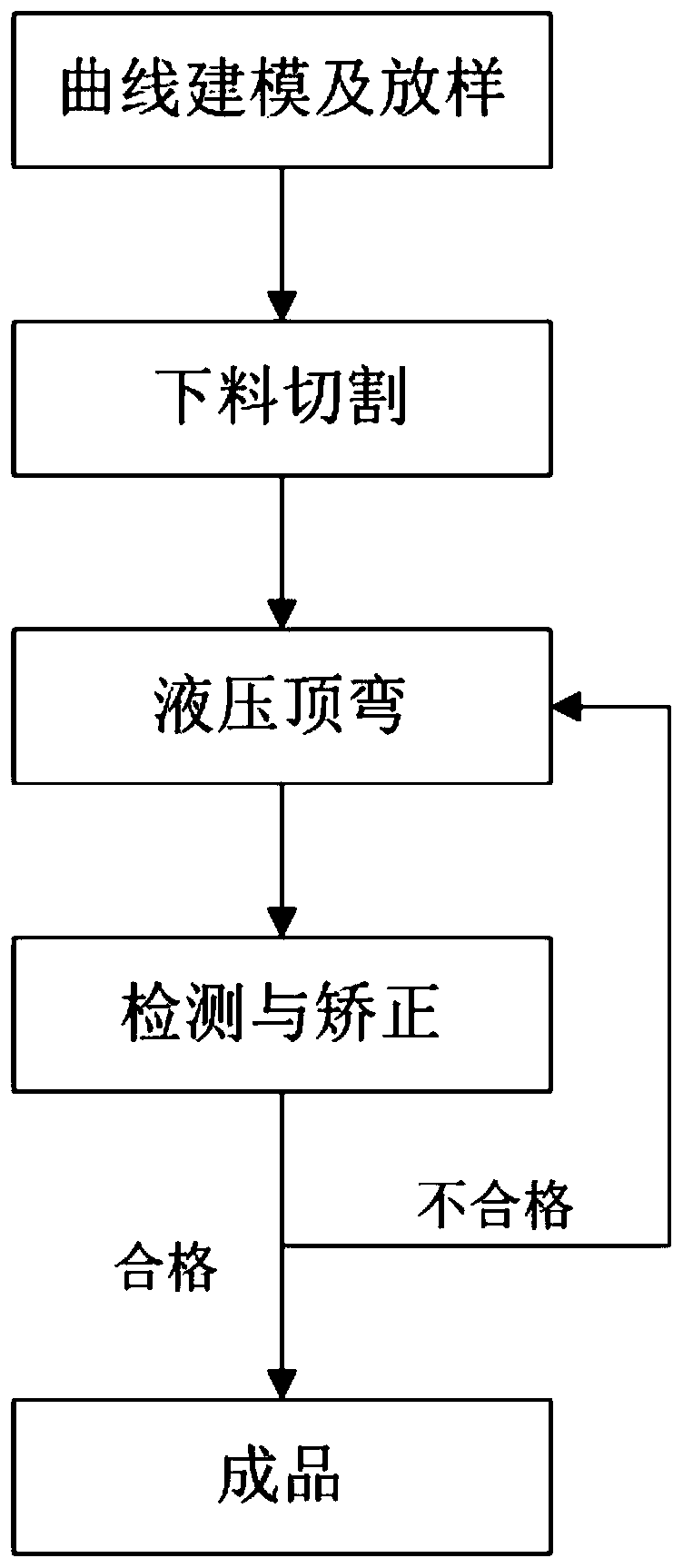

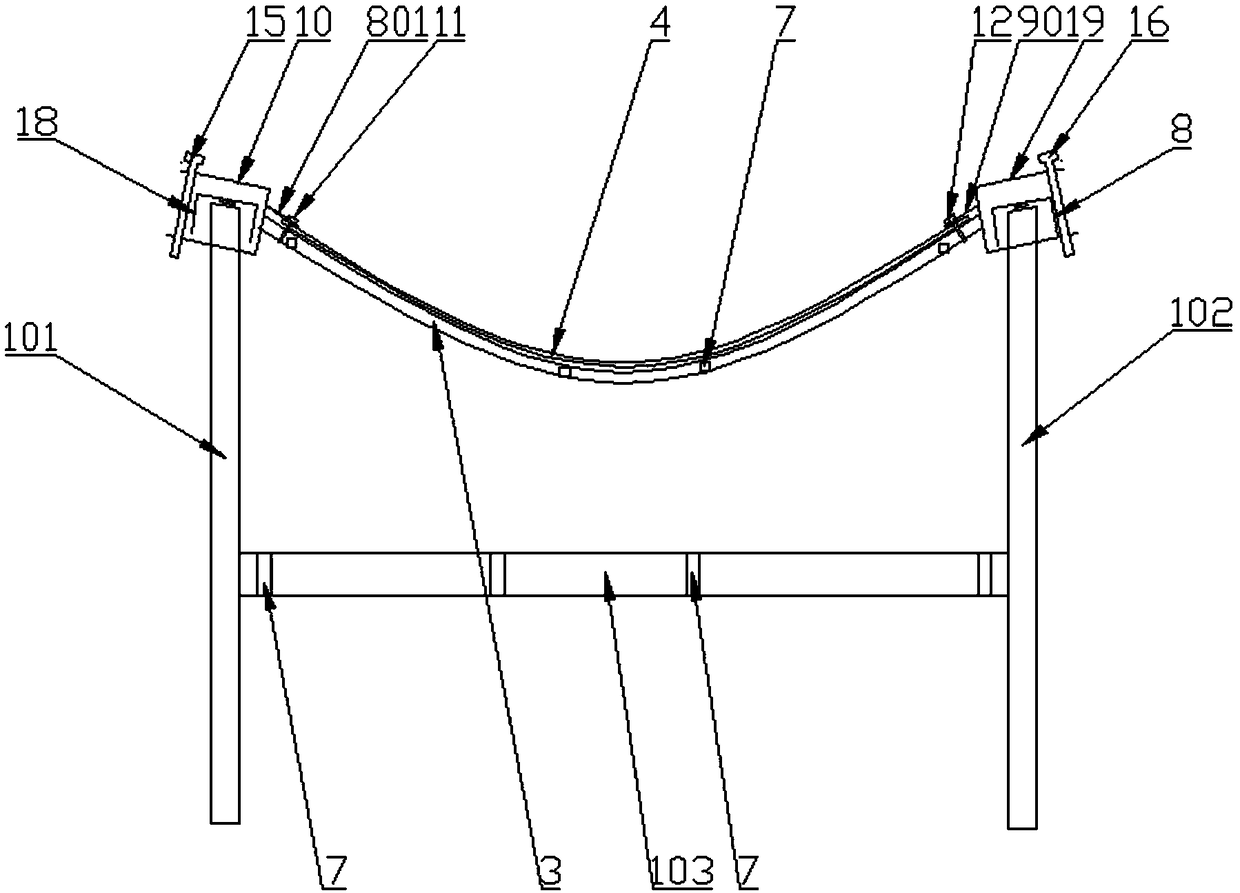

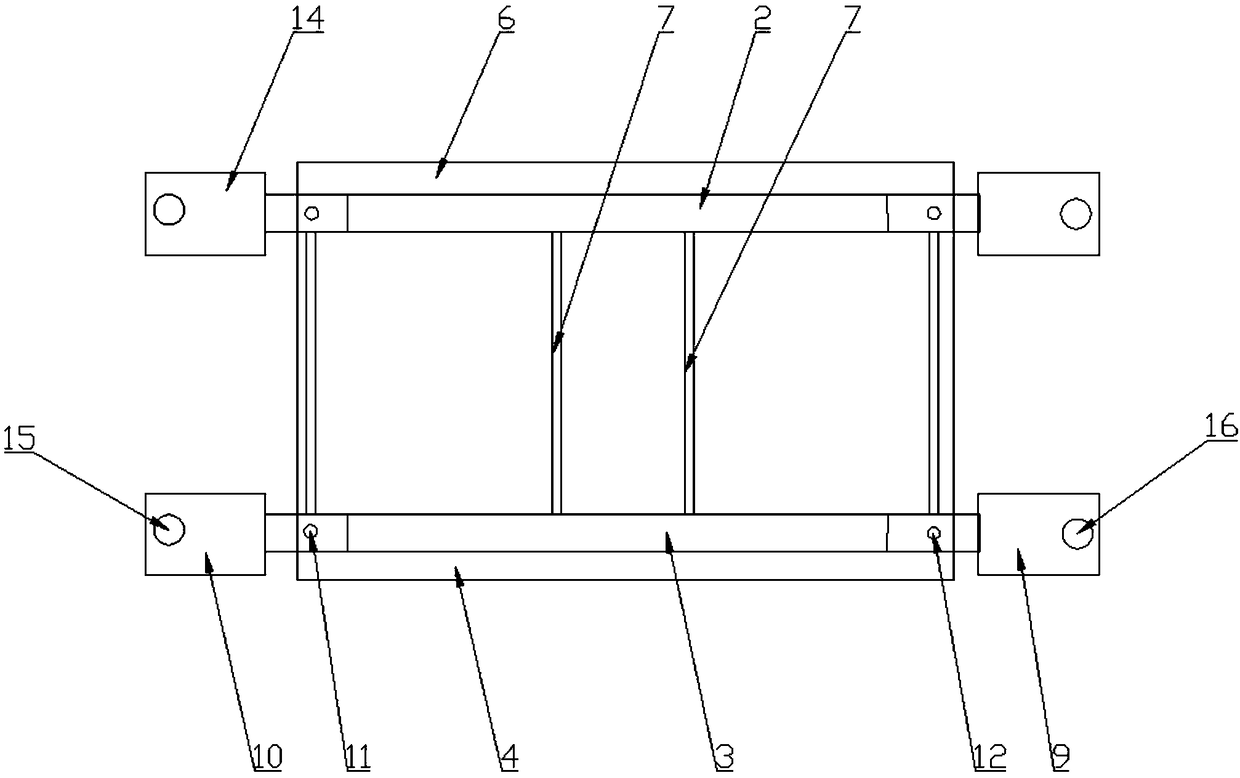

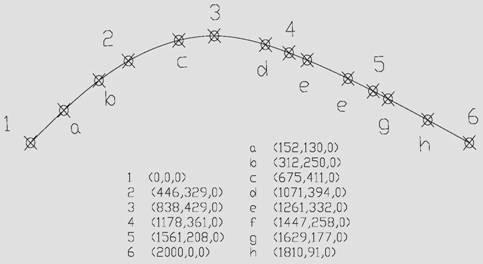

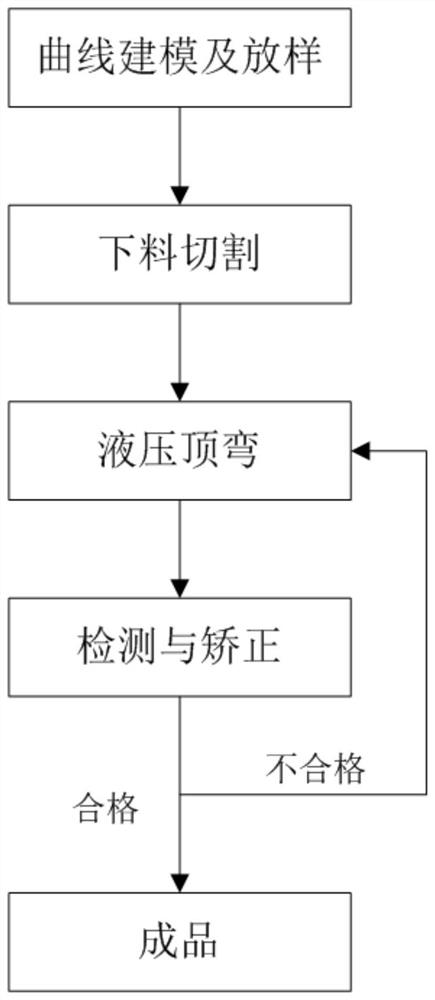

Cold bending manufacturing method for large-diameter steel pipe

ActiveCN110116153ASolve the problem of precision control of bending formingControl moldingMetal working apparatusSocial benefitsEconomic benefits

The invention provides a cold bending manufacturing method for a large-diameter steel pipe. By means of the cold bending manufacturing method, the defects and problems of labor and time consuming anddifficultly in precision control by flame bending are overcome and solved, and the problems of precision control on bending forming of the large-diameter steel pipe and the like are effectively solved. By means of the cold bending manufacturing method, a steel pipe with fixed curvature, steel pipes with variable curvature, and planar or irregular circular steel pipes can be bent; before pipe bending is carried out by adopting the cold bending manufacturing method, with the full utilization of computer-aided software, coordinate values of bending control points equally spaced at a certain axisare given through plane or space lofting, so as to control pipe bending manufacturing and forming; and by adopting the cold bending manufacturing method for bending the steel pipe, the equipment investment is little, the operation is convenient, the quality is good, the working efficiency is high, and the economic benefits, safety benefits and social benefits are obvious.

Owner:安徽建工路港建设集团有限公司

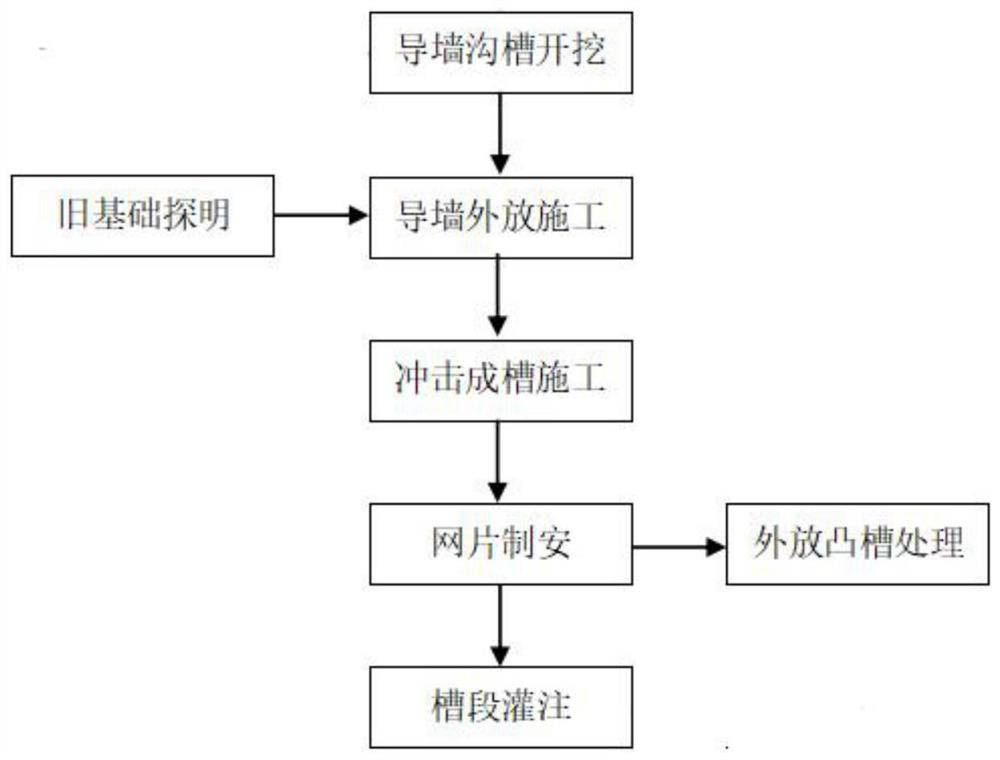

Old foundation treatment construction method for underground diaphragm wall

ActiveCN112854198AEffective contactAvoid Handling Incomplete SituationsBulkheads/pilesArchitectural engineeringMesh reinforcement

The invention provides an old foundation treatment construction method for an underground diaphragm wall. The method comprises the following steps that S1, a guide wall groove is excavated; S2, a guide wall is constructed, wherein after the guide wall groove is excavated and an old foundation is ascertained, the excavation width of the guide wall groove is expanded according to the position of the old foundation, then a groove bottom cushion layer and guide wall steel bars are subjected to binding construction, the guide wall steel bars are bound according to the expansion of the groove, and after that, single-side formwork erection and