Generator set three-stage parallel serial connection bypass system and adjusting method thereof

A technology of bypass system and generator set, applied in the direction of heating system, engine components, machines/engines, etc., can solve the problems of exacerbating the contradiction of non-fossil energy consumption, difficulty in peak regulation, insufficient peak regulation capacity of power grid, etc., to eliminate The effect of solid particle erosion, increased flexibility, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

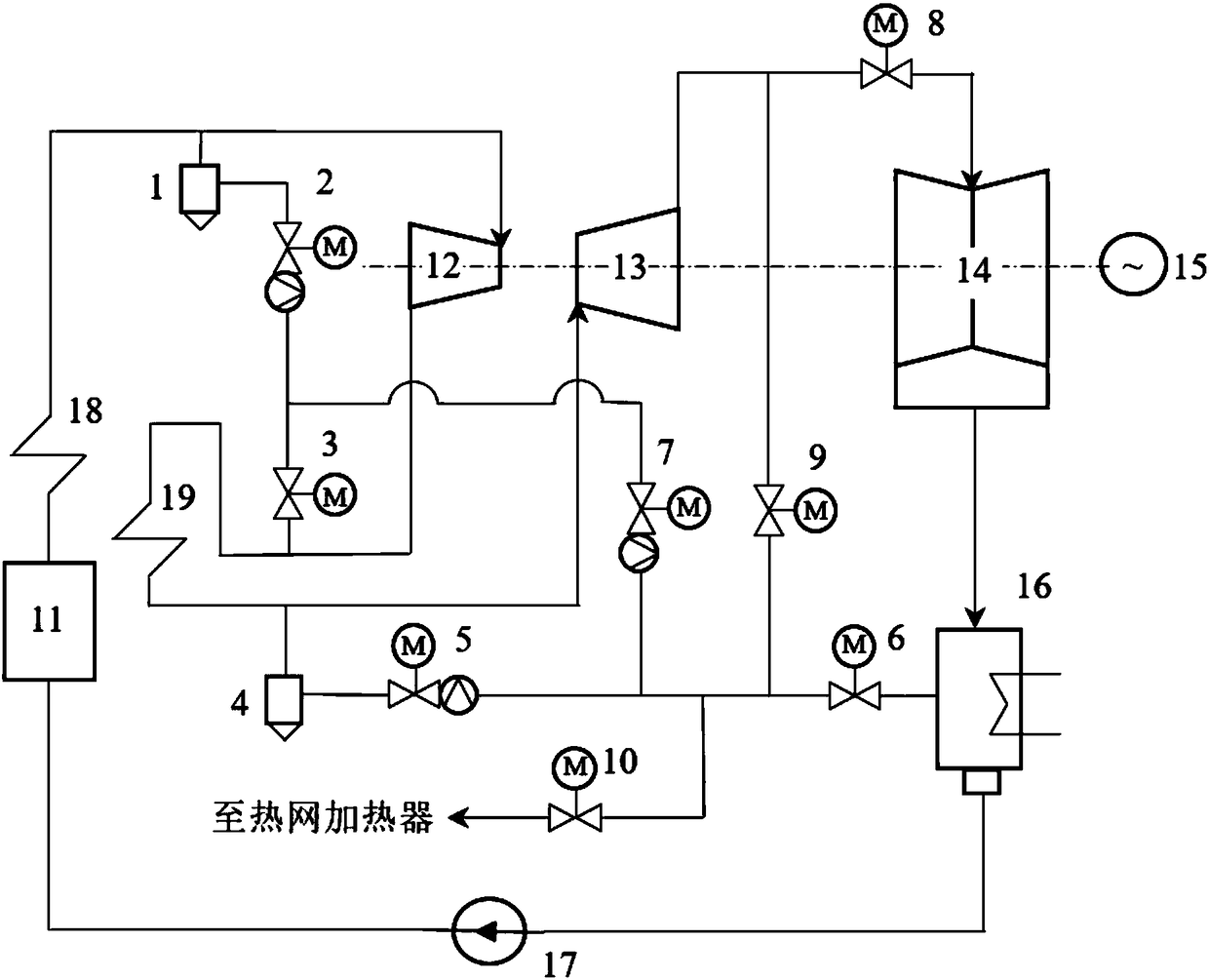

[0051] Taking a 600MW heating unit as an example, the existing two-stage series bypass is transformed into a three-stage hybrid bypass. When starting, close the high and low pressure bypass connecting valve 7, the medium pressure exhaust and low pressure bypass connecting valve 9 and the low pressure bypass heating regulating valve 10; open the high pressure bypass filter 1, the high pressure bypass isolation valve 3, the low pressure bypass Filter 4 and low-pressure bypass isolation valve 6; according to the normal start-up, grid connection and loading of the two-stage series bypass system.

[0052] During deep peak regulation, open the high and low pressure bypass connecting valve 7, the medium pressure exhaust and low pressure bypass connecting valve 9 and the low pressure bypass heating regulating valve 10; close the high pressure bypass isolation valve 3 and the low pressure bypass isolation valve 6; adjust High-pressure bypass valve 2 and high-low pressure bypass connect...

Embodiment 2

[0056] Taking a 600MW heating unit as an example, the existing two-stage series bypass is transformed into a three-stage hybrid bypass.

[0057] If it is found that there is oxide scale falling off in the superheater during operation, the scale separation of the superheater during operation can be used: close the high-pressure bypass isolation valve 3, the low-pressure bypass valve 5, the medium-pressure exhaust low-pressure bypass connecting valve 9 and the low-pressure bypass valve. Bypass heating regulating valve 10; open high pressure bypass filter 1, low pressure bypass isolation valve 6; adjust high pressure bypass valve 2, high and low pressure bypass connecting valve 7; make the scale in the superheater be carried to high pressure by hot steam The bypass filter 1 is separated, and the separated steam is recovered to the condenser 12; after the separation, the high pressure bypass filter 1, the low pressure bypass isolation valve 6, the high pressure bypass valve 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com