Fire refining method of crude tin

A pyro-refining and crude tin technology, applied in the field of crude tin refining, can solve the problems of high environmental pollution, high labor intensity of workers, poor operating environment, etc., and achieve huge environmental protection benefits, reduce labor intensity of workers, and facilitate the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

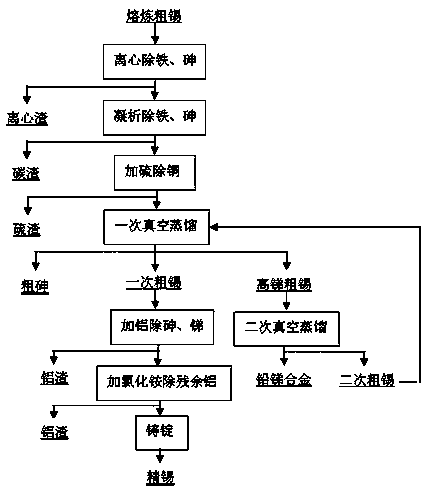

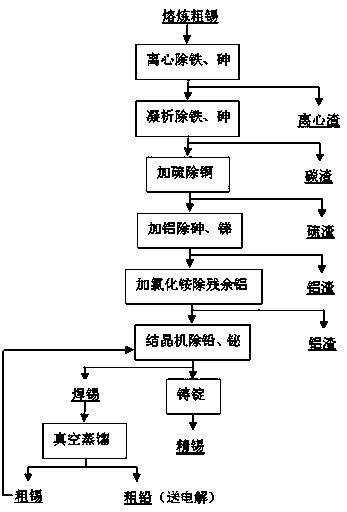

Method used

Image

Examples

Embodiment 1

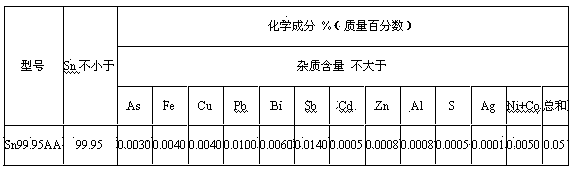

[0024] First, the crude tin melt is removed by a centrifuge to remove iron and arsenic; condensate to remove iron and arsenic; add sulfur to remove copper, then conduct a vacuum distillation to remove lead, bismuth, arsenic, and antimony; then add aluminum to remove arsenic and antimony, and finally After the process of removing residual aluminum, refined tin is obtained. Specifically include the following steps:

[0025] (1) Using the traditional method, 100t of crude tin melt containing Sn>75% obtained by electric furnace melting (Sn 83.80%; Pb 8.31%; Sb 6.77%; Bi 0.27%; As 0.388%; Cu 0.221%; Fe 0.228%), to remove iron and arsenic by centrifuge and condensate to remove iron and arsenic, so that the iron content in the crude tin melt is 0.0023%;

[0026] (2) Using traditional methods, the crude tin melt obtained in step (1) is subjected to sulfuration and copper removal operations, so that the copper content in the crude tin melt is 0.0032%;

[0027] (3) The crude tin melt ...

Embodiment 2

[0030] First, the crude tin melt is removed by a centrifuge to remove iron and arsenic; condensate to remove iron and arsenic; add sulfur to remove copper, then conduct a vacuum distillation to remove lead, bismuth, arsenic, and antimony; then add aluminum to remove arsenic and antimony, and finally After the process of removing residual aluminum, refined tin is obtained. The method for pyro-refining of described crude tin specifically comprises the steps:

[0031] (1) Using the traditional method, 70t of crude tin melt containing Sn>75% obtained by smelting in a reverberatory furnace (Sn 96%; Pb 1.15%; Sb 1.27%; Bi 0.087%; As 0.47%; Cu 0.25%; Fe 0.748%), to remove iron and arsenic by centrifuge and condensate to remove iron and arsenic, so that the iron content in the crude tin melt is 0.0036%;

[0032] (2) Using traditional methods, the crude tin melt obtained in step (1) is subjected to sulfuration and copper removal operations, so that the copper content in the crude tin ...

Embodiment 3

[0036] Remove iron and arsenic from the crude tin melt through a centrifuge; condensate to remove iron and arsenic; add sulfur to remove copper; Remove iron and arsenic; condensate to remove iron and arsenic; add sulfur to remove copper, then carry out a vacuum distillation to remove lead, bismuth, arsenic and antimony; then add aluminum to remove arsenic and antimony, and finally go through the process of removing residual aluminum to obtain refined tin. The method for pyro-refining of described crude tin specifically comprises the steps:

[0037] (1) Using the traditional method, 100t of crude tin melt with Sn content > 75% obtained by smelting 100t in Ausmelt furnace (Sn 86.80%; Pb 5.34%; Sb 6.74%; Bi 0.42%; As 0.248%; Cu 0.210%; Fe 0.251%), to remove iron and arsenic by centrifuge and condensate to remove iron and arsenic, so that the iron content in the crude tin melt is 0.0026%;

[0038] (2) Using traditional methods, the crude tin melt obtained in step (1) is subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com