guide wall concrete pouring construction are conducted; S3, old foundation impact treatment is conducted, wherein after the guide wall maintenance reaches the age, the old foundation in a groove section is subjected to impact crushing; S4, grooving construction is performed, wherein grooving construction is conducted after old foundation impact treatment is completed; S5, reinforcing meshes are manufactured and installed; and S6, the groove section is poured. According to the method, the material waste in the construction process and the later bulge treatment difficulty are reduced at the same time, the diaphragm wall construction quality is guaranteed, and the economic, quality and safety benefits of implementation and application are remarkable.

Owner:中煤江南建设发展集团有限公司

Drilling and blasting method tunnel assembly type blasting construction method

ActiveCN113432498ARealize intelligent blasting operationPrecise control of detonation timeMining devicesBlastingDetonationDynamite

The invention relates to a drilling and blasting method tunnel assembly type blasting construction method, and belongs to the field of tunnel drilling and blasting method construction. A single-hole dynamite container is prefabricated in advance according to the collected blast hole surrounding rock information, and the dynamite container is put quickly on site, so that charging convenience is realized. Slurry is packaged in charging pipes of the single-hole dynamite containers for peripheral holes, hydraulic fracturing blasting is achieved, and the blasting efficiency is improved. An unmanned mechanical arm is used for installing the single-hole dynamite containers, personnel participation is reduced, and the construction safety level is improved. The single-hole dynamite containers are provided with blasting control terminals, information interaction is carried out between remote blasting control equipment and the blasting control terminals, after all the single-hole dynamite containers are installed, position information is sent to locate the positions of blast holes, and the remote blasting control equipment carries out blast hole identification and detonation delay time design according to the position information of the blast holes and by means of a preset program, and intelligent blasting is achieved. The blasting control terminals are provided with clock units for overall timing, and when a communication signal is delayed, the blasting time is accurately controlled through the clock units.

