Method for removing arsenic impurities from tin

A technology of impurities and impurity elements, applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of reducing the economic benefits of enterprises, high labor intensity of workers, affecting the direct yield of tin, etc. Highly adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

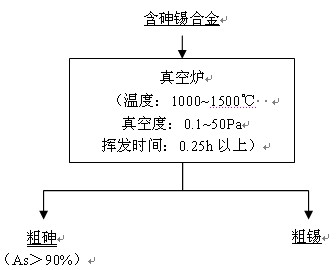

[0012] Embodiment 1: see figure 1 , put 10t crude tin raw material (Sn 81.54%; Pb 9.14%; Sb0.094%; Bi 0.184%; As3.30%) into the vacuum furnace, control the pressure in the vacuum furnace in the range of 0.5~6Pa, 1500℃, Vacuum volatilization for 1.5 hours, the impurity element arsenic volatilizes from the tin alloy melt, volatilizes into the condenser in a gaseous state, condenses to obtain crude arsenic with a content of 98%, and recovers, so that arsenic and tin are separated. The removal rate of arsenic is 95%.

Embodiment 2

[0013] Example 2: see figure 1 , put 10t crude tin raw material (Sn 86.88%; Pb 6.16%; Sb6.77%; Bi 0.23%; As 1.27%) into the vacuum furnace, control the pressure in the furnace to 45~50Pa, temperature 1300℃, and carry out continuous vacuum Volatilize for 1 hour to volatilize the impurity element arsenic from the tin alloy melt, volatilize in a gaseous state into the condenser, condense to obtain crude arsenic with a content of 99%, and recover it to separate arsenic from tin. A total of 116.7kg of crude arsenic was collected, and the removal rate of arsenic was 91%.

Embodiment 3

[0014] Embodiment 3: see figure 1 , 20t crude tin raw material (Sn84.68%; Pb 7.37%; Sb3.93%; Bi 2.61%; As 0.51%) was sent into the vacuum furnace, and the pressure in the furnace was 20~24Pa, 1200℃, for continuous vacuum Volatilize for 2 hours to volatilize the impurity element arsenic from the tin alloy melt and volatilize into the condenser in a gaseous state, condense to obtain crude arsenic with a content of 96%, and recover it to separate arsenic from tin. A total of 95.6 kg of crude arsenic was collected, and the removal rate of arsenic was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com