Owner:CHONGQING VOCATIONAL INST OF ENG

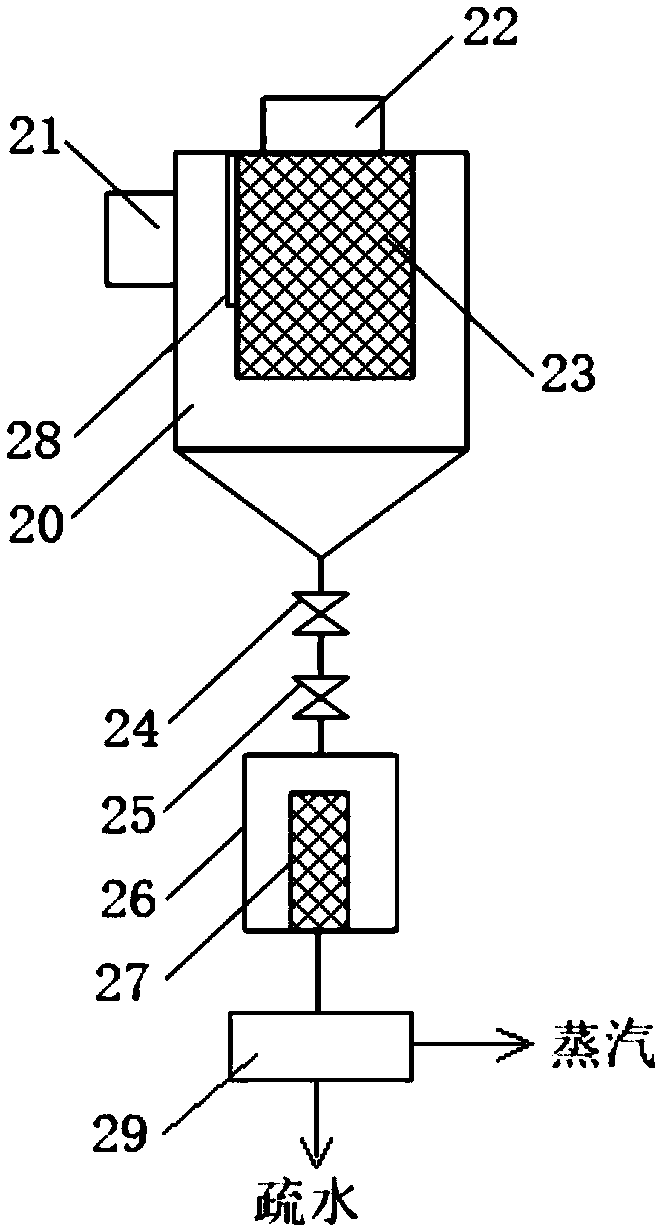

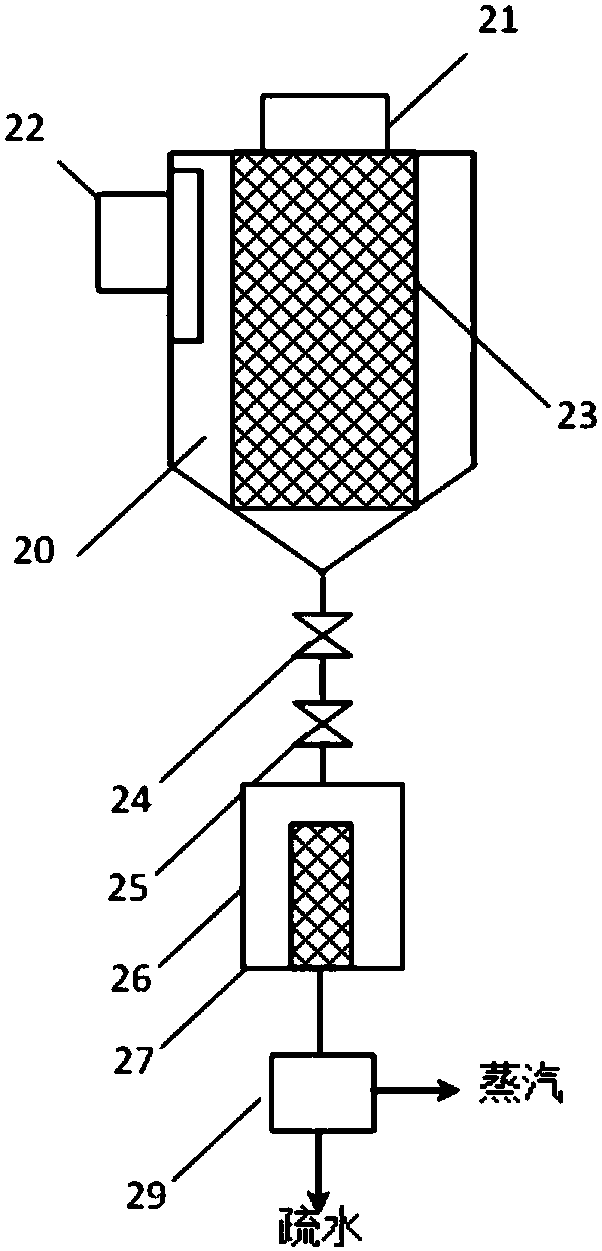

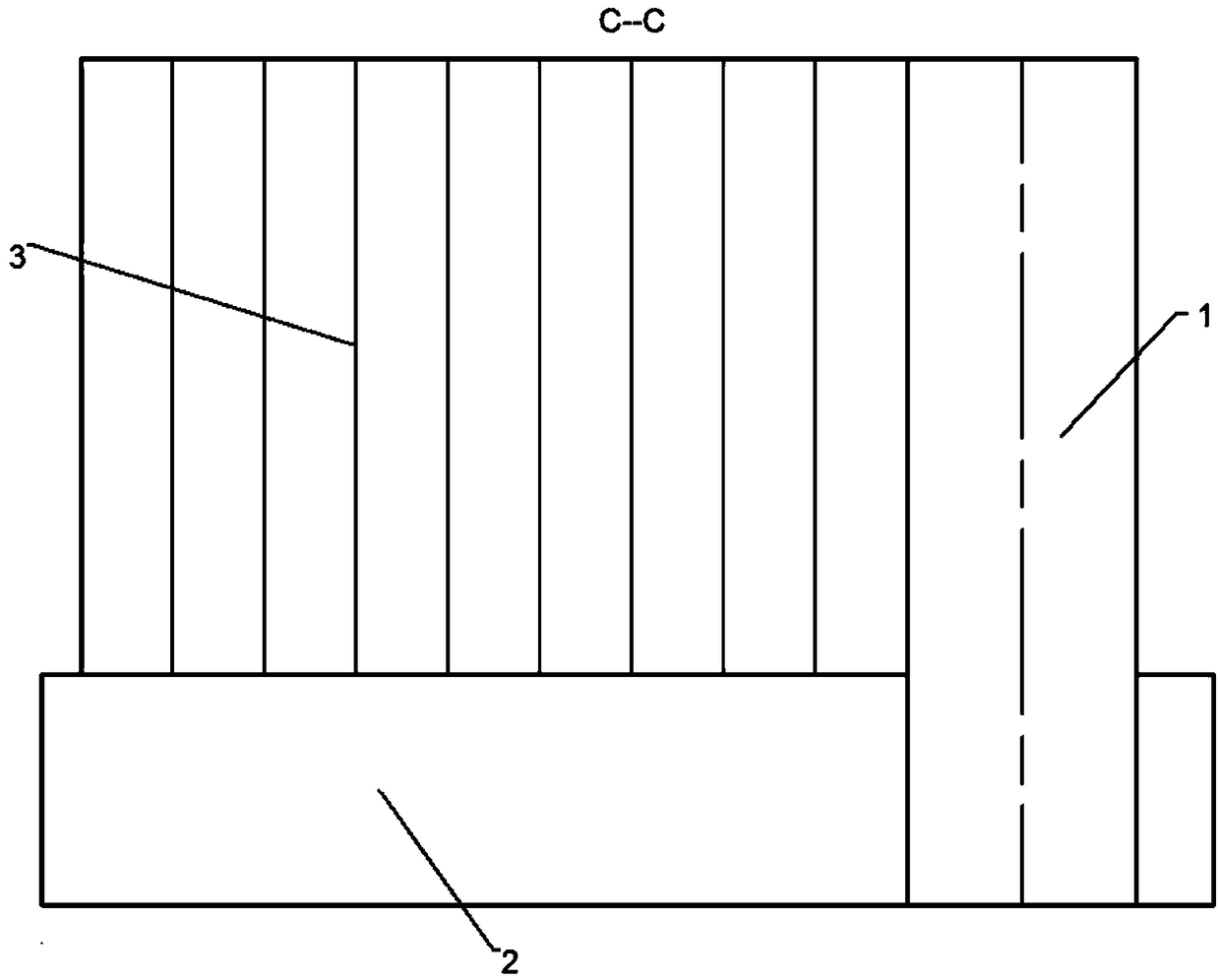

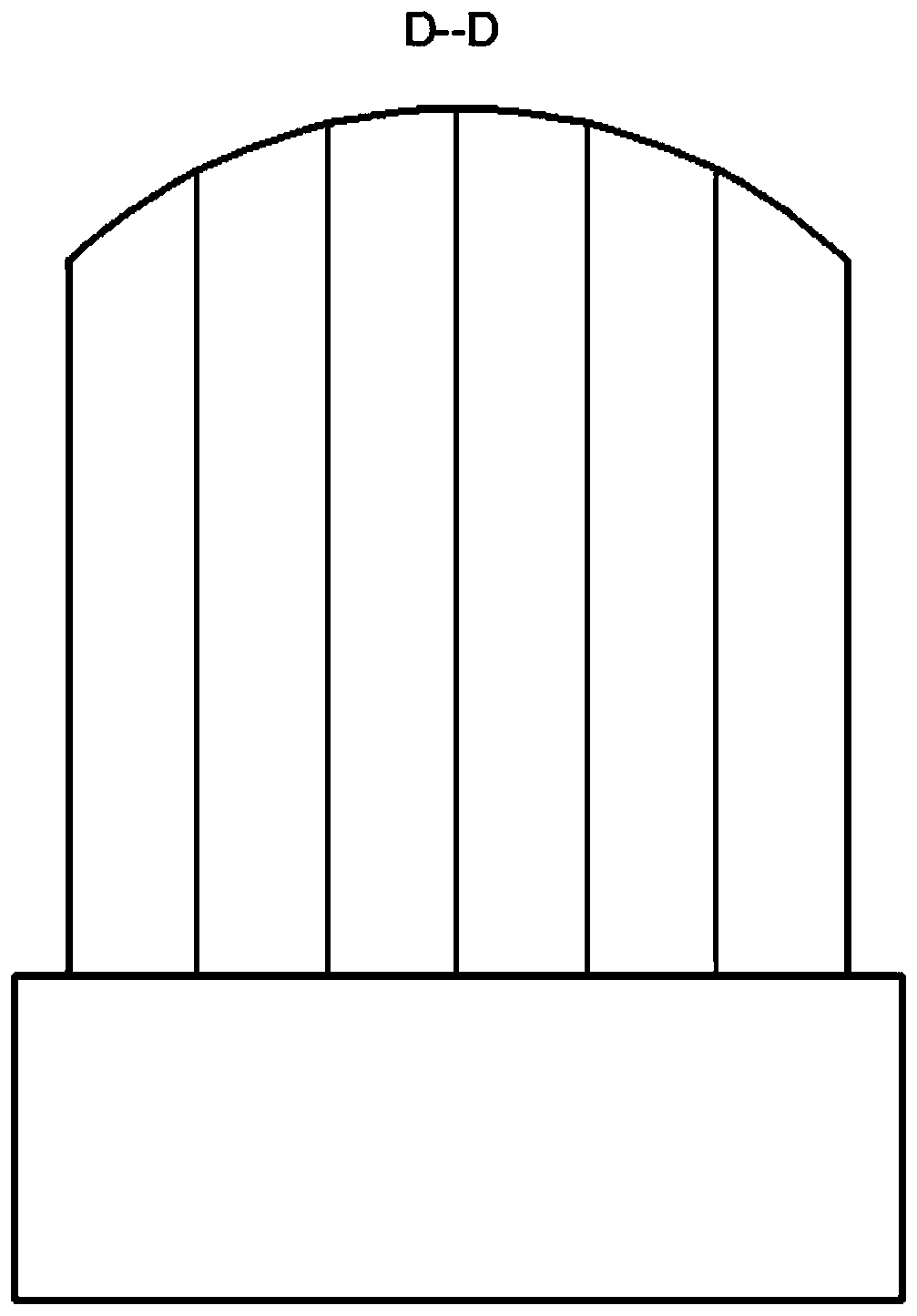

Coal chute with air-returning preventing device

InactiveCN104019457AReduced chances of extinguishing firePrevent the phenomenon of coal cut and return airLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPositive pressureEngineering

The invention relates to a coal chute capable of preventing coal outage and air returning of a positive pressure direct-fired coal pulverizing system, and discloses a coal chute with an air-returning preventing device. A coal chute body is provided with a baffle set, a heavy hammer mechanism and a sealing chamber. The baffle set is composed of one or more baffles, and the baffles are hinged to the inner wall of the coal chute body. The sealing chamber is formed in the outer wall of the coal chute body and communicated with the interior of the coal chute body through an open hole formed in the wall of the coal chute body. The heavy hammer mechanism is arranged in the sealing chamber, a connection rod of the heavy hammer mechanism extends into the coal chute body to support the baffles, and the baffles swing on the inner wall of the coal chute body under the supporting effect of the connection rod to control opening and closing of a coal falling opening of the coal chute body. The baffle set is opened in the normal coal falling process and is closed in the coal outage process, and therefore the phenomena of coal outage and air returning are prevented, and the safety performance is high.

Owner:DATANG LUOYANG CO GENERATION POWER

Plate paint spraying device for electric fire box production

The invention relates to the technical field of plate paint spraying, in particular to a plate paint spraying device for electric fire box production. The device comprises a rolling barrel conveyor and a support; the top ends of the rolling barrel conveyor on the front side and the rear side are rotationally connected with the bottom end of the support, a spring is fixedly connected to the rear end of the support at the front side, and a rubber disc is rotationally connected to the rear end of the spring at the front side; a horizontally arranged plate is arranged at the rear end of the rubberdisc at the front side, and a gear is fixedly connected to the outer side of the rubber disc, the reverse rotation of the plate is realized through the rubber disc. According to the device, the rubber disc, the gear and a rack are arranged, the reverse rotation of the plate is realized, painting of the back face and the side face of the plate are facilitated, the side face of the plate is prevented from being affected with damp deformation, the electric fire box can be conveniently and stably spliced, manual painting is not needed, time and labor are saved, leakage coating is prevented, and quality of a finished product paint plate is guaranteed; and the design concept is ingenious, the design is reasonable, huge safety benefits and wide application prospects are achieved, and the deviceis worthy of popularization and use.

Owner:苏州家望宝科技有限公司

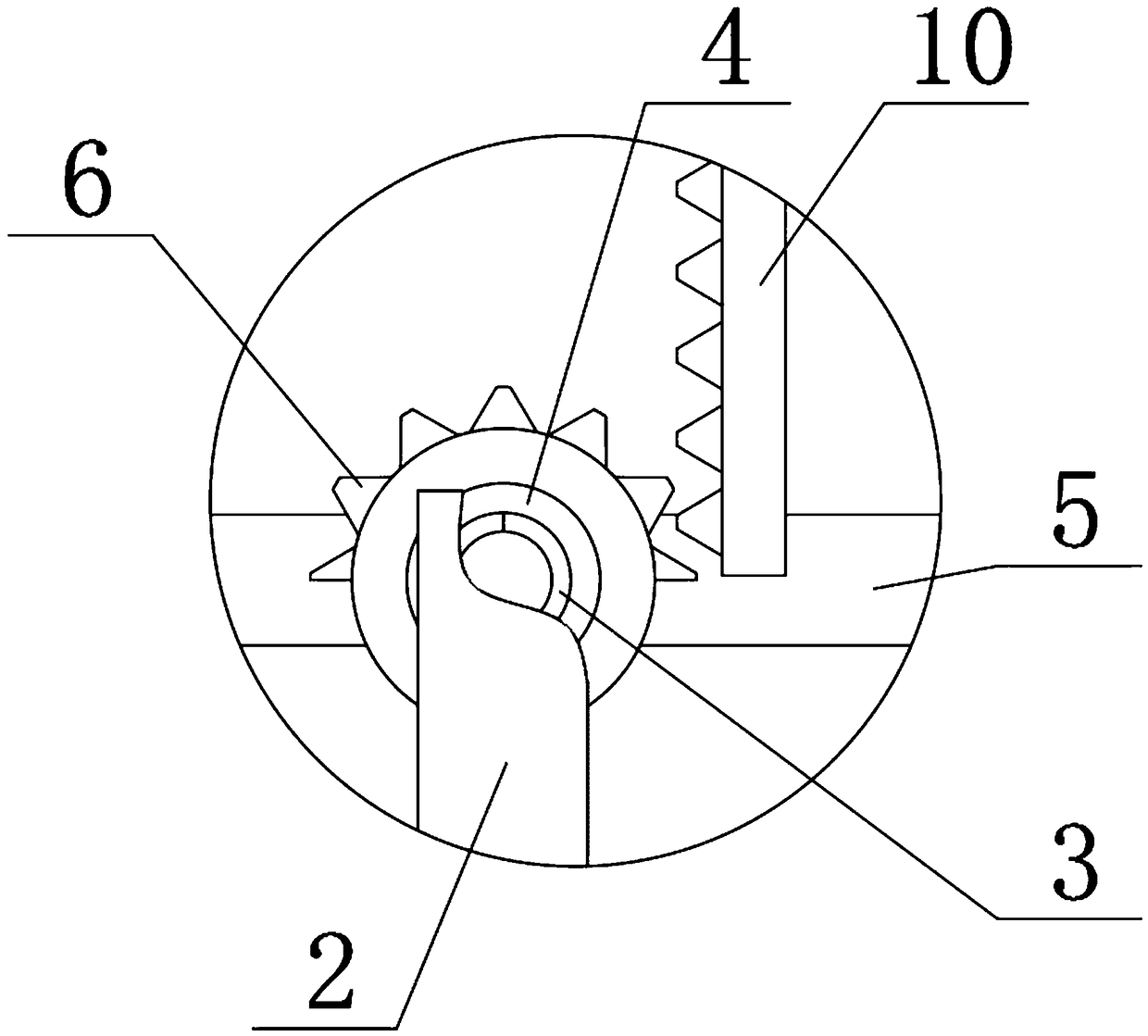

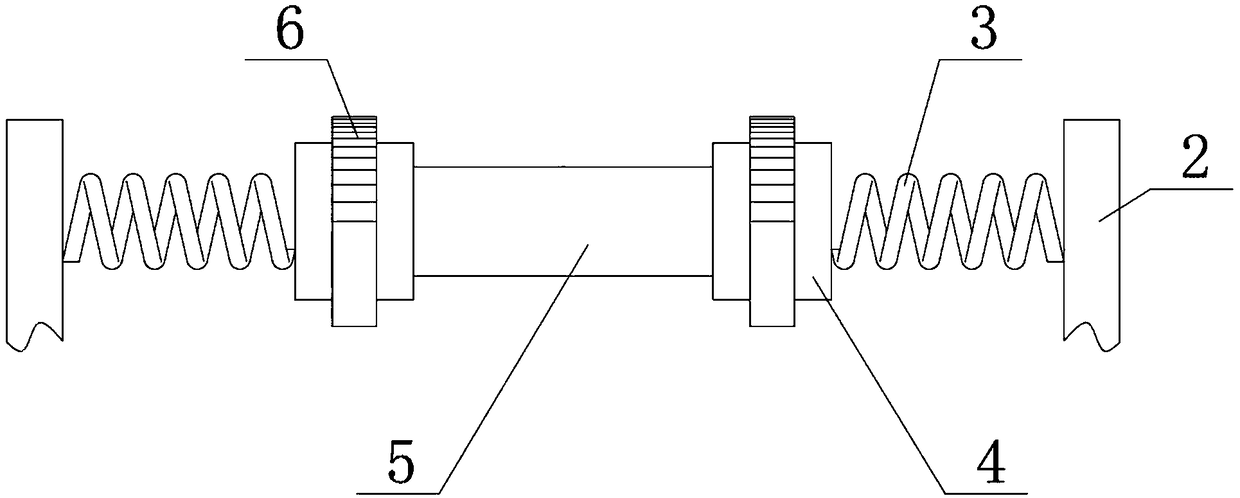

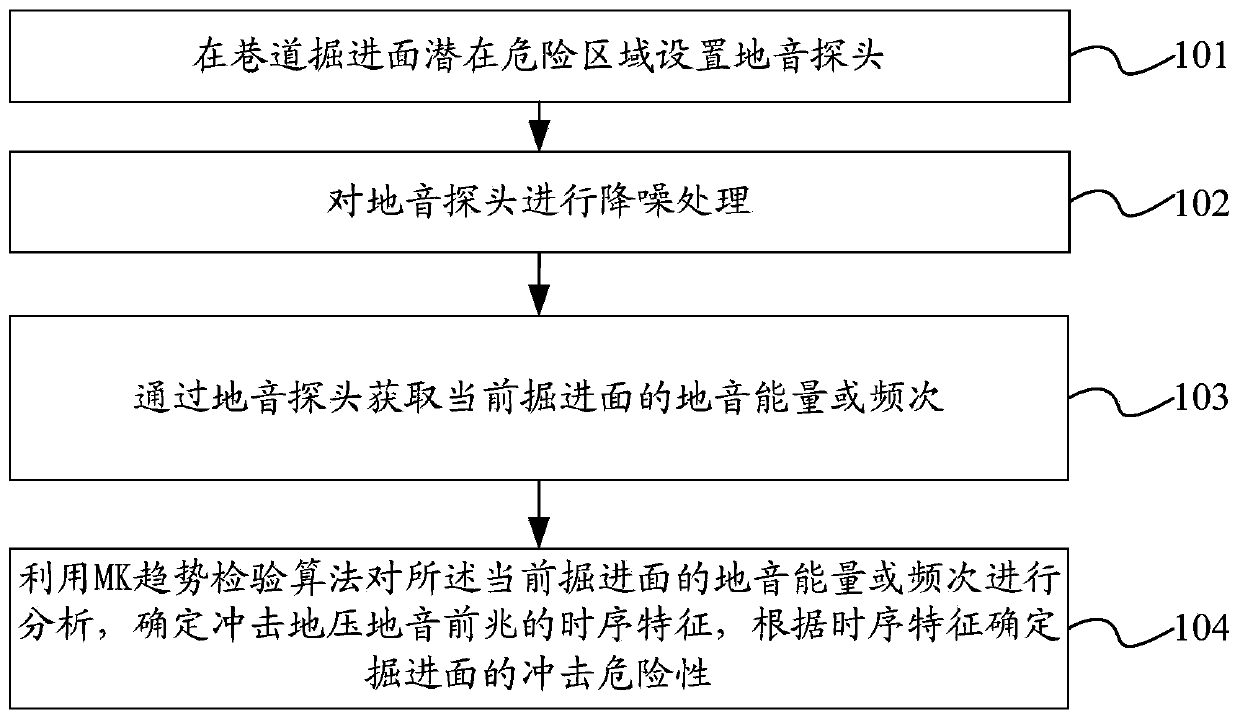

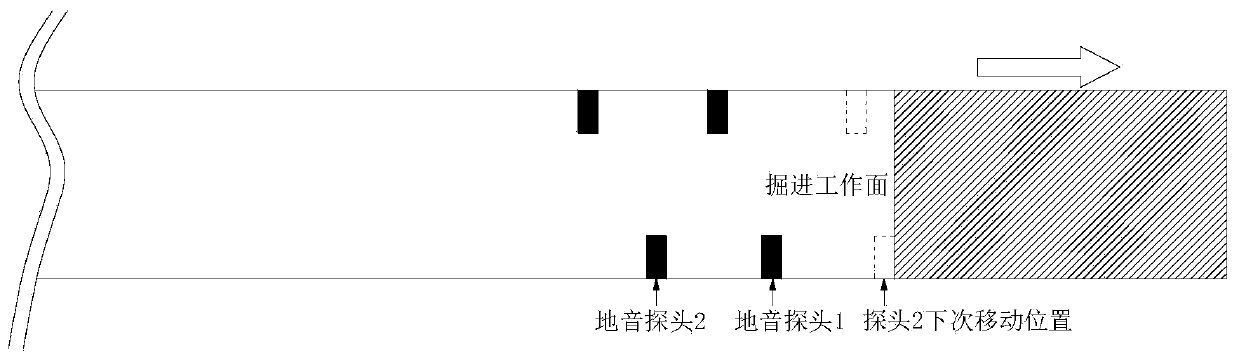

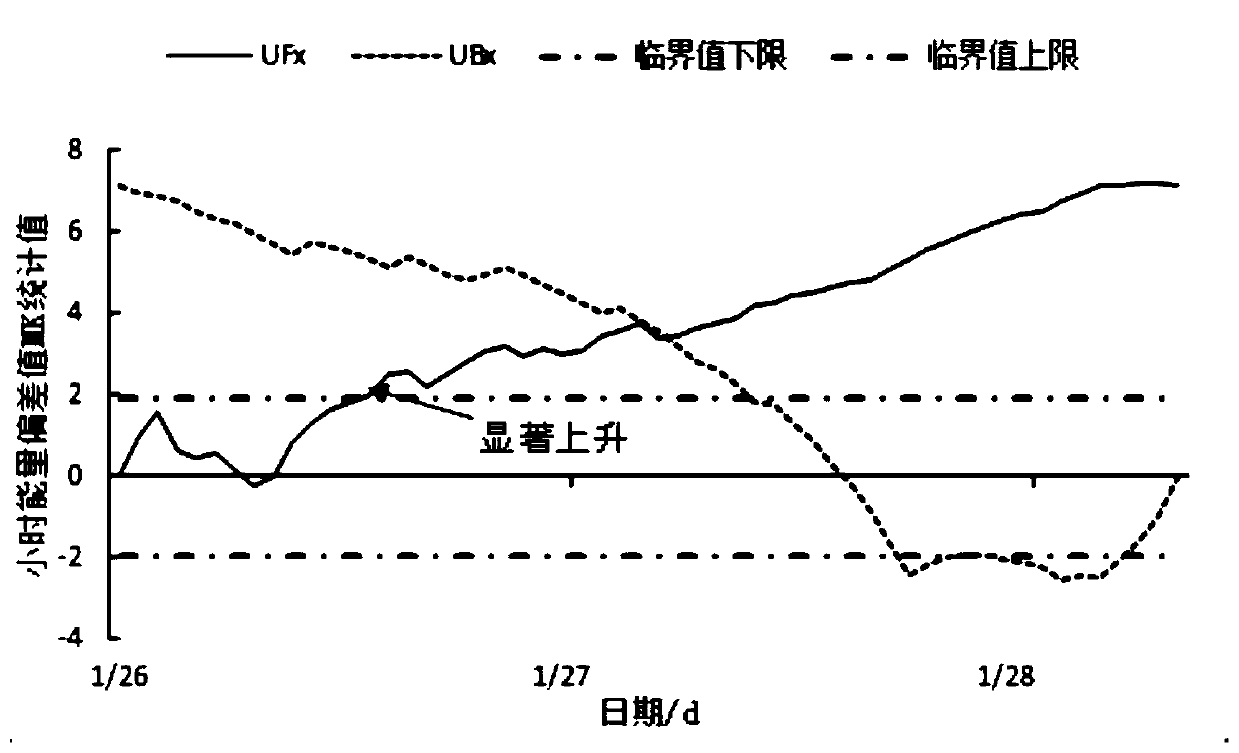

Tunneling roadway impact ground pressure ground sound pre-warning method and device

ActiveCN111350548AIncreased riskImprove real-time performanceMining devicesSeismic signal receiversSound energyEngineering

The embodiment of the invention discloses a tunneling roadway impact ground pressure ground sound pre-warning method and device. The method includes the steps that ground sound probes are arranged inpotential dangerous zones of a roadway tunneling surface; the ground sound probes are subjected to noise reduction; the ground sound probes are used for acquiring the ground sound energy or frequencyof the current tunneling surface; and the ground sound energy or frequency of the current tunneling surface is analyzed through an MK trend test algorithm, time sequence characteristics of impact ground pressure ground sound precursors are determined, and the impact danger of the tunneling surface is determined according to the time sequence characteristics. The time sequence characteristics of ground sound monitoring data of the roadway tunneling working surface can be fully analyzed, and precursor information of impact ground pressure can be caught in time. By means of the method, danger evaluation and short-time real-time pre-warning of a ground sound monitoring system for the impact ground pressure of the tunneling working surface are effectively improved.

Owner:TIANDI SCI & TECH CO LTD

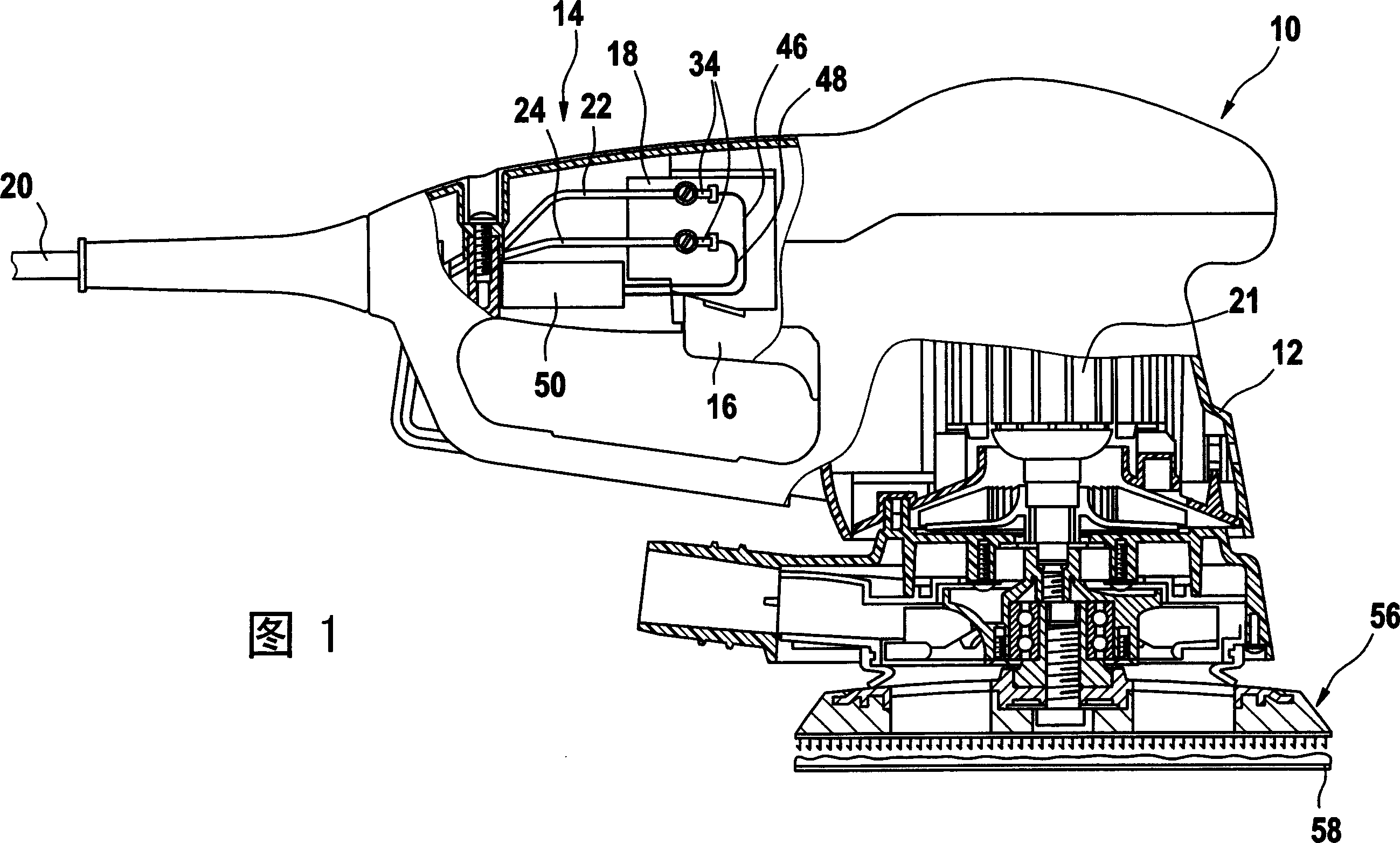

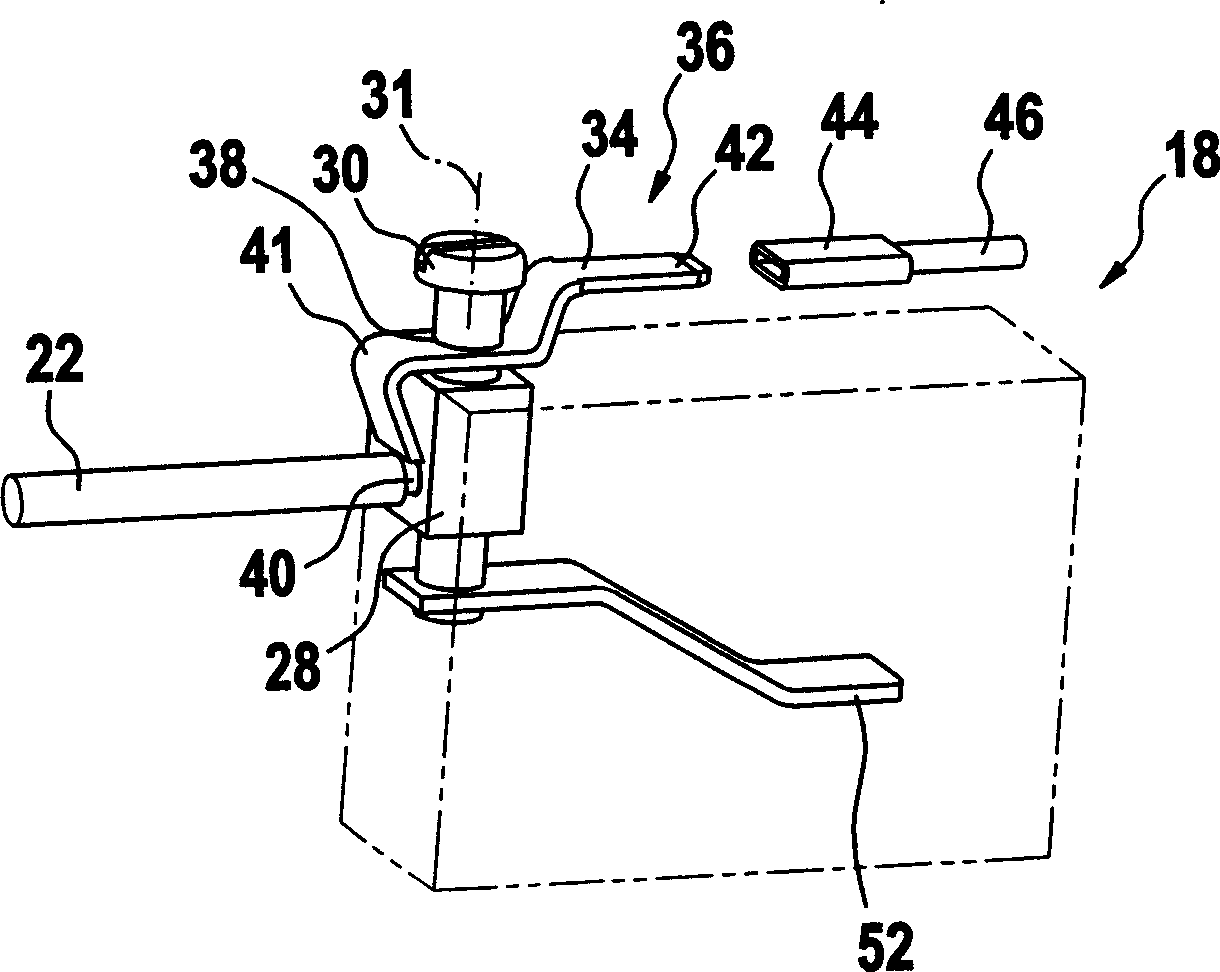

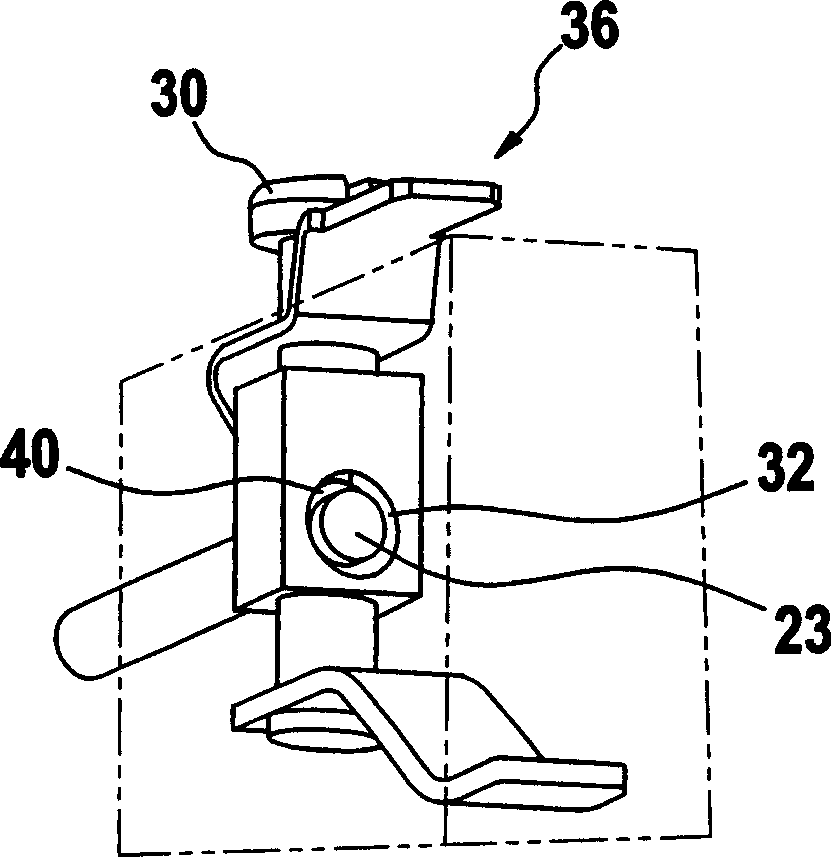

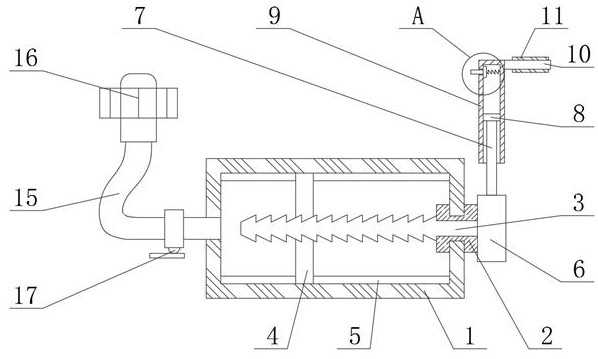

Handheld type electric tool machine

InactiveCN1738161ASignificant safety benefitsEasy to replaceCoupling contact membersPortable percussive toolsElectricityElectrical connection

The invention relates to a manually-operated electric tool which comprises a switch (18) for switching on or switching off the circuit of an electric driver (21) thereof, and electric connection devices (26, 28) arranged in the circuit. The manually-operated electric tool can be easily modified by adding circuits to meet the corresponding newly requirements for safety. The manually-operated electric tool further comprises a coupling device (36) used for subsequent electrical connections of the circuit, particularly electrical connection with electric and / or electronic circuits (50) that are not originally provided in the power circuit.

Owner:ROBERT BOSCH GMBH

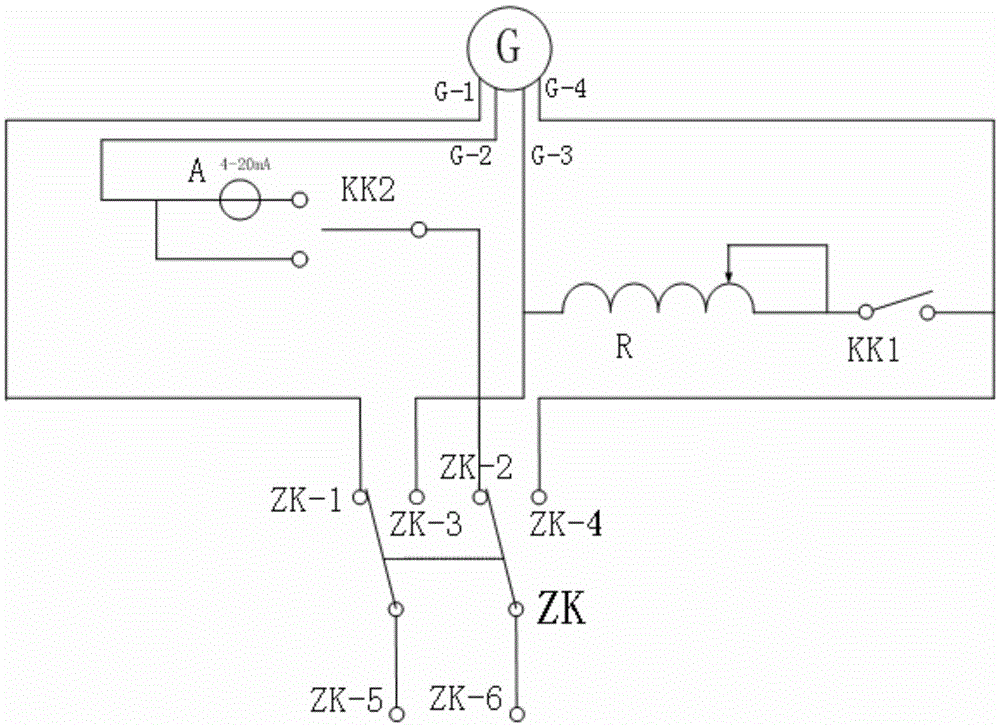

Transformer or reactor oil temperature detection and simulation device

InactiveCN103776553BImprove work efficiencyGuaranteed accuracyThermometers using electric/magnetic elementsUsing electrical meansEngineeringOil temperature

The invention relates to a transformer or electric reactor oil temperature detecting and simulating device which is characterized by comprising a multifunctional meter (G). A first detecting terminal (G-1) and a third detecting terminal (G-3) of the multifunctional meter (G) are connected with a first output terminal (ZK-1) and a third output terminal (ZK-3) of a function switch (ZK) respectively, and a second detecting terminal (G-2) and a fourth detecting terminal (G-4) of the multifunctional meter (G) are connected with a second output terminal (ZK-2) and a fourth detecting terminal (ZK-4) of the function switch (ZK). Trial proves that after the transformer or electric reactor oil temperature detecting and simulating device is used for carrying out oil temperature detection and defect overcoming on transformers or electric reactors of 220kV or higher-voltage transformer substations, the working efficiency is greatly improved, more importantly, due to the fact that defects are timely overcome, the accuracy of device monitoring is guaranteed, a reliable basis is provided for timely observing faults, and the safety benefits are obvious.

Owner:STATE GRID CORP OF CHINA +1

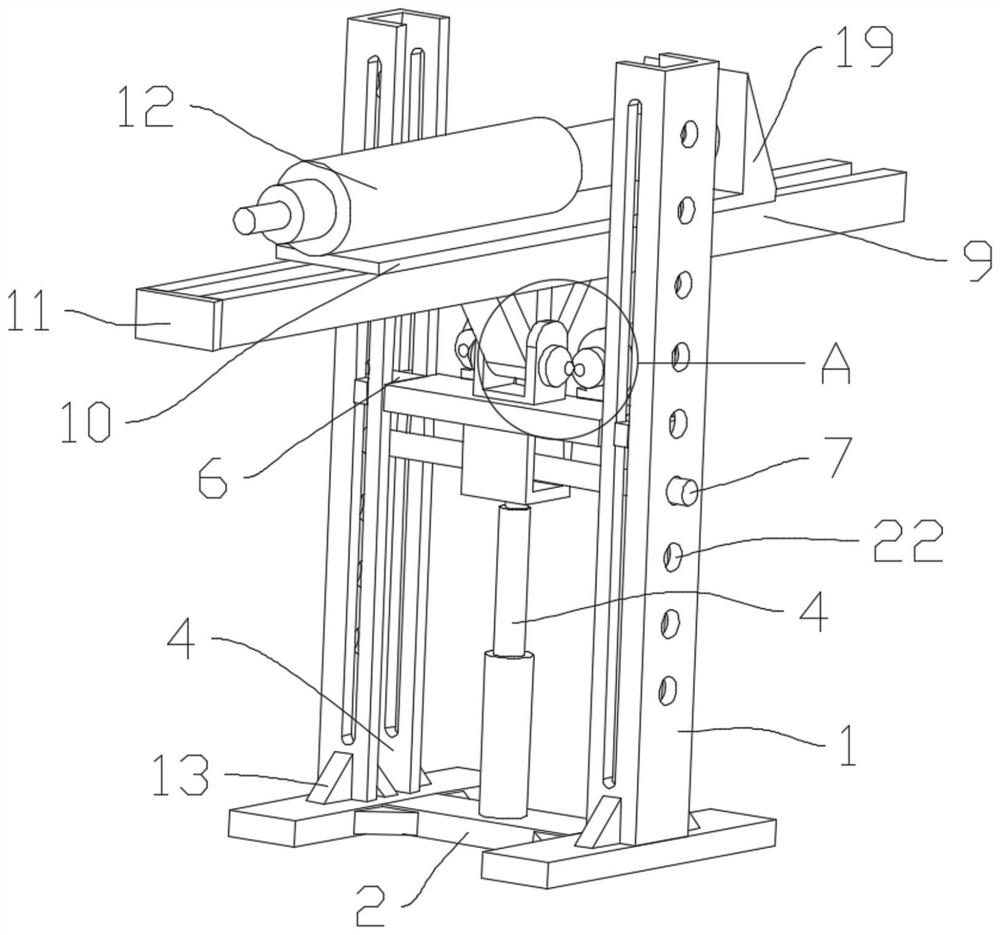

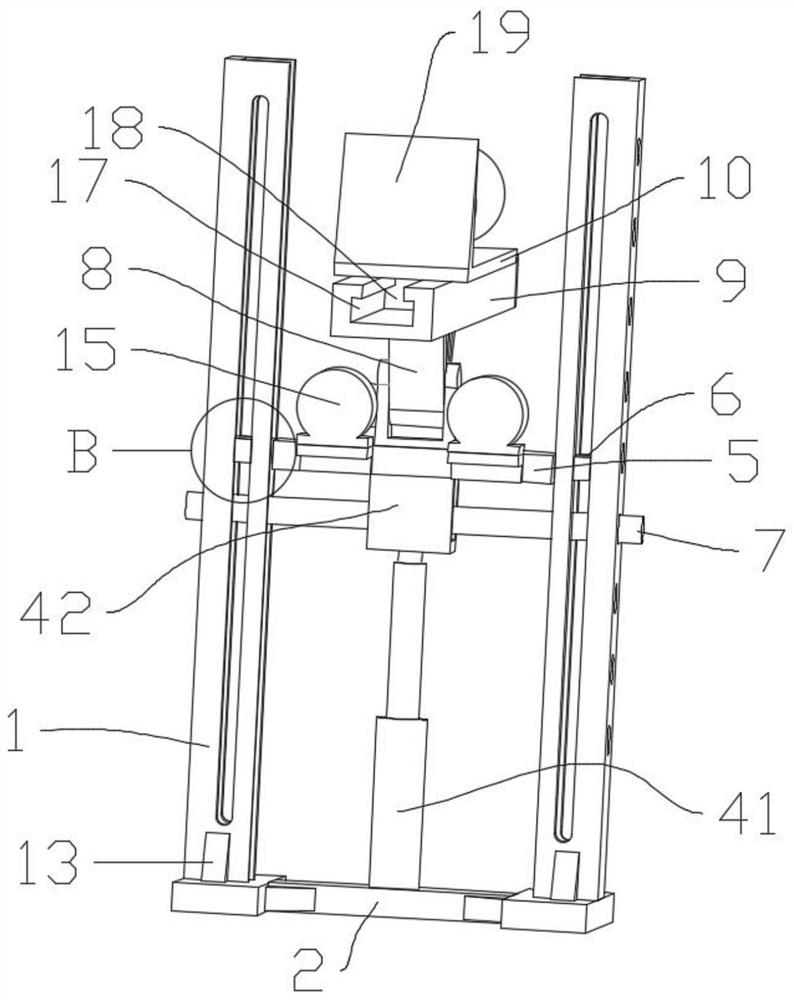

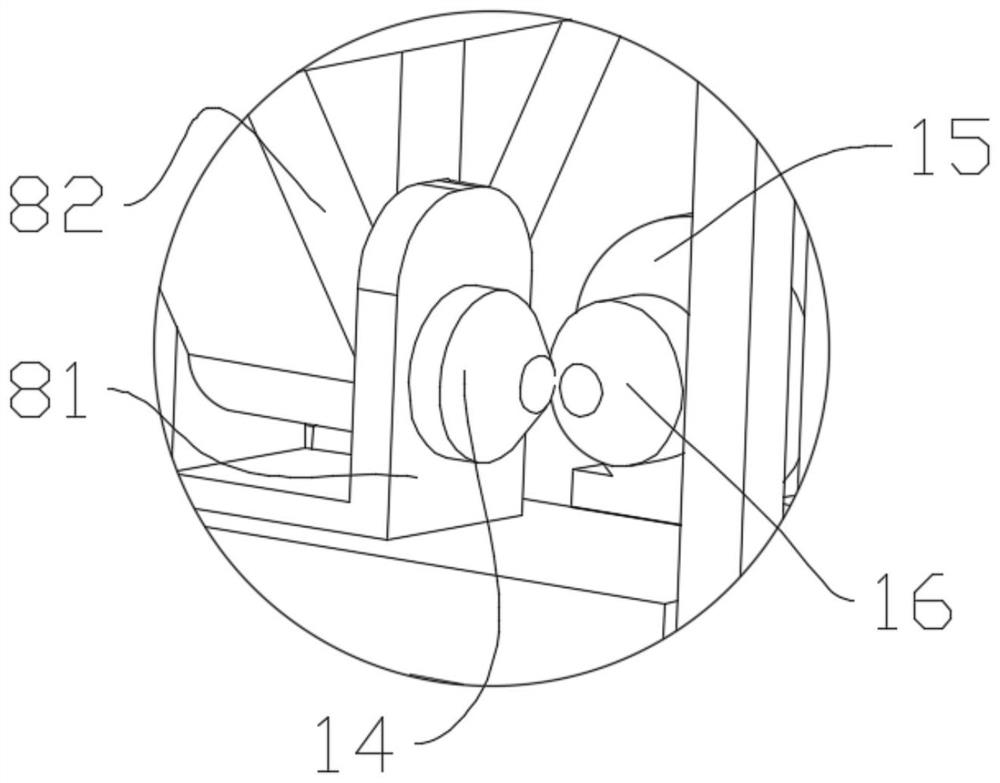

Multi-position anchor cable construction device

PendingCN114738016AIncrease the effective vertical anchorage depthAvoid snippingHydro energy generationAnchoring boltsCable machineArchitectural engineering

The invention provides a multi-position anchor cable construction device, and belongs to the technical field of anchor cable construction. Comprising two symmetrical T-shaped supports, a connecting plate is welded between the two T-shaped supports, sliding grooves are formed in the T-shaped supports, a height adjusting assembly is installed on the connecting plate, a supporting plate is fixedly installed on the height adjusting assembly, sliding blocks are installed on the two sides of the supporting plate in a sliding mode, and a hinge assembly is installed on the supporting plate. A bottom bracket is fixedly installed on the hinge assembly, a walking frame is installed on the bottom bracket in a sliding mode, an anchor cable machine is installed on the walking frame, the structure is simple, installation and use are convenient, the angle of an anchor cable can be rotated according to needs, the problems of construction shoulder nests of the anchor cable machine and the angle of an anchor cable on the upper portion are solved, the effective vertical anchoring depth of the anchor cable is increased, and the construction efficiency is improved. The anchor cable is prevented from being cut off, the accident that the anchor cable base plate falls off and hurts people is eradicated, top plate accidents are greatly reduced, and safety benefits are good.

Owner:HUAIBEI MINING IND

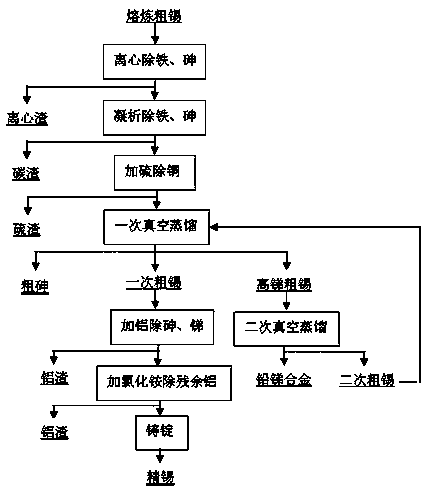

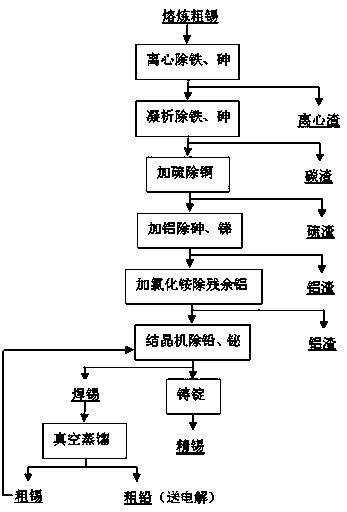

Fire refining method of crude tin

The invention provides a method for refining crude tin by fire. First, the crude tin melt is removed through a centrifuge to remove iron and arsenic; it is condensed to remove iron and arsenic; after adding sulfur to remove copper, a vacuum distillation is performed to remove lead, bismuth, and Arsenic and antimony; then add aluminum to remove arsenic and antimony, and finally go through the process of removing residual aluminum to obtain refined tin. The key to the method provided by the invention is to use a vacuum distillation process instead of a continuous crystallizer process to remove lead and bismuth, which reduces the labor intensity of workers, greatly reduces the amount of aluminum metal and the production of slag (AlAs, AlSb), and improves the direct recovery of tin. It has huge environmental benefits, economic benefits and safety benefits for tin production enterprises. The entire process is safe and controllable, easy to operate, requires simple equipment, has high universal applicability to raw materials, can effectively process crude tin with different tin compositions, has a high direct tin recovery rate, and produces less waste residue.

Owner:KUNMING UNIV OF SCI & TECH

Spraying device with adjustable connecting rod

InactiveCN111838116AGood for work healthRealize the reflow functionInsect catchers and killersPhysicsOccupational Illnesses

The invention relates to the technical field of spraying devices and particularly relates to a spraying device with an adjustable connecting rod. The spraying device comprises a shell body and a sealing ring, wherein the inner side of the right end of the shell body is fixedly connected with the outer side of the sealing ring, the inner side of the sealing ring is rotatably connected with a rotarycolumn which is horizontally arranged, a piston plate is arranged at the outer side of the rotary column, the right end of the sealing ring is rotatably connected with a rotating plate which is arranged vertically, and the top end of the rotating plate is fixedly connected with a connecting rod which is arranged vertically. According to the spraying device with the adjustable connecting rod, a hand grip position on the connecting rod can be adjusted through an arranged spring, a rubber block and a piston, free adjustment can be performed according to difference of arm lengths and force applying habits of all practitioners, occupational disease symptoms such as arthritis and scapulohumeral periarthritis caused by long-term manual work are avoided and reduced, and thus, health of work of the practitioners is facilitated; and this design is novel in conception and is scientific, so that the spraying device has huge safety benefits and extensive market prospects and is worthy of popularization.

Owner:马玉荣

Belt mechanism with anti-derailing function under large-dip-angle underhand stoping condition

The invention provides a belt mechanism with an anti-derailing function under a large-dip-angle underhand stoping condition, and relates to the technical field of large-dip-angle underhand stoping belt coal transportation galloping prevention. The belt mechanism comprises a first belt H frame and a second belt H frame, wherein the first belt H frame and the second belt H frame are parallel to eachother and spaced. A first semicircular belt bracket is arranged above the first belt H frame, first damping skin is arranged above the first semicircular belt bracket, and the first damping skin is fixedly connected with the first semicircular belt bracket. A second semicircular belt bracket is arranged above the second belt H frame, second damping skin is arranged above the second semicircular belt bracket, and the second damping skin is fixedly connected with the second semicircular belt bracket. A belt of a belt conveyor is arranged above the first damping skin and the second damping skinand slidingly connected with the first damping skin and the second damping skin. Friction between the belt and the damping skin is improved by increasing the damping skin, friction force is generatedbetween the belt and the damping skin, and the purpose of large-dip-angle transportation galloping prevention of the belt conveyor is completely solved.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD

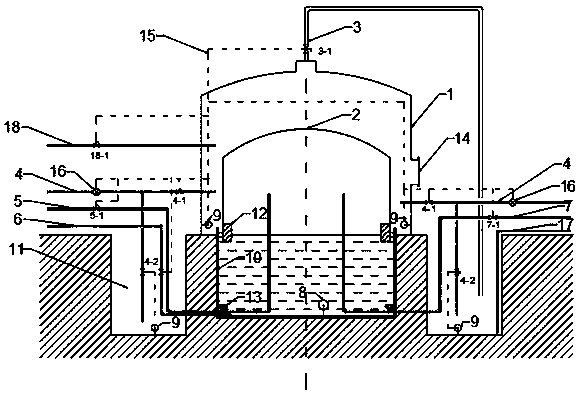

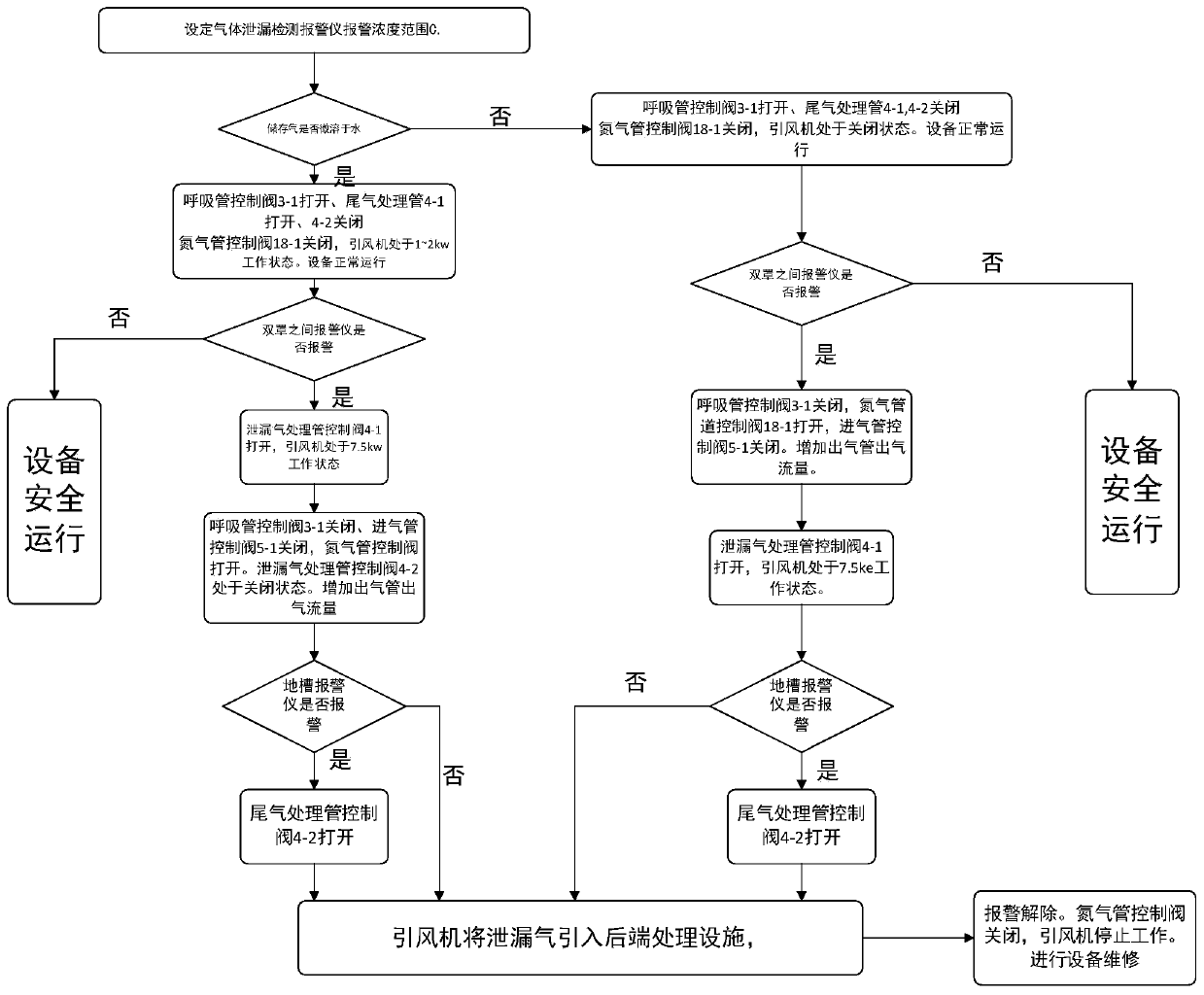

Double-cover semi-underground wet-type gas cabinet capable of automatically treating leakage and method for automatically treating leakage

ActiveCN110332454AInhibition releaseSignificant safety benefitsVariable capacity gas holdersNitrogenEngineering

The invention relates to a double-cover semi-underground wet-type gas cabinet capable of automatically treating leakage and a method for automatically treating leakage, and belongs to the technical field of safety of chemical production equipment. The double-cover semi-underground wet-type gas cabinet capable of automatically treating leakage comprises a leakage-proof cover, a bell cover, a breathing pipe, a leakage gas treating main pipe, an air inlet pipe, a water inlet / outlet pipe, an air outlet pipe, a liquid level meter, a combustible or toxic and harmful gas leakage detection alarm, a water seal groove, a trough, a manhole, an interlocking control connecting wire, an induced draft fan, a nitrogen pipe and an industrial personal computer. According to the double-cover semi-undergroundwet-type gas cabinet capable of automatically treating leakage and the method for automatically treating leakage, combustible or toxic harmful gases can be safely and reliably stored in the chemicalproduction process and can be prevented from entering the environment to cause safe production accidents and environmental pollution problems due to leakage, and early warning and emergency treatmentafter gas leakage can be made in time.

Owner:KUNMING UNIV OF SCI & TECH +1

Manufacturing Method of Cold Bending of Large Diameter Steel Pipe

ActiveCN110116153BSolve the problem of precision control of bending formingControl moldingMetal working apparatusSocial benefitsEconomic benefits

The invention provides a cold bending manufacturing method for a large-diameter steel pipe. By means of the cold bending manufacturing method, the defects and problems of labor and time consuming anddifficultly in precision control by flame bending are overcome and solved, and the problems of precision control on bending forming of the large-diameter steel pipe and the like are effectively solved. By means of the cold bending manufacturing method, a steel pipe with fixed curvature, steel pipes with variable curvature, and planar or irregular circular steel pipes can be bent; before pipe bending is carried out by adopting the cold bending manufacturing method, with the full utilization of computer-aided software, coordinate values of bending control points equally spaced at a certain axisare given through plane or space lofting, so as to control pipe bending manufacturing and forming; and by adopting the cold bending manufacturing method for bending the steel pipe, the equipment investment is little, the operation is convenient, the quality is good, the working efficiency is high, and the economic benefits, safety benefits and social benefits are obvious.

Owner:安徽建工路港建